Escolar Documentos

Profissional Documentos

Cultura Documentos

Synthesis and Utility of Starch Based Polymers - A Short Review

Enviado por

IOSRjournalTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Synthesis and Utility of Starch Based Polymers - A Short Review

Enviado por

IOSRjournalDireitos autorais:

Formatos disponíveis

IOSR Journal of Applied Chemistry (IOSR-JAC)

e-ISSN: 2278-5736.Volume 8, Issue 12 Ver. II (Dec. 2015), PP 27-30

www.iosrjournals.org

Synthesis and Utility of Starch Based Polymers- A Short Review

Ritwick Sinha

La Martiniere for Boys, Kolkata, West Bengal, India.

Abstract: The present study is a modest attempt to develop a method of synthesis and examine the utility of

starch based polymers in agro-medicinal fields. The enviromental impact of the pestilent synthetic plastic is

profound; production may be cheap, however, disposal is difficult. Incineration of these non-biodegradable

polymers leads to generation of toxic, hazardous fumes detrimental to human health and welfare. In addition to

the dangers, petroleum resources are limited; so, generation of such non-biodegradable, synthetic polymers on

an industrial scale cannot be sustained for a fesible, economically productive time period.

I.

Introduction

The polymers that can be broken down rapidly by enzyme based catalyst reactions are called

biodegradabl polymers. The enzymes are produced by microorganisms. When the polymer is buried as waste,

microorganisms present in the soil can degrade the polymer. One method of making a polymer biodegradable

involves inserting a hydrolysable ester group into the polymer.

The ester link being a weak link is suceptable to enzyme catalysed hydrolysis.

Among the most common biodegradable polymers are polyglycolic acid (PGA), polylactic acid (PLA)

and polyhydroxy butyrate (PHB).

The biodegradable polymers are primarily used in agriculture and medicine. Intensive research in these

fields has resulted in the development of specialized commercial products.

This concept of Green chemistry was introduced in 1990. It refers to the production of articles of daily

use using chemicles in an enviromnentally friendly and cost effective manner.

II.

Classification:

Natural polymers

The are called natural polymers because they are formed during the growth cycles of organisms within

their cells due to a plethora of metabolic processes.

Common polymers produced by bacteria and fungi include hyduromic acid and pullulan.

Starch is a polymer of hexacarbon monosaccharideD-glucose. It is extremely abundant in corn seeds,

potato tubers, and the roots and stems of other plants. The D-glucose structure can exist both in open chain and

in ring forms; the ring configuration is ascribed to D-glucopyranose. The pyranose ring is a more

thermodynamically stable structure and it constitutes the sugar structure in the solutions.

Starch

Starch is mainly composed of D-glucopyranosis polymers bound by 1,4- and 1,6-glycoside links. These

links are formed between the first carbon atom (C1) of one molecule and the fourth (C4) or sixth (C6) of the

second one. As the aldehyde group on one end of a starch polymer is always free, these starch polymers always

possess at least one reducing tip. The other end of the polymer is an irreducible tip.

Studies on starchs chemical properties and structure have established that it is composed of two components,

DOI: 10.9790/5736-081222730

www.iosrjournals.org

27 |Page

Synthesis And Utility Of Starch Based Polymers- A Short Review

both also polysaccharides: amylose (2035%) and amylopectin. The ratio of these components varies, subject to

the source of origin. Amylose is a linear polymer, whereas the amylopectin molecule is substantially bigger and

branched. These structural differences cause marked differences in starchs characteristics and functions.

Amylopectin, dominant in most starch kinds, is a branched polymer of substantially larger size than

amylose. Amylopectin consists of 1,4-bonded glucose segments, linked by 1,6 bonds at the branching sites.

Estimates are that around 46% of bonds in a standard amylopectin molecule appear to be 1,6 links, which

results in over 20,000 branchings in a molecule, although the branchings are not large. Studies suggest a

bimodal size distribution of polymer chains: namely small and large chains. Small chains have an average

degree of polymerization (DP) of about 15, whereas the bigger chains have DPs of around 45. This unique

configuration contributes to the crystalline nature of amylopectin and to ordered arrangements of amylopectin

molecules within the starch granule. The branched chains of amylopectin behave just like those of amylose, but

in the case of amylopectin whole chainsor more often their fragmentscan be twisted spirally

Amylosefrom different botanic sources shows varying degrees of polymerization (DPs), about 1500

6000, whereas the considerably bigger amylopectin molecules exhibit DPs from around 3000003000000. From

these figures and from the molecular weight (MW) of anhydrous glucose (162), the MW of amylose can range

from 243 000 up to 972 000. Reports say, however, that amylose from potato starch is of 1000000 MW, but its

mean molecular weight is usually under 500 000. The MW of amylopectin varies between 10000000 and

500000000.

III.

Methodology

The experiment was performed with the primary objective being the creation of a biodegradable plastic

film in a cost effective manner.

The ram materials used in this study include Glycerol ( Propan-1,2,3-triol) and potato starch extracted

by the dehydration of potato pulp.

For the creation of an experimental ammount of the film, the following procedure was carried out:

Water and potato starch were combined in a 5:1 ratio. To this, about 2ml of concentrated hydrochloric acid and

3ml of glycerol were added.

The mixture was heated until a gel-like consistency was achieved.

The solution was then neutralized using sodium hydroxide solution.

The gel was then dried in a heating cabinet at 90 degrees Celsius.

Thus, the plastic film was created.

IV.

Applications:

Medical Applications

The developed biodegradable synthetics serve as surgical implants in the blood vessels, in orthopedic

surgery as implantable matrices for controlled long-term drug release in an organism, and as absorbable surgical

sutures, as well as for eye treatment. Recently the term biomaterial has been defined as a non-living material

used in medical device applications for interaction with a biological system. It is important that the term

DOI: 10.9790/5736-081222730

www.iosrjournals.org

28 |Page

Synthesis And Utility Of Starch Based Polymers- A Short Review

biocompatibility was also formulated; it determines how a tissue responds to foreign material.

Biocompatibility is the ability of a material to coexist with some hosts reactions in a specific use.

Surgical Sutures

Tissue damage causes loss of structural integrity: a deep cut in soft tissue or a bone fracture, for

example, may or may not be capable of spontaneous healing. Insertion of material or an instrument to hold the

wound edges together may facilitate the therapy. The classic example is application of sutures to hold both deep

and surface wounds together. When the healing is complete, the sutures are redundant and may disturb healthy

tissues. It is then helpful for the material to be removable from the site either physically or by degradation.

Synthetic, absorbable sutures were developed in the 1960s, and thanks to their good compatibility in

tissues are widely used in general and tracheobronchial surgery. The sutures used most often are multifilament,

with good handling characteristics. The most popular and commercially available are the sutures made from

PGA, PLA and their copolymers. For laying continuous sutures, however, braided sutures with non-smooth

surfaces are not useful. In such cases only mono- filament sutures with smooth surfaces are useful, because PGA

or PLA proved to be too stiff and inflexible. The more flexible polydioxanones and polyglyconates can be used

as sutures thanks to their low bending moduli. In addition, polymers of polycaprolactone are also bioabsorbable,

elastic materials, so their clinical use is under study.

Bone-Fixation Devices

Although metal fixation is an efficient method for undisturbed bone treatment, bone and metal have

completely different mechanical properties. The elasticity constant of bone is only a tenth that of implanted

steel, whereas its tensile strength is 10 times lower. Because of this, removal of metal implants can bring about

bone weakness and fracture can recur.

In contrast, biodegradable implants can adapt to the dynamic processes of bone healing through

decreasing amounts of weight-bearing material. Over a few months the introduced material disappears and there

is no need to operate on a patient to remove it. In this field, PGA, PLA, PHD, and polydioxanone can potentially

be used. Polydioxanones have been recommended for clinical use to protect ligament augmentation, for securing

ligament sutures, and as a sort of internal splinting suture to allow early motion after an operation.

Agricultural Applications

Since the introduction in the 1930s and 1940s of plastic films for greenhouse covering, chemical plant

protection, and mulching in fields, polymer use in agriculture has developed at a great rate. All the main classes

of polymersthat is, plastics, coating, elastomers, fibers, and water-soluble polymersare nowadays used for

controlled release of pesticides and nutrients, soil fertilization, seed coatings, and plant protection. Degradable

plastics are also of serious interest as materials for crop mulching in fields or as agricultural plant containers.

Their biodegradation mode (i.e., composting) is of great significance because it allows various biodegradable

materials to be combined and processed into useful materials to improve the state of the soil.

Controlled Release of Agricultural Chemicals

Controlled release (CR) is a method by which active chemicals are provided to specific plant species at

preset rates and times. Polymers are mainly used to control the delivery rates, mobilities, and periods of

effectiveness of the chemicals. The main benefit of the CR method is that if fewer chemicals are used for the

protected plants over the predetermined period, then the effect on the other plant species is less, while leaching,

volatilization, and degradation are reduced. The macromolecular character of polymers is the key to reduction of

chemical loss throughout the production.

CR polymer systems can be divided into two categories. In the first, the active agent is dissolved,

dispersed, or encapsulated within the polymeric matrix or coating. Its release takes place through diffusion or

after biological or chemical breakdown of the polymer. In the second category, the active agent either itself

constitutes a part of the macromolecular backbone or is attached to it. Here its release is the result of biological

or chemical cleavage of the bond between the polymer and bioactive agent.

Physical systems into which agricultural chemicals have been introduced include microcapsules,

physical blends, and dispersions in plastics, laminates, hollow fibers, and membranes. Kinetic models for

chemical release have been developed for each of the above systems.

Of the natural polymers, starch, cellulose, chitin, alginic acid, and lignin are used in CR systems. Their

advantages are availability, relatively low cost, and biodegradability. Although these materials have

functionality for derivatization, they have one significant drawback: that is, their insolubility in standard

solvents for formulation, encapsulation, and dispersion. This drawback is overcome when a chemical is

encapsulated in situ, with, for instance, gelatinized starch cross- linked with a chosen pesticide by calcium

chloride or boric acid. As a consequence, the pesticide is trapped within the granular particles formed.

DOI: 10.9790/5736-081222730

www.iosrjournals.org

29 |Page

Synthesis And Utility Of Starch Based Polymers- A Short Review

One of the most important applications of CR technology in agriculture is fertilization. Urea, a main

nitrogen source, readily reacts with formaldehyde to form a polymer. The subsequent hydrolysis of polymer

releases urea, so it is a simple and inexpensive CR system.

A small niche for degradable plastics is the use of polycaprolactone for small agricultural planting

containers. It is not a broad field for use of biodegradable synthetics, but it is one of the few applications in

which the polymer used undergoes biodegradation within a reasonable period. Polycaprolactone planting

containers have been used in automated machine planting for tree seedlings. It was found that the

polycaprolactone had undergone substantial degradation after being in soil for six months, having lost 48% of its

original weight, with 95% weight loss within a year.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

Duncan, R. and Kopecek, J. (1984) Soluble synthetic polymers as potential drug carriers. Journal of Advanced Polymer Science, 57.

Andreopoulos, A.G. (1994) Plasticization of biodegradable polymers for use in controlled release. Clinical Materials, 15.

Dubois, P. (1978) Plastics in Agriculture, Applied Science Publishers, London, 24 et al.

Buttrey, D. (1972) Modern Plastics International, 2.

Frazza, E.J. and Schmitt, E.E. (1971) A new absorbable suture. Journal of Biomedical Materials Research, 15.

Tokiwa, Y. and Suzuki, T. (1977) Hydrolysis of polyesters by lipases. Nature, 270.

Fukumura, T. (1966) Two bacterial enzymes hydrolyzing oligomers of 6-aminocaproic acid. The Journal of Biochemistry, 59, 537.

DOI: 10.9790/5736-081222730

www.iosrjournals.org

30 |Page

Você também pode gostar

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocumento7 páginasSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocumento5 páginas"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocumento5 páginasAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocumento7 páginasComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocumento5 páginasRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocumento6 páginasThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Documento15 páginasA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)Ainda não há avaliações

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocumento4 páginasInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocumento7 páginasA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- The Impact of Technologies On Society: A ReviewDocumento5 páginasThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- Assessment of The Implementation of Federal Character in Nigeria.Documento5 páginasAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)Ainda não há avaliações

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocumento14 páginasAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocumento6 páginasRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocumento7 páginasTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocumento5 páginasEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocumento5 páginasDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalAinda não há avaliações

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocumento6 páginasImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- The Lute Against Doping in SportDocumento5 páginasThe Lute Against Doping in SportInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- An Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsDocumento6 páginasAn Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Beowulf: A Folktale and History of Anglo-Saxon Life and CivilizationDocumento3 páginasBeowulf: A Folktale and History of Anglo-Saxon Life and CivilizationInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Classical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahDocumento9 páginasClassical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Human Rights and Dalits: Different Strands in The DiscourseDocumento5 páginasHuman Rights and Dalits: Different Strands in The DiscourseInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Transforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweDocumento9 páginasTransforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Motivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweDocumento8 páginasMotivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Women Empowerment Through Open and Distance Learning in ZimbabweDocumento8 páginasWomen Empowerment Through Open and Distance Learning in ZimbabweInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Micro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaDocumento3 páginasMicro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Substance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaDocumento11 páginasSubstance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- A Study On The Television Programmes Popularity Among Chennai Urban WomenDocumento7 páginasA Study On The Television Programmes Popularity Among Chennai Urban WomenInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Kinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationDocumento6 páginasKinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- Design Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextDocumento6 páginasDesign Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- IMCI Chart BookletDocumento66 páginasIMCI Chart Bookletnorwin_033875Ainda não há avaliações

- Ucmc DepartmentsDocumento39 páginasUcmc DepartmentsAllen ZhuAinda não há avaliações

- Swami Paramarthananda's Talks on Self-KnowledgeDocumento332 páginasSwami Paramarthananda's Talks on Self-Knowledgemuralipmd100% (1)

- Pes WesDocumento12 páginasPes WesjotapintorAinda não há avaliações

- Errata: Shadow of The Demon LordDocumento3 páginasErrata: Shadow of The Demon LordKaio CorsatoAinda não há avaliações

- Modern Wound Care Practical Aspects of Non Interventional Topical Treatment of Patients With Chronic WoundsDocumento14 páginasModern Wound Care Practical Aspects of Non Interventional Topical Treatment of Patients With Chronic WoundsDauz ArashAinda não há avaliações

- IsolationDocumento5 páginasIsolationapi-392611220Ainda não há avaliações

- Medicine, Coptic.: Chronological Table of Ostraca and Papyri Dealing With MedicineDocumento7 páginasMedicine, Coptic.: Chronological Table of Ostraca and Papyri Dealing With MedicinePaula VeigaAinda não há avaliações

- The Herbal Market of Thessaloniki N GreeDocumento19 páginasThe Herbal Market of Thessaloniki N GreeDanaAinda não há avaliações

- Nadi Literally MeansDocumento9 páginasNadi Literally MeansThomas DürstAinda não há avaliações

- Research Background: (Budget 2016: Chapter 5 - An Inclusive and Fair Canada, 2021)Documento4 páginasResearch Background: (Budget 2016: Chapter 5 - An Inclusive and Fair Canada, 2021)Talha NaseemAinda não há avaliações

- 2 Months To LiveDocumento26 páginas2 Months To LivedtsimonaAinda não há avaliações

- Barack Huessein Obama Is The Most Dangerous Man To Ever LiveDocumento3 páginasBarack Huessein Obama Is The Most Dangerous Man To Ever LivetravisdannAinda não há avaliações

- Thyroidectomy Nursing CareDocumento73 páginasThyroidectomy Nursing CareZNEROL100% (1)

- Red Cross Blood Donation CaseDocumento12 páginasRed Cross Blood Donation CaseYajuvender SinghAinda não há avaliações

- Aspirin: The widely used pain reliever and fever reducerDocumento4 páginasAspirin: The widely used pain reliever and fever reducerEithel EithelAinda não há avaliações

- Risk Management in Medical LaboratoriesDocumento32 páginasRisk Management in Medical Laboratoriesapanisile14142Ainda não há avaliações

- 9 Hair CleanseDocumento11 páginas9 Hair CleanseSeetha ChimakurthiAinda não há avaliações

- Ubd Stage 1-3Documento24 páginasUbd Stage 1-3api-336167164Ainda não há avaliações

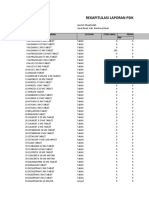

- Rekapitulasi Laporan Psikotropika Bandung BaratDocumento8 páginasRekapitulasi Laporan Psikotropika Bandung BaratFajarRachmadiAinda não há avaliações

- AntiemeticDocumento36 páginasAntiemeticravannofanizza100% (1)

- Guidance For Installation and Testing AcceptanceDocumento32 páginasGuidance For Installation and Testing AcceptanceMun WaiAinda não há avaliações

- ECTDocumento22 páginasECTRubz Bulquerin0% (1)

- Mu 089Documento4 páginasMu 089Rahul RaiAinda não há avaliações

- 86 MRCP Part 2 Sample QuestionsDocumento86 páginas86 MRCP Part 2 Sample QuestionsJa Gh50% (2)

- Dr. Jinitha K.S. - Assorted Essays On Classical and Technical LiteratureDocumento137 páginasDr. Jinitha K.S. - Assorted Essays On Classical and Technical LiteratureSasi KadukkappillyAinda não há avaliações

- The SCARE Statement Consensus-Based Surgical Case ReportDocumento7 páginasThe SCARE Statement Consensus-Based Surgical Case ReportIhsan KAinda não há avaliações

- Safety Precautions When Driving: Seatbelt and SRS AirbagDocumento7 páginasSafety Precautions When Driving: Seatbelt and SRS AirbagPeter InfanteAinda não há avaliações

- Genetic Polymorphism of Cyp2d6Documento23 páginasGenetic Polymorphism of Cyp2d6Oscar Velasco0% (1)

- Botany Vol-2 - EMDocumento232 páginasBotany Vol-2 - EMVandanaAinda não há avaliações