Escolar Documentos

Profissional Documentos

Cultura Documentos

Inident Investigation Root Cause Analysis

Enviado por

baaziz2015Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Inident Investigation Root Cause Analysis

Enviado por

baaziz2015Direitos autorais:

Formatos disponíveis

Incident Investigation & Root Cause Analysis

1.0

Incident Investigation An Introduction

1.1 Fundamental Defininitions / Terminology.

Incident:

Work related events in which an injury or ill health (Regardless of severity) or

fatality occurred or could have occurred.

Accident:

An event that results in harm to persons or property.

Near Miss Incident:

An unplanned, uncontrolled event that can cause or has the potential to cause

injury to personnel or damage to equipment.

Unsafe Act / Practice / Behavior:

Any human action(s) that could result in a near miss, incident or injury

Unsafe Condition

Any situation in a workplace that, if left uncorrected, could result in a near-miss or

incident.

Minor First Aid Injury:

An accident that results in an injury for which no medical care beyond first aid is

required.

Recordable Injury/Illness:

An on-the-job injury/illness that results in required medical attention beyond first

aid, initial doctors visit, including stitches, loss of consciousness, use of

prescription drugs, and/or work restriction.

Lost Time Accident /Lost time illness:

A work-related injury/illness that results in a loss of at least one full scheduled

workday or shift.

1.2 Incident Reporting

Statutory and Regulatory Requirements

Nature and type of incidents to be reported are classified into three main categories:

Operational:

Electricity generation, transmission, distribution

Desalinated water production, transmission

Health and Safety:

Fatality

Major Injury

Ill-health and

Dangerous Occurrences

Environmental

Air, Water, Land

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 1 of 61

Incident Investigation & Root Cause Analysis

NOMAC Requirements

All employees and contractors are required to report any of the following to their

immediate supervisor:

Incidents resulting in injury or illness of any magnitude, including those injuries

requiring the administration of minor first-aid measures

Motor vehicle accident that involves a company vehicle or a rented or a personal

vehicle on a company business

Incidents resulting in production interruption and property or equipment damage of

any magnitude

Incidents resulting in environmental damage of any magnitude

Incidents resulting in a security consequence of any magnitude

Incidents resulting in customer related non productive time or company financial loss

A near-miss incident due to an unsafe act / practices and/or conditions at a

workplace.

The supervisor will fill up the Initial Incident Reporting form to his departmental

Managers with a copy to PGM / PM and Site HSE Engineer/Officer.

1.3 Incident Analysis

An analysis shall be conducted as soon as reasonably practical following the event. All

accidents and incidents shall be analyzed regardless of whether or not there are

injuries or equipment damage. The seriousness or severity potential should dictate the

level to which an incident is analyzed.

More seriousness or high potential severity incidents shall be investigated more

thoroughly.

1.4 Incident Investigation

Incident investigation is a systematic effort to record all relevant facts and evidence

related to how and why an incident happened. Since unsafe act / practices /

behaviours and conditions cause incidents, we must determine where the HSE

programs failed to control unsafe acts / practices or conditions.

Effective incident investigation will accomplish this through a fact-finding process as

opposed to fault-finding or apportioning blame process. This fact-finding process shall

determine all issues that led to the incidents, both the basic and the root causes. Then

it should demonstrate how control can be re-established by management and

employees.

Incident investigations team must be formed under the chairmanship of a senior

management member to establish and carry out the following:

Determine Who, What, When, Where and How?

Identify causes both basic and root causes

Determine the plan or management system failure

Develop and assign corrective and preventive action items

Track action items to completion

Communicate lessons learned to all company staff as

appropriate to prevent recurrence throughout the company plants

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 2 of 61

Incident Investigation & Root Cause Analysis

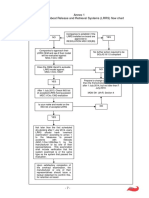

1.5 Incident Reporting and Investigation Process

The following schematic diagram outlines the significant steps of the process and their

usual sequence.

Incident Report

Analysis of

Incident

Incident

Investigation

Investigation

Report

Trend Analysis &

Corrective

Actions

End

1.6 The Typical Accident Investigation.

The typical accident investigation starts when the investigator is informed of the

accident, usually in terms of the harm or loss that occurred. With this as the starting

point, the investigator begins to look backwards for causes or causal factors to explain

how and why the harm or loss occurred. When the investigator arrives at an accident

scene, he surveys the situation and makes an initial and overall assessment. Then the

investigator starts a search for the facts or the situation or the information that will

enable the investigator to find the cause of the accident or its causal factors.

There are several sources of accident facts or data, such as people, physical objects,

surroundings, the condition, location and relative position of various persons and

objects, etc. The data and facts thus gathered are assimilated, sifted, organized and

then analyzed by the investigator. These analyses may permit the investigator to

develop one or more possible accident scenarios about how and why the harm or loss

occurred.

The typical investigation is ended when the investigator finds what could be termed

the cause of the accident. These conclusions are generally in the form of a set of

statements about the sequential events that led to the final harm or loss and a cause

statement.

Finally, based on the facts, the description of the events leading to the harm or loss

and the conclusions drawn, the investigator recommends actions whose

implementation should prevent the accident the next time.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 3 of 61

Incident Investigation & Root Cause Analysis

1.7 Accident Investigation Key Facts Checklist

Should determine:

What happened

How it happened

Why it happened

What should be done to avoid recurrence

The objective is to identify the causal factors and recommend

corrective actions. The investigation report should offer adequate,

but not excessive, recommendations for corrective actions.

Check list for identifying key facts:

1.

2.

Nature of Injury.

Foreign body

Cut

Bruises

Strain & sprain

Fracture

Burns

Amputation

Puncture wound

Hernia

Dermatitis

Abrasions

Others

Part of Body.

Head &neck (scalp, eyes, ears, mouth, teeth, neck, face, skull, etc.)

Upper extremities (shoulders, arms, elbows, forearms, wrists, hands, fingers,

thumbs, palms, etc.)

Body, back, chest, abdomen, groin, etc.

Lower extremities (hips, thighs, legs, knees, ankles, feet, toes, etc.)

3.

Accident Type.

Stuck against rough / sharp object

Struck by flying objects

Struck by sliding, falling or other moving

objects

Caught in or in between

Falls (on same level or to different level)

Over exertion

Slip, Burns

Contact with temperature extremes

Inhalation, absorption, ingestion, poisoning

Electric shock

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 4 of 61

Incident Investigation & Root Cause Analysis

4.

Hazardous Condition.

Improperly / inadequately guarded or unguarded

Defective tools, equipment, substances

Unsafe design or construction

Hazardous arrangement / layout / congested area

Improper illumination / ventilation

Improper dress / PPE

Poor housekeeping

5.

6.

Agency of Accident.

Machines

Vehicles

Hand tools

Sheet stock / scrap

Conveyors & elevators

Hoists / cranes

Floors & surfaces

Chemicals

Electrical apparatus

Fire

High pressure / temperature releases

Stairs/ladders/platforms/ scaffoldings

Unsafe Acts.

Operating without authority

Operating at off-design conditions

Making safety devices inoperative

Failure to warn / secure

Using defective equipment / materials/ tools / vehicles

Failure to use proper personal protective equipment

Poor housekeeping

Unsafe loading / placing / mixing

Horseplay

Unsafe lifting / carrying

Taking an unsafe position

Adjusting / cleaning machinery in motion

7.

Contributing Factors.

Disregard of instructions

Bodily defects

Lack of knowledge or skill

Act of other than injured

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 5 of 61

Incident Investigation & Root Cause Analysis

2.0 Incident Investigation The Four Step Process

Investigation is a four-step process comprising the following necessary stages:

Control the Scene (Initial Response)

Gather Data (Implementation & Research)

Analyze Data (Analysis)

Write Report (Correction)

These steps in accident investigation are simple: the accident investigators gather

information, analyze it, draw conclusions, and make recommendations. Although the

procedures are straightforward, each step can have its pitfalls. As mentioned earlier,

an open mind is necessary in accident investigation: preconceived notions may result

in some wrong paths being followed while leaving some significant facts uncovered.

All possible causes should be considered. Making notes of ideas as they occur is a

good practice but conclusions should not be drawn until all the information is

gathered.

2.1 Initial Response

The first response must be to:

Take all steps necessary to provide emergency

rescue and medical help for the injured.

Take those actions that will prevent or minimize the

risk of further accidents, injury or property damage.

These immediate actions may include:

Securing, barricading or isolating the scene

Collecting transient or perishable evidence

Determining the extent of damage to equipment, material or building facilities

Restoring the operating functions

An effective initial response includes the following essential steps

1. Take Control

2. Ensure First Aid

3. Control Secondary Accidents

4. Identify Sources of Evidence

5. Preserve Evidence

6. Determine Loss Potential

7. Notify Managers

The above steps do not have to be in the same sequence. The actual sequence will be

determined by the nature of the incident and the circumstances surrounding it.

A proper & positive initial response results in the following benefits:

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 6 of 61

Incident Investigation & Root Cause Analysis

Valuable opportunity to reduce the extent of loss

Preserve valuable information necessary to learn what actually happened

Key to getting the investigation on the right track

2.2 Gathering Data

The next step of the investigation process is gathering data. There are four major

categories of data or sources of evidence. These are referred to as the four Ps:

Positions

People

Parts

Paper

Positions

This is the most fragile of all evidence as it can

be easily moved / altered. It includes, among

other things:

Hand notes,

Sketches, maps & measurements

Photographs

As little time as possible should be lost between the moment of an accident or near

miss and the beginning of the investigation. In this way, one is most likely to be able to

observe the conditions as they were at the time, prevent disturbance of evidence, and

identify witnesses. The tools that members of the investigating team may need (pencil,

paper, camera, film, camera flash, tape measure, etc.) should be immediately available

so that no time is wasted.

The physical environment, and especially sudden changes to that environment, are

factors that need to be identified. The situation at the time of the accident is what is

important, not what the "usual" conditions were. For example, accident investigators

may want to know:

What were the weather conditions?

Was poor housekeeping a problem?

Was it too hot or too cold?

Was noise a problem?

Was there adequate light?

Were toxic or hazardous gases, dusts, or fumes present?

Before attempting to gather information, examine the site for a quick overview, take

steps to preserve evidence, and identify all witnesses. Physical evidence is probably

the most non-controversial information available. It is also subject to rapid change or

obliteration; therefore, it should be the first to be recorded. Based on your knowledge

of the work process, you may want to check items such as:

positions of injured workers

equipment being used

materials being used

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 7 of 61

Incident Investigation & Root Cause Analysis

safety devices in use

position of appropriate guards

position of controls of machinery

damage to equipment

housekeeping of area

weather conditions

lighting levels

noise levels

You may want to take photographs before anything is moved, both of the general area

and specific items. Later careful study of these may reveal conditions or observations

missed previously. Sketches of the accident scene based on measurements taken may

also help in subsequent analysis and will clarify any written reports. Broken equipment,

debris, and samples of materials involved may be removed for further analysis by

appropriate experts. Even if photographs are taken, written notes about the location of

these items at the accident scene should be prepared.

People

In some situations witnesses may be your primary

source of information because you may be called

upon to investigate an accident without being able to

examine the scene immediately after the event.

Because witnesses may be under severe emotional

stress or afraid to be completely open for fear of

recrimination, interviewing witnesses is probably the

hardest task facing an investigator.

Witnesses should be interviewed as soon as practicable after the accident. If witnesses

have an opportunity to discuss the event among themselves, individual perceptions

may be lost in the normal process of accepting a consensus view where doubt exists

about the facts.

Witnesses should be interviewed alone, rather than in a group. You may decide to

interview a witness at the scene of the accident where it is easier to establish the

positions of each person involved and to obtain a description of the events. On the

other hand, it may be preferable to carry out interviews in the quiet of an office where

there will be fewer distractions. The decision may depend in part on the nature of the

accident and the mental state of the witnesses.

This category of evidence includes:

Direct Witnesses

Injured / Co-workers

Others in area

Indirect Witnesses

Contractors

Maintenance Personnel

Equipment Designers

Spares Purchasers

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 8 of 61

Incident Investigation & Root Cause Analysis

The major technique or method for obtaining information from people is through

interviews. All witnesses should be interviewed, because it may require several

witnesses versions to determine or reconstruct the entire series of events.

Confirmation of observations by various witnesses is very important.

Developing a scenario is a good idea if certain questions are unanswered, particularly

questions that have to do with the exact physical relationship between the employee

and his or her environment. Typical questions during interviews may include:

Was a safe work procedure used?

Had conditions changed to make the normal procedure unsafe?

Were the appropriate tools and materials available?

Were they used?

Were safety devices working properly?

Was lockout used when necessary?

For most of these questions, an important follow-up question is "If not, why not?"

The physical and mental condition of those individuals directly involved in the event

may be explored. The purpose for investigating the accident is not to establish blame

against someone but the personal characteristics still need to be considered. Some

factors will remain essentially constant while others may vary from day to day:

Were workers experienced in the work being done?

Had they been adequately trained?

Can they physically do the work?

What was the status of their health?

Were they tired?

Were they under stress (work or personal)?

Management holds the legal responsibility for the safety of the

workplace and therefore the role of supervisors and higher

management must always be considered in an accident

investigation.

Answers to any of the preceding types of questions logically lead to further questions

such as:

Were rules communicated to and understood by all employees?

Were written procedures available?

Were they being enforced?

Was there adequate supervision?

Were workers trained to do the work?

Had hazards been previously identified?

Had procedures been developed to overcome them?

Were unsafe conditions corrected?

Was regular maintenance of equipment carried out?

Were regular safety inspections carried out?

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 9 of 61

Incident Investigation & Root Cause Analysis

Interviewing

Interviewing is an art that cannot be given justice in a brief document such as this, but

a few do's and don'ts can be mentioned. The purpose of the interview is to establish an

understanding with the witness and to obtain his own words describing the event:

DO...

put the witness, who is probably upset, at ease

emphasize the real reason for investigation, to determine what happened and why

let the witness talk, listen

confirm that you have the statement correct

try to sense any underlying feelings of the witness

make short notes only during the interview

DO NOT...

intimidate the witness

interrupt

prompt

ask leading questions

show your own emotions

make lengthy notes while the witness is talking

Ask open-ended questions that cannot be answered by simply "yes" or "no". The actual

questions you ask the witness will naturally vary with each accident, but there are

some general questions that should be asked each time:

Where were you at the time of the accident?

What were you doing at the time?

What did you see, hear?

What were the environmental conditions (weather, light, noise, etc.) at the time?

What was (were) the injured worker(s) doing at the time?

In your opinion, what caused the accident?

How might similar accidents be prevented in the future?

If you were not at the scene at the time, asking questions is a straightforward approach

to establishing what happened. Obviously, care must be taken to assess the credibility

of any statements made in the interviews. Answers to a first few questions will

generally show how well the witness could actually observe what happened.

Generally, people aren't used to being interviewed. After a traumatic experience, a

witness may not be able to recall the details. But, witnesses should be interviewed as

soon as possible. People react differently. Don't be surprised if a witness who was

close to the incident has an entirely different story from someone who saw it at a

distance. Witnesses may remember more clues after the shock has worn off, so be

open to follow-up sessions. Some witnesses may offer biased testimony if they feel a

need to influence the findings. Witnesses may omit entire sequences of events if they

don't realize their importance. Finally, eyesight, hearing, reaction time, and the general

condition of each witness may affect his or her ability to observe.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 10 of 61

Incident Investigation & Root Cause Analysis

Good interviewing skills are developed with experience. The most experienced team

member should lead the interviews. It may be helpful to have someone with a legal

background on the interview team. Use the checklist below to help with your interviews.

After the interviews, the team should analyze each witness' statement, and may want

to re-interview some witnesses to confirm or clarify key points. Even with

inconsistencies in the statements, the investigation team should assemble all of the

available testimony into a logical order. Consider the statements along with data from

the incident site in your report.

Have you appointed a speaker for the team?

Have you obtained preliminary statements as soon as possible from all witnesses?

Has each witness located his or her position on a map of the site (including the

direction of view)?

Is the interview conducted at a convenient time and place?

Have you told the witnesses that the investigation's purpose is accident

prevention?

Have you introduced the team and tried to make the witness comfortable?

Do you record each witness' identity and qualifications?

Are your questions worded carefully, and do you ensure the witness understands

each question?

Do you ask open-ended questions requiring more than a "yes" or "no" reply?

Do you let the witness speak freely while you listen?

Do you take notes without distracting the witness and use a tape recorder only with

the witness' consent?

Do you record the witness' exact words?

Do you let the witness use sketches and diagrams?

Do you confirm direct observation and identify opinion or hearsay?

Are you polite and careful not to lead the witness or to argue?

Do you supply each witness with a copy of his or her statement?

Gather just the facts make no judgments or statements

Conduct interviews one on one

Be friendly but professional

Interview all supervisors

Use sketches & diagrams to help witness.

Let each witness speak freely & take notes without distracting witness (avoid use of

tape recorder).

Emphasize areas of direct observation & label hearsay accordingly.

Provide feedback but dont lead the witness or put the person on defensive or give

a true-false test.

Look out for corroborations & inconsistencies.

End with a positive note & keep the line open

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 11 of 61

Incident Investigation & Root Cause Analysis

Interviewing Process

Parts

The third category of evidence is parts and includes physical evidence such as:

Tools, equipment, parts, materials & PPE

Worn or failed equipment parts

Improper tools & equipment

Incorrect use of tools & equipment

Process liquid/solid samples; before & after

To seek out possible causes resulting from the

equipment and materials used, investigators might ask:

Was there an equipment failure?

What caused it to fail?

Was the machinery poorly designed?

Were hazardous substances involved?

Were they clearly identified?

Was a less hazardous alternative substance possible and available?

Was the raw material substandard in some way?

Should personal protective equipment (PPE) have been used?

Was the PPE used?

Again, each time the answer reveals an unsafe condition, the investigator must ask

why this situation was allowed to exist.

Paper

This is the last category of evidence and includes:

Maintenance logs & schedules

Employee training records

Work procedures & practices, codes & regulations

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 12 of 61

Incident Investigation & Root Cause Analysis

Checklists, work orders, work permits, etc.

Building plans, layouts, Flow diagrams, P&Ids

Safety Inspections, audits, observations, etc.

Similar investigation reports

Employee medical history & health records

Job / shift schedules, overtime records

Parts / equipment / materials inspection & certification

Equipment / instruments calibration records

Design specifications & materials of construction

MSDS / Chemical analysis report

Risk assessments & HAZOP

Contractor prequalification & contract terms & conditions

Environmental monitoring / emission reports

These are seldom at the scene of the incident & hence, are often neglected.

Consequently, it is often an overlooked source of information, All available and relevant

information must be extracted and recorded from documents such as technical data

sheets, maintenance reports, past accident reports, formalized safe-work procedures,

and training reports. Any pertinent information should be studied to see what might

have happened, and what changes might be recommended to prevent recurrence of

similar accidents.

Summarizing the information gathered

Where and when did the adverse event happen?

Who was injured/suffered ill health or was otherwise involved with the adverse

event?

How did the adverse event happen? (Note any equipment involved).

What activities were being carried out at the time?

Was there anything unusual or different about the working conditions?

Were there adequate safe working procedures and were they followed?

What injuries or ill health effects, if any, were caused?

If there was an injury, how did it occur and what

caused it?

Was the risk known? If so, why wasnt it controlled?

If not, why not?

Did the organization and arrangement of the work

influence the adverse event?

Was maintenance and cleaning sufficient? If not,

explain why not.

Were the people involved competent and suitable?

Did the workplace layout influence the adverse

event?

Did the nature or shape of the materials influence the adverse event?

Did difficulties using the plant and equipment influence the adverse event?

Was the safety equipment sufficient?

Did other conditions influence the adverse event?

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 13 of 61

Incident Investigation & Root Cause Analysis

2.3 Collecting & Sifting Evidence (Analysis)

Facts must be separated from opinions, direct evidence from circumstantial evidence

and eyewitness statements from hearsay testimony. Your investigation should be

exhaustive. Look for all relevant facts, not just the obvious. Usually an accident has

several causal factors, yet some investigators will stop after discovering the first one.

Study the accident scene carefully.

Divide the data collected into following categories:

Hard Evidence.

Data that usually cannot be disputed, e.g., time & place of accident, logs & other

written reports & the position of physical evidence (providing investigators can

establish that it has not been moved).

Witness Statement.

Statements from persons who saw the accident happen & from those who came upon

the scene immediately afterwards

Circumstantial Evidence.

The logical interpretation of facts that leads to a single, but un-proven conclusion.

Critical Factors

Negative events or undesirable conditions that influence the course of events

Major contributions to the incident

Events or conditions, which if eliminated, would have either prevented the

occurrence or reduced its severity

An investigator who believes that incidents are caused by unsafe conditions will likely

try to uncover conditions as causes. On the other hand, one who believes they are

caused by unsafe acts will attempt to find the human errors that are causes. Therefore,

it is necessary to examine briefly some underlying factors in a chain of events that

ends in an accident.

The important point is that even in the most seemingly straightforward incidents,

seldom, if ever, is there only a single cause. For example, an "investigation" which

concludes that an accident was due to worker carelessness, and goes no further, fails

to seek answers to several important questions such as:

Was the worker distracted? If yes, why was

the worker distracted?

Was a safe work procedure being followed?

If not, why not?

Were safety devices in order? If not, why

not?

Was the worker trained? If not, why not?

An inquiry that answers these and related

questions will probably reveal conditions that

are more open to correction than attempts to

prevent "carelessness".

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 14 of 61

Incident Investigation & Root Cause Analysis

2.4 The Written Report (Correction)

The most important final step is to come up with a set of well-considered

recommendations designed to prevent recurrences of similar accidents. Resist the

temptation to make only general recommendations to save time and effort.

For example, you have determined that a blind corner contributed to an accident.

Rather than just recommending "eliminate blind corners" it would be better to suggest:

install mirrors at the northwest corner of building X (specific to this accident)

install mirrors at blind corners where required throughout the worksite (general)

Never make recommendations about disciplining persons who may have been at fault.

This would not only be counter to the real purpose of the investigation, but it would

jeopardize the chances for a free flow of information in future accident investigations.

In the unlikely event that you have not been able to conclusively determine the causes

of an accident, you probably still have uncovered safety weaknesses in the operation.

It is appropriate that recommendations be made to correct these deficiencies.

If your organization has a standard form that must be used, you will have little choice in

the form that your written report is to be presented. Nevertheless, you should be aware of,

and try to overcome, shortcomings such as:

If a limited space is provided for an answer, the tendency will be to answer in that

space despite recommendations to "use back of form if necessary."

If a checklist of causes is included, possible causes not listed may be overlooked.

Headings such as "unsafe condition" will usually elicit a single response even when

more than one unsafe condition exists.

Differentiating between "primary cause" and "contributing factors" can be misleading.

All accident causes are important and warrant consideration for possible corrective

action.

Your previously prepared draft of the sequence of events can now be used to describe

what happened. Remember that readers of your report do not have the intimate

knowledge of the accident that you have so include all pertinent detail. Photographs and

diagrams may save many words of description. Identify clearly where evidence is based

on certain facts, eyewitness accounts, or your assumptions.

If doubt exists about any particular part, say so. The reasons for your conclusions should

be stated and followed by your recommendations. Weed out extra material that is not

required for a full understanding of the accident and its causes such as photographs that

are not relevant and parts of the investigation that led you nowhere. The measure of a

good accident report is quality, not quantity.

What should be done if the investigation reveals "human error"?

A difficulty that has bothered many investigators is the idea that one does not want to lay

blame. However, when a thorough worksite accident investigation reveals that some

person or persons among management, supervisor, and the workers were apparently at

fault, then this fact should be pointed out. The intention here is to remedy the situation, not

to discipline an individual.

Failing to point out human failings that contributed to an accident will not only downgrade

the quality of the investigation. Furthermore, it will also allow future accidents to happen

from similar causes because they have not been addressed.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 15 of 61

Incident Investigation & Root Cause Analysis

Corrective Actions

Temporary actions (immediate)

generally address the unsafe acts & conditions

Permanent actions (long-term)

generally address personal & job factors

Aimed at:

Reducing likelihood of occurrence

Reducing severity of consequences

Corrective Actions General Principles

Recommendations must be based on key contributory factors and underlying

causes.

Must be appropriate and adequate

Recommendation(s) must be communicated clearly.

Must be S.M.A.R.T. (smart, measurable, achievable, realistic, time

bound

Strict time table must be established.

Follow up must be conducted.

What are the existing barriers in place to prevent this incident?

Why didnt the existing barriers work

Fix or improve existing barriers before creating new ones.

Make sure each cause you identify is covered by a corrective action.

Ensure that the corrective actions meet the following criteria

Report Forms and Formats

Statutory and Regulatory Reports

All incidents shall be reported by the PGM / PM or his representative to the project

company in accordance with the following:

a)

The ECRA Initial Incident Reporting Form should be submitted by the Project

Company or owner to the office of Vice Governor Regulatory Affairs within two

business days of the occurrence of an Incident.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 16 of 61

Incident Investigation & Root Cause Analysis

Structure of Initial Incident Reporting Form Contents:

1. General information

Name of licensee / Company,

Incident reference,

Location of incident-area, unit, equipment,

Date and time of incident start, finish.

2. Contact details

Name of person making notification,

Contact details- telephone number, e-mail, etc.,

Date and time of notification to Authority.

3. Incident classification

Operational electricity, desalinated water,

Health & safety fatality, major injury, III- health,

Dangerous occurrence,

Environmental air, water, land.

4. Incident description

Sequence of events description of events leading to incident,

Consequences impact on operations, people or environment,

Causation immediate causes, nature of defect, failures, etc.,

Remedial actions present status, actions taken to rectify situation.

5. Other information

Any other relevant information police presence, media interest, etc.

b)

The ECRA Incident Investigation Report should be submitted by the project company

or owner to the office of Vice Governor Regulatory Affairs within 20 business days of

the occurrence of an Incident or any other shorter period as decided by the ECRA.

Structure of Incident Investigation Report Contents

1. Executive summary

A brief description of the incident

the consequential losses (people, assets, demand and / or Generation affected (MW)

Environment and licensee reputation and major recommendations.

2. Introduction

A brief description of why the report is being prepared and legal obligations for

undertaking the investigation.

3. Incident description

Detailed description of scene location, people involved, etc.,

Sequence of events

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 17 of 61

Incident Investigation & Root Cause Analysis

Impact of the event people, environment and property

Emergency procedures actions taken, agencies involved

Work activities identified and controlled

4. Investigation and observations

Investigation procedure background information

Documentation review

Interviews and discussions

Site visits

Equipment analysis and review

5. Analysis and conclusions

Summary of key findings

Immediate causes

Root causes

6. Recommendations and action plan

Immediate actions short term

Follow up actions long term

Action plan tracking, times and responsibilities

7. Appendices

Documentation examples but not limited to;

Letters, emails, faxes, minutes of meetings, contracts, etc.

Log sheets, work permits, etc.

HSE plans, risk assessments, method statements, etc.

Surveys, inspections, etc.

Excerpts from procedures, manuals, instructions, etc.

Testing and inspection certificates, etc.

Charts, maps, illustrations, sketch, etc.

Photos with narrative

c)

The ECRA Final Close-out Report should be submitted to the office of Vice Governor

Regulatory Affairs within the period agreed with the Authority.

As a minimum, the final close-out report shall contain:

1. a summary of the incident;

2. a review of the main and contributory causes;

3. a review of key issues identified and preventative action taken and

4. a table listing original recommendations, action parties and action taken to closeout each point.

5. Basic information regarding equipments to the incident occurring.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 18 of 61

Incident Investigation & Root Cause Analysis

NOMAC Reports

The site first aider or doctor shall fill the First Aid Treatment form

(NC/QHSE/SP-006/FM-001) for Injury incidents requiring first aid treatment.

The immediate supervisor shall fill the Initial Incident Report form

(NC/QHSE/SP-006/FM-002) within 24 hours of the incident occurrence.

Any employee observing a Near Miss, unsafe act or condition shall fill the

Near Miss Reporting form (NC/QHSE/SP-006/FM-003) and drop the form in

designated Near Miss stations/ boxes. These forms shall be collected by the

site HSEE/O.

All final written investigation reports shall be completed and approved within 3 weeks

(15 working days) of the incident occurrence by the incident investigation team leader.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 19 of 61

Incident Investigation & Root Cause Analysis

3.0 Root Cause Analysis

System Defects > Root Causes > Immediate Causes > Contact > Incident

Possible Immediate Causes

ACTIONS:

Not following procedures

Improper use of tools or equipment

Inadequate use of protective methods

Inattention / lack of awareness

CONDITIONS:

Inadequate protective systems

Inadequate tools, equipment & vehicles

Work exposures

Workplace environment / layout

Examples of unsafe acts:

Unauthorized operation of equipment

Running - Horse Play

Not following procedures

By-passing safety devices

Not using protective equipment

Under influence of drugs or alcohol

Taking short-cuts

Do not use examples such as carelessness or not using common sense. (These are

neither visible not measurable)

Examples of unsafe conditions:

Ergonomic Hazards

Environmental hazards

Inadequate housekeeping

Blocked walkways

Improper or damaged PPE

Inadequate machine guarding

Root or System Causes

The most basic causes that can reasonably be identified, that management has control

to fix, and for which effective corrective actions for preventing recurrence can be

generated.

Possible Basic (System) Causes

PERSONAL FACTORS:

Physical capability

Physical condition

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 20 of 61

Incident Investigation & Root Cause Analysis

Mental state

Mental Stress

Behavior

Skill level

JOB FACTORS:

Training / knowledge transfer

Management leadership/employee leadership

Contractor selection & oversight

Engineering / design

Work planning

Purchasing, mtrl. handling & mtrl. control

Tools & equipment

Work rules/policies/standards/procedures(PSP)

Communication

Examples of personal factors:

Lack of knowledge & Lack of skill

Lack of physical capability

Lack of mental capability

Physical stress

Mental stress

Improper motivation

Examples of job factors:

Inadequate leadership

Inadequate engineering

Inadequate purchasing

Inadequate maintenance

Inadequate tools & inadequate equipment

Inadequate work standards

There are several techniques available for carrying out Root Cause Analysis each

having its own advantages and disadvantages and specific areas of application. We

will use the Comprehensive List of Causes (CLC) as our primary technique using the

CLC Chart and the Glossary to the Chart given at the end of this manual.

However, we will also have an overview of the other common techniques used for

conducting a root cause analysis. Some of the significant techniques include:

Documentation Review

Legislation Review

5 Why

Fish Bone

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 21 of 61

Incident Investigation & Root Cause Analysis

Event & Condition Mapping

Human Error Analysis

Change Analysis

The main classes of accident models are (based on Kjelln, 2000):

Causal-sequence models

Process models

Energy model

Logical tree models

Human information-processing models

SHE management models

Some of the Core Analytical Techniques include:

Event & Causal Factor Charting & Analysis (ECFA)

Barrier Analysis

Change Analysis

Causal Factor Analysis

Some of the more Complex Analytical Techniques include:

Fault Tree Analysis

MORT (Management Oversight Risk Tree)

PET (Project Evaluation Tree Analysis)

Tripod Beta

Tap-RooT

These techniques are generally used for complex accidents with multiple system

failures.

In addition to these, certain Specific Analytical Techniques include:

Human Factor Analysis

Failure Modes & Effect Analysis

Software Hazards Analysis

Materials & Structure Analysis

Atmospheric Dispersion Analysis

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 22 of 61

Incident Investigation & Root Cause Analysis

DOEs core analytical techniques5

Events and causal factors charting (ECFC)

Events and causal factors charting is a graphical display of the accidents chronology and is

used primarily for compiling and organizing evidence to portray the sequence of the

accidents events.

The events and causal factor chart is easy to develop and provides a clear depiction of the

data. Keeping the chart up-to-date helps insure that the investigation proceeds smoothly,

that gaps in information are identified, and that the investigators have a clear representation

of accident chronology for use in evidence collection and witness interviewing.

Events and causal factors charting is useful in identifying multiple causes and graphically

depicting the triggering conditions and events necessary and sufficient for an accident to

occur.

Events and causal factors analysis is the application of analysis to determine causal factors

by identifying significant events and conditions that led to the accident. As the results from

other analytical techniques are completed, they are incorporated into the events and causal

factors chart. Assumed events and conditions may also be incorporated in the chart.

The following figure gives an overview over symbols used in an event and causal factor

chart and some guidelines for preparing such a chart.

The Figure below shows a simplified event and causal factors chart in general.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 23 of 61

Incident Investigation & Root Cause Analysis

Barrier analysis

Barrier analysis is used to identify hazards associated with an accident and the barriers that

should have been in place to prevent it. A barrier is any means used to control, prevent, or

impede the hazard from reaching the target.

Barrier analysis addresses:

Barriers that were in place and how they performed

Barriers that were in place but not used

Barriers that were not in place but were required

The barrier(s) that, if present or strengthened, would prevent the same or similar accidents

from occurring in the future.

The following Figure shows types of barriers that may be in place to protect workers from

hazards.

Physical barriers are usually easy to identify, but management system barriers may be less

obvious (e.g. exposure limits). The investigator must understand each barriers intended

function and location, and how it failed to prevent the accident. There exists different ways in

which defences or barriers may be categorized, i.e. active or passive barriers (see e.g.

Kjelln, 2000), hard or soft defences (see e.g. Reason, 1997), but this topic will not be

discussed any further in this report.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 24 of 61

Incident Investigation & Root Cause Analysis

To analyze management barriers, investigators may need to obtain information about

barriers at three organizational levels responsible for the work; the activity, facility and

institutional levels. For example, at the activity level, the investigator will need information

about the work planning and control processes that governed the work activity, as well as

the relevant safety management systems. The investigator may also need information about

safety management systems at the facility level. The third type of information would be

information about the institutional-level safety management direction and oversight provided

by senior line management organizations.

The basic steps of a barrier analysis are:

Step 1 Identify the hazard and the target. Record them at the top of the worksheet

Step 2 Identify each barrier. Record in column one.

Step 3 Identify how the barrier performed (What was the barriers purpose? Was the barrier

in place or not in place? Did the barrier fail? Was the barrier used if it was in place?) Record

in column two.

Step 4 Identify and consider probable causes of the barrier failure. Record in column three.

Step 5 Evaluate the consequences of the failure in this accident. Record in column four.

The investigator should use barrier analysis to ensure that all failed, unused, or uninstalled

barriers are identified and that their impact on the accident is understood. The analysis

should be documented in a barrier analysis worksheet.

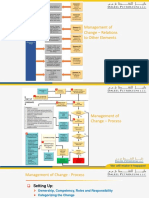

Change analysis

Change is anything that disturbs the balance of a system operating as planned. Change is

often the source of deviations in system operations.

Change analysis examines planned or unplanned changes that caused undesired outcomes.

In an accident investigation, this technique is used to examine an accident by analysing the

difference between what has occurred before or was expected and the actual sequence of

events.

The investigator performing the change analysis identifies specific differences between the

accidentfree situation and the accident scenario. These differences are evaluated to

determine whether the differences caused or contributed to the accident.

The change analysis process is described in the following Figure.

When conducting a change analysis, investigators identify changes as well as the results of

those changes. The distinction is important, because identifying only the results of change

may not prompt investigators to identify all causal factors of an accident. When conducting a

change analysis, it is important to have a baseline situation that the accident sequence may

be compared to.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 25 of 61

Incident Investigation & Root Cause Analysis

The table below shows a simple change analysis worksheet.

The investigators should first categorize the changes according to the questions shown in

the left column of the worksheet, i.e., determine if the change pertained to, for example, a

difference in:

What events, conditions, activities, or equipment were present in the accident situation that

were not present in the baseline (accident-free, prior, or ideal) situation (or vice versa)

When an event or condition occurred or was detected in the accident situation versus the

baseline situation

Where an event or condition occurred in the accident situation versus where an event or

condition occurred in the baseline situation

Who was involved in planning, reviewing, authorizing, performing, and supervising the

work activity in the accident versus the accident-free situation.

How the work was managed and controlled in the accident versus the accident-free

situation.

To complete the remainder of the worksheet, first describe each event or condition of

interest in the second column. Then describe the related event or condition that occurred (or

should have occurred) in the baseline situation in the third column. The difference between

the event and conditions in the accident and the baseline situations should be briefly

described in the fourth column. In the last column, discuss the effect that each change had

on the accident.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 26 of 61

Incident Investigation & Root Cause Analysis

The differences or changes identified can generally be described as causal factors and

should be noted on the events and causal factors chart and used in the root cause analysis.

A potential weakness of change analysis is that it does not consider the compounding

effects of incremental change (for example, a change that was instituted several years

earlier coupled with a more recent change). To overcome this weakness, investigators may

choose more than one baseline situation against which to compare the accident scenario.

Events and causal factors analysis

The events and causal factors chart may also be used to determine the causal factors of an

accident, as illustrated in the Figure below. This process is an important first step in later

determining the root causes of an accident. Events and causal factors analysis requires

deductive reasoning to determine which events and/or conditions that contributed to the

accident.

Before starting to analyse the events and conditions noted on the chart, an investigator must

first ensure that the chart contains adequate detail.

Examine the first event that immediately precedes the accident. Evaluate its significance in

the accident sequence by asking:

If this event had not occurred, would the accident have occurred?

If the answer is yes, then the event is not significant. Proceed to the next event in the chart,

working backwards from the accident. If the answer is no, then determine whether the event

represented normal activities with the expected consequences. If the event was intended

and had the expected outcomes, then it is not significant. However, if the event deviated

from what was intended or had unwanted consequences, then it is a significant event.

Carefully examine the events and conditions associated with each significant event by

asking a series of questions about this event chain, such as:

Why did this event happen?

What events and conditions led to the occurrence of the event?

What went wrong that allowed the event to occur?

Why did these conditions exist?

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 27 of 61

Incident Investigation & Root Cause Analysis

How did these conditions originate?

Who had the responsibility for the conditions?

Are there any relationships between what went wrong in this event chain and other events

or conditions in the accident sequence?

Is the significant event linked to other events or conditions that may indicate a more

general or larger deficiency?

The significant events, and the events and conditions that allowed the significant events to

occur, are the accidents causal factors.

Root cause analysis

Root cause analysis is any analysis that identifies underlying deficiencies in a safety

management system that, if corrected, would prevent the same and similar accidents from

occurring. Root cause analysis is a systematic process that uses the facts and results from

the core analytic techniques to determine the most important reasons for the accident. While

the core analytic techniques should provide answers to questions regarding what, when,

where, who, and how, root cause analysis should resolve the question why. Root cause

analysis requires a certain amount of judgment.

A rather exhaustive list of causal factors must be developed prior to the application of root

cause analysis to ensure that final root causes are accurate and comprehensive.

Fault tree analysis

Fault tree analysis is a method for determining the causes of an accident (or top event). The

fault tree is a graphic model that displays the various combinations of normal events,

equipment failures, human errors, and environmental factors that can result in an accident.

An example of a fault tree is shown in the Figure below.

A fault tree analysis may be qualitative, quantitative, or both. Possible results from the

analysis may be a listing of the possible combinations of environmental factors, human

errors, normal events and component failures that may result in a critical event in the system

and the probability that the critical event will occur during a specified time interval.

The strengths of the fault tree, as a qualitative tool is its ability to break down an accident

into root causes.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 28 of 61

Incident Investigation & Root Cause Analysis

The undesired event appears as the top event. This event is linked to the basic failure

events by logic gats and event statements. A gate symbol can have one or more inputs, but

only one output. A summary of common fault tree symbols is given in the Figure below.

Event tree analysis

An event tree is used to analyse event sequences following after an initiating event. The

event sequence is influenced by either success or failure of numerous barriers or safety

functions/ systems. The event sequence leads to a set of possible consequences. The

consequences may be considered as acceptable or unacceptable. The event sequence is

illustrated graphically where each safety system is modelled for two states, operation and

failure.

The following Figure illustrates an event tree of the situation on Rrosbanen just before the

sta-accident. This event tree reveals the lack of reliable safety barriers in order to prevent

train collision at Rrosbanen at that time.

An event tree analysis is primarily a proactive risk analysis method used to identify possible

event sequences. The event tree may be used to identify and illustrate event sequences and

also to obtain a qualitative and quantitative representation and assessment. In an accident

investigation we may illustrate the accident path as one of the possible event sequences.

This is illustrated with the thick line in the Figure below.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 29 of 61

Incident Investigation & Root Cause Analysis

MORT

MORT provides a systematic method (analytic tree) for planning, organizing, and conducting

a comprehensive accident investigation. Through MORT analysis, investigators identify

deficiencies in specific control factors and in management system factors. These factors are

evaluated and analyzed to identify the causal factors of the accident.

Basically, MORT is a graphical checklist which contains generic questions that investigators

attempt to answer using available factual data. This enables investigators to focus on

potential key causal factors. The upper levels of the MORT diagram are shown in the Figure.

MORT requires extensive training to effectively perform an in-depth analysis of complex

accidents involving multiple systems. The first step of the process is to select the MORT

chart for the safety program area of interest. The investigators work their way down through

the tree, level by level. Events should be coded in a specific color relative to the significance

of the accident. An event that is deficient or Less Than Adequate (LTA) in MORT

terminology is marked red. The symbol is circled if suspect or coded in red if confirmed. An

event that is satisfactory is marked green in the same manner. Unknowns are marked in

blue, being circled initially and colored if sufficient data do not become available, and an

assumption must be made to continue or conclude the analysis.

When the appropriate segments of the tree have been completed, the path of cause and

effect (from lack of management control, to basic causes, contributory causes, and root

causes) can easily be traced back through the tree. The tree highlights quite clearly where

controls and corrective actions are needed and can be effective in preventing recurrence of

the accident.

PET (Project Evaluation Tree) and SMORT (Safety Management and Organisations Review

Technique) are both methods based on MORT but simplified and easier to use. PET and

SMORT will not be described further. PET is described by DOE (1999) and SMORT by

Kjelln et al (1987).

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 30 of 61

Incident Investigation & Root Cause Analysis

Systematic Cause Analysis Technique (SCAT)

The International Loss Control Institute (ILCI) developed SCAT for the support of

occupational incident investigation. The ILCI Loss Causation Model is the framework for the

SCAT system (see Figure below).

The result of an accident is loss, e.g. harm to people, properties, products or the

environment. The incident (the contact between the source of energy and the victim) is the

event that precedes the loss.

The immediate causes of an accident are the circumstances that immediately precede the

contact. They usually can be seen or sensed. Frequently they are called unsafe acts or

unsafe conditions, but in the ILCI-model the terms substandard acts (or practices) and

substandard conditions are used. Substandard acts and conditions are listed in the Figure

below.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 31 of 61

Incident Investigation & Root Cause Analysis

Basic causes are the diseases or real causes behind the symptoms, the reasons why the

substandard acts and conditions occurred. Basic causes help explain why people perform

substandard practices and why substandard conditions exists. An overview of personal and

job factors are given in the following Figure.

There are three reasons for lack of control:

1. Inadequate program

2. Inadequate program standards and

3. Inadequate compliance with standards

The following Figure shows the elements that should be in place in a safety program. The

elements are based on research and experience from successful safety programs in

different companies.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 32 of 61

Incident Investigation & Root Cause Analysis

The Systematic Cause Analysis Technique is a tool to aid an investigation and evaluation of

incidents through the application of a SCAT chart. The chart acts as a checklist or reference

to ensure that an investigation has looked at all facets of an incident. There are five blocks

on a SCAT chart. Each block corresponds to a block of the loss causation model. Hence, the

first block contains space to write a description of the incident. The second block lists the

most common categories of contact that could have led to the incident under investigation.

The third block lists the most common immediate causes, while the fourth block lists

common basic causes. Finally, the bottom block lists activities generally accepted as

important for a successful loss control program. The technique is easy to apply and is

supported by a training manual.

STEP (Sequential timed events plotting)

The STEP-method was developed by Hendrick and Benner (1987). They propose a

systematic process for accident investigation based on multi-linear events sequences and a

process view of the accident phenomena.

STEP builds on four concepts:

1. Neither the accident nor its investigation is a single linear chain or sequence of events.

Rather, several activities take place atthe same time.

2. The event Building Block format for data is used to develop the accident description in a

worksheet. A building block describes one event, i.e. one actor performing one action.

3. Events flow logically during a process. Arrows in the STEP worksheet illustrate the flow.

4. Both productive and accident processes are similar and can be understood using similar

investigation procedures. They both involve actors and actions, and both are capable of

being repeated once they are understood.

With the process concept, a specific accident begins with the action that started the

transformation from the described process to an accident process, and ends with the last

connected harmful event of that accident process.

The STEP-worksheet provides a systematic way to organise the building blocks into a

comprehensive, multi-linear description of the accident process. The STEP-worksheet is

simply a matrix, with rows and columns. There is one row in the worksheet for each actor.

The columns are labeled differently, with marks or numbers along a time line across the top

of the worksheet. The time scale does not need to be drawn on a linear scale, the main point

of the time line is to keep events in order, i.e., how they relate to each other in terms of time.

An event is one actor performing one action. An actor is a person or an item that directly

influences the flow or events constituting the accident process. Actors can be involved in two

types of changes, adaptive changes or initiating changes. They can either change reactively

to sustain dynamic balance or they can introduce changes to which other actors must adapt.

An action is something done by the actor. It may be physical and observable, or it may be

mental if the actor is a person. An action is something that the actor does and must be

stated in the active voice.

The STEP worksheet provides a systematic way to organise the building blocks (or events)

into a comprehensive, multi-linear description of the accident process. Figure 23 shows an

example on a STEP-diagram of an accident where a stone block falls off a truck and hits a

car.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 33 of 61

Incident Investigation & Root Cause Analysis

The above STEP-diagram also shows the use of arrows to link tested relationships among

events in the accident chain. An arrow convention is used to show precede/follow and logical

relations between two or more events. When an earlier action is necessary for a latter to

occur, an arrow should be drawn from the preceding event to the resultant event. The

thought process for identifying the links between events is related to the change of state

concepts underlying STEP methods. For each event in the worksheet, the investigator asks,

Are the preceding actions sufficient to initiate this actions (or event) or were other actions

necessary? Try to visualize the actors and actions in a mental movie in order to develop

the links.

MTO-analysis

The basis for the MTO-analysis is that human, organizational, and technical factors should

be focused equally in an accident investigation. The MTO-analysis is based on three

methods:

1. Structured analysis by use of an event- and cause-diagram.

2. Change analysis by describing how events have deviated from earlier events or common

practice.

3. Barrier analysis by identifying technological and administrative barriers in which have

failed or are missing.

The first step in an MTO-analysis is to develop the event sequence longitudinally and

illustrate the event sequence in a block diagram. Identify possible technical and human

causes of each event and draw these vertically to each event in the diagram.

Further, analyze which technical, human or organizational barriers that have failed or was

missing during the accident progress.

Assess which deviations or changes in which differ the accident progress from the normal

situation. These changes are also illustrated in the diagram.

The basic questions in the analysis are:

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 34 of 61

Incident Investigation & Root Cause Analysis

What may have prevented the continuation of the accident sequence?

What may the organization have done in the past in order to prevent the accident?

The last important step in the MTO-analysis is to identify and present recommendations. The

recommendations should be as realistic and specific as possible, and might be technical,

human or organizational.

A checklist for identification of failure causes is also part of the MTO-methodology. The

checklist contains the following factors:

1. Organization

2. Work organization

3. Work practice

4. Management of work

5. Change procedures

6. Ergonomic / deficiencies in the technology

7. Communication

8. Instructions/procedures

9. Education/competence

10. Work environment

For each of these failure causes, there is a detailed checklist for basic or fundamental

causes. Examples on basic causes for the failure cause work practice are:

Deviation from work instruction

Poor preparation or planning

Lack of self inspection

Use of wrong equipment

Wrong use of equipment

TRIPOD

The idea behind TRIPOD is that organisational failures are the main factors in accident

causation. These factors are more latent and, when contributing to an accident, are always

followed by a number of technical and human errors. The following diagram shows the logic.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 35 of 61

Incident Investigation & Root Cause Analysis

Substandard acts and situations do not just occur. They are generated by mechanisms

acting in organizations, regardless whether there has been an accident or not. Often these

mechanisms result from decisions taken at high level in the organization. These underlying

mechanisms are called Basic Risk Factors (BSFs). These BSFs may generate various

psychological precursors in which may lead to substandard acts and situations. Examples on

psychological precursors of slips, lapses and violations are time pressure, being poorly

motivated or depressed. According to this model, eliminating the latent failures categorized

in BRFs or reducing their impact will prevent psychological precursors, substandard acts and

the operational disturbances. Furthermore, this will result in prevention of accidents.

The identified BRFs cover human, organizational and technical problems. The different

Basic Risk Factors are defined in the Table below. Ten of these BRFs leading to the

operational disturbance (the preventive BRFs), and one BRF is aimed at controlling the

consequences once the operational disturbance has occurred (the mitigation BRF). There

are five generic prevention BRFs (6 10 in the Table) and five specific BRFs (1 5 in the

Table). The specific BRFs relate to latent failures that are specific for the operations to be

investigated (e.g. the requirements for Tools and Equipment are quite different in a oil drilling

environment compared to an intensive care ward in a hospital).

These 11 BRFs have been identified as a result of brainstorming, a study of audit reports,

accident scenarios, a theoretical study, and a study on offshore platforms. The division is

definitive and has shown to be valid for all industrial applications.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 36 of 61

Incident Investigation & Root Cause Analysis

CLC Glossary Guidance

This Glossary is provided to the user of Comprehensive List of Causes (CLC) chart, as a

guide to further define and explain the various causes. Since the causes selected will be

used for trend analysis, accuracy in selecting the appropriate cause is important. Users are

expected to use this Glossary to ensure proper understanding of each cause category.

In each category, Other is listed as the last option, in case none of the above causes fit the

circumstances. While appropriate in some cases, the use of Other should be minimized, as

it adds little value in trend analysis. In all cases if you use the other cause, you must

explain what that cause is.

Users are reminded that any cause selected must meet two conditions. First, it must be

supported by the facts of the case. Additionally, a selected cause must help explain why the

Critical Factor under consideration existed at the time of the incident.

One of the key issues for a quality investigation is ensuring each selected cause is

addressed through an appropriate recommendation to avoid similar events in the future.

There must be symmetry between the cause selected and the type of recommendation.

Guidance is provided in the right hand column of this Glossary to help the investigator to

achieve this symmetry.

Glossary

Possible immediate causes

Immediate causes are covered in the first two sections entitled: Actions and Conditions.

Actions

There are four major categories of actions, with an additional level of detail under each of the

major categories. In actions we are focused on people and their behavior.

1. Did not follow existing procedures

1.1 Violation (by individual): One individual

intentionally chose to violate an established

safety practice.

An investigation team should only select this

cause when there is a clear safety practice

or rule in place & that practice or rule is

known by the person involved. Violations

are behaviors, and require a behavioral

recommendation. An additional A-B-C

analysis can be useful.

1.2 Violation (by group): more than one

individual was involved in the decision to

intentionally violate an established safety

practice.

See above. Additionally, if a procedure has

been routinely violated by many, this is an

indication of an organizational or cultural

issue, which can be further explored in

Columns 16, 17 and 22.

1.3 Violation (by supervisor): a supervisor or

other management person either personally

violated an established safety practice or

directed people under their supervision to do

so.

See above.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 37 of 61

Incident Investigation & Root Cause Analysis

1.4 Procedure not available: the person doing This can be addressed either by reinforcing

the work did not have access to the procedure Stop work when not sure or by making the

and consequently relied on memory to do the procedure available.

work properly.

1.5 Procedure was not understood: the

person relying on the procedure could not

comprehend the procedure, due to language,

technical capability or complexity.

This is a training issue, which can be

addressed either by additional training or

assignment of different personnel. The

quality / content of the procedure is covered

in column 22 Standards/

Practices/Procedures.

1.6 Other: must define.

The use of other without comment or

explanation has no value to your

investigation. See above.

2. Use of tools, plant/equipment or vehicle

2.1 Plant/Equipment or vehicle used in the

wrong way: equipment or vehicle was used for

activities for which it was not designed or the

equipment or vehicle was misused, for

example, using a forklift to lift a pallet for use

as a work platform, or using a handrail as a

ladder.

To make a good recommendation,

investigation needs to determine if this

action was intentional or due to lack of

knowledge. If intentional, this is a behavioral

issue which requires a behavioral

recommendation. An A-B-C analysis can

help understand why the person acted this

way. If lack of knowledge, then a training

solution is appropriate.

2.2 Tools used in the wrong way: tools were

See above.

used for activities for which they were not

designed or tools were misused, for example,

using a wrench as a hammer, or a screwdriver

as a pry bar.

2.3 Use of plant/equip or vehicle with known

defect: the person using the equip had

identified it as being defective, yet continued

to use that equip, for example, using a vehicle

with inoperative lights or a ladder with a

broken rung. (Hidden or unidentified defects

are covered in Column 6 Tools, Plant/Equip

& Vehicles.)

Since the defect was identified, this is a

behavioral issue, and requires a behavioral

recommendation. An A-B-C analysis can be

helpful in identifying factors which caused

the person to act this way.

2.4 Use of tools with a known defect: the

person using the tool had identified it as being

defective, yet continued to use that tool, for

example, using a grinder without a guard, or a

extension cord with frayed wires. (Hidden or

unidentified defects are covered in Column 6.)

See above.

H|S|E|Q Trainers, Consultants and Risk Management Advisors

Page 38 of 61

Incident Investigation & Root Cause Analysis