Escolar Documentos

Profissional Documentos

Cultura Documentos

Hoja de Datos Bombas Sumergibles

Enviado por

Ricardo BarrosDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hoja de Datos Bombas Sumergibles

Enviado por

Ricardo BarrosDireitos autorais:

Formatos disponíveis

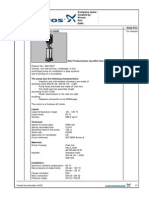

Data sheet

Customer item no.:

Communication dated:

Doc. no.:

Quantity: 2

Number: ES 4077476

Item no.: 100

Date: 13/01/2016

Page: 1 / 7

Version no.: 1

KRTF 80-250/194UGH-S

Operating data

Requested flow rate

Requested developed head

Pumped medium

Ambient air temperature

Fluid temperature

Fluid density

30.000 l/s

35.00 m

Wastewater, municipal

mechanically treated

Not containing chemical and

mechanical substances which

affect the materials

20.0 C

20.0 C

1000 kg/m

Fluid viscosity

Max. power on curve

1.00 mm/s

25.11 kW

Actual flow rate

Actual developed head

Efficiency

Power absorbed

Pump speed of rotation

Shutoff head

Design

Performance test

28.591 l/s

31.79 m

56.1 %

15.84 kW

1752 rpm

38.88 m

Twin system one full duty +

one standby pump

No

tolerances to ISO 9906 class

2B

Design

Design

Orientation

Suction flange pump

according to(DN1)

Discharge flange pump

according to(DN2)

Shaft seal

Manufacturer

Type

Close-coupled submersible

Vertical

unmachined

EN 1092-2 / DN 80 / PN 16

Material code

Impeller type

Impeller diameter

Free passage size

Direction of rotation from drive

Color

SIC/SIC/NBR

Free flow (vortex) impeller (F)

265.0 mm

76.0 mm

Clockwise

Ultramarine blue (RAL 5002)

KSB-blue

Motor service factor

Temperature sensor

Motor winding

Number of poles

Starting mode

Connection mode

Motor cooling method

Motor version

Cable design

Cable entry

Power cable

Number of power cables

Moisture sensor

1.15

Bimetal switch 2x

460 V

4

Direct-on-line starting

Delta

Surface cooling

U

Rubber hose

Sealed along entire length

AWG 11-7+15-5

1

With

Cable length

10.00 m

2 mech. seals in tandem

arrangement with oil reservoir

KSB

MG

Driver, accessories

Driver type

Model (make)

Motor const. type

NEMA code letter

Speed control selection

Frequency

Rated voltage

Rated power P2

Available reserve

Rated current

Starting current ratio

Insulation class

Motor enclosure

Cos phi at 4/4 load

Motor efficiency at 4/4 load

Electric motor

KSB

KSB Sub. motor

G

Specified speed

60 Hz

460 V

18.64 kW

17.70 %

30.3 A

6.1

F to IEC 34-1

IP68

0.86

89.9 %

Data sheet

Customer item no.:

Communication dated:

Doc. no.:

Quantity: 2

Number: ES 4077476

Item no.: 100

Date: 13/01/2016

Page: 2 / 7

Version no.: 1

KRTF 80-250/194UGH-S

Materials GH

Pump casing (101)

Intermediate casing (113)

Discharge cover (163)

Shaft (210)

Impeller (230)

Cast iron A 48 Class 35 B

High chrome white iron A 532

IIC 15% CrMo-Hc

High chrome white iron A 532

IIC 15% CrMo-Hc

Chrome steel A 276 Type 410

T

High chrome white iron A 532

IIC 15% CrMo-Hc

O-Ring (412)

Motor housing (811)

Motor cable (824)

Screw (900)

Nitrile rubber NBR

Cast iron A 48 Class 35 B

Chloroprene rubber

Stainless steel A 193 B8M

International

Duplicate nameplate

With

Stationary with guide wire

Pump with installation parts

4.50 m

GH

Type

Material

Length

Max. load

Chain

CrNiMo steel 1.4404

5.00 m

400 kg

Nameplates

Nameplates language

Installation parts

Installation type

Scope of supply

Installation depth

Material concept

Duckfoot bend

Size

Flange design

Duckfoot bend size (DN2 /

DN3)

Material

Mounting type

Foundation rail

DN 80

ASME

DN 80 Drilled according to

ASME

Grey cast iron EN-GJL-250

Composite anchor bolts

Without

Claw

Design

Size

Lifting chain / -rope

straight

DN 80

Performance curve

Customer item no.:

Communication dated:

Doc. no.:

Quantity: 2

Number: ES 4077476

Item no.:100

Date: 13/01/2016

Page: 3 / 7

Version no.: 1

KRTF 80-250/194UGH-S

Qmin

Total developed head

40

Qmax

Qmax

[m]

Qmin

20

265.0

190.0

0

0

20

[l/s]

40

60

80

100

120

140

160

20

[l/s]

40

60

80

100

120

140

160

20

[l/s]

40

60

80

100

120

140

160

20

[l/s]

40

60

80

Flow

100

120

140

160

NPSH req.

15

[m]

10

Efficiency

50

[%]

Power Input

20

[kW]

Curve data

Speed of rotation

Fluid density

Viscosity

Flow rate

Requested flow rate

Total developed head

Requested developed head

1752 rpm

1000 kg/m

1.00 mm/s

28.591 l/s

30.000 l/s

31.79 m

35.00 m

Efficiency

Power absorbed

NPSH required

Curve number

Effective impeller diameter

Acceptance standard

56.1 %

15.84 kW

5.95 m

K43060s

265.0 mm

tolerances to ISO 9906

class 2B

Speed curve

Customer item no.:

Communication dated:

Doc. no.:

Quantity: 2

Number: ES 4077476

Item no.:100

Date: 13/01/2016

Page: 4 / 7

Version no.: 1

KRTF 80-250/194UGH-S

Qmin

Total developed head

40

Qmax

Qmax

[m]

20

1752 1/min

0

0

20

[l/s]

40

60

80

100

120

140

160

20

[l/s]

40

60

80

100

120

140

160

20

[l/s]

40

60

80

100

120

140

160

20

[l/s]

40

60

80

Flow

100

120

140

160

NPSH req.

15

[m]

10

Efficiency

50

[%]

Power Input

20

[kW]

Curve data

Fluid density

Viscosity

Flow rate

Requested flow rate

1000 kg/m

1.00 mm/s

28.591 l/s

30.000 l/s

Total developed head

31.79 m

Requested developed head 35.00 m

Effective impeller diameter 265.0 mm

Motor data sheet

Customer item no.:

Communication dated:

Doc. no.:

Quantity: 2

Number: ES 4077476

Item no.:100

Date: 13/01/2016

Page: 5 / 7

Version no.: 1

KRTF 80-250/194UGH-S

Motor data

Motor manufacturer

Motor size

Motor construction type

Motor material

Efficiency class

Rated voltage

Frequency

Motor power

Rated current

KSB

19

KSB Sub. motor

Grey cast iron EN-GJL-250

not classified

460 V

60 Hz

18.64 kW

30.3 A

Rated speed

Starting current ratio

Starting mode

Power cable

Number of power cables

Power cable min.

Power cable max.

Cable standard

Switching frequency

1770 rpm

6.1

Direct-on-line starting

AWG 11-7+15-5

1

21.0 mm

23.0 mm

NEC

10.00 1/h

Curve data

The no-load point is not a guarantee point within the meaning of IEC 60034

Load

0.0 %

25.0 %

50.0 %

P2

0.00 kW

4.66 kW

9.32 kW

n

1800 rpm

1793 rpm

1785 rpm

P1

1.30 kW

5.82 kW

10.57 kW

I

10.2 A

13.5 A

17.9 A

Eta

0.0 %

80.1 %

88.2 %

cos phi

0.16

0.54

0.74

75.0 %

13.98 kW

1778 rpm

15.54 kW

23.5 A

90.0 %

0.83

100.0 %

18.64 kW

1770 rpm

20.74 kW

30.3 A

89.9 %

0.86

1800

[rpm]

n

1760

0

200

[kW]

10

12

14

16

18

20

100

1.0

100

0.8

80

60

0.6

60

80

40

0.4

40

60

[kW]

[1]

[%]

40

20

0.2

20

0.0

180

160

eta

80

cos phi

140

120

100

P1

[A]

I

20

0

0

[kW]

10

12

mechanical pow er P2

14

16

18

20

Installation plan

Customer item no.:

Communication dated:

Doc. no.:

Quantity: 2

Number: ES 4077476

Item no.:100

Date: 13/01/2016

Page: 6 / 7

Version no.: 1

KRTF 80-250/194UGH-S

60

10

85

690

590

165

470

153

864

1)

DN3

692

(Lifting bail optional)

380

min 300

200

DN1

76

18

140

125

810

1) Minimum water level t1

202

382

150

min 500

Access opening

220

min 650

Drawing is not to scale

Dimensions in mm

Installation plan

Customer item no.:

Communication dated:

Doc. no.:

Quantity: 2

Number: ES 4077476

Item no.:100

Date: 13/01/2016

Page: 7 / 7

Version no.: 1

KRTF 80-250/194UGH-S

Motor

Motor manufacturer

Motor size

Motor power

Number of poles

Speed of rotation

KSB

19

18.64 kW

4

1770 rpm

Connections

Suction flange pump

according to(DN1)

Duckfoot bend size (DN2 /

DN3)

Weight net

Pump, Motor, Cable

Claw / Foot

Total

Connect pipes without stress or strain!

Dimensional tolerances for shaft axis height:

Dimensions without tolerances, middle tolerances to:

Connection dimensions for pumps:

Dimensions without tolerances - welded parts:

Dimensions without tolerances - gray cast iron parts:

DIN 747

ISO 2768-m

EN735

ISO 13920-B

ISO 8062-CT9

unmachined

DN 80 Drilled according to

ASME

213 kg

10 kg

223 kg

For auxiliary connections see

separate drawing.

Você também pode gostar

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- Hoja de Datos Bomba Sumergible Amarex KRTDocumento8 páginasHoja de Datos Bomba Sumergible Amarex KRTRicardo BarrosAinda não há avaliações

- 2020 KRT 200 330Documento10 páginas2020 KRT 200 330Ramón OvalleAinda não há avaliações

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- Hoja de Datos Bombas RAS PTARDocumento8 páginasHoja de Datos Bombas RAS PTARRicardo BarrosAinda não há avaliações

- Boiler Feed Water PumpDocumento7 páginasBoiler Feed Water PumphadijawaidAinda não há avaliações

- Ed 1 DF 66 DDocumento5 páginasEd 1 DF 66 DSurangaG100% (1)

- KSB Technical DatasheetDocumento4 páginasKSB Technical DatasheetJj Oredina50% (2)

- KSB Bomba PrincipalDocumento6 páginasKSB Bomba PrincipalCarlos VegaAinda não há avaliações

- Option 3bDocumento6 páginasOption 3bdeepakjoyinAinda não há avaliações

- 3SV03F0056M: Operating DataDocumento3 páginas3SV03F0056M: Operating DatajtorerocAinda não há avaliações

- CR 3-25 A-Fgj-A-E Hqqe: Position Qty. Description Single PriceDocumento7 páginasCR 3-25 A-Fgj-A-E Hqqe: Position Qty. Description Single PriceYanuar ZulkarnainAinda não há avaliações

- 50 - 20T X 29.5m DG Crane - R3Documento13 páginas50 - 20T X 29.5m DG Crane - R3Rv VaghasiaAinda não há avaliações

- Etanorm G 150-315 G10Documento6 páginasEtanorm G 150-315 G10Guillermo GuzmánAinda não há avaliações

- Bomba Desaladora AlternativaDocumento6 páginasBomba Desaladora AlternativawaricateAinda não há avaliações

- Anonymous 1-1en PDFDocumento6 páginasAnonymous 1-1en PDFAlexander BrewerAinda não há avaliações

- SSWP Datasheet Horizontal OptionDocumento2 páginasSSWP Datasheet Horizontal OptionshimrozkhanAinda não há avaliações

- VX136 105 Pos1 Piggy BackDocumento3 páginasVX136 105 Pos1 Piggy BackCretu DanAinda não há avaliações

- KSB KRTK 150-401206ug-S Ie2Documento8 páginasKSB KRTK 150-401206ug-S Ie2Alexandru LipanAinda não há avaliações

- CR 3-17Documento6 páginasCR 3-17dvdatAinda não há avaliações

- Description Value: Printed From Grundfos CAPSDocumento1 páginaDescription Value: Printed From Grundfos CAPSYanuar ZulkarnainAinda não há avaliações

- CR 20-5Documento7 páginasCR 20-5Shahzad SaeedAinda não há avaliações

- Min1244a12 - Tag 130-Pu-029Documento7 páginasMin1244a12 - Tag 130-Pu-029Monty MathewsAinda não há avaliações

- Pompa Namol Secundar - RefDocumento3 páginasPompa Namol Secundar - RefCretu DanAinda não há avaliações

- Data Sheet - GBL Tag No. P-765P-ADocumento7 páginasData Sheet - GBL Tag No. P-765P-ARajendra GuptaAinda não há avaliações

- Data Sheet - GBL Tag No. P309P-ADocumento7 páginasData Sheet - GBL Tag No. P309P-ARajendra GuptaAinda não há avaliações

- KRT-Caracteristicas TecnicasDocumento41 páginasKRT-Caracteristicas TecnicasJjoseph MaquAinda não há avaliações

- Chapter 5Documento7 páginasChapter 5Harjith VaibavAinda não há avaliações

- CRN 32-6 A-F-G-V HQQV: Position Qty. Description Single PriceDocumento6 páginasCRN 32-6 A-F-G-V HQQV: Position Qty. Description Single PriceJoshi DhvanitAinda não há avaliações

- CB3033BS66,1MI4P LS71 0,09kW 365V 87HzDocumento4 páginasCB3033BS66,1MI4P LS71 0,09kW 365V 87Hzmagda_biricaAinda não há avaliações

- PDS1 KRTK GermanyDocumento5 páginasPDS1 KRTK Germanyfirman syahAinda não há avaliações

- Motor Siemens 1LG6317-4MA90 L2F DatasheetDocumento1 páginaMotor Siemens 1LG6317-4MA90 L2F DatasheetFrancisco ArauzAinda não há avaliações

- 1LA9133-4KA60-Z D34 Datasheet enDocumento1 página1LA9133-4KA60-Z D34 Datasheet enCésar VásquezAinda não há avaliações

- Slurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Documento5 páginasSlurry Pumps WH Agitator - Models - HSD, KTV, KRS, NKZ, GPN, Gsz-6Guilherme CamposAinda não há avaliações

- Inline Pump 35 MDocumento10 páginasInline Pump 35 Mbipan rawatAinda não há avaliações

- 2009 02 M HD 319 0Documento5 páginas2009 02 M HD 319 0ZoebairAinda não há avaliações

- Data SheetDocumento10 páginasData SheetVuk VujatovicAinda não há avaliações

- Data SheetDocumento5 páginasData SheetHardikAinda não há avaliações

- Electrical Data /: General Data /:: Datasheet For Three-Phase Squirrel-Cage-MotorsDocumento1 páginaElectrical Data /: General Data /:: Datasheet For Three-Phase Squirrel-Cage-MotorsDoaa El MelegyAinda não há avaliações

- HRD Hot Water Pump P001Documento6 páginasHRD Hot Water Pump P001nguyenquoc1988Ainda não há avaliações

- CR 64-5 A-F-A-E HQQE: Position Qty. Description Single PriceDocumento3 páginasCR 64-5 A-F-A-E HQQE: Position Qty. Description Single Priceshameer_febiAinda não há avaliações

- WW Pump 900 m3Documento12 páginasWW Pump 900 m3Iskandar Zulkarnain HasibuanAinda não há avaliações

- 5T X 25.5m DG CraneDocumento10 páginas5T X 25.5m DG CraneRv VaghasiaAinda não há avaliações

- FHRDocumento5 páginasFHRJavier Melendez RomanAinda não há avaliações

- 1 6001 PDFDocumento12 páginas1 6001 PDFoleg-spbAinda não há avaliações

- Ventiloconvectoare CITIZEN 2011Documento6 páginasVentiloconvectoare CITIZEN 2011office8200Ainda não há avaliações

- Motor Data Sheets - 125HPDocumento6 páginasMotor Data Sheets - 125HPEdwin PrinceAinda não há avaliações

- 15SV04F0556T: Operating DataDocumento4 páginas15SV04F0556T: Operating DataRoger Quevedo MachucaAinda não há avaliações

- Technical Data Sheet - IBG-1423-27 I VT-52-66Documento8 páginasTechnical Data Sheet - IBG-1423-27 I VT-52-66Dinesh BhardwajAinda não há avaliações

- Pompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsDocumento11 páginasPompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsewamihawkAinda não há avaliações

- VPC (Flowserve)Documento5 páginasVPC (Flowserve)Wissam JarmakAinda não há avaliações

- HDD Arx F065-150 - 018c4usg - 200Documento7 páginasHDD Arx F065-150 - 018c4usg - 200Henry Bajaña GuevaraAinda não há avaliações

- Boltup V2.6 Calculator Record of Calculation Tightening Method: TensionDocumento1 páginaBoltup V2.6 Calculator Record of Calculation Tightening Method: TensionΈνκινουαν Κόγκ ΑδάμουAinda não há avaliações

- DPV10-10B 4kwDocumento4 páginasDPV10-10B 4kwNovak OtaševićAinda não há avaliações

- Amacan PDocumento52 páginasAmacan PGogyAinda não há avaliações

- Datasheet of Equipment - ANNAMDocumento8 páginasDatasheet of Equipment - ANNAMhuyly34Ainda não há avaliações

- Motor Data Sheet 1A 1#360kW, 4pole, 6600VDocumento3 páginasMotor Data Sheet 1A 1#360kW, 4pole, 6600Vasyyas100% (1)

- Data Sheet Tag 180-Pu-011eDocumento8 páginasData Sheet Tag 180-Pu-011eSarah PerezAinda não há avaliações

- CHW Pump - HotelDocumento7 páginasCHW Pump - HotelTiffany CombsAinda não há avaliações

- KSB Movitec Type Series BookletDocumento60 páginasKSB Movitec Type Series BookletRicardo BarrosAinda não há avaliações

- KSB Wastewater Training GuideDocumento24 páginasKSB Wastewater Training GuideRicardo BarrosAinda não há avaliações

- Correction of High Vibration On A VTP With A Dynamic Vibration AbsorberDocumento18 páginasCorrection of High Vibration On A VTP With A Dynamic Vibration AbsorberRicardo Barros100% (1)

- Din-Dvgwtype Examination Certificate: Din-Dvgw-BaumusterprüfzertifikatDocumento2 páginasDin-Dvgwtype Examination Certificate: Din-Dvgw-BaumusterprüfzertifikatRicardo BarrosAinda não há avaliações

- KSB AmamixDocumento84 páginasKSB AmamixRicardo BarrosAinda não há avaliações

- Ecoline EST 150-300 FBDocumento7 páginasEcoline EST 150-300 FBRicardo BarrosAinda não há avaliações

- Type Series Booklet Sewatec ASME-NEMA MotorsDocumento44 páginasType Series Booklet Sewatec ASME-NEMA MotorsRicardo Barros100% (1)

- Cobra TDC BrochureDocumento7 páginasCobra TDC BrochureRicardo BarrosAinda não há avaliações

- UPA Type Series BookletDocumento122 páginasUPA Type Series BookletRicardo BarrosAinda não há avaliações

- KSB Submersible Borehole Pumps 60 HZ PDFDocumento114 páginasKSB Submersible Borehole Pumps 60 HZ PDFRicardo Barros100% (2)

- KSB Psa KHG-WDocumento4 páginasKSB Psa KHG-WRicardo BarrosAinda não há avaliações

- Amaline, 60 HZDocumento58 páginasAmaline, 60 HZRicardo BarrosAinda não há avaliações

- BOA H DatabookletDocumento14 páginasBOA H DatabookletRicardo BarrosAinda não há avaliações

- BOA-RFV Type Leaflet R1Documento5 páginasBOA-RFV Type Leaflet R1Ricardo BarrosAinda não há avaliações

- UMA Motors Technical BrochureDocumento40 páginasUMA Motors Technical BrochureRicardo Barros100% (1)

- Catalogo Amarex KRT 60 HZDocumento32 páginasCatalogo Amarex KRT 60 HZRicardo Barros100% (1)

- Ecoline GTC 150-600Documento12 páginasEcoline GTC 150-600Ricardo BarrosAinda não há avaliações

- Final Report Project Cartagena A Free Flood CityDocumento222 páginasFinal Report Project Cartagena A Free Flood CityRicardo BarrosAinda não há avaliações

- COR5500U Series: Digital and CRT Readout OscilloscopeDocumento7 páginasCOR5500U Series: Digital and CRT Readout OscilloscopeFlavio FalcãoAinda não há avaliações

- Chemistry Lab ReportDocumento9 páginasChemistry Lab Reportapi-327824087Ainda não há avaliações

- MECH0018.1 Assignment 2 QP Fall 2021Documento17 páginasMECH0018.1 Assignment 2 QP Fall 2021saleem razaAinda não há avaliações

- Aviation MagazinesDocumento46 páginasAviation Magazinesyogaga100% (1)

- ITAD BIR RULING NO. 026-18, March 5, 2018Documento10 páginasITAD BIR RULING NO. 026-18, March 5, 2018Kriszan ManiponAinda não há avaliações

- Bold Face Actions - G 450Documento4 páginasBold Face Actions - G 450sohaib arifAinda não há avaliações

- CN 235 Aircraft DefinitionDocumento22 páginasCN 235 Aircraft DefinitionMoch Dedy100% (4)

- DP16B Bench Drill PressDocumento20 páginasDP16B Bench Drill Pressalfri7370% (1)

- Action Research MAPEHDocumento9 páginasAction Research MAPEHEloPoPo100% (4)

- Smart City Scheme GuidelinesDocumento48 páginasSmart City Scheme GuidelinesKarishma Juttun100% (1)

- CatalogDocumento52 páginasCatalogtalabiraAinda não há avaliações

- Part PabrikDocumento2 páginasPart PabrikNaldy NaldyAinda não há avaliações

- 10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtDocumento145 páginas10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtVuong DiepAinda não há avaliações

- MOE XT2-XT4 110... 125V Ac/dcDocumento3 páginasMOE XT2-XT4 110... 125V Ac/dcLê Xuân ĐịnhAinda não há avaliações

- Higher Unit 11 Topic Test: NameDocumento17 páginasHigher Unit 11 Topic Test: NamesadiyaAinda não há avaliações

- Marcelo - GarciaDocumento6 páginasMarcelo - GarciaNancy FernandezAinda não há avaliações

- HorticultureDocumento12 páginasHorticultureवरुण राठीAinda não há avaliações

- Gem WK6/WK8 Service ManualDocumento18 páginasGem WK6/WK8 Service Manualalex_seidiu100% (5)

- Manual de Despiece Honda Beat 100Documento84 páginasManual de Despiece Honda Beat 100jorgeeu8833% (3)

- Ref Manual - Additives For MA Spinel PDFDocumento5 páginasRef Manual - Additives For MA Spinel PDFRITWIK SARKARAinda não há avaliações

- Group6 3b QDDocumento27 páginasGroup6 3b QDCalvinderwin MatanguihanAinda não há avaliações

- EPTT5100 - Pressure - Temperature Sensor - 1308 - GDocumento2 páginasEPTT5100 - Pressure - Temperature Sensor - 1308 - GHendry Putra RahadiAinda não há avaliações

- Journal of Environmental Management: Ajay Singh TDocumento7 páginasJournal of Environmental Management: Ajay Singh TNestor Garay CahuanaAinda não há avaliações

- Whirlpool Adg 789Documento22 páginasWhirlpool Adg 789Laurentiu GramaAinda não há avaliações

- Kids and Their Favourite Food Key Reading Comprehension Exercises - 34436Documento2 páginasKids and Their Favourite Food Key Reading Comprehension Exercises - 34436MonicaMartirosyanAinda não há avaliações

- Web Based Bus Tracking SystemDocumento4 páginasWeb Based Bus Tracking SystemKrishna EelaAinda não há avaliações

- Yu-Gi-Oh GX Duel Academy - Written ExamDocumento26 páginasYu-Gi-Oh GX Duel Academy - Written ExamisishamalielAinda não há avaliações

- C P P P: Rain'S Etrophysical Ocket ALDocumento54 páginasC P P P: Rain'S Etrophysical Ocket ALviya7100% (4)

- Art Lab For Little Kids - Susan Schwake PDFDocumento146 páginasArt Lab For Little Kids - Susan Schwake PDFEmma Alfonzo67% (3)

- Kingspan 30 GSNDocumento1 páginaKingspan 30 GSNNoella AguiarAinda não há avaliações

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseNo EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseNota: 5 de 5 estrelas5/5 (3)

- Civil Engineer's Handbook of Professional PracticeNo EverandCivil Engineer's Handbook of Professional PracticeNota: 4.5 de 5 estrelas4.5/5 (2)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesAinda não há avaliações

- A Place of My Own: The Architecture of DaydreamsNo EverandA Place of My Own: The Architecture of DaydreamsNota: 4 de 5 estrelas4/5 (242)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedNo EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedNota: 5 de 5 estrelas5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionNo EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionNota: 4.5 de 5 estrelas4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1No EverandBuilding Construction Technology: A Useful Guide - Part 1Nota: 4 de 5 estrelas4/5 (3)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyNo EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyNota: 4 de 5 estrelas4/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialAinda não há avaliações

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNo EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNota: 3.5 de 5 estrelas3.5/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsNo EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsNota: 1 de 5 estrelas1/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideNo Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideNota: 3.5 de 5 estrelas3.5/5 (7)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishNo EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishNota: 4 de 5 estrelas4/5 (3)

- Estimating Construction Profitably: Developing a System for Residential EstimatingNo EverandEstimating Construction Profitably: Developing a System for Residential EstimatingAinda não há avaliações

- Advanced Production Decline Analysis and ApplicationNo EverandAdvanced Production Decline Analysis and ApplicationNota: 3.5 de 5 estrelas3.5/5 (4)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AAinda não há avaliações

- Real Life: Construction Management Guide from A-ZNo EverandReal Life: Construction Management Guide from A-ZNota: 4.5 de 5 estrelas4.5/5 (4)

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyNo EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyNota: 4 de 5 estrelas4/5 (1)

- Power Electronics Diploma Interview Q&A: Career GuideNo EverandPower Electronics Diploma Interview Q&A: Career GuideAinda não há avaliações