Escolar Documentos

Profissional Documentos

Cultura Documentos

Unit4 Gears

Enviado por

Gokulraju RangasamyTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Unit4 Gears

Enviado por

Gokulraju RangasamyDireitos autorais:

Formatos disponíveis

ME 44 Kinematics of Machines

Chapter 4: Gears

ME44 KINEMATICS OF MACHINES

Dr.T.V.Govindaraju

Principal, Shirdi Sai Engineering College

Anekal, Bangalore-562 106

email: govindaraju_tv@yahoo.com

Dr. T.V.Govindaraju. SSEC

ME 44 Kinematics of Machines

Chapter 4: Gears

4.0 Gears:

Introduction: The slip and creep in the belt or rope drives is a common phenomenon, in the

transmission of motion or power between two shafts. The effect of slip is to reduce the velocity

ratio of the drive. In precision machine, in which a definite velocity ratio is importance (as in

watch mechanism, special purpose machines..etc), the only positive drive is by means of gears or

toothed wheels.

Friction Wheels: Kinematiclly, the motion and

power transmitted by gears is equivalent to that

transmitted by friction wheels or discs in contact

with sufficient friction between them. In order to

understand motion transmitted by two toothed

wheels, let us consider the two discs placed together

as shown in the figure 4.1.

Figure 4.1

When one of the discs is rotated, the other disc will be rotate as long as the tangential force

exerted by the driving disc does not exceed the maximum frictional resistance between the two

discs. But when the tangential force exceeds the frictional resistance, slipping will take place

between the two discs. Thus the friction drive is not positive a drive, beyond certain limit.

Gears are machine elements that transmit motion by means of successively engaging teeth. The

gear teeth act like small levers. Gears are highly efficient (nearly 95%) due to primarily rolling

contact between the teeth, thus the motion transmitted is considered as positive.

Gears essentially allow positive engagement between teeth so high forces can be transmitted

while still undergoing essentially rolling contact. Gears do not depend on friction and do best

when friction is minimized.

Some common places that gears can normally be found are:

Printing machinery parts

Rotary die cutting

machines

Blow molding machinery

Agricultural equipment

High volume vacuum

pumps

Boat out drives

Hoists and Cranes

Automotive prototype and

reproduction

Diesel engine builders

Dr. T.V.Govindaraju. SSEC

Newspaper Industry

Plastics machinery builders

Book binding machines

Injection molding machinery

Motorcycle Transmissions (street Heavy earth moving to

and race applications)

personal vehicles

Polymer pumps

High volume water pumps for

municipalities

Turbo boosters for automotive

Marine applications

applications

Special offshore racing drive

Canning and bottling

systems

machinery builders

Commercial and Military

Military offroad vehicles

operations

Low volume automotive

Stamping presses

production

Special gear box builders

Many different special

machine tool builders

ME 44 Kinematics of Machines

Chapter 4: Gears

4.1 Gear Classification: Gears may be classified according to the relative position of the axes of

revolution. The axes may be

1.

2.

3.

Gears for connecting parallel shafts,

Gears for connecting intersecting shafts,

Gears for neither parallel nor intersecting shafts.

Gears for connecting parallel shafts

1. Spur gears: Spur gears are the most common type of gears. They have straight teeth, and

are mounted on parallel shafts. Sometimes, many spur gears are used at once to create very

large gear reductions. Each time a gear tooth engages a tooth on the other gear, the teeth

collide, and this impact makes a noise. It also increases the stress on the gear teeth. To

reduce the noise and stress in the gears, most of the gears in your car are helical.

Spur gears (Emerson Power Transmission Corp)

External contact

Iinternal contact

Spur gears are the most commonly used gear type. They are characterized by teeth, which are

perpendicular to the face of the gear. Spur gears are most commonly available, and are

generally the least expensive.

Limitations: Spur gears generally cannot be used when a direction change between the two

shafts is required.

Advantages: Spur gears are easy to find, inexpensive, and efficient.

2. Parallel helical gears: The teeth on helical gears are cut at an angle to the face of the gear.

When two teeth on a helical gear system engage, the contact starts at one end of the tooth

and gradually spreads as the gears rotate, until the two teeth are in full engagement.

Helical gears

(EmersonPower Transmission Corp)

Dr. T.V.Govindaraju. SSEC

Herringbone gears

(or double-helical gears)

ME 44 Kinematics of Machines

Chapter 4: Gears

This gradual engagement makes helical gears operate much more smoothly and quietly than spur

gears. For this reason, helical gears are used in almost all car transmission.

Because of the angle of the teeth on helical gears, they create a thrust load on the gear when they

mesh. Devices that use helical gears have bearings that can support this thrust load.

One interesting thing about helical gears is that if the angles of the gear teeth are correct, they

can be mounted on perpendicular shafts, adjusting the rotation angle by 90 degrees.

Helical gears to have the following differences from spur gears of the same size:

o

o

o

Tooth strength is greater because the teeth are longer,

Greater surface contact on the teeth allows a helical gear to carry more load than a spur

gear

The longer surface of contact reduces the efficiency of a helical gear relative to a spur

gear

Rack and pinion (The rack is like a gear whose axis is at

infinity.): Racks are straight gears that are used to convert

rotational motion to translational motion by means of a

gear mesh. (They are in theory a gear with an infinite pitch

diameter). In theory, the torque and angular velocity of the

pinion gear are related to the Force and the velocity of the

rack by the radius of the pinion gear, as is shown.

Perhaps the most well-known application of a rack is the rack and pinion steering system

used on many cars in the past

Gears for connecting intersecting shafts: Bevel gears are useful when the direction of a

shaft's rotation needs to be changed. They are usually mounted on shafts that are 90 degrees

apart, but can be designed to work at other angles as well.

The teeth on bevel gears can be straight, spiral or hypoid. Straight bevel gear teeth actually have

the same problem as straight spur gear teeth, as each tooth engages; it impacts the corresponding

tooth all at once.

Just like with spur gears, the solution to this problem is to curve the gear teeth. These spiral teeth

engage just like helical teeth: the contact starts at one end of the gear and progressively spreads

across the whole tooth.

Straight bevel gears

Dr. T.V.Govindaraju. SSEC

Spiral bevel gears

ME 44 Kinematics of Machines

Chapter 4: Gears

On straight and spiral bevel gears, the shafts must

be perpendicular to each other, but they must also

be in the same plane. The hypoid gear, can engage

with the axes in different planes.

This feature is used in many car differentials. The

ring gear of the differential and the input pinion

gear are both hypoid. This allows the input pinion

to be mounted lower than the axis of the ring gear.

Figure shows the input pinion engaging the ring

gear of the differential. Since the driveshaft of the

car is connected to the input pinion, this also lowers Hypoid gears (Emerson Power Transmission Corp)

the driveshaft. This means that the driveshaft

doesn't pass into the passenger compartment of the car as much, making more room for people

and cargo.

Neither parallel nor intersecting shafts: Helical gears may be used to mesh two shafts that

are not parallel, although they are still primarily use in parallel shaft applications. A special

application in which helical gears are used is a crossed gear mesh, in which the two shafts are

perpendicular to each other.

Crossed-helical gears

Worm and worm gear: Worm gears are used when large gear

reductions are needed. It is common for worm gears to have

reductions of 20:1, and even up to 300:1 or greater.

Many worm gears have an interesting property that no other

gear set has: the worm can easily turn the gear, but the gear

cannot turn the worm. This is because the angle on the worm

is so shallow that when the gear tries to spin it, the friction

between the gear and the worm holds the worm in place.

This feature is useful for machines such as conveyor systems,

in which the locking feature can act as a brake for the

conveyor when the motor is not turning. One other very

interesting usage of worm gears is in the Torsen differential,

which is used on some high-performance cars and trucks.

Dr. T.V.Govindaraju. SSEC

ME 44 Kinematics of Machines

Chapter 4: Gears

4.3 Terminology for Spur Gears

Figure 4-4 Spur Gear

Dr. T.V.Govindaraju. SSEC

ME 44 Kinematics of Machines

Chapter 4: Gears

Terminology:

Addendum: The radial distance between the Pitch Circle and the top of the teeth.

Arc of Action: Is the arc of the Pitch Circle between the beginning and the end of the

engagement of a given pair of teeth.

Arc of Approach: Is the arc of the Pitch Circle between the first point of contact of the gear

teeth and the Pitch Point.

Arc of Recession: That arc of the Pitch Circle between the Pitch Point and the last point of

contact of the gear teeth.

Backlash: Play between mating teeth.

Base Circle: The circle from which is generated the involute curve upon which the tooth profile

is based.

Center Distance: The distance between centers of two gears.

Chordal Addendum: The distance between a chord, passing through the points where the Pitch

Circle crosses the tooth profile, and the tooth top.

Chordal Thickness: The thickness of the tooth measured along a chord passing through the

points where the Pitch Circle crosses the tooth profile.

Circular Pitch: Millimeter of Pitch Circle circumference per tooth.

Circular Thickness: The thickness of the tooth measured along an arc following the Pitch Circle

Clearance: The distance between the top of a tooth and the bottom of the space into which it fits

on the meshing gear.

Contact Ratio: The ratio of the length of the Arc of Action to the Circular Pitch.

Dedendum: The radial distance between the bottom of the tooth to pitch circle.

Diametral Pitch: Teeth per mm of diameter.

Dr. T.V.Govindaraju. SSEC

ME 44 Kinematics of Machines

Chapter 4: Gears

Face: The working surface of a gear tooth, located between the pitch diameter and the top of the

tooth.

Face Width: The width of the tooth measured parallel to the gear axis.

Flank: The working surface of a gear tooth, located between the pitch diameter and the bottom

of the teeth

Gear: The larger of two meshed gears. If both gears are the same size, they are both called

"gears".

Land: The top surface of the tooth.

Line of Action: That line along which the point of contact between gear teeth travels, between

the first point of contact and the last.

Module: Millimeter of Pitch Diameter to Teeth.

Pinion: The smaller of two meshed gears.

Pitch Circle: The circle, the radius of which is equal to the distance from the center of the gear

to the pitch point.

Diametral pitch: Teeth per millimeter of pitch diameter.

Pitch Point: The point of tangency of the pitch circles of two meshing gears, where the Line of

Centers crosses the pitch circles.

Pressure Angle: Angle between the Line of Action and a line perpendicular to the Line of

Centers.

Profile Shift: An increase in the Outer Diameter and Root Diameter of a gear, introduced to

lower the practical tooth number or acheive a non-standard Center Distance.

Ratio: Ratio of the numbers of teeth on mating gears.

Root Circle: The circle that passes through the bottom of the tooth spaces.

Root Diameter: The diameter of the Root Circle.

Working Depth: The depth to which a tooth extends into the space between teeth on the mating

gear.

Dr. T.V.Govindaraju. SSEC

ME 44 Kinematics of Machines

Chapter 4: Gears

4.2 Gear-Tooth Action

4.2.1 Fundamental Law of Gear-Tooth

Action

Figure 5.2 shows two mating gear teeth, in

which

Tooth profile 1 drives tooth profile 2 by

acting at the instantaneous contact point K.

N1N2 is the common normal of the two

profiles.

N1 is the foot of the perpendicular from O1

to N1N2

N2 is the foot of the perpendicular from O2

to N1N2.

Although the two profiles have different

velocities V1 and V2 at point K, their velocities

along N1N2 are equal in both magnitude and

direction. Otherwise the two tooth profiles

would separate from each other. Therefore, we

have

O1 N 1 1 O2 N 2 2

4.1

or

1 O2 N 2

2 O1 N 1

4.2

Figure 5-2 Two gearing tooth profiles

We notice that the intersection of the tangency N1N2 and the line of center O1O2 is point P,

and from the similar triangles,

O1 N 1 P O2 N 2 P

4.3

Thus, the relationship between the angular velocities of the driving gear to the driven gear, or

velocity ratio, of a pair of mating teeth is

1 O2 P

2 O1 P

4.4

Point P is very important to the velocity ratio, and it is called the pitch point. Pitch point divides

the line between the line of centers and its position decides the velocity ratio of the two teeth.

The above expression is the fundamental law of gear-tooth action.

From the equations 4.2 and 4.4, we can write,

Dr. T.V.Govindaraju. SSEC

ME 44 Kinematics of Machines

Chapter 4: Gears

1 O2 P O2 N 2

2 O1 P O1 N 1

4.5

which determines the ratio of the radii of the two base circles. The radii of the base circles is

given by:

O1 N 1 O1 P cos

and

O2 N 2 O2 P cos

4.6

Also the centre distance between the base circles:

O1O2 O1 P O2 P

O1 N 1 O2 N 2 O1 N 1 O2 N 2

cos cos

cos

4.7

where is the pressure angle or the angle of obliquity. It is the angle which the common normal

to the base circles make with the common tangent to the pitch circles.

4.2.2 Constant Velocity Ratio

For a constant velocity ratio, the position of P should remain unchanged. In this case, the motion

transmission between two gears is equivalent to the motion transmission between two imagined

slip-less cylinders with radius R1 and R2 or diameter D1 and D2. We can get two circles whose

centers are at O1 and O2, and through pitch point P. These two circles are termed pitch circles.

The velocity ratio is equal to the inverse ratio of the diameters of pitch circles. This is the

fundamental law of gear-tooth action.

The fundamental law of gear-tooth action may now also be stated as follow (for gears with

fixed center distance)

A common normal (the line of action) to the tooth profiles at their point of contact must, in all

positions of the contacting teeth, pass through a fixed point on the line-of-centers called the pitch

point

Any two curves or profiles engaging each other and satisfying the law of gearing are conjugate

curves, and the relative rotation speed of the gears will be constant(constant velocity ratio).

4.2.3 Conjugate Profiles

To obtain the expected velocity ratio of two tooth profiles, the normal line of their profiles must

pass through the corresponding pitch point, which is decided by the velocity ratio. The two

profiles which satisfy this requirement are called conjugate profiles. Sometimes, we simply

termed the tooth profiles which satisfy the fundamental law of gear-tooth action the conjugate

profiles.

Although many tooth shapes are possible for which a mating tooth could be designed to satisfy

the fundamental law, only two are in general use: the cycloidal and involute profiles. The

involute has important advantages; it is easy to manufacture and the center distance between a

pair of involute gears can be varied without changing the velocity ratio. Thus close tolerances

between shaft locations are not required when using the involute profile. The most commonly

used conjugate tooth curve is the involute curve. (Erdman & Sandor).

Dr. T.V.Govindaraju. SSEC

10

ME 44 Kinematics of Machines

Chapter 4: Gears

conjugate action : It is essential for correctly meshing gears, the size of the teeth ( the module )

must be the same for both the gears.

Another requirement - the shape of teeth necessary for the speed ratio to remain constant during

an increment of rotation; this behavior of the contacting surfaces (ie. the teeth flanks) is known

as conjugate action.

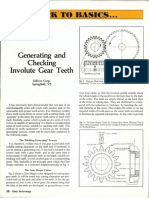

4.3 Involute Curve

The following examples are involute spur gears. We use the word involute because the contour

of gear teeth curves inward. Gears have many terminologies, parameters and principles. One of

the important concepts is the velocity ratio, which is the ratio of the rotary velocity of the driver

gear to that of the driven gears.

4.1 Generation of the Involute Curve

The curve most commonly used for gear-tooth

profiles is the involute of a circle. This involute

curve is the path traced by a point on a line as

the line rolls without slipping on the

circumference of a circle. It may also be defined

as a path traced by the end of a string, which is

originally wrapped on a circle when the string is

unwrapped from the circle. The circle from

which the involute is derived is called the base

circle.

4.2 Properties of Involute Curves

Figure 4.3 Involute curve

1. The line rolls without slipping on the circle.

2. For any instant, the instantaneous center of the motion of the line is its point of tangent with

the circle.

Note: We have not defined the term instantaneous center previously. The instantaneous center

or instant center is defined in two ways.

1. When two bodies have planar relative motion, the instant center is a point on one body about

which the other rotates at the instant considered.

Dr. T.V.Govindaraju. SSEC

11

ME 44 Kinematics of Machines

Chapter 4: Gears

2. When two bodies have planar relative motion, the instant center is the point at which the

bodies are relatively at rest at the instant considered.

3. The normal at any point of an involute is tangent to the base circle. Because of the property

(2) of the involute curve, the motion of the point that is tracing the involute is perpendicular

to the line at any instant, and hence the curve traced will also be perpendicular to the line at

any instant.

There is no involute curve within the base circle.

Cycloidal profile:

Epicycliodal Profile:

Hypocycliodal Profile:

The involute profile of gears has important advantages;

It is easy to manufacture and the center distance between a pair of involute gears can be

varied without changing the velocity ratio. Thus close tolerances between shaft locations

are not required. The most commonly used conjugate tooth curve is the involute curve.

(Erdman & Sandor).

2. In involute gears, the pressure angle, remains constant between the point of tooth engagement

and disengagement. It is necessary for smooth running and less wear of gears.

Dr. T.V.Govindaraju. SSEC

12

ME 44 Kinematics of Machines

Chapter 4: Gears

But in cycloidal gears, the pressure angle is maximum at the beginning of engagement,

reduces to zero at pitch point, starts increasing and again becomes maximum at the end of

engagement. This results in less smooth running of gears.

3. The face and flank of involute teeth are generated by a single curve where as in cycloidal

gears, double curves (i.e. epi-cycloid and hypo-cycloid) are required for the face and flank

respectively. Thus the involute teeth are easy to manufacture than cycloidal teeth.

In involute system, the basic rack has straight teeth and the same can be cut with simple tools.

Advantages of Cycloidal gear teeth:

1. Since the cycloidal teeth have wider flanks, therefore the cycloidal gears are stronger than the

involute gears, for the same pitch. Due to this reason, the cycloidal teeth are preferred specially

for cast teeth.

2. In cycloidal gears, the contact takes place between a convex flank and a concave surface,

where as in involute gears the convex surfaces are in contact. This condition results in less wear

in cycloidal gears as compared to involute gears. However the difference in wear is negligible

3. In cycloidal gears, the interference does not occur at all. Though there are advantages of

cycloidal gears but they are outweighed by the greater simplicity and flexibility of the involute

gears.

Properties of involute teeth:

1. A normal drawn to an involute at pitch point is a tangent to the base circle.

2. Pressure angle remains constant during the mesh of an involute gears.

3. The involute tooth form of gears is insensitive to the centre distance and depends only on the

dimensions of the base circle.

4. The radius of curvature of an involute is equal to the length of tangent to the base circle.

5. Basic rack for involute tooth profile has straight line form.

6. The common tangent drawn from the pitch point to the base circle of the two involutes is the

line of action and also the path of contact of the involutes.

7. When two involutes gears are in mesh and rotating, they exhibit constant angular velocity ratio

and is inversely proportional to the size of base circles. (Law of Gearing or conjugate action)

8. Manufacturing of gears is easy due to single curvature of profile.

Dr. T.V.Govindaraju. SSEC

13

ME 44 Kinematics of Machines

Chapter 4: Gears

System of Gear Teeth

The following four systems of gear teeth are commonly used in practice:

1. 14 O Composite system

2. 14 O Full depth involute system

3. 20O Full depth involute system

4. 20O Stub involute system

The 14O composite system is used for general purpose gears.

It is stronger but has no interchangeability. The tooth profile of this system has cycloidal curves

at the top and bottom and involute curve at the middle portion.

The teeth are produced by formed milling cutters or hobs.

The tooth profile of the 14O full depth involute system was developed using gear hobs for spur

and helical gears.

The tooth profile of the 20o full depth involute system may be cut by hobs.

The increase of the pressure angle from 14o to 20o results in a stronger tooth, because the tooth

acting as a beam is wider at the base.

The 20o stub involute system has a strong tooth to take heavy loads.

Dr. T.V.Govindaraju. SSEC

14

ME 44 Kinematics of Machines

Chapter 4: Gears

Involutometry

Addendum Circle

Pitch Circle

C

B

r

ra

E

F

Gear

Base Circle

The study of the geometry of the involute profile for gear teeth is called involumetry. Consider

an involute of base circle radius ra and two points B and C on the involute as shown in figure.

Draw normal to the involute from the points B and C. The normal BE and CF are tangents to the

Base circle.

Let

ra= base circle radius of gear

rb= radius of point B on the involute

rc= radius of point C on the involute

and

b= pressure angle for the point B

c= pressure angle for the point C

tb= tooth thickness along the arc at B

tc= tooth thickness along the arc at C

From OBE and

OCF

ra rb cos b

(1)

ra rc cos c

Therefore

rb cos b rc cos c

Dr. T.V.Govindaraju. SSEC

15

ME 44 Kinematics of Machines

Chapter 4: Gears

From the properties of the Involute:

Arc AE = Length BE and

Arc AF = Length CF

ArcAE BE

tan b

OE

OE

AOB AOE b tan b b

AOE

Inv.b tan b b

Expression tan b b is

called involute function

Similarly:

ArcAF BE

tan c

OF

OF

AOC AOF c tan C C

AOF

Inv.c tan c c

At the po int B

AOD AOB

tb

2rb

tan b b

tb

2rb

At the po int C

AOD AOC

tc

2rb

tan c c

tc

2rc

Equating the above equations :

tan b b

inv. b

tb

t

tan c c c

2rb

2rc

tb

t

inv.c c

2rb

2rc

t

tc inv.b inv. c b 2rc

2rb

tooth thickness at C

Using this equation and knowing tooth thickness at any point on the tooth, it is possible to

calculate the thickness of the tooth at any point

Dr. T.V.Govindaraju. SSEC

16

ME 44 Kinematics of Machines

Chapter 4: Gears

Path of contact:

O2

Wheel

RA

R

N

L

P

Base Circle

Pitch

Circle

Addendum

Circles

M

r

ra

O1

Pinion

Pitch

Circle

Base Circle

Consider a pinion driving wheel as shown in figure. When the pinion rotates in clockwise, the

contact between a pair of involute teeth begins at K (on the near the base circle of pinion or the

outer end of the tooth face on the wheel) and ends at L (outer end of the tooth face on the pinion

or on the flank near the base circle of wheel).

MN is the common normal at the point of contacts and the common tangent to the base circles.

The point K is the intersection of the addendum circle of wheel and the common tangent. The

point L is the intersection of the addendum circle of pinion and common tangent.

The length of path of contact is the length of common normal cut-off by the addendum circles of

the wheel and the pinion. Thus the length of part of contact is KL which is the sum of the parts of

path of contacts KP and PL. Contact length KP is called as path of approach and contact length

PL is called as path of recess.

ra = O1L = Radius of addendum circle of pinion,

and

R A = O2K = Radius of addendum circle of wheel

r = O1P = Radius of pitch circle of pinion,

and

R = O2P = Radius of pitch circle of wheel.

Radius of the base circle of pinion = O1M = O1P cos = r cos

and

Dr. T.V.Govindaraju. SSEC

17

ME 44 Kinematics of Machines

Chapter 4: Gears

radius of the base circle of wheel = O2N = O2P cos = R cos

From right angle triangle O2KN

KN

O2 K 2 O2 N 2

RA R 2 cos 2

PN O2 P sin R sin

2

Path of approach: KP

KP KN PN

RA R 2 cos 2 R sin

Similarly from right angle triangle O1ML

2

ML

O1L 2 O1M 2

ra 2 r 2 cos 2

MP O1 P sin r sin

Path of recess: PL

PL ML MP

r r 2 cos 2 r sin

Length of path of contact = KL a

2

KL KP PL

RA 2 R 2 cos 2 ra 2 r 2 cos 2 R r sin

Arc of contact: Arc of contact is the path traced by a point on the pitch circle from the

beginning to the end of engagement of a given pair of teeth. In Figure, the arc of contact is EPF

or GPH.

O2

Wheel

RA

R

N

L

Gear

Profile

E

P

Pitch

Circle

Addendum

Circles

M

r

ra

O1

Dr. T.V.Govindaraju. SSEC

Pinion

Pitch

Circle

Base Circle

18

ME 44 Kinematics of Machines

Chapter 4: Gears

Considering the arc of contact GPH.

The arc GP is known as arc of approach and the arc PH is called arc of recess. The angles

subtended by these arcs at O1 are called angle of approach and angle of recess respectively.

Length of arc of approach = arc GP

Length of arc of recess = arc PH

Lenght of path of approach

KP

cos

cos

Lenght of path of recess

PL

cos

cos

Length of arc contact = arc GPH = arc GP + arc PH

KP

PL

KL

Length of path of contact

cos cos cos

cos

Contact Ratio (or Number of Pairs of Teeth in Contact)

The contact ratio or the number of pairs of teeth in contact is defined as the ratio of the length of

the arc of contact to the circular pitch.

Mathematically,

Where:

Length of the arc of contact

PC

and

m = Module.

PC Circular pitch m

Contat ratio

Number of Pairs of Teeth in Contact

Continuous motion transfer requires two pairs of teeth in contact at the ends of the path of

contact, though there is only one pair in contact in the middle of the path, as in Figure.

The average number of teeth in contact is an important parameter - if it is too low due to the use

of inappropriate profile shifts or to an excessive centre distance.The manufacturing inaccuracies

may lead to loss of kinematic continuity - that is to impact, vibration and noise.

The average number of teeth in contact is also a guide to load sharing between teeth; it is termed

the contact ratio

Dr. T.V.Govindaraju. SSEC

19

ME 44 Kinematics of Machines

Chapter 4: Gears

Length of path of contact for Rack and Pinion:

PITCH LINE

Pc

h

a

b

T

c

RACK

Base Circle

PINION

PITCH LINE

RACK

Let

r

= Pitch circle radius of the pinion = O1P

= Pressure angle

ra. = Addendu m radius of the pinion

a = Addendum of rack

EF = Length of path of contact

EF = Path of approach EP + Path of recess PF

sin

AP

a

EP EP

a

sin

Path of recess PF NF NP

Path of approach EP

(1)

( 2)

(3)

From triangle O1 NP :

NP O1 P sin r sin

O1 N O1 P cos r cos

Dr. T.V.Govindaraju. SSEC

20

ME 44 Kinematics of Machines

Chapter 4: Gears

From triangle O1NF:

NF O1 F 2 O1 N 2

r

1

2

2

a

r 2 cos 2

1

2

Substituting NP and NF values in the equation (3)

Path of racess PF ra2 r 2 cos 2

1

2

r sin

Path of length of contact EF EP PF

Exercise problems refer presentation slides

a

ra2 r 2 cos 2

sin

1

2

r sin

Interference in Involute Gears

O2

Wheel

Base Circle

RA

R

N

L

P

Pitch

Circle

Addendum

Circles

K

M

Pitch

Circle

ra

O1

Pinion

Base Circle

Figure shows a pinion and a gear in mesh with their center as O1andO2 respectively. MN is the

common tangent to the basic circles and KL is the path of contact between the two mating teeth.

Consider, the radius of the addendum circle of pinion is increased to O 1N, the point of contact L

will moves from L to N. If this radius is further increased, the point of contact L will be inside of

base circle of wheel and not on the involute profile of the pinion.

The tooth tip of the pinion will then undercut

the tooth on the wheel at the root and

damages part of the involute profile. This

effect is known as interference, and occurs

when the teeth are being cut and weakens the

tooth at its root.

In general, the phenomenon, when the tip of

tooth undercuts the root on its mating gear is

known as interference.

Dr. T.V.Govindaraju. SSEC

Wheel

Undercut

Pinion

21

ME 44 Kinematics of Machines

Chapter 4: Gears

Similarly, if the radius of the addendum circles of the wheel increases beyond O 2M, then the tip

of tooth on wheel will cause interference with the tooth on pinion. The points M and N are called

interference points.

Interference may be avoided if the path of the contact does not extend beyond interference

points. The limiting value of the radius of the addendum circle of the pinion is O1N and of the

wheel is O2M.

The interference may only be prevented, if the point of contact between the two teeth is always

on the involute profiles and if the addendum circles of the two mating gears cut the common

tangent to the base circles at the points of tangency.

When interference is just prevented, the maximum length of path of contact is MN.

Maximum path of approach MP r sin

Maximum path of recess PN R sin

Maximum length of path of contact MN

MN MP PN r R sin

Maximum length of arc of contact

r R sin r R tan

cos

Methods to avoid Interference

1.

Height of the teeth may be reduced.

2. Under cut of the radial flank of the pinion.

3. Centre distance may be increased. It leads to increase in pressure angle.

4. By tooth correction, the pressure angle, centre distance and base circles remain unchanged, but

tooth thickness of gear will be greater than the pinion tooth thickness.

Minimum number of teeth on the pinion avoid Interference

The pinion turns clockwise and drives the gear as shown in Figure.

Points M and N are called interference points. i.e., if the contact takes place beyond M and N,

interference will occur.

The limiting value of addendum circle radius of pinion is O1N and the limiting value of

addendum circle radius of gear is O2M. Considering the critical addendum circle radius of gear,

the limiting number of teeth on gear can be calculated.

Let

= pressure angle

Dr. T.V.Govindaraju. SSEC

22

ME 44 Kinematics of Machines

Chapter 4: Gears

R = pitch circle radius of gear = mT

r = pitch circle radius of pinion = mt

T & t = number of teeth on gear & pinion

m = module

O2

Wheel

RA

R

Base Circle

N

L

P

Pitch

Circle

Max.

Addendum

Circles

K

M

r

ra

O1

Pinion

Pitch

Circle

Base Circle

aw = Addendum constant of gear (or) wheel

ap = Addendum constant of pinion

aw. m = Addendum of gear

ap. m = Addendum of pinion

G = Gear ratio = T/t

From triangle O1NP, Applying cosine rule

O1 N 2 O1 P 2 NP 2 2 O1 P PN cos O1 PN

r 2 R 2 sin 2 2 r R sin cos90

r 2 R 2 sin 2 2 r R sin 2

R 2 sin 2 2 R sin 2

RR

2

2

r 2 1

r 1 2 sin

2

r

r

rr

PN O2 P sin R sin

Limiting radius of the pinion addendum circle:

1

RR

2 mt T T

2

O1 N r 1 2 sin 2

1 2 sin 2

2 tt

rr

Dr. T.V.Govindaraju. SSEC

23

ME 44 Kinematics of Machines

Chapter 4: Gears

Addendum of the pinion = O1N - O1P

1

2 mt

mt T T

apm

1 2 sin 2

2 tt

2

mt T T

2 2

1 2 sin 1

2

tt

Addendum of the pinion = O1N - O1P

1

t T T

2 2

a p 1 2 sin 1

2

tt

2a p

t

1

2

2 1

G

G

2

sin

The equation gives minimum number of teeth required on the pinion to avoid interference.

If the number of teeth on pinion and gear is same: G=1

2a p

2

1 3 sin

1. 14 O Composite system

2. 14 O Full depth involute system

3. 20O Full depth involute system

4. 20O Stub involute system

1

2

=

=

=

=

12

32

18

14

Minimum number of teeth on the wheel avoid Interference

From triangle O2MP, applying cosine rule and simplifying, The limiting radius of wheel addendum

circle:

1

rr

2

O2 M R 1 2 sin 2

RR

mT

tt

2 2

1

sin

T T

Addendum of the pinion = O2 M- O2P

Dr. T.V.Govindaraju. SSEC

24

ME 44 Kinematics of Machines

Chapter 4: Gears

O2

Wheel

RA

Base Circle

N

L

P

Max.

Addendum

Circles

K

M

ra

O1

1 t

T

Pitch

Circle

mT

aw m

2

Pitch

Circle

Base Circle

Pinion

t

2 2

2 sin 1

T

tt

2 2

aw 1 2 sin 1

2 T T

2aW

T

1

1

1

2

1 2 sin 1

G G

The equation gives minimum number of teeth required on the wheel to avoid interference.

Minimum number of teeth on the pinion for involute rack to avoid Interference

The rack is part of toothed wheel of

infinite diameter. The base circle

diameter and profile of the involute teeth

are straight lines.

Pc

PITCH LINE

RACK

T

c

Dr. T.V.Govindaraju. SSEC

25

ME 44 Kinematics of Machines

Chapter 4: Gears

PINION

PITCH LINE

H

P

K

RACK

Let

t = Minimum number of teeth on the pinion

r = Pitch circle radius of the pinion = mt

= Pressure angle

AR.m = Addendum of rack

The straight profiles of the rack are tangential to the pinion profiles at the point of contact and

perpendicular to the tangent PM. Point L is the limit of interference.

Addendum of the rack:

AR m LH PL sin

OP sin sin

OP sin 2

r sin 2

mt

sin 2

2

2 AR

To avoid interference : t

sin 2

Backlash:

The gap between the non-drive face of the pinion tooth and the adjacent wheel tooth is known as

backlash.

If the rotational sense of the pinion were to reverse, then a period of unrestrained pinion motion

would take place until the backlash gap closed and contact with the wheel tooth re-established

impulsively.

Dr. T.V.Govindaraju. SSEC

26

ME 44 Kinematics of Machines

Chapter 4: Gears

Backlash is the error in motion that occurs when gears change direction. The term "backlash" can

also be used to refer to the size of the gap, not just the phenomenon it causes; thus, one could

speak of a pair of gears as having, for example, "0.1 mm of backlash."

A pair of gears could be designed to have zero backlash, but this would presuppose perfection in

manufacturing, uniform thermal expansion characteristics throughout the system, and no

lubricant.

Therefore, gear pairs are designed to have some backlash. It is usually provided by reducing the

tooth thickness of each gear by half the desired gap distance.

In the case of a large gear and a small pinion, however, the backlash is usually taken entirely off

the gear and the pinion is given full sized teeth.

Backlash can also be provided by moving the gears farther apart. For situations, such as

instrumentation and control, where precision is important, backlash can be minimised through

one of several techniques.

Standard

(cutting)

Pitch Circle

O2

O2

RA

R

Wheel

R'

Wheel

Base Circle

N'

'

c'

Operating

Pitch Circle

M

r

Standard

(cutting)

Pitch Circle

ra

M'

Pinion

'

O1

r'

Pinion

Figure a

Standard

(cutting)

Pitch Circle

O1

Standard

(cutting)

Pitch Circle

Base Circle

Figure b

Let

r = standard pitch circle radius of pinion

R = standard pitch circle radius of wheel

c = standard centre distance = r +R

r = operating pitch circle radius of pinion

R = operating pitch circle radius of wheel

Dr. T.V.Govindaraju. SSEC

27

ME 44 Kinematics of Machines

Chapter 4: Gears

c = operating centre distance = r + R

= Standard pressure angle

= operating pressure angle

h = tooth thickness of pinion on standard pitch circle= p/2

h = tooth thickness of pinion on operating pitch circle

Let

H = tooth thickness of gear on standard pitch circle

H1 = tooth thickness of gear on operating pitch circle

p = standard circular pitch = 2 r/ t = 2R/T

p = operating circular pitch = 2 r1/t = 2R1/T

C = change in centre distance

B = Backlash

t

= number of teeth on pinion

T = number of teeth on gear.

Involute gears have the invaluable ability of providing conjugate action when the gears' centre

distance is varied either deliberately or involuntarily due to manufacturing and/or mounting

errors.

r R c

r ' R' c'

c' cos ' c cos

cos

c' c

cos '

Now

c c'c c

cos

cos

c c

1

cos '

cos

'

On the operating pitch circle:

Operating pitch sum of tooth thickness Backlash

p ' h' H ' B

(1)

Dr. T.V.Govindaraju. SSEC

28

ME 44 Kinematics of Machines

Chapter 4: Gears

By involutometry :

h

h' 2r ' inv. inv. '

2r

H ' 2 R ' inv. inv. '

2 R

Substituting h and H in the equation (1):

h

h

p ' 2r ' inv. inv. ' 2 R ' inv. inv. '

B

2r

2 R

r ' R'

p ' h 2 inv. r ' R ' 2 inv. ' r ' R ' B

r R

c' c'

p ' h 2 c' inv. 2 c' inv. ' B

c c

c'

2c' inv. 'inv.

c

2r '

2r c'

B

2

2c' inv. 'inv.

t

2t c

2

c'

B

r ' r 2c' inv. 'inv.

t

c

B p 2h

2

r'

r ' r 2c' inv. 'inv.

t

r

Backlash B 2c' inv. 'inv.

B

There is an infinite number of possible centre distances for a given pair of profile shifted gears,

however we consider only the particular case known as the extended centre distance.

Non Standard Gears:

The important reason for using non standard gears are to eliminate undercutting, to prevent

interference and to maintain a reasonable contact ratio.

The two main non- standard gear systems:

(1) Long and short Addendum system and

(2) Extended centre distance system.

Long and Short Addendum System:

The addendum of the wheel and the addendum of the pinion are generally made of equal lengths.

Dr. T.V.Govindaraju. SSEC

29

ME 44 Kinematics of Machines

Chapter 4: Gears

Here the profile/rack cutter is advanced to a certain increment towards the gear blank and the

same quantity of increment will be withdrawn from the pinion blank.

Therefore an increased addendum for the pinion and a decreased addendum for the gear is

obtained. The amount of increase in the addendum of the pinion should be exactly equal to the

addendum of the wheel is reduced.

The effect is to move the contact region from the pinion centre towards the gear centre, thus

reducing approach length and increasing the recess length. In this method there is no change in

pressure angle and the centre distance remains standard.

Extended centre distance system:

Reduction in interference with constant contact ratio can be obtained by increasing the centre

distance. The effect of changing the centre distance is simply in increasing the pressure angle.

In this method when the pinion is being cut, the profile cutter is withdrawn a certain amount

from the centre of the pinion so the addendum line of the cutter passes through the interference

point of pinion. The result is increase in tooth thickness and decrease in tooth space.

Now If the pinion is meshed with the gear, it will be found that the centre distance has been

increased because of the decreased tooth space. Increased centre distance will have two

undesirable effects.

NOTE: Please refer presentation slides also for more figure, photos and exercise problems

References:

1.

Theory of Machines and Mechanisms by Joseph Edward Shigley and John Joseph

Uicker,Jr. McGraw-Hill International Editions.

2.

Kinematics and Dynamics of Machines by George H.Martin. McGraw-Hill

Publications.

3.

Mechanisms and Dynamics of Machinery by Hamilton H. Mabie and Fred W.

Ocvirk. John Wiley and Sons.

4.

5.

Theory of Machines by V.P.Singh. Dhanpat Rai and Co.

The Theory of Machines through solved problems by J.S.Rao. New age

international publishers.

6.

A text book of Theory of Machines by Dr.R.K.Bansal. Laxmi Publications (P) Ltd.

7.

Internet: Many Web based e notes

Dear Staff and Students, please give the feed back to improve the contents.

Dr. T.V.Govindaraju. SSEC

30

Você também pode gostar

- GE6075 PEE OldDocumento18 páginasGE6075 PEE OldGokulraju RangasamyAinda não há avaliações

- MG6851-Principles of ManagementDocumento17 páginasMG6851-Principles of ManagementGokulraju RangasamyAinda não há avaliações

- Introductionto My SelfDocumento1 páginaIntroductionto My SelfGokulraju RangasamyAinda não há avaliações

- 2017 Regulation SyllabusDocumento113 páginas2017 Regulation SyllabusGokulraju RangasamyAinda não há avaliações

- Ge6075 & Professional Ethics in EngineeringDocumento17 páginasGe6075 & Professional Ethics in EngineeringGokulraju RangasamyAinda não há avaliações

- GE6075 PEE OldDocumento18 páginasGE6075 PEE OldGokulraju RangasamyAinda não há avaliações

- Lab Chart DOMDocumento1 páginaLab Chart DOMGokulraju RangasamyAinda não há avaliações

- Unit IDocumento6 páginasUnit IGokulraju RangasamyAinda não há avaliações

- CNCDocumento36 páginasCNCGokulraju RangasamyAinda não há avaliações

- UNIT-V Friction & Belt DrivesDocumento37 páginasUNIT-V Friction & Belt DrivesGokulraju RangasamyAinda não há avaliações

- Statics: Vector Mechanics For EngineersDocumento30 páginasStatics: Vector Mechanics For EngineersGokulraju RangasamyAinda não há avaliações

- Unit - 1 FinalDocumento59 páginasUnit - 1 FinalGokulraju RangasamyAinda não há avaliações

- Engineering Ethics-V UNIT FinalDocumento18 páginasEngineering Ethics-V UNIT FinalGokulraju RangasamyAinda não há avaliações

- TEMPLATEDocumento138 páginasTEMPLATEGokulraju RangasamyAinda não há avaliações

- Manufacturing Technology Unit IVDocumento51 páginasManufacturing Technology Unit IVGokulraju RangasamyAinda não há avaliações

- S.No Date: Department of Mechatronics Engineering 2016-2017 - Even Semester Academic ScheduleDocumento60 páginasS.No Date: Department of Mechatronics Engineering 2016-2017 - Even Semester Academic ScheduleGokulraju RangasamyAinda não há avaliações

- Department of Mechatronics EngineeringDocumento1 páginaDepartment of Mechatronics EngineeringGokulraju RangasamyAinda não há avaliações

- Department of Mechatronics EngineeringDocumento1 páginaDepartment of Mechatronics EngineeringGokulraju RangasamyAinda não há avaliações

- Shear Centre PDFDocumento18 páginasShear Centre PDFGokulraju RangasamyAinda não há avaliações

- CT 1Documento1 páginaCT 1Gokulraju RangasamyAinda não há avaliações

- Department of Mechatronics EngineeringDocumento1 páginaDepartment of Mechatronics EngineeringGokulraju RangasamyAinda não há avaliações

- Wk1 - Introduction To CNCDocumento34 páginasWk1 - Introduction To CNCViktor NenomatausAinda não há avaliações

- StepperDocumento12 páginasStepperGokulraju RangasamyAinda não há avaliações

- 2.university Calendar Ug & PG - Even Sem (Revised)Documento1 página2.university Calendar Ug & PG - Even Sem (Revised)Gokulraju RangasamyAinda não há avaliações

- Som IndexDocumento75 páginasSom IndexGokulraju RangasamyAinda não há avaliações

- Unit5-Gear TrainsDocumento18 páginasUnit5-Gear TrainsGokulraju RangasamyAinda não há avaliações

- Research Article PreparationDocumento12 páginasResearch Article PreparationGokulraju Rangasamy100% (1)

- NEW AuthorInstructionsDocumento2 páginasNEW AuthorInstructionsTariq RahimAinda não há avaliações

- Unit6 CAMSDocumento27 páginasUnit6 CAMSGokulraju RangasamyAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Involute Spur GearsDocumento109 páginasInvolute Spur GearsBORNASCHAinda não há avaliações

- Gear Hobbing, Shaping and Shaving - A Guide To Cycle Time Estimating and Process Planning PDFDocumento183 páginasGear Hobbing, Shaping and Shaving - A Guide To Cycle Time Estimating and Process Planning PDFГьоксель Гриша Джансевен Попов100% (18)

- OmniGear Tech Info BinderDocumento86 páginasOmniGear Tech Info BinderMiguel Matias ReineroAinda não há avaliações

- Spur Gear Tooth Stress Analysis and Stress Reduction: V.Rajaprabakaran Mr.R.AshokrajDocumento11 páginasSpur Gear Tooth Stress Analysis and Stress Reduction: V.Rajaprabakaran Mr.R.AshokrajJojee MarieAinda não há avaliações

- Gear Tooth ProfileDocumento5 páginasGear Tooth ProfilepremnathgopinathanAinda não há avaliações

- Physics GearsDocumento101 páginasPhysics Gearssungjoo75Ainda não há avaliações

- Ar-Cutting Text PDFDocumento394 páginasAr-Cutting Text PDFdgg3565Ainda não há avaliações

- Me6401 Kinematics - of - Machinery QBDocumento20 páginasMe6401 Kinematics - of - Machinery QBparameshAinda não há avaliações

- Gear and Gear Unit DesignDocumento22 páginasGear and Gear Unit Designaditya v s sAinda não há avaliações

- Gears NBH FinalDocumento75 páginasGears NBH FinalSaikat Bhowmick100% (1)

- DMM PDFDocumento6 páginasDMM PDFtarunAinda não há avaliações

- Mod-3. Spur GearDocumento18 páginasMod-3. Spur GearSharthak GhoshAinda não há avaliações

- Assignment 3Documento20 páginasAssignment 3Siddhesh RaulAinda não há avaliações

- Kuliah Ke-4Documento59 páginasKuliah Ke-4Rafael PriambadhaAinda não há avaliações

- Maag, Tooth F Lank ModificationsDocumento8 páginasMaag, Tooth F Lank ModificationsPeter CardenAinda não há avaliações

- CH 15Documento93 páginasCH 15Sky 6794Ainda não há avaliações

- Helical3D User's Manual: Advanced Numerical SolutionsDocumento192 páginasHelical3D User's Manual: Advanced Numerical Solutionscmm5477Ainda não há avaliações

- Presentation 1 EvolutesandinvolutesDocumento15 páginasPresentation 1 EvolutesandinvolutesPrajwal P Churi100% (1)

- Interference: Design of Power Transmission SystemDocumento5 páginasInterference: Design of Power Transmission SystemJai SharmaAinda não há avaliações

- Lecture Slides: Gears - GeneralDocumento24 páginasLecture Slides: Gears - GeneralEhsan LayeghAinda não há avaliações

- Spur Gear Problems PDFDocumento79 páginasSpur Gear Problems PDFSharmila Shetty100% (1)

- Gear DetailsDocumento19 páginasGear DetailsSathya DharanAinda não há avaliações

- For High Velocity, High Horsepower and High Efficiency Drives With Smooth Transmission of Load in A Compact SpaceDocumento7 páginasFor High Velocity, High Horsepower and High Efficiency Drives With Smooth Transmission of Load in A Compact SpacepabloasotoAinda não há avaliações

- Be Mechanical-Engineering Semester-4 2019 May Kinematics-Of-Machinery-CbcgsDocumento29 páginasBe Mechanical-Engineering Semester-4 2019 May Kinematics-Of-Machinery-CbcgsHarsh KbddhsjAinda não há avaliações

- GearsDocumento3 páginasGearsNuAinda não há avaliações

- Gear Teeth CalculationsDocumento11 páginasGear Teeth CalculationsKrishna PrasadAinda não há avaliações

- Gears - General: Shigley's Mechanical Engineering DesignDocumento229 páginasGears - General: Shigley's Mechanical Engineering DesignbasitAinda não há avaliações

- Gear Trax ManualDocumento70 páginasGear Trax Manualjasbir999Ainda não há avaliações

- Mechanical Software Design ManualDocumento310 páginasMechanical Software Design ManualManoj SinghAinda não há avaliações

- B.1.1 Spur Gears With Gearwheels-10Documento34 páginasB.1.1 Spur Gears With Gearwheels-10Ganapathy Subramaniam100% (1)