Escolar Documentos

Profissional Documentos

Cultura Documentos

Cement Tesis Austtria

Enviado por

Hector Ruben Farje BautistaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cement Tesis Austtria

Enviado por

Hector Ruben Farje BautistaDireitos autorais:

Formatos disponíveis

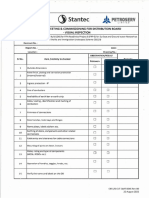

16. - 18. 10.

2013, Brno, Czech Republic, EU

INFLUENCE OF NANO-SILICA ADDITION ON PROPERTIES OF FRESH AND HARDENED

CEMENT MORTAR

Sayed ABD EL-BAKYa, Sameh YEHIAb, Ibrahim S. KHALILa

a

Housing & Building National Research Centre, Cairo, Egypt

b

Shorouk Academy, Cairo, Egypt

Abstract

The aim of this study is to investigate the influence of adding nano-silica particles, on the properties of fresh

and hardened cement mortar through measurements of workability, compressive and flexure strengths in

addition to measuring by SEM analysis. Nano-silica particles with size of 19 nm have been used as a cement

addition by 1, 3, 5, 7 and 10 % by weight of cement content. Results indicated that the cement mortar

workability decrease with increasing nano-silica addition. On the other hand, the percentage of 7 % of nanosilica recorded as optimum percentage in compressive and flexure strength measured for cement mortar

mixed with the nano-silica. The improvement in compressive and flexure strength measured as 55.7 % and

46.9 % respectively, compared with the conventional mortar, especially at early ages. In addition, the

scanning electron microscope (SEM) analysis of the microstructures showed that the nano silica filled the

cement paste pores, more homogeneity for cement paste and interfacial zone, by reacting with calcium

hydroxide crystals forming more calcium silicate hydration.

Keywords: Nano-Silica, Mortar,SEM

1.

INTRODUCTION

Recently, there are large numbers of applications of nanotechnology in the construction engineering field.

Nanomaterials (Pertaining to things on a scale of approximately 1 to 100 nanometers (nm)), [1], is an evergrowing multidisciplinary field of study attracting tremendous interest and have been applied in many fields to

fabricate new materials with novel functions due to their unique physical and chemical properties, [2].Cement

mortar, one of the most ubiquitous material in the world, is a nanostructured, multi-phase and composite

material that ages over time. It is composed of an amorphous phase, nanometer to micrometer size crystals,

and bound water. Using pozzolanic material such as silica fume (SF) is necessary for improving the

properties of both concrete and cement mortar, because the significant improvement occurred in the inter [3].

Therefore, for similar purposes, a stable gel structure can be formed and the mechanical properties of

hardened cement paste can be improved when a smaller amount of nano-silica is added [4]. The

microstructure of the mortar containing nano-silica (NS) was denser and more uniform than that of the

conventional mortar microstructure and that containing silica fume [5], [7], [14].

2.

EXPERIMENTAL PROGRAM

2.1.

Materials and Mix Proportions

2.1.1. Cement

The cement used is Portland Cement, (PC), (CEM I 42.5 - N) and the properties are shown in Table 1.

2.1.2. Aggregate

In this research natural siliceous sand with specific gravity of 2.6 and particles size from 0.06 mm to 5 mm

were used. It should be mentioned that aggregate were granulated based on ASTMC 136-96 standards.

16. - 18. 10. 2013, Brno, Czech Republic, EU

2.1.3. Water

Tap water used in this experiment.

Table 1 Chemical Composition of PC and NS

PC

Oxide Composition,

Wt %

CaO

63.3

SiO2

20.7

Al2O3

4.63

Fe2O3

3.63

MgO

1.63

SO3

3.25

K2O

0.87

Na2O

0.21

TiO2

--P2O5

--Ignition Loss

1.90

NS

Wt %

--99.9

----------------------------

2.1.4. Nano-Silica

The nano-silica used in this research is powder type. The chemical and physical specifications are given in

Table 1 and Table 2, respectively. The morphology of nano particles studied using Transmission Scanning

Election Microscopy (TEM), as Shown in Fig. 1.

Table 2 Physical Specifications of Consumed Nano-Silica

Specific Surface

Diameter of

Density

Purity

(m2/g)

Particles (nm)

(g/cm3)

Percentage

19

2.2.

2.12

160

99.9

Test Program and Specimens Fabrication

The test program of this research consist of 6 mixes

with different addition of NS percentages ranged

from 0% to 10% and added as a replacement of

cement content of mortar mixes, as shown in table

(3).the specimens fabrication is done as follows.

Firstly, mixing nano-silica with cement by ball miller,

type PM100 shown in Fig. 2, using four balls

(13mm) for 10 minuets, forming nano-silica and

cement composite.

After completing mixing

process nano-silica-cement composite prepared

and placed in the mixer, shown in Fig. 3. Fine

aggregate was added to the dry composite and

mixed together, then gently adding mixing water.

The final fresh mortar is poured into oiled molds

and after pouring, an external vibrator is used to

facilitate compaction and decrease the amount of

Fig. 1 TEM Micrograph of Nano-Silica

Figure 8(a): ball miller

16. - 18. 10. 2013, Brno, Czech Republic, EU

air bubbles. The specimens were demolded after 24hr and cured in a standard water tank at temperature of

203C.

Fig. 3 Mixer and Vibratory

Fig. 2 Ball Mill, Type PM100

2.3.

Testing Methods:

For each mix 9 cubes of 505050 mm were

tested in compressive according to ASTM

C109-99 at 3, 7 and 28 days. Also 9 prism

were tested for each mix in flexural according

to ASTM C 348-97 at 3, 7 and 28 days. A

displacement control machine for compression

and flexural tests is used as shown in Figure

(4). Table 3 shows the mixes proportions

based on ASTM standard of different mortar

mixes containing different percentage of NS.

3.

TEST RESULTS AND DISCUSSIONS

3.1.

Mortar Flow

270

260

flow diameter (mm)

The flowability test of

different cement mortars

were carried out according

to ASTM C1437. Results

refer to a flow reduction are

proportional

with

the

increasing

of

NS

percentages

in

cement

mortar up to 7 %, as apart

of

mixing

water

was

exhausted in the activation

of NS particles due to the

large specific surface area

of NS particles as seen in

Fig. 5. However, this

Fig. 4 Compression and Flexural Machine

250

240

230

220

210

200

1

3

4

nano-pow der(%)

Fig. 5 Mortar Flow

16. - 18. 10. 2013, Brno, Czech Republic, EU

behavior is changed when using 10 % of NS particles, the flow started to re-increase due to the remaining of

the excess NS particles without activation. So nano-silica absorbs amount of the mixing water, reducing

workability. However, the excess of nano-silica up to the interactive amount work as lubrication so reincrease the flow of the mortar.

Table 3 Mix Proportions, Compressive and Flexural Strengths of Different Mixes

Compressive strength

Mix Proportion

2

(kg/cm )

Flow

Sample

(mm)

C

NS

W

Sand

3D

7D

28D

%

%

%

%

NS1

100

0

48.5

275

260

159.3

214.5

240.6

NS2

99

1

48.5

275

255

197.4

291.9

305.0

NS3

97

3

48.5

275

240

212.5

297.2

318.5

NS4

95

5

48.5

275

225

218.8

323.8

341.2

NS5

93

7

48.5

275

220

275.9

347.1

374.7

NS6

90

10

48.5

275

223

258.5

232.7

336.1

7D

28D

24.41

28.5

32.21

33.81

39.94

35.63

32.63

42.00

45.75

46.69

52.50

47.06

36.38

43.31

49.50

52.88

58.31

53.44

Flexural Strengths:

Fig.7 shows the flexural strength of all

mixes at 3, 7 and 28 days. Results

showed that the improvement for

flexural strength for nano-silica cement

mortar, which replaced by cement

content equal 7 % gives optimum

percentage in improvement. All results

400

Compressive strength (kg/m2)

Fig. 6 shows the compressive strength

of all mixes at 3, 7 and 28 days.

Results showed that the optimum

percentage adding nano-silica as a

replacement of cement content was

7%, which improves compressive

strength by 55.7% at 28 days. As

shown in Table 3, the results

proportionally to Tobon, J.I [6] who

said that nano-silica up to 10 % NS,

can improves compressive strength by

86.9 %.When nano-silica is added by

different percentages, both the effect

and the amount of improvement of

compressive strength of mortar can

be enhanced. This result due to the

increasing of the bond strength of

cement paste-fine aggregate interface

by means of the filling, which will be

discussed in part 3.4 for SEM

(Scanning

Electron

Microscope)

analysis.

3.3.

3D

Compressive Strengths:

350

300

3 days

7 days

28 days

250

200

150

100

50

0

0

10

NS %

Fig 6 Effect of NS percentage on the Compressive Strengths

70

60

Flexural strength (kg/m2)

3.2.

Flexural Strength

2

(kg/cm )

50

3 days

7 days

28 days

40

30

20

10

0

0

10

NS%

Fig. 7 Effect of NS percentage on the Flexural Strengths

16. - 18. 10. 2013, Brno, Czech Republic, EU

showed that, when nano particles (nano-silica) is added as a replacement of cement content, but by different

percentage, the effect and amount of improvement of flexural strength of mortar can be enhanced. This

result is attributed to increasing the bond strength of cement paste-fine aggregate interfacial zone.

3.4.

SEM analysis

Fig 8 - (a, b and c), are shown SEM micrographs of reference mortar and mortar with 7 % nano-silica

respectively. The SEM shows that the microstructure of the nano-silica mortar, is denser and more

homogeneous than of the conventional mortar because of the pozzolanic reaction by consumption of

Ca(OH)2, and formation an additional C-S-H which fill the pores system and causing densification effect

which improve the microstructure of mortar. Proportionally to Paramita, [7] who said that were 18 % nanosilica added for concrete mixes; the volume fraction of high-stiffness C-S-H was high as 50%.Cement pastes

with nano-silica proved that nano-silica increases the average chain length of C-S-H gel.

ITZ

Aggregate

CSH

Crack

CH

Voids

Fig. 8-a SEM of Conventional Mortar for (ITZ)

Fig. 8-b SEM of Mortar with 7 % NS

ITZ

Aggregate

Fig. 8-c SEM of Mortar with 7 % NS

4.

CONCLUSIONS

Based on the experimental results presented in this research, the following conclusions can be drawn:

16. - 18. 10. 2013, Brno, Czech Republic, EU

Workability of cement mortar which decreased by increasing the amount of interactive nano-silica as

long as the inserted nano-silica can be interactive with calcium hydroxide resulting from hydration

process of cement with water.

Compressive and flexural strength of the cement mortar increases proportionally with increasing the

amount of nano-silica, especially at early ages. Until achieving the optimum percentage, NS at 7%,

then decreases due to the decreasing of calcium hydroxide that exhausted in the activation process by

7% nano-silica. As any amount more than that have no activation and take place of cement by inert

powder, so it's naturally to decrease the strengths.

Cement mortar containing nano-silica have more homogeneity binder, less pores, more adhesion at

interfacial zone which is clarified in SEM analysis.

LITERATURE

[1]

ASTM E2456-06, Standard Terminology Relating to Nanotechnology.

[2]

Proceedings of ACI Session on, Nanotechnology of Concrete: Recent Developments and Future Perspectives

November 7, 2006, Denver, USA, pp 15-28.

[3]

M. Mazloom a, A.A. Ramezanianpour b, J.J. Brooks, Effect of Silica Fume on Mechanical Properties of HighStrength Concrete, Cement & Concrete Composites 26 (2004) 347357.

[4]

Ye Qing a,b, , Zhang Zenan, Kong Deyu, Chen Rongshen , Influence of Nano-SiO2 Addition on Properties of

Hardened Cement Paste as Compared with Silica Fume, Cement & Concrete Composites 26 (2004) 347357.

[5]

Ashwni K.Ranal, Significance of Nanotechnology in Construction Engineering, International Journal of Recent

Trends in Engineering , Vol 1, No. 4, May 2009.

[6]

Tobn, J. I Comparative Analysis of Performance of Portland Cement Blended with Nano Silica and Silica Fume

, Universidad Nacional de Colombia September, 2010, pp. 3746.

[7]

Paramita Mondal, Comparative Study of the Effects of Microsilica and Nanosilica in Concrete, Journal of the

Transportation Research Board, 2010.

[8]

Mostafa.Khanzadi, Influence of Nano-Silica Particles on Mechanical Propertie and Permeability of Concrete s,

Journal of the Transportation Research Board, 2010.

[9]

Ali Nazari, Shadi Riahi, The Effects of SiO2 Nano Particles on Physical and Mechanical Properties of High

Strength Compacting Concrete, Elsevier compositesb journal 2010.

[10]

ASTM C 109/ C 109M-02, Standard Test Method for Compressive Strength of Hydraulic Cement mortars (Using

2-in. or [50-mm] Cube Specimens) .

[11]

ASTM C348-97, Standard Test Method for flexural strength of Hydraulic-cement mortar.

[12]

ASTM C230/c230M-98e1, "Standard Test Method for Flow Table for Use in Tests of Hydraulic cement.

[13]

Gengying Li, Properties of hHigh-Volume Fly Ash Concrete Incorporating Nano-SiO2 Cement and Concrete

Research 34 (2004) 10431049.

[14]

Zhi Ge, Applications of Nanotechnology and Nanomaterials in Construction, First International Conference on

Construction In Developing Countries (ICCIDCI), August 4-5, 2008, Karachi,, Pakistan.

[15]

Florence Sanchez, Nanotechnology in Concrete A Review, Construction and Building Materialsanchez 24

(2010) 20602071.

[16]

Jonathan S. Belkowitz1, An Investigation of Nano Silica in the Cement Hydration Process, 2010 Concrete

Sustainability Conference.

[17]

S. S. Shebl Mechanical Behavior of Activated Nano Silicate Filled Cement Binders, J Mater Sci (2009) 44:1600

1606.

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- DB ChecklistDocumento4 páginasDB ChecklistJabinAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- IJRASETDocumento7 páginasIJRASETCharlosAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Gate 2018 Ce Set1 Madeeasy PDFDocumento42 páginasGate 2018 Ce Set1 Madeeasy PDFShivangi MishraAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Water Properties Lab ReportDocumento2 páginasWater Properties Lab Reportapi-454228134100% (2)

- Polimorfismos de Benzocaina PDFDocumento9 páginasPolimorfismos de Benzocaina PDFDiegoAndrésYiZapataAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Chapter 1 Stress ProblemsDocumento5 páginasChapter 1 Stress Problemsiceskater23320Ainda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Sae j419 1983 Methods of Measuring Decarburization PDFDocumento8 páginasSae j419 1983 Methods of Measuring Decarburization PDFSumeet SainiAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Non-Destructive Testing MCQ Type Question Bank-1: Piezoelectric EffectDocumento6 páginasNon-Destructive Testing MCQ Type Question Bank-1: Piezoelectric EffectMegha DixitAinda não há avaliações

- Pliotec hdt12 Technical Data Sheet PDFDocumento3 páginasPliotec hdt12 Technical Data Sheet PDFNatalia RodriguezAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Introduction To NanotechnologyDocumento37 páginasIntroduction To NanotechnologyBhupesh Chandra GuptaAinda não há avaliações

- All Functional Materials For Material EngineeringDocumento27 páginasAll Functional Materials For Material Engineeringeddula ganeshAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Percdc Cns Geas 1Documento9 páginasPercdc Cns Geas 1Charles Adrian CAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Two Cycle Heat Treatment (Austempering + Tempering) of Low C Equivalent Ductile IronDocumento58 páginasTwo Cycle Heat Treatment (Austempering + Tempering) of Low C Equivalent Ductile IronsaltbathAinda não há avaliações

- 名 称(Title) 2016-N D0031Documento25 páginas名 称(Title) 2016-N D0031jenwitbunjongsatAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- MEMS & NEMS PresentationDocumento16 páginasMEMS & NEMS PresentationAhmed ElswifyAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Optimum Design of Pressure Vessel Subjected To Autofrettage ProcessDocumento6 páginasOptimum Design of Pressure Vessel Subjected To Autofrettage ProcessPierluigiBusettoAinda não há avaliações

- Lecture1 - Diodes - ApplicationsDocumento54 páginasLecture1 - Diodes - ApplicationsTuanHungAinda não há avaliações

- TDS Airex C70 e - 1106Documento3 páginasTDS Airex C70 e - 1106aAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Gato Electric Fence Price List For DistributorsDocumento6 páginasGato Electric Fence Price List For DistributorsDaniel MekonnenAinda não há avaliações

- AB Wool GlasswoolDocumento2 páginasAB Wool GlasswoolCatur Oka Nurfansyah0% (1)

- Kaowool Papers Morgan CeramicsDocumento3 páginasKaowool Papers Morgan CeramicsGurdeep Sungh AroraAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Quantum Materials Science EngineeringDocumento2 páginasQuantum Materials Science Engineeringvisheshp961Ainda não há avaliações

- Air Sea ExchangeDocumento10 páginasAir Sea Exchangedist2235Ainda não há avaliações

- Adobe Scan 23 May 2023Documento9 páginasAdobe Scan 23 May 2023Wanderer YashAinda não há avaliações

- Unit Test 1 (Et 1)Documento2 páginasUnit Test 1 (Et 1)vkesavakannanAinda não há avaliações

- Rigid Pavement: Postgraduate Studies Highways EngineeringDocumento15 páginasRigid Pavement: Postgraduate Studies Highways EngineeringHANAN HUSSAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- As-Design of Column SpliceDocumento22 páginasAs-Design of Column SplicedominiquedAinda não há avaliações

- Hist Som Ch4 Lecture22Documento4 páginasHist Som Ch4 Lecture22Nirmal K.c.Ainda não há avaliações

- Mechanical Properties of Solids: Section-ADocumento11 páginasMechanical Properties of Solids: Section-AKirtiMishraAinda não há avaliações

- (Volume 2) David Halliday, Robert Resnick - Physics - Part II 2 (1978, Wiley) - Libgen - LiDocumento646 páginas(Volume 2) David Halliday, Robert Resnick - Physics - Part II 2 (1978, Wiley) - Libgen - LicrmzAinda não há avaliações