Escolar Documentos

Profissional Documentos

Cultura Documentos

Delphi 9322a000

Enviado por

BaytolgaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Delphi 9322a000

Enviado por

BaytolgaDireitos autorais:

Formatos disponíveis

Test Plan: 9322A000

Applic:

Issue No:

Date:

Pumps covered:

Lister Petter 1500 rpm Gen

8

00/00/00

9322A000G 9322A001G 9322A003G

PUMP SPECIFICATION

Rotation:

Governor type:

Gov. Link Length:

Gov. Link Length:

(DP210 Workshop Manual Section 4.6.4)

Plunger Diameter:

Drive Type:

Transfer pressure:

Viscosity compensating device in end plate.

Cambox pressurising valve.

Servo Advance with:

- LLA & CA

Torque trimmer, excess fuel only.

Solenoid voltage:

OEM Code:

Clockwise.

Mechanical all-speed.

41.5 0.5 mm.

10.1 0.5 mm.

7.0 mm (2 off).

Supported shaft.

adjustable.

See Service Instruction Note DT294.

903-21240/ Setting Code:

.....

ISO TEST CONDITIONS.

This data is only valid for the test conditions specified

and the

following test benches:

Test Fluid:

Inlet feed pressure:

Nozzles:

Nozzle Opening Pressure:

Nozzle Holder:

H.P. pipes:

Backleak pressure:

PRE-TEST NOTES

Screw transfer pressure adjuster fully out and then

1.0 turns in before commencing test.

No additional shimming is required.

CA solenoid to be de-energised unless otherwise stated.

Un-lock and fully unscrew the idle screw.

Torque trimmer plug to be flush with end of housing.

HA3000/HA2500/HA700/AVM/PGM

ISO 4113 at 40 2C.

5.0 psi

YDB286 (BDL0S6844)

172 + 3 - 0 bar.

ISO 7440 + YDB288 Edge filter assy.

6 x 1.8 x 450 mm

5.0 psi

Latch valve adjuster, if fitted, screw fully in then

2 turns out

Turn light load adjuster valve fully in ,then 2 turns out.

ISO TEST PROCEDURE

Test

De-energise CA solenoid.

Operation

S/C

1.

Priming

(C) 200

RPM Requirements

Obtain delivery from all

injectors

and backleak.

Close throttle.

Stabilise. Cycle speed between 100 to 500

rpm 4 times.

Open throttle.

2.

Transfer

Press.

Governor

(S) 750 75 to 77 psi

3.

Stabilise. Cycle speed between 100 to 850

rpm 5 times.

Stabilise and run at 750 rpm until backleak

temperature

is 38C min.

4.

Delivery

Back

5.

leakage.

Cambox

6.

Press.

Transfer

7.

Press.

Run test machine down to 0 rpm.

Transfer

8.

Press

If incorrect repeat from test (7 ).

Transfer

9.

Press.

Stop test machine.

Remove pressure gauges and fit stop

solenoid or plug.

10.

Advance

11.

Advance

Stop test machine.

Energise CA solenoid.

12.

Advance

De-energise CA solenoid.

(S) 820 6.0 to 10.0 mm3/st.

13.

(S) 750

Advance -

(S) 750 39.0 0.3 mm3/st.

Flow rate 450 to 950

(C) 750

cm3/min.

(C) 750 8 to 12 psi

(C) 750

Press at test(6 ) + 65to

67psi

(C) 750 As test (7 ) 1.0 psi

(C) 100 Minimum 10 psi.

(S) 500 0 (Datum advance gauge)

(C) 750 0.5 Max.

(C) 750 7.0 to 9.0.

0.8to 1.2 23.0to

27.0mm3/st

Light load

Adjust throttle/torque screw

& LLA valve.

Run test machine down to 0 rpm.

14.

Advance Light load

15.

Advance Light load

0.8to 1.2 25.0

2.0mm/3st.

Use throttle/Torque screw.

6.8to 7.2 10.0

(C) 750

3.0mm/3st.

Use throttle/Torque screw.

(C) 750

Open throttle.

16.

Max.

Delivery

(S) 750 39.0 0.2 mm3/st.

Max. spread 6.0 mm3/st.

Run test machine down to 0 rpm.

17.

Delivery

18.

Delivery

If incorrect, stop test machine.

Adjust latch valve screw & lock or change

plug if fitted.

Repeat from test (17).

19.

Delivery

20.

Stop test machine.

21.

22.

23.

24.

25.

Solenoid

(C) 150 Minimum 25.0 mm3/st.

De-energise solenoid, wait

(C) 500

5 seconds.

Max. 2.0 mm3/st.

Delivery

Governor

Gov. cut-off

Delivery

(C)

(S)

(C)

(C)

Shut-off -

Dynamic

timing

speed

.

ISO OVERCHECK PROCEDURE

.

The Overcheck section of this plan has

been developed in

conjunction with the Original Equipment

Manufacturer.

Providing all values are achieved, the

pump settings will

(C) 220 Minimum 37.0 mm3/st.

As test (17) - 10.0 7.0

(C) 280

mm3/st.

750 Record delivery mm3/st.

800 6.0 to 10.0 mm3/st.

830 Maximum 3.0 mm3/st.

750 Throttle as test (22).

Minimum as test (21) - 1.0

mm3/st.

Refer to SIN DT339

Piezo sensor, outlet U

Off-set angle 4.1

(S) 750 Trigger level 25 %

maintain the original homologated engine

performance. Failure to

attain any one of the values will indicate a

pump setting or

function failure and require further

investigation.

.

PRE-OVERCHECK NOTES

Dynamic timing - record zero angle - (refer

to DT339)

Drive shaft lock bolt to remain locked until

zero angle

recorded.

CA advance motor to be de-energised

unless otherwise stated.

No adjustments to be made unless

otherwise stated.

Un-lock and fully unscrew the idle screw.

Close throttle.

Stabilise. Cycle speed between 100 to 500

rpm 4 times.

Open throttle.

Stabilise and run at 750 rpm until backleak

temperature

is 38C min.

26.

Advance

Back

27.

leakage.

Stop test machine.

Energise CA solenoid.

28.

Advance

De-energise CA solenoid.

29.

Advance

30.

Delivery

31.

Shut-off Solenoid

Stop test machine.

32.

33.

34.

35.

36.

Delivery

(S) 500 0 (Datum advance gauge)

Flow rate 450 to 950

(C) 750

cm3/min.

(C) 750 7.0 to 9.0.

(C) 750 0.5 Max.

(C) 750 37.0 to 41.0 mm3/st.

De-energise solenoid, wait

(C) 500

5 seconds.

Max. 2.0 mm3/st.

(C) 150 Minimum 25.0 mm3/st.

0.8to 1.2 26.0

Advance (C) 750

4.0mm/3st.

Light load

Use throttle/Torque screw.

6.8to 7.2 10.0

Advance (C) 750

5.0mm/3st.

Light load

Use throttle/Torque screw.

Gov. cut-off (C) 830 Maximum 3.0 mm3/st.

Dynamic

Refer to SIN DT339

timing

speed

Piezo sensor, outlet U

Off-set angle 4.1

(S) 750 Trigger level 25 %

Você também pode gostar

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocumento3 páginasTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- 8520A060A TestplanDocumento2 páginas8520A060A TestplanBaytolga can100% (1)

- Optimize pump specification test plan titleDocumento4 páginasOptimize pump specification test plan titleLIONN SOFTWARESAinda não há avaliações

- 9521A030H DATA CatalogDocumento3 páginas9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- (Oto-Hui - Com) Edc Hino s05Documento2 páginas(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500Ainda não há avaliações

- 3042f843 Plano de TesteDocumento1 página3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- Test Plan: Pump SpecificationDocumento4 páginasTest Plan: Pump SpecificationBaytolgaAinda não há avaliações

- Ford HSDI pump specification and ISO test procedureDocumento2 páginasFord HSDI pump specification and ISO test proceduretaniaAinda não há avaliações

- EU/5/2360 Test PlanDocumento2 páginasEU/5/2360 Test PlanOseasJuniorAinda não há avaliações

- Test Plan: 9521A030: Pump SpecificationDocumento3 páginasTest Plan: 9521A030: Pump Specificationjohnny sabinAinda não há avaliações

- Test Plan Delphi TechnologiesDocumento2 páginasTest Plan Delphi TechnologiesFRANCISCOAinda não há avaliações

- Test Plan: Pump SpecificationDocumento3 páginasTest Plan: Pump SpecificationBaytolgaAinda não há avaliações

- db4429 5514Documento4 páginasdb4429 5514WillianPachecoAinda não há avaliações

- STANADYNEDocumento4 páginasSTANADYNECHRISTIAN LOZANOAinda não há avaliações

- StanadyneDocumento4 páginasStanadynemurillo_rodriguez8382Ainda não há avaliações

- 093400-5350 Mitsubishi PDFDocumento2 páginas093400-5350 Mitsubishi PDFBaytolgaAinda não há avaliações

- Test SpecificationsDocumento2 páginasTest SpecificationsBest Auto Tech100% (1)

- Test PlanDocumento4 páginasTest PlanOFFICE DANACAinda não há avaliações

- 9161Documento5 páginas9161BaytolgaAinda não há avaliações

- Calibration Data AdjustmentDocumento4 páginasCalibration Data AdjustmentMas Inyeccion ElectronicaAinda não há avaliações

- Dpico: Inj. Pump Calibration DataDocumento4 páginasDpico: Inj. Pump Calibration DataGiovaniBalzaniAinda não há avaliações

- EE4760Documento2 páginasEE4760OFFICE DANACAinda não há avaliações

- 606 9460Documento2 páginas606 9460Alex PakitoAinda não há avaliações

- vp44 Pump Detail Schematic PDF FreeDocumento7 páginasvp44 Pump Detail Schematic PDF Freepablo pérezAinda não há avaliações

- Injection Pump Calibration DataDocumento2 páginasInjection Pump Calibration DataСергей ВладимировичAinda não há avaliações

- 816C1 Instruction ManualDocumento10 páginas816C1 Instruction Manualmaheshaeee_796422500100% (1)

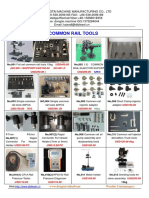

- Diesel Fuel Injection Pump Disassemble Retainer Tools For SaleDocumento3 páginasDiesel Fuel Injection Pump Disassemble Retainer Tools For SaleChrisAinda não há avaliações

- Nozzles and Spare Parts For: Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPSDocumento5 páginasNozzles and Spare Parts For: Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPSAnonymous AF2Rv0Kaxc100% (1)

- Injection Pump Specification ©Documento4 páginasInjection Pump Specification ©LIONN SOFTWARESAinda não há avaliações

- Carburetors to Forced Induction: A Guide to Fuel SystemsDocumento29 páginasCarburetors to Forced Induction: A Guide to Fuel SystemsMuhammad ArslaanAinda não há avaliações

- Injection Pump Calibration Data: 1. Test ConditionsDocumento3 páginasInjection Pump Calibration Data: 1. Test ConditionsElson DorigonAinda não há avaliações

- Ak TrainingDocumento40 páginasAk TrainingBatuhanÇetinGüven100% (1)

- 0 460 413 028Documento2 páginas0 460 413 028Yunus RazviAinda não há avaliações

- 00000774Documento18 páginas00000774roberto lopezAinda não há avaliações

- Bosch Inline Piezo Injector Delivery PlanDocumento9 páginasBosch Inline Piezo Injector Delivery PlandieseldvAinda não há avaliações

- Temp 753Documento2 páginasTemp 753Neelakandan Krishnan100% (1)

- VE Pump TrainingDocumento36 páginasVE Pump TrainingNarendra FirmansyahAinda não há avaliações

- Catalog Stand Pompa Web - 110 - enDocumento15 páginasCatalog Stand Pompa Web - 110 - enGrig Radu100% (1)

- 9320A522T Parts CatalogDocumento7 páginas9320A522T Parts CatalogLIONN SOFTWARESAinda não há avaliações

- Bosch EP test values for diesel fuel injection equipmentDocumento3 páginasBosch EP test values for diesel fuel injection equipmentTamer Moustafa100% (1)

- DATODocumento1 páginaDATOMiguel RojasAinda não há avaliações

- Injection Pump Test SpecificationsDocumento1 páginaInjection Pump Test SpecificationsMiguel RojasAinda não há avaliações

- Product Data Sheet High Pressure SensorDocumento2 páginasProduct Data Sheet High Pressure SensorAntonino ScordatoAinda não há avaliações

- Dpico: Inj. Pump Calibration DataDocumento6 páginasDpico: Inj. Pump Calibration DataGiovaniBalzaniAinda não há avaliações

- VI - O55 - 6b - MotorDocumento26 páginasVI - O55 - 6b - MotorDJJ ManutençãoAinda não há avaliações

- CR Tools and Spare Parts NEWDocumento21 páginasCR Tools and Spare Parts NEWeber granadosAinda não há avaliações

- Capitol 5HD200-service-manual PDFDocumento46 páginasCapitol 5HD200-service-manual PDFlabatea100% (1)

- BOSCH EP test values for diesel fuel injection equipmentDocumento3 páginasBOSCH EP test values for diesel fuel injection equipmentNemo NeoAinda não há avaliações

- Test and diagnose Bosch VE EDC diesel pump actuator faultsDocumento1 páginaTest and diagnose Bosch VE EDC diesel pump actuator faultsCharaf-eddine RamehAinda não há avaliações

- SB373AR2Documento8 páginasSB373AR2GiovaniBalzaniAinda não há avaliações

- f797 PDFDocumento2 páginasf797 PDFBest Auto TechAinda não há avaliações

- CALIBRATION DATA FOR INJECTION PUMPDocumento2 páginasCALIBRATION DATA FOR INJECTION PUMPMiguel RojasAinda não há avaliações

- 104740-4734 - Test PlanDocumento2 páginas104740-4734 - Test PlanMihai-Eugen Popa100% (1)

- Illidio SerraDocumento24 páginasIllidio SerraVictor GarciaAinda não há avaliações

- Injection Pump Test SpecificationsDocumento3 páginasInjection Pump Test Specificationsadmin tigasaudaraAinda não há avaliações

- FORD Puma Common Rail SystemDocumento18 páginasFORD Puma Common Rail Systemtomek luciwAinda não há avaliações

- Hino FuelPump Calibrate 098000-1150Documento2 páginasHino FuelPump Calibrate 098000-1150คุณชายธวัชชัย เจริญสุข100% (2)

- 9322A010Documento5 páginas9322A010BaytolgaAinda não há avaliações

- 9320A020GDocumento6 páginas9320A020GBaytolgaAinda não há avaliações

- 9520A192G - PlanDocumento3 páginas9520A192G - PlanMihai-Eugen Popa100% (1)

- Injection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxDocumento3 páginasInjection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxBaytolga100% (3)

- 8920A360 - New Holland 7740 TractorDocumento13 páginas8920A360 - New Holland 7740 TractorBaytolgaAinda não há avaliações

- Test Plan 8443B250DDocumento2 páginasTest Plan 8443B250DЕвгенийAinda não há avaliações

- 104740-0976 - Ford RangerDocumento6 páginas104740-0976 - Ford RangerBaytolgaAinda não há avaliações

- 8444B360ADocumento2 páginas8444B360ABaytolgaAinda não há avaliações

- Test Plan 8443B250DDocumento2 páginasTest Plan 8443B250DЕвгенийAinda não há avaliações

- 9322a050 - Erkunt Servet 80 TDocumento6 páginas9322a050 - Erkunt Servet 80 TBaytolgaAinda não há avaliações

- Test Plan: 8921A000: Pump SpecificationDocumento3 páginasTest Plan: 8921A000: Pump SpecificationBaytolgaAinda não há avaliações

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Documento6 páginasS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaAinda não há avaliações

- 9322A010Documento5 páginas9322A010BaytolgaAinda não há avaliações

- 9320A020GDocumento6 páginas9320A020GBaytolgaAinda não há avaliações

- 9320A070GDocumento7 páginas9320A070GBaytolgaAinda não há avaliações

- 8522a090 Delphi PDFDocumento7 páginas8522a090 Delphi PDFBaytolgaAinda não há avaliações

- 101491-9530 Mazda PDFDocumento10 páginas101491-9530 Mazda PDFBaytolgaAinda não há avaliações

- OT Outside Tolerance (X Is Set)Documento3 páginasOT Outside Tolerance (X Is Set)BaytolgaAinda não há avaliações

- Inj. Pump Calibration Data: 1. Test ConditionsDocumento4 páginasInj. Pump Calibration Data: 1. Test ConditionsBaytolgaAinda não há avaliações

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Documento8 páginasS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaAinda não há avaliações

- Series CRV Brass Product Literature 1Documento2 páginasSeries CRV Brass Product Literature 1enghassanain6486Ainda não há avaliações

- Kodak Automixer II Plus - User ManualDocumento36 páginasKodak Automixer II Plus - User ManualNikolay PenevAinda não há avaliações

- Revised Boq For Office & Linlk Building R01 12.05.2021Documento5 páginasRevised Boq For Office & Linlk Building R01 12.05.2021SajeshKumarAinda não há avaliações

- d301244x012 PDFDocumento330 páginasd301244x012 PDFFIRMANSYAH100% (1)

- Gate, Globe, Check Valve Material OptionsDocumento1 páginaGate, Globe, Check Valve Material OptionsSSSAinda não há avaliações

- Thermal Oxidation Stability of Aviation Turbine Fuels: Standard Test Method ForDocumento21 páginasThermal Oxidation Stability of Aviation Turbine Fuels: Standard Test Method ForDaniel HernandezAinda não há avaliações

- Boiler Termoelectric AristonDocumento36 páginasBoiler Termoelectric AristonRadu TaşcăAinda não há avaliações

- Rocket and Missiles NotesDocumento118 páginasRocket and Missiles NotesT.ARULMOZHINATHAN HICET STAFF AERO100% (1)

- 980c Especificaciones InglesDocumento19 páginas980c Especificaciones InglesEdgar TorresAinda não há avaliações

- Westbay Mechanial SpecsDocumento174 páginasWestbay Mechanial SpecsHARISH ROHANAinda não há avaliações

- Solenoid SIN45V To VDE 0580 Plug Plate To ISO 4400 / DIN 43650 Protection Class IP65Documento2 páginasSolenoid SIN45V To VDE 0580 Plug Plate To ISO 4400 / DIN 43650 Protection Class IP65sexmanijakAinda não há avaliações

- Sun-Sub Technical O&MDocumento32 páginasSun-Sub Technical O&MSebastian Ramirez100% (1)

- Dosing Equipments PDF Document Aqua Middle East FZCDocumento40 páginasDosing Equipments PDF Document Aqua Middle East FZCAdolfsmith69Ainda não há avaliações

- ETS 608, Engineering Technical Spec, Pipework, Pipework - General RequirementsDocumento6 páginasETS 608, Engineering Technical Spec, Pipework, Pipework - General RequirementsElmokadem EinsteinAinda não há avaliações

- Alup Allegroi AIR CONTROL 3 PDFDocumento48 páginasAlup Allegroi AIR CONTROL 3 PDFsebastian100% (6)

- AM-07 Vacuum Toilet SystemDocumento111 páginasAM-07 Vacuum Toilet SystemAlexandru Alex100% (2)

- TVS Dazz Parts CatalogueDocumento59 páginasTVS Dazz Parts CatalogueGoutamAinda não há avaliações

- Relief and Flare SystemsDocumento1 páginaRelief and Flare SystemsalijadoonAinda não há avaliações

- Model 30R: - Sizes 1 - " To 8" - Iron - Threaded or FlangedDocumento2 páginasModel 30R: - Sizes 1 - " To 8" - Iron - Threaded or FlangedCristian Villagra EscobarAinda não há avaliações

- Engineering Standart For Fire Fighting PDFDocumento33 páginasEngineering Standart For Fire Fighting PDFHans HanantaAinda não há avaliações

- Serie-Duo D FLDocumento28 páginasSerie-Duo D FLEduardo LeytonAinda não há avaliações

- HD 191 Bladder TankDocumento5 páginasHD 191 Bladder TankPiyush JainAinda não há avaliações

- Transparent Level GaugesDocumento4 páginasTransparent Level GaugesAlfonso BlancoAinda não há avaliações

- Models A & B Automatic Pressure Maintenance DevicesDocumento4 páginasModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASAinda não há avaliações

- Directional Valves WebinarDocumento18 páginasDirectional Valves WebinarhaggAinda não há avaliações

- ED-7960 (Hydraulics Trainer)Documento1 páginaED-7960 (Hydraulics Trainer)Opu AntamAinda não há avaliações

- Piping Systems for Dry Chlorine PamphletDocumento81 páginasPiping Systems for Dry Chlorine PamphletIgnacio Hiram M RoqueAinda não há avaliações

- PL-PSN 005Documento3 páginasPL-PSN 005Manju JunoAinda não há avaliações

- Carte Tehnica Alfa RomeoDocumento66 páginasCarte Tehnica Alfa RomeoIndianaJones2000Ainda não há avaliações

- Manual Hd20fnmdl1smDocumento23 páginasManual Hd20fnmdl1smFelipe BrainAinda não há avaliações