Escolar Documentos

Profissional Documentos

Cultura Documentos

Selvedge

Enviado por

muhidul7Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Selvedge

Enviado por

muhidul7Direitos autorais:

Formatos disponíveis

Selvedge

Functions of selvedge:

To lock & prevent any fraying out of warp.

To prevent weft contraction of fabric.

To provide extra strength at the edges of the fabric so that they can

withstand the tensile & gripping forces during transportation through machines.

Different types of selvedges used in woven fabric:

The different types of selvedges used in woven fabric are given below:

1.

Both edge bounded selvedges or conventional selvedge (It is

produced on shuttle loom).

2.

One-end bounded selvedge. (Produced on rapier loom)

3.

Fringed selvedge (Produced on airjet, projectile loom etc).

4.

Leno selvedge.

5.

Tucked in selvedge (Produced on modern loom)

6.

Stitched selvedge.

7.

Adhesive bonded selvedge.

8.

Fused selvedge.

9.

Dummy selvedge.

10.

Twisted selvedge.

(a) Half twisted.

(b) Full twisted (most commonly used.)

11.

Combined selvedge.

(a) Fringe twisted selvedge.

(b) Fringe + dummy + Leno selvedge.

Waste due to selvedge:

Two types of waste:

1. Warp waste.

2. Weft waste.

Warp waste:

Dummy selvedge:

If dummy is in both side of the fabric than wastage is more. No of dummy

warp in each side are around 12. Dummy warp always do not come from the

warp beam, it comes from extra bobbin normally synthetic yarn. Dummy warp

waste% decreases with the no of warp in the fabric and also with the width of

the fabric.

Extra warp for the conventional selvedge or different warp in the

conventional selvedge is included in the warp beam during warping. And

conventional selvedge is not the part of the fabric. In case of modern selvedge no

extra warps are included in the warp beam during warping.

Weft waste:

1. Conventional selvedge:

The wastage due to conventional selvedge happens by the following three

reasons.

a. Breakage of weft.

b. Residual waste in pirn due to changing mechanism.

c. Initial wastage of pirn due to threading. Weft wastage% increases with

the width of the loom. Waste% increases with the coarseness of the

yarn and also with the small size of the pirn.

2. Fringed selvedge:

Projected out weft yarn in each side of the selvedge is about 1 cm. Waste%

increases with the PPI, with the coarseness of yarn. Waste% decreases with the

width of the fabric.

3. Tucked in selvedge:

Projected out weft yarn in each side of the selvedge is about 1.5 cm. Waste%

increases with the PPI.

4. Dummy selvedge:

Projected out weft yarn in each side of the selvedge is around 8 cm per

pick. So waste% increases with the PPI and also with the width of the fabric.

Calculation of waste:

Warp waste:

For example:

Number of extra warp = 12 2 = 24

Length of fabric = 10000 m

Count of extra warp = 10s (Ne)

Wt of warp waste = ?

12 2 10000 1.09

kg. = 14.12 kg.

840 10 2.2046

Weft waste:

Length of extended weft beyond fabric = 8 cm/pick

Wt =

PPI = 140, Fabric length = 20000 m, linear density of yarn = 34 tex =

= 17.36 Ne

Weight of weft waste = ?

Wt =

8 140 39.37 20000

kg. = 299.99 kg.

100 0.9144 840 17.36 2.2046

590.5

34

Você também pode gostar

- SelvedgeDocumento16 páginasSelvedgejony_nsu022Ainda não há avaliações

- Advantage and Disadvantage of Conventional and Unconventional LoomsDocumento18 páginasAdvantage and Disadvantage of Conventional and Unconventional LoomsSushma BalgarAinda não há avaliações

- Combing ProcessDocumento12 páginasCombing ProcessSenthil Kumar100% (1)

- Yarn WindingDocumento22 páginasYarn WindingPRAKASH B. MALAKANE0% (1)

- Blending at BlowroomDocumento3 páginasBlending at Blowroommoosking100% (1)

- Draw Frame Hooks ControlDocumento17 páginasDraw Frame Hooks ControlNeelakandan DAinda não há avaliações

- Textile Processing and Properties: Preparation, Dyeing, Finishing and PerformanceNo EverandTextile Processing and Properties: Preparation, Dyeing, Finishing and PerformanceNota: 5 de 5 estrelas5/5 (5)

- Shuttle Less Weaving 1Documento9 páginasShuttle Less Weaving 1sethup_1Ainda não há avaliações

- Rotor PrincipleDocumento12 páginasRotor PrincipleAnkit Balotia100% (1)

- What Are The Advantages and Disadvantages of Rotor Spun Yarn and Approach To Minimize and Reduced ThemDocumento15 páginasWhat Are The Advantages and Disadvantages of Rotor Spun Yarn and Approach To Minimize and Reduced ThemMuhammad Farooq KokabAinda não há avaliações

- Carding: Q. Define Carding/Heart of SpinningDocumento31 páginasCarding: Q. Define Carding/Heart of SpinningSantoshAinda não há avaliações

- Raymond UCO DenimDocumento25 páginasRaymond UCO DenimChaitanya Gajbhiye100% (1)

- Blow RoomDocumento42 páginasBlow RoomSiva Jagadish Kumar MAinda não há avaliações

- F Ancy Yarn Production: Chapters 2 3Documento19 páginasF Ancy Yarn Production: Chapters 2 3TKK-TEXTILE PSG CT100% (1)

- Weft Knitting PDFDocumento64 páginasWeft Knitting PDFBala SaravananAinda não há avaliações

- Improving Productivity of Ring FramesDocumento8 páginasImproving Productivity of Ring FramesAmrit virkAinda não há avaliações

- Fabric DefectsDocumento33 páginasFabric DefectsAzeem Akbar92% (13)

- Ring SpinningDocumento12 páginasRing Spinningshakil parvej100% (3)

- Wet Processing 1Documento47 páginasWet Processing 1Rahul ThomasAinda não há avaliações

- Effect of Cleaning Point of Uniclean Machine in Blow Room On Cleaning Efficiency and Yarn QualityDocumento21 páginasEffect of Cleaning Point of Uniclean Machine in Blow Room On Cleaning Efficiency and Yarn QualitySantoshAinda não há avaliações

- Modern Developmens in WarpingDocumento30 páginasModern Developmens in Warpingsandippatil03100% (1)

- What Is Sectional Warping?: Creel Drum BeamDocumento6 páginasWhat Is Sectional Warping?: Creel Drum Beamamar9247Ainda não há avaliações

- Yarn AssignmentDocumento10 páginasYarn AssignmentHIMASHA SAMARANAYAKAAinda não há avaliações

- Knitting TechnologyDocumento31 páginasKnitting Technologyagga1111Ainda não há avaliações

- Fully FashionDocumento30 páginasFully FashiondewAinda não há avaliações

- Unit - IiDocumento27 páginasUnit - IiJoseph KuruvilaAinda não há avaliações

- Yarn Breakage in WarpingDocumento36 páginasYarn Breakage in WarpingSyed Salahuddin Munna100% (1)

- Advanced Fabric Structure PDFDocumento35 páginasAdvanced Fabric Structure PDFManoj Mondal83% (6)

- Man Made Fiber Textile ProcessDocumento39 páginasMan Made Fiber Textile ProcessGarmentLearnerAinda não há avaliações

- Weaving Commission CalculationsDocumento1 páginaWeaving Commission Calculationsraj_85Ainda não há avaliações

- Yarn Clearing SystemsDocumento11 páginasYarn Clearing SystemsLohit MohapatraAinda não há avaliações

- Preparatory Process For WeavingDocumento6 páginasPreparatory Process For Weavingsimple_simple100% (2)

- Air Jet SpinningDocumento7 páginasAir Jet SpinningAbi NikilAinda não há avaliações

- Yarn Short Questions PDFDocumento16 páginasYarn Short Questions PDFNasir Sarwar100% (2)

- Sequence of Process in Worsted SpinningDocumento4 páginasSequence of Process in Worsted SpinningArunraj Arumugam100% (4)

- Lect5 - Carding Machine 2Documento13 páginasLect5 - Carding Machine 2Mina Samy abd el zaherAinda não há avaliações

- Air Jet SpinningDocumento32 páginasAir Jet SpinningdrskathirrveluAinda não há avaliações

- Yarn-1, Report On Mill VisitDocumento11 páginasYarn-1, Report On Mill VisitBoier Sesh Pata100% (2)

- Air Jet LoomsDocumento6 páginasAir Jet LoomsJuhi Nath100% (2)

- Ring FrameDocumento13 páginasRing FrameAnkit Kumar0% (1)

- Weaving TechnologyDocumento26 páginasWeaving TechnologyimmmranAinda não há avaliações

- SanforizingDocumento2 páginasSanforizingFernando Harahap100% (1)

- Maintenance of Textile MachineryDocumento27 páginasMaintenance of Textile Machineryhmsohag100% (2)

- Nannu Spinning Mills Limited Quality Control Department: Melange YarnDocumento10 páginasNannu Spinning Mills Limited Quality Control Department: Melange YarnAhmed LikhonAinda não há avaliações

- Bobtex Spinning ProcessDocumento8 páginasBobtex Spinning Processvermadeen0% (1)

- Air Vortex SpinningDocumento35 páginasAir Vortex Spinningdrskathirrvelu100% (9)

- What Is AutolevellerDocumento3 páginasWhat Is AutolevellersafiaAinda não há avaliações

- Afis and HviDocumento3 páginasAfis and HviNirbhay Sharma100% (1)

- Yarn Making ProcessDocumento4 páginasYarn Making ProcessAshwani MittalAinda não há avaliações

- Yarn Defect-Final - ReadyDocumento47 páginasYarn Defect-Final - Readyparash rajAinda não há avaliações

- Spinning Geometry of Ring Spinning MachineDocumento19 páginasSpinning Geometry of Ring Spinning MachineSahlu Klemewerk DagetAinda não há avaliações

- Staple Cotton Spinning SystemsDocumento24 páginasStaple Cotton Spinning Systemsagga1111Ainda não há avaliações

- Woven Fabric FeaturesDocumento16 páginasWoven Fabric FeaturesRauf SyahAinda não há avaliações

- Knitter S Handy Book of Top Down BLAD WebDocumento8 páginasKnitter S Handy Book of Top Down BLAD Webhello hi0% (2)

- NotcherDocumento2 páginasNotcherMukul KashyapAinda não há avaliações

- 3rd PT in TLE G8Documento3 páginas3rd PT in TLE G8Leni May N. LuistroAinda não há avaliações

- Chapter I. Clothing ConsiderationsDocumento11 páginasChapter I. Clothing ConsiderationscharmaineAinda não há avaliações

- Eco FriendlyDocumento8 páginasEco FriendlyShagun SinhaAinda não há avaliações

- JasonpatternDocumento13 páginasJasonpatternEchoAinda não há avaliações

- Dyeing AND Printing: Assignment-2Documento21 páginasDyeing AND Printing: Assignment-2Kumar GauravAinda não há avaliações

- Road Less TravelledDocumento4 páginasRoad Less TravelledAle De La FuenteAinda não há avaliações

- Sweet Oddity Art: Sunny The Elephant Crochet PatternDocumento20 páginasSweet Oddity Art: Sunny The Elephant Crochet PatternDrey Tabilog100% (3)

- Parts List: Model 590Documento15 páginasParts List: Model 590AstraluxAinda não há avaliações

- Beer US - Pattern - SweetBear - byPolushkaBunnyDocumento7 páginasBeer US - Pattern - SweetBear - byPolushkaBunnyeM100% (6)

- Different Types of StitchesDocumento13 páginasDifferent Types of Stitcheshabibitltd100% (5)

- Andean Pre-Hispanic TextilesDocumento59 páginasAndean Pre-Hispanic TextilesYesmar ConsultoresAinda não há avaliações

- Holowicki Ind5Documento8 páginasHolowicki Ind5api-558593025Ainda não há avaliações

- (AQA GCSE (9-1) Design and Technology) Bennett, Andrea - Birdman - Douglas, Stuart - Taylor, Saul - AQA GCSE (9-1) Design & Technology - Textile-Based Materials-Hodder Education (2017)Documento232 páginas(AQA GCSE (9-1) Design and Technology) Bennett, Andrea - Birdman - Douglas, Stuart - Taylor, Saul - AQA GCSE (9-1) Design & Technology - Textile-Based Materials-Hodder Education (2017)Param BhimaniAinda não há avaliações

- Cost Sheet Woven Basic ShirtDocumento2 páginasCost Sheet Woven Basic ShirtShiblyAinda não há avaliações

- Basic Hand StitchesDocumento8 páginasBasic Hand StitchesCherish Nymph Maniquez Celestino100% (4)

- Woodland PatternDocumento17 páginasWoodland PatternBrandie PayneAinda não há avaliações

- Yarn: .: Yarn Is A Long Continuous Length of Interlock Fiber, Suitable For Use in The Production of TextilesDocumento18 páginasYarn: .: Yarn Is A Long Continuous Length of Interlock Fiber, Suitable For Use in The Production of TextilesMahedi HasanAinda não há avaliações

- BaluchariDocumento3 páginasBalucharinikkiiitttaaaAinda não há avaliações

- LS50 Double Gauze Top InstructionsDocumento3 páginasLS50 Double Gauze Top InstructionsYessenia GuardadoAinda não há avaliações

- Crochet DOG Pattern Svetaminka2Documento13 páginasCrochet DOG Pattern Svetaminka2Gabriela MassuttiAinda não há avaliações

- Geotextile (Soil)Documento27 páginasGeotextile (Soil)Anwar Hossain PolasAinda não há avaliações

- Alternative Rounder Head 2020: Standard Size Weebee DollDocumento2 páginasAlternative Rounder Head 2020: Standard Size Weebee DollRaquel BaisanequeAinda não há avaliações

- GOLDEN TERRY ProfileDocumento15 páginasGOLDEN TERRY ProfileMuru GanAinda não há avaliações

- ACC320 Exam 2Documento4 páginasACC320 Exam 2santiAinda não há avaliações

- Lesson 7Documento23 páginasLesson 7Debayn OliquianoAinda não há avaliações

- Grioup 4 Business Plan Macrame 1Documento54 páginasGrioup 4 Business Plan Macrame 1oliveAinda não há avaliações

- Apparel Cost Sheet SampleDocumento3 páginasApparel Cost Sheet SampleAbhinav Verma85% (13)

- Carmella CardiganDocumento4 páginasCarmella CardiganRoganAinda não há avaliações

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNo Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNota: 5 de 5 estrelas5/5 (2)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNo Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesAinda não há avaliações

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNo EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsAinda não há avaliações

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Ainda não há avaliações

- House Rules: How to Decorate for Every Home, Style, and BudgetNo EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetAinda não há avaliações

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsNo EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsNota: 4.5 de 5 estrelas4.5/5 (10)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsNo EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsAinda não há avaliações

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsNo EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsAinda não há avaliações

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNo EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNota: 4 de 5 estrelas4/5 (3)

- The Martha Manual: How to Do (Almost) EverythingNo EverandThe Martha Manual: How to Do (Almost) EverythingNota: 4 de 5 estrelas4/5 (11)

- Art Journals & Creative Healing: Restoring the Spirit through Self-ExpressionNo EverandArt Journals & Creative Healing: Restoring the Spirit through Self-ExpressionNota: 3 de 5 estrelas3/5 (7)

- Edward's Menagerie: Dogs: 50 canine crochet patternsNo EverandEdward's Menagerie: Dogs: 50 canine crochet patternsNota: 3 de 5 estrelas3/5 (5)

- Crochet Impkins: Over a million possible combinations! Yes, really!No EverandCrochet Impkins: Over a million possible combinations! Yes, really!Nota: 4.5 de 5 estrelas4.5/5 (10)

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsNo EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsNota: 5 de 5 estrelas5/5 (3)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeNo EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeNota: 5 de 5 estrelas5/5 (1)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNo EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNota: 5 de 5 estrelas5/5 (1)

- Funny Amigurumi: 16 Creatures & Their Accessories to CrochetNo EverandFunny Amigurumi: 16 Creatures & Their Accessories to CrochetNota: 5 de 5 estrelas5/5 (1)

- Crochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreNo EverandCrochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreNota: 4 de 5 estrelas4/5 (6)

- How to Embroider Almost Everything: A Sourcebook of 500+ Modern Motifs & Easy Stitch TutorialsNo EverandHow to Embroider Almost Everything: A Sourcebook of 500+ Modern Motifs & Easy Stitch TutorialsNota: 4.5 de 5 estrelas4.5/5 (4)

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldNo EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldNota: 4.5 de 5 estrelas4.5/5 (30)

- Change Your Clothes, Change Your Life: Because You're Worth ItNo EverandChange Your Clothes, Change Your Life: Because You're Worth ItNota: 4 de 5 estrelas4/5 (32)

- Little Happy Circus: 12 Amigurumi Crochet Toy Patterns for Your Favourite Circus PerformersNo EverandLittle Happy Circus: 12 Amigurumi Crochet Toy Patterns for Your Favourite Circus PerformersNota: 5 de 5 estrelas5/5 (3)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersNo EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersNota: 3.5 de 5 estrelas3.5/5 (3)

- Textiles Transformed: Thread and thrift with reclaimed textilesNo EverandTextiles Transformed: Thread and thrift with reclaimed textilesAinda não há avaliações

- Modern Embroidery: A Book of Stitches to Unleash CreativityNo EverandModern Embroidery: A Book of Stitches to Unleash CreativityAinda não há avaliações

- Edward's Crochet Doll Emporium: Flip the mix-and-match patterns to make and dress your favourite peopleNo EverandEdward's Crochet Doll Emporium: Flip the mix-and-match patterns to make and dress your favourite peopleNota: 5 de 5 estrelas5/5 (1)

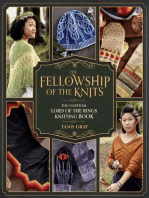

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookNo EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookNota: 4.5 de 5 estrelas4.5/5 (2)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestNo EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestNota: 5 de 5 estrelas5/5 (2)

- Crochet Ragdoll Friends: 36 New Dolls to MakeNo EverandCrochet Ragdoll Friends: 36 New Dolls to MakeNota: 4.5 de 5 estrelas4.5/5 (2)