Escolar Documentos

Profissional Documentos

Cultura Documentos

Review of Effect On Turbocharge System With Inter Cooling Process

Enviado por

IJIRSTTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Review of Effect On Turbocharge System With Inter Cooling Process

Enviado por

IJIRSTDireitos autorais:

Formatos disponíveis

IJIRST International Journal for Innovative Research in Science & Technology| Volume 2 | Issue 06 | November 2015

ISSN (online): 2349-6010

Review of Effect on Turbocharge System with

Inter Cooling Process

Ghanshyam Pradhan

Student

Department of Mechanical Engineering

Kirodimal Institute of Technology, Raigarh (C.G.)

Gopal Sahu

Lecturer

Department of Mechanical Engineering

Kirodimal Institute of Technology, Raigarh (C.G.)

Prakash Kumar Sen

Lecturer

Department of Mechanical Engineering

Kirodimal Institute of Technology, Raigarh (C.G.)

Ritesh Sharma

Lecturer

Department of Mechanical Engineering

Kirodimal Institute of Technology, Raigarh (C.G.)

Shailendra Bohidar

Lecturer

Department of Civil Engineering

Kirodimal Institute of Technology, Raigarh (C.G.)

Abstract

In this paper we writing in turbocharged diesel engine with inter cooling process, the turbocharged diesel engine using the intercooler and increased the performance of turbocharger system (turbocharged diesel engine).the intercooler are this two type are

generally used air-to-air intercooler and air-to-water intercooler. Increasing fuel prices and more strin-gent emission regulations

are the most powerful driving force behind the developments. This particularly applies in the commercial vehicle sector, where

optimal efficiency is the permanent objective. The commercial vehicle of the future is characterized by high cost-effectiveness

and meets all applicable emission regulations. Mobility will remain at least at the cur-rent level, but will more likely increase.

Coolers of different constructions and versions are used for the charge air inter cooling.

Keywords: Turbocharge System, Inter Cooling Process, Charge Air Cooler

_______________________________________________________________________________________________________

I. INTRODUCTION

This paper are analyze the turbocharged diesel engine using inter-cooling and inter-cooling process .The inter-cooling work are

the intercooler is any mechanical device used to cool a fluid, including liquids or gases, between stages of a multi-stage heating

process, typically a heat exchanger that removes waste heat in a gas compressor. They are used in many applications, including

air compressors, air conditioners, refrigerators, and gas turbines, and are widely known in automotive use as an air-to-air or airto-liquid cooler for forced induction (turbocharged or supercharged) internal combustion engines to improve their volumetric

efficiency by increasing intake air charge density through nearly isobaric (constant pressure) cooling. And inter cooling of filling

medium has also been used for almost a hundred years. From the mentioned it results that not only theoretical fundamentals of

turbo-charging and supercharging of combustion engines fuelled by liquid and gas fuels but also their practical utilization have

been well-known and widely recognized. The share of production and utilization of turbo-charging or supercharging combustion

engines has significantly increased recently. It is the case of both supercharged compression ignition engines and also of

supercharged spark ignition engines.

Fig. 1: Turbo-charger system with intercooler system

All rights reserved by www.ijirst.org

75

Review of Effect on Turbocharge System with Inter Cooling Process

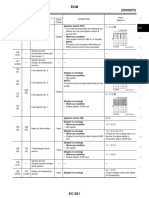

(IJIRST/ Volume 2 / Issue 06/ 013)

II. INTERCOOLING MODEL

The intercooler is modelled as a heat exchanger with fixed area, heat transfer coefficient and cooling volumetric flow. Decrease

of charge air temperature determined from heat exchanger

.

Effectiveness (

where is:

rtemp(2), K compressor discharge temperature,

hi(3),

K intercooler discharge temperature and

hi(2),

K Coolant inlet temperature ( is assumed to be fixed).

Fig. 2: schematic of intercooler

The heat exchanger effectiveness can be derived from graphic correlations for the various types heat exchanger (6). Effectiveness

can be determined with capacity ratio and the number of heat transfer unit, the expression for effectiveness is a simple from

Number of heat

Transfer unit (Ns) is determined from:

Where is

S, m2

Surface area heat Exchange (is fixed),

U, J/m2K

heat transfer coefficient based on surface area S and

Cmap (1) , kg/s flow rates charge air and

cp, J/kgK

specific heats at constant pressure.

III. CONTENTS

1)

2)

3)

Internal combustion engines

Air-to-liquid intercoolers

Charge air cooler

IV. INTERNAL COMBUSTION ENGINES

Intercoolers increase the efficiency of the induction system by reducing induction air heat created by the turbocharger and

promoting more thorough combustion. This removes the heat of compression (i.e., the temperature rise) that occurs in any gas

when its pressure is raised or its unit mass per unit volume (density) is increased.

Intercoolers also eliminate the need for using the wasteful method of lowering intake charge temperature by the injection of

excess fuel into the cylinders' air induction chambers, to cool the intake air charge, prior to its flowing into the cylinders.

This term is now considered archaic in modern automobile terminology, since most forced-induction vehicles have singlestage turbochargers, although "after cooler" is still in common use in the piston-engine aircraft industry. In a vehicle fitted with

All rights reserved by www.ijirst.org

76

Review of Effect on Turbocharge System with Inter Cooling Process

(IJIRST/ Volume 2 / Issue 06/ 013)

two-stage turbocharging, it is possible to have both an intercooler (between the two turbocharger units) and an after cooler

(between the second-stage turbo and the engine. In general, an intercooler or after cooler is said to be a charge-air cool.

Compression by the turbocharger causes the intake air to heat up and heat is added due to compressor inefficiencies (adiabatic

efficiency).

Fig. 3: Courses on temperature on engine entry

V. AIR-TO-LIQUID INTERCOOLERS

A custom-built air-to-water intercooler, as used in a time attack car, Air-to-liquid intercoolers are heat exchangers that transfer

intake charge heat to an intermediate fluid, usually water, which finally rejects heat to the air. These systems use radiators in

other locations, usually due to space constraints, to reject unwanted heat, similar to an automotive radiator cooling system. Airto-liquid intercoolers are usually heavier than their air-to-air counterparts due to additional components making up the system

(water circulation pump, radiator, fluid, and plumbing.

Air-to-liquid intercoolers are by far the most common form of intercooler found on marine engines, given that a limitless

supply of cooling water is available and most engines are located in closed compartments where obtaining a good flow of

cooling air for an air-to-air unit would be difficult. In such a system, the intercooler will be attached to the sea water circuit and

placed before the engine's own heat exchanger to ensure a supply of cool water.

VI. CHARGE AIR COOLER

A charge air cooler is used to cool engine air after it has passed through a turbocharger, but before it enters the engine. The idea

is to return the air to a lower temperature, for the optimum power for the combustion process within the engine.

A charge-air cooler is simply an all-encompassing term, meaning that it cools the turbo's air charge before it is routed into the

engine. Usually a charge-air cooler means an air-to-air cooler where the heat is rejected using ambient air flowing through the

heat exchanger, much like the engine's coolant radiator.

An intercooler, or "Charge-Air Cooler", is an air-to-air or air-to-liquid heat exchange device used on turbocharged internal

combustion engines to improve their volumetric efficiency by increasing intake air-charge density through isochoric cooling. In

general, an intercooler or after-cooler is said to be a Charge-Air Cooler.

VII. FUTURE PROSPECT

In relation to possible cost savings, measures involving other engine components are being looked into, as well as measures

involving the PBS module itself, such as the use of plastic components. In particular, the possibility of producing the compressor

wheel from the turbocharger out of steel or a ferrous alloy is currently being looked into. Compressor wheels of turbochargers

are increasingly being made from titanium alloys instead of aluminum alloys, due to the current charging-air pressure

requirements. This involves considerable costs. Compression wheels made from ferrous alloys are normally not conceive-able,

All rights reserved by www.ijirst.org

77

Review of Effect on Turbocharge System with Inter Cooling Process

(IJIRST/ Volume 2 / Issue 06/ 013)

due to their high mass/ inertia and the associated response drawbacks. Simulations carried out have shown that these response

drawbacks are more than compensated.

VIII. CONCLUSION

Efficient way which currently uses to reduce the fuel consumption is based in reduction cylinder volume of internal combustion

engine and power to be same or higher. Key component is turbocharged diesel internal combustion engine. It is possible and

practical to use heat transfer calculations when sizing a turbocharger cooling system. However, one must take into consideration

the operational environment and flow characteristics of the system in order to make an informed decision on which system to

install. Mutual confrontation of output of simulation and experiment will be employed in the improvement of further steps to be

taken to make the obtained results accessible. The engine tests were carried out in five points of its external rotation

characteristic.

REFERENCES

[1]

[2]

[3]

[4]

Dr. Manuel Marx,Project Manager PBS at the Knorr Bremse Systeme fr NFZ GmbH in Munich (Germany), Improving the Torque Behaviour of

Turbocharged Diesel Engines by Injecting Compressed Air.

Vladimr Hlavana, University of ilina, Department of Automotive Technology, the influence of intensity of charge air inter-cooling on diesel engine gas.

Jenelle Pope,A Rensselaer Polytechnic Institute, Analysis of a Turbocharger System for a Diesel Engine.

Dr. sc. Naser B. Lajqi, University of Prishtina, Mechanical Engineering Faculty Prishtina,Republic of Kosova, effect of intercooler on turbocharged diesel

engine performance

All rights reserved by www.ijirst.org

78

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Postprocessing of Compacted Images Through Consecutive DenoisingDocumento4 páginasPostprocessing of Compacted Images Through Consecutive DenoisingIJIRSTAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemDocumento9 páginasThe Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemIJIRSTAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Experimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061Documento7 páginasExperimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061IJIRSTAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Development of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalDocumento7 páginasDevelopment of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalIJIRSTAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Vibration Analysis of Composite Leaf Spring by Finite Element MethodDocumento7 páginasVibration Analysis of Composite Leaf Spring by Finite Element MethodIJIRSTAinda não há avaliações

- Patterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduDocumento10 páginasPatterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduIJIRSTAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Currency Recognition Blind Walking StickDocumento3 páginasCurrency Recognition Blind Walking StickIJIRSTAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Reconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewDocumento3 páginasReconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewIJIRSTAinda não há avaliações

- Multi-Physics Based Simulations of A Shock Absorber Sub-SystemDocumento7 páginasMulti-Physics Based Simulations of A Shock Absorber Sub-SystemIJIRSTAinda não há avaliações

- Satellite Dish Positioning SystemDocumento5 páginasSatellite Dish Positioning SystemIJIRST100% (1)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Manganese: Affecting Our Environment (Water, Soil and Vegetables)Documento7 páginasManganese: Affecting Our Environment (Water, Soil and Vegetables)IJIRSTAinda não há avaliações

- Physico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduDocumento3 páginasPhysico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduIJIRSTAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Custom ROMDocumento3 páginasCustom ROMIJIRSTAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Arduino-UNO Based Magnetic Field Strength MeasurementDocumento4 páginasArduino-UNO Based Magnetic Field Strength MeasurementIJIRSTAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Experimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandDocumento6 páginasExperimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandIJIRSTAinda não há avaliações

- Study On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)Documento10 páginasStudy On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)IJIRSTAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Performance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointDocumento5 páginasPerformance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointIJIRSTAinda não há avaliações

- Induction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationDocumento7 páginasInduction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationIJIRSTAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Impact of Different Soils and Seismic Zones On Varying Height of Framed StructuresDocumento8 páginasImpact of Different Soils and Seismic Zones On Varying Height of Framed StructuresIJIRSTAinda não há avaliações

- Experimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesDocumento7 páginasExperimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesIJIRSTAinda não há avaliações

- Development of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesDocumento4 páginasDevelopment of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesIJIRSTAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Efficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeDocumento6 páginasEfficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeIJIRSTAinda não há avaliações

- Literature Review For Designing of Portable CNC MachineDocumento3 páginasLiterature Review For Designing of Portable CNC MachineIJIRSTAinda não há avaliações

- Women Protection Mechanism With Emergency Communication Using Hand Waving PatternDocumento5 páginasWomen Protection Mechanism With Emergency Communication Using Hand Waving PatternIJIRSTAinda não há avaliações

- Intelligent Irrigation SystemDocumento5 páginasIntelligent Irrigation SystemIJIRSTAinda não há avaliações

- Rock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)Documento5 páginasRock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)IJIRSTAinda não há avaliações

- Analysis of Agent Oriented Software EngineeringDocumento5 páginasAnalysis of Agent Oriented Software EngineeringIJIRSTAinda não há avaliações

- Comparative Study of Inner Core, Peripheral and RC Shear Wall SystemDocumento8 páginasComparative Study of Inner Core, Peripheral and RC Shear Wall SystemIJIRSTAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Infiltration, Permeability, Liquid Limit and Plastic Limit of SoilDocumento12 páginasInfiltration, Permeability, Liquid Limit and Plastic Limit of SoilIJIRSTAinda não há avaliações

- Para-Flex Couplings: Includes ATEX Certified Couplings Instruction ManualDocumento4 páginasPara-Flex Couplings: Includes ATEX Certified Couplings Instruction Manualrrobles011Ainda não há avaliações

- CATIA Apt CodeDocumento24 páginasCATIA Apt CodeparipasuAinda não há avaliações

- Arduino Code Dual AxisDocumento2 páginasArduino Code Dual AxissunilkumareceAinda não há avaliações

- Gravimetic FeedersDocumento26 páginasGravimetic FeedersLyndsey Cooper100% (1)

- Swimming Pool Heat PumpDocumento2 páginasSwimming Pool Heat PumpMohammed ErshadAinda não há avaliações

- Kel 4. C-D6R TextsDocumento22 páginasKel 4. C-D6R TextsGregk Dirgantara100% (4)

- Despiece YamahaDocumento55 páginasDespiece Yamahagustavo barbozaAinda não há avaliações

- Teknik Kendaraan Ringan OtomotifDocumento5 páginasTeknik Kendaraan Ringan OtomotifSupriyadi donopawiroAinda não há avaliações

- Powertrain Troubleshooting (Test and Adjust)Documento11 páginasPowertrain Troubleshooting (Test and Adjust)Jean Jacques ouanda100% (1)

- 0h0983 B PDFDocumento156 páginas0h0983 B PDFjulio cesar100% (2)

- Tutorial Spur GearDocumento2 páginasTutorial Spur GearMayankVijayAinda não há avaliações

- Jeknavorian Emviar Alis AditivosDocumento3 páginasJeknavorian Emviar Alis AditivosHuaman Chavez Jesus AngelAinda não há avaliações

- Parts - 3121245 GM Engine Parts Supplement - 12-30-13 - Global - English PDFDocumento100 páginasParts - 3121245 GM Engine Parts Supplement - 12-30-13 - Global - English PDFivanAinda não há avaliações

- 6 Causes of Decanter Centrifuge Vibration and How To Fix ThemDocumento9 páginas6 Causes of Decanter Centrifuge Vibration and How To Fix ThemNESAEIDARYOUSHAinda não há avaliações

- Automatic Transmission: Group 23ADocumento178 páginasAutomatic Transmission: Group 23ADaniel QuisbertAinda não há avaliações

- f24 English 406 Ec 0551Documento1 páginaf24 English 406 Ec 0551Arkady GrandsonAinda não há avaliações

- Mercury Verado Gen4Documento5 páginasMercury Verado Gen4이영석Ainda não há avaliações

- 668 Sello Cierre Tipò DFL108Documento2 páginas668 Sello Cierre Tipò DFL108RPINILLA (EICO S.A.)Ainda não há avaliações

- Group 3 Tests and Adjustments: 1. Clutch Cut-Off Pressure Switch TestDocumento3 páginasGroup 3 Tests and Adjustments: 1. Clutch Cut-Off Pressure Switch TestHenry Valeriano MaqueraAinda não há avaliações

- 4R70W Rebuild ChecklistDocumento26 páginas4R70W Rebuild ChecklistSamuel Zuniga88% (8)

- Cross Reference PM Family Old Spare Parts To New KitsDocumento4 páginasCross Reference PM Family Old Spare Parts To New KitsLuis Angulo CaroAinda não há avaliações

- Propel SystemsDocumento32 páginasPropel SystemsPerrote Caruso Perrito100% (1)

- 70ZV 2 (EU Trouble)Documento115 páginas70ZV 2 (EU Trouble)Halil KaraAinda não há avaliações

- Grados de Heidelberg SM 102 4 PDF FreeDocumento16 páginasGrados de Heidelberg SM 102 4 PDF FreeMinhduclabels Sales100% (1)

- TEXPACK TemplateDocumento43 páginasTEXPACK TemplatekallatisAinda não há avaliações

- GT Traning - M701F - Cilegon (Text) PDFDocumento121 páginasGT Traning - M701F - Cilegon (Text) PDFAna Jochrana100% (2)

- Fabrication of Spark Plug Testing Machine PDFDocumento2 páginasFabrication of Spark Plug Testing Machine PDFTasha0% (1)

- Charging Systems: in This Presentation You Will: Identify Different Types of Charging SystemsDocumento24 páginasCharging Systems: in This Presentation You Will: Identify Different Types of Charging SystemsEnoch MwesigwaAinda não há avaliações

- Japanese Tool Box PlanDocumento2 páginasJapanese Tool Box PlanRJ Bevy67% (3)

- db4429 5514Documento4 páginasdb4429 5514WillianPachecoAinda não há avaliações

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseNo EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseNota: 4.5 de 5 estrelas4.5/5 (51)

- The Laws of Thermodynamics: A Very Short IntroductionNo EverandThe Laws of Thermodynamics: A Very Short IntroductionNota: 4.5 de 5 estrelas4.5/5 (10)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionNo EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionNota: 4.5 de 5 estrelas4.5/5 (3)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNo EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNota: 5 de 5 estrelas5/5 (1)