Escolar Documentos

Profissional Documentos

Cultura Documentos

845 1520 1 PB PDF

Enviado por

Erin WalkerDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

845 1520 1 PB PDF

Enviado por

Erin WalkerDireitos autorais:

Formatos disponíveis

ENERGY

Mathias Effenberger, Rainer Kissel, Andreas Lehner and Andreas Gronauer, Freising

Technical Assessment

of Agricultural Biogas plants

Utilization Ratio and Energy Efficiency

Technical indicators of six selected modern agricultural biogas plants were determined to evaluate utilization ratio and

energy efficiency. In all of these plants, renewable raw materials were treated in combination with animal manure.At a specific

installed electrical capacity between 0.09

and 0.25 kWm-3 usable digester volume,

electrical utilization ratios of 88 to 98 %

were achieved. The combination of these

two characteristic values may be used as a

first indicator of process stability and

functionality of a BGP. The external utilization ratio for the off-heat from the

combined-heat-and-power unit was between 0 and 46 %.

n the last few years, the market for biogas

plants (BGP) in the German agricultural

sector has seen a dynamic development. This

was driven by the amendment of the Renewable Energy Sources Act (EEG) as of 2004

that brought about a significant increase in

compensation for electricity produced from

renewable raw materials (RRM). Consequently, in the years 2005 and 2006, 1,450

new biogas plants for biogas production

from mainly RRM were erected. In comparison to 2004, this was an increase in the number of BGP of 71 %. In 2007, due to massive rises in prices for grain and maize, the

boom came to a sudden end. The second

amendment of the EEG this year is supposed

to revive the development of the biogas sector and to promote the use of animal manure.

In the past, the focus used to be on the

amount of electricity produced from biogas

and fed into the grid. However, in order to

achieve an economical and environmentally

sustainable operation of a BGP, the overall

utilization ratio of the biogas fuel value has

to be maximized. In this paper, technical indicators of modern BGP in agriculture are

presented and the efficiency of biogas production and utilization is analyzed. The data

are based on extensive monitoring of fullscale BGP in Bavaria.

Description of Biogas Plants

and Methodology

Dr.-Ing. Mathias Effenberger, Dipl.-Ing. (FH) Rainer

Kissel and Dipl.-Ing. agr. Andreas Lehner are

scientists in the working-group Biogastechnologie

und Reststoffmanagement (Head: Dr. agr. Andreas

Gronauer) at the Institut of Agricultural Engineering

and Animal Husbandry of the Bavarian Research

Station of Agriculture, Vttinger Str. 36, 85354

Freising; e-mail: mathias.effenberger@LfL.bayern.de.

The studies were sponsored by the Bayerische

Staatsministerium fr Landwirtschaft und Forsten as

well as by the Fachagentur Nachwachsende

Rohstoffe e.V..

Keywords

Biogas, efficiency, technology, renewable primary

products, animal manure

290

In this paper, selected data from six BGP

commissioned between the years 2002 and

2006 are presented. In all of these plants,

RRM / energy crops are digested in mixture

with animal manure (Table 1).

All six BGP are operated in the mesophilic temperature range. The biogas is utilized

in combined-heat-and-power units (CHPU),

using reciprocating piston engines. Plants A,

D and F have upright vertical digesters as

first stage; plants B, C and E feature horizontal cuboid primary digesters. If applicable, the secondary stage is designed as an

upright vertical digester. The specific installed electrical capacity of the plants ranges

between 0.09 and 0.25 kW per m3 of usable

digester volume.

In order to properly evaluate and compare

the performance of BGP that differ in size

and design, a consistent data model and the

definition of appropriate indicators are required [1]. Table 2 provides an overview of

some of the measuring data needed for determining relevant indicator values. Depending on the individual plant, the analysis presented here is based on an observation period of between 215 and 455 days. All the

reported indicators were calculated as average values over the whole observation period.

The measured biogas and methane yields

were compared to prognoses, based on

guideline values according to KTBL ([2];

Table 3). The net utilization ratio biogas refers to the proportion of the total fuel value

of the biogas that is supplied to external

users in the form of electrical or thermal

energy.

Table 1: Characteristics of the investigated biogas plants

Anlagen ID

A

B

C

D

E

F

Jahr der Inbetriebnahme

2005

2005

2002

2004

2006

2004

Anzahl Prozessstufen

2

2

2

2

1

2

3600

2800

3200

3800

2100

2100

Gesamt-Nutzvolumen*

m3

Gesamt-Lagervolumen

m3

1200

2400

4800

1500

3000

2300

Mittlere Prozesstemperatur

Fermenter

C

43

42

41

42

42

43

BHKW Motortyp

G

G

G

ZS

G

ZS

Elektrische Nennleistung

kW

329

347

526

580

526

250

0,09

0,12

0,16

0,15

0,25

0,12

Spez. elektr. Nennleistung

kWm-3

Thermische Nennleistung

kW

447

432

633

600

567

230

*) Summe der Nutzvolumina aller Prozessstufen (ohne Grrestlager); ZS: Zndstrahl-Motor; G: Gas-OttoMotor

63 LANDTECHNIK 5/2008

Table 2: Description of measuring parameters

Messgre

Masse der Einsatzstoffe

Volumen der Einsatzstoffe

Einheit

t

m3

Messintervall

Tag

Tag

Messvorrichtung

Wgezellen; dynamisches Wgesystem

magnetisch-induktiver Durchflussmesser;

Pumpenlaufzeit

Trockenrckstand der

Einsatzstoffe

%

Glhrckstand der Einsatzstoffe

%

Biogas-Volumenstrom

m3h-1

Biogastemperatur

C

Biogasdruck

hPa

Biogas-Massestrom

kgh-1

Biogas-Methangehalt

Vol.-%

Biogas-Kohlendioxidgehalt

Vol.-%

Biogas-Sauerstoffgehalt

Vol.-%

Brutto-Strom BHKW

kWh

Brutto-Wrme BHKW

kWh

Strombedarf BGA

kWh

Monat

Monat

kontinuierlich

kontinuierlich

kontinuierlich

kontinuierlich

1-2 Stunden

1-2 Stunden

1-2 Stunden

kontinuierlich

kontinuierlich

kontinuierlich

Wrmeabsatz

kontinuierlich

Waage, Trockenschrank

Waage, Muffelofen

strmungsmechanischer Durchflussmesser

PT100

Druckmessumformer

thermischer Massestrommesser

IR-Sensor

IR-Sensor

elektrochemischer Sensor

Stromzhler Generatorklemmen

Wrmemengenzhler

Stromzhler Gesamtanlage oder Stromaufnahme Einzelaggregate

Wrmemengenzhler

kWh

Results and Discussion

Maize silage is still the predominant input

material for biogas plants in the agricultural

sector. This is also true for the six BGP analyzed in this work. Other renewable raw materials are whole grain crop silage, grass

silage and bruised grain. For those three

plants that treat solid poultry manure, the

overall dry matter content in the input mixture is significantly higher than for the other

three plants using liquid manure. Those

plants feature a reclined primary digester

which works more reliably with the relatively dry and heterogeneous poultry manure.

Plant E with the highest overall organic loading rate is also the only single-stage plant

(Table 3).

Apart from Plant A, the measured biogas

and methane yields exceed the projected values. However, in the case of plant B (and

possibly E) the discrepancy is implausible.

This is likely due to an erroneous volumetric

flow measurement of biogas and a high variability in the composition of the poultry

manure. Overall, in comparison to our measurements, the guideline values for biogas

yield appear rather conservative.

If larger amounts of liquid manure are

used, the biogas yield remains significantly

below 200 Nm3 per ton of fresh matter. The

values of biogas and methane yields with respect to fresh matter for the different plants

are quite comparable. However, the measured yields from organic dry matter input appear too high, particularly for plants F and E.

For plant E the volumetric biogas flow was

likely overestimated, since at the same time,

the value of electrical efficiency seems too

low. Potential errors from biogas flow measurement may be eliminated by determining

the electricity yield with respect to the input

of fresh matter (Table 4).

63 LANDTECHNIK 5/2008

In this paper we use the term electrical efficiency factor for what corresponds approximately to electrical efficiency. However, it

is impracticable to measure electrical efficiency according to the respective DIN specifications over such long periods. As mentioned above, the rather low values of the

electrical efficiency factor suggest overestimation of the biogas flow rate. Regarding the

electrical utilization ratio, all six BGP reach

satisfying to excellent values between 90 and

over 95 %. This is a good basis for the profitable operation of a biogas plant (Table 4).

Regarding the share of parasitic electricity demand, the largest difference is found

between plant E with 5.4 % and plant A with

9.1 %. Plant E features only one process

stage while in the case of plant A, the six propeller mixers installed at the four tanks exhibit a relatively high electricity demand.

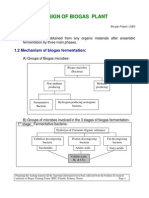

If electrical utilization ratio is plotted over

specific installed electrical capacity, it is

possible to draw some conclusions with respect to the stability and possible limitations

of the anaerobic digestion process. Figure 1

shows data from the monitoring of 25 BGP

including the six plants discussed in this paper. In the diagram, two lines were plotted

that may be termed efficiency border (horizontal) and capacity border (vertical).

The efficiency border crosses the ordinate

at a value of 86 % utilization ratio, corresponding to approximately 7,500 full load

hours per year. In fact, given a difficult business environment, the utilization ratio

should reach a value of at least 90 %. The

capacity border crosses the abscissa at a

value of 0.25 kWm-3. On the basis of our

data from 25 BGP, this value is the current

benchmark for the specific installed electrical capacity of biogas plants treating RRM

and animal manure. Plants in the bottom left

section of the diagram are likely to have a

problem with a limitation of the anaerobic

digestion process or other deficiencies (deficiency sector). Plants to the right of the

Table 3: Characteristic values of biogas production

Anlagen ID

Auswertungszeitraum

Einsatzstoffe

(Massenanteile)

A

B

C

215

385

455

R-Glle

H-Mist

H-Mist

(30 %)

(16 %)

(20 %)

MS (42 %) MS (49 %) MS (55 %)

GS (16 %)

Wasser

GPS

GPS (10 %)

(35 %)

(11 %)

sonstige

Schrot

(2 %)

(13 %)

sonstige

(1 %)

D

E

F

365

378

406

R-Glle/

P-Mist R-Glle

S-Glle

(5 %)

(26 %)

(47 %) MS (83%) MS (64%)

MS (44 %)

GPS

GS

GS (1 %)

(6 %)

(1 %)

GPS (3 %)

LKS

GPS

Schrot

(3 %)

(9 %)

(4 %)

Schrot

(2 %)

Gesamtmasse der

Einsatzstoffe

(ohne Wasser)

t

6.403

6.614

12.444

17.937

10.238

6.141

Durchschnittlicher TS-Gehalt der Einsatzstoffe

%

21

40

41

19

31

21

Ges.Raumbelast. kg oTS(m3d)-1

2,1

2,4

3,0

2,7

4,0

1,6

Projektion Biogasertrag*

Nm3

908.706

1.218.910 2.144.376

2.297.018 2.036.885

902.401

Gemessener Biogasertrag Nm3

865.933

1.751.726 2.446.904

2.457.369 2.416.193

964.163

Abweichung

%

-4,7

43,7

14,1

7,0

18,6

6,8

Projektion Methanertrag* Nm3

478.054

631.132 1.122.005

1.204.906 1.060.644

470.671

Gemessener Methanertrag Nm3

454.500

915.909 1.226.226

1.253.796 1.249.049

521.999

Abweichung

%

-4,9

45,1

9,3

4,1

17,8

10,9

Biogasausbeute

Nm3t-1

135

265

197

137

236

157

Nlkg oTS-1

624

664

464

716

780

753

71

138

99

69,9

122

85

Methanausbeute

Nm3t-1

Nlkg oTS-1

328

347

232

366

405

408

Methanproduktivitt Nm3(m3d)-1

0,70

0,85

0,69

0,90

1,57

0,60

448

443

339

280

441

317

Stromausbeute

kWht-1

*) basierend auf Richtwerten gem [2]; R-Glle: Rinderglle; S-Glle: Schweineglle; H-Mist: Hhnchenmist; P-Mist: Putenmist; MS: Maissilage; LKS: Lieschkolbensilage; GS: Grassilage; GPS: GetreideGanzpflanzensilage

291

ENERGY

capacity border and below the efficiency

border are under-dimensioned with respect

to the current state of the technology (development sector). The top right section of

the diagram represents the innovation sector. According to this simple categorization

scheme, all six plants discussed in this paper

are within the efficiency sector.

Data about the utilization of the off-heat at

the BGP are incomplete, since it was not

possible to install heat meters in all cases

(Table 4). However, external heat use was

measured for all plants so that external heat

utilization could be calculated. In those

cases where the average thermal energy output was not available, it was estimated from

the nominal output and the electrical utilization ratio of the engine. The ratio of external

heat utilization showed a wide range of 0 to

46 % with respect to the available off-heat.

For the 25 BGP that had been monitored, the

parasitic heat demand reached a maximum

of 30 % and was clearly below 25 % in

most cases. This means that on biogas plants

a considerable potential of thermal energy is

currently wasted. The monitoring indicated

that over the whole year, a high ratio of heat

utilization can only be achieved with a combination of community heating and drying of

agricultural goods. So far, the off-heat from

biogas plants is very seldom used to supply

process heat to small and medium-sized businesses although this would be an option

that is more or less independent of season.

The positive result of high electrical utilization ratios is overshadowed once the net

utilization ratio of the biogas fuel value is examined (Table 4). Here, only two out of six

plants reach a value of more than 50 %. Naturally, in the BGP without any external heat

use, two thirds of the biogas energy is wasted. The energy balance becomes worse if the

energy input for producing the RRM is also

considered.

Conclusions and Outlook

In this paper, results from a comprehensive

monitoring program at agricultural BGP

Fig. 1: Specific rated

electrical capacity and

electrical utilization ratio

of 25 agricultural biogas

plants in Bavaria

were presented. Data on methane yield, utilization ratio of the combined-heat-andpower unit and the net utilization ratio of the

biogas fuel value were discussed. In most

cases, the values of biogas and methane

yields that were measured at the BGP exceeded the respective guideline values.

However, besides the weighing of the input

materials the measurement of biogas volume

is considered the most frequent source of

systematic error during the monitoring of

BGP in practice.

All of the plants presented in this paper exhibited a satisfactory to excellent electrical

utilization ratio. This indicates a stable anaerobic digestion process and a sound operational management. Up to a level of approximately 0.25 kWm-3 the electrical utilization ratio was independent of overall reactor

volume but somehow dependent on reactor

design. The combination of utilization ratio

and specific installed electrical capacity can

therefore be used as a first indicator of process stability and functionality of a biogas

plant. Currently, BGP with a significantly

smaller specific reactor volume are not stateof-the-art for the anaerobic treatment of agricultural raw materials and residues. More

technical development is needed to improve

the specific power output of agricultural

BGP. At the same time, there is still a high

demand for improving the process stability

in BGP with conventional dimensioning.

The results for the net utilization ratio of

biogas fuel value indicate a considerable potential for improvement. Achieving a net utilization of more than 50 % the whole year

round requires a well thought-out concept

for the utilization of the off-heat.

Finally, the methods of evaluating the performance of biogas plants that were presented here do not cover all relevant aspects.

There are other technical as well as economical and ecological criteria that have to be

taken into consideration.

Literature

Books are marked by

[1] Strobl, M., und U. Keymer : Technische und

konomische Kennzahlen landwirtschaftlicher

Biogasanlagen. Landtechnik 61 (2006), H. 5,

S. 266-267

[2] KTBL : Gasausbeuten in landwirtschaftlichen

Biogasanlagen. KTBL , Darmstadt, 2005

Table 4: Characteristic values of biogas utilization

Anlagen ID

Auswertungszeitraum

d

Elektrischer Nutzungsgrad

%

Mittl. elektr. Leistungsabgabe

kW

Spez. elektr. Leistungsabgabe

kWm3

Elektrischer Ausnutzungsgrad

%

Anteil Stromeigenverbrauch

%

Mittl. therm. Leistungsabgabe

kW

Externe verwertete therm. Leistung kW

Wrmeeigenbedarf Fermenterheizung %

Anteil externer Wrmenutzung

%

Abwrmeanteil

%

Netto-Nutzungsgrad Biogasenergie

%

n.v.: nicht verfgbar

292

A

215

37,3

327

0,09

97,7

9,1

415

0

12,3

0

87,7

33,9

B

385

33,8

335

0,12

96,4

7,0

416

143

n.v.

34,4

n.v.

46,0

C

455

43,7

481

0,15

91,5

7,2

518

222

10,7

42,9

41,2

60,8

D

365

37,5

573

0,13

89,9

7,5

n.v.

285

n.v.

45,6

n.v.

57,6

E

378

35,2

515

0,23

92,2

5,4

n.v.

186

n.v.

32,8

n.v.

48,8

F

0

39,2

222

0,11

88,4

6,7

n.v.

47

n.v.

20,2

n.v.

49,8

63 LANDTECHNIK 5/2008

Você também pode gostar

- English For Ethiopia: Student Textbook Grade 1 Book 2Documento111 páginasEnglish For Ethiopia: Student Textbook Grade 1 Book 2Erin Walker97% (29)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- English For Ethiopia: Student Textbook Grade 2 Book 1Documento230 páginasEnglish For Ethiopia: Student Textbook Grade 2 Book 1Erin WalkerAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Course Materials: TextDocumento32 páginasCourse Materials: TextErin WalkerAinda não há avaliações

- Workbook On The Epistle To The: HebrewsDocumento36 páginasWorkbook On The Epistle To The: HebrewsErin WalkerAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- (Ray C. Stedman, Haddon W. Robinson, Grant R. Osbo (B-Ok - Xyz) PDFDocumento94 páginas(Ray C. Stedman, Haddon W. Robinson, Grant R. Osbo (B-Ok - Xyz) PDFErin WalkerAinda não há avaliações

- MATH408: Probability & Statistics Summer 1999 Week 1Documento54 páginasMATH408: Probability & Statistics Summer 1999 Week 1Erin WalkerAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Review On Factors Which Affect Coffee (Coffea Arabica L.) Quality in South Western, EthiopiaDocumento8 páginasReview On Factors Which Affect Coffee (Coffea Arabica L.) Quality in South Western, EthiopiaErin WalkerAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hand Pump Spare Part ShopsDocumento1 páginaHand Pump Spare Part ShopsErin WalkerAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Arriaga 10a PDFDocumento7 páginasArriaga 10a PDFErin WalkerAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Ergonomic DesignDocumento132 páginasErgonomic DesignErin WalkerAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Maheshwari 1996-InfiltrometerDocumento7 páginasMaheshwari 1996-InfiltrometerErin WalkerAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Usda-Ars Western Regional Research Center Healthy Processed Foods Research UnitDocumento1 páginaUsda-Ars Western Regional Research Center Healthy Processed Foods Research UnitErin WalkerAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- SET Manual English 08 PDFDocumento77 páginasSET Manual English 08 PDFErin Walker0% (1)

- Publications - Design Biogas PlantDocumento12 páginasPublications - Design Biogas Planttssa100% (15)

- QA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #Documento3 páginasQA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #deva017Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Training Form PDFDocumento2 páginasTraining Form PDFZurika WarniAinda não há avaliações

- Dehp 780 MPDocumento104 páginasDehp 780 MPVitorAinda não há avaliações

- Color Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Documento14 páginasColor Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Adam Michael GreenAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Healthy PC. Preventive Care and Home Remedies For Your Computer - Carey Holzman PDFDocumento257 páginasThe Healthy PC. Preventive Care and Home Remedies For Your Computer - Carey Holzman PDFLeonardoMartinAinda não há avaliações

- E3D2 1version-1Documento12 páginasE3D2 1version-1Nikolay NachevAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Lighting Layout Power Layout: Single Line Diagram LegendDocumento1 páginaLighting Layout Power Layout: Single Line Diagram LegendAnieken AyoAinda não há avaliações

- MclogitDocumento19 páginasMclogitkyotopinheiroAinda não há avaliações

- Email Id of Controllers PDFDocumento10 páginasEmail Id of Controllers PDFAbhishek KumarAinda não há avaliações

- Commercial Vehicles BrochureDocumento20 páginasCommercial Vehicles Brochurebinhtb14Ainda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- ORF Issue Brief 309 SpaceLawDocumento12 páginasORF Issue Brief 309 SpaceLawNitish KumarAinda não há avaliações

- Technology and Culture - ReadingDocumento3 páginasTechnology and Culture - ReadingBraulio Pezantes100% (1)

- NessusDocumento23 páginasNessusShivaprakash TimmapurAinda não há avaliações

- Eminence Deltalite II 2515Documento1 páginaEminence Deltalite II 2515Suto BandAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Arun Et al-2019-ChemistrySelectDocumento8 páginasArun Et al-2019-ChemistrySelectRavi Kumar ARunAinda não há avaliações

- ECS Florida SOQ - 2018 - FT MyersDocumento11 páginasECS Florida SOQ - 2018 - FT MyersPaul BenvieAinda não há avaliações

- Brosur Hari GuruDocumento8 páginasBrosur Hari GuruFitri SharifAinda não há avaliações

- DBMS-LM Kavi With MinipjtDocumento56 páginasDBMS-LM Kavi With Minipjtkavi_mithuAinda não há avaliações

- Principles of Accounting, Volume 2: Managerial AccountingDocumento59 páginasPrinciples of Accounting, Volume 2: Managerial AccountingVo VeraAinda não há avaliações

- Chapter 5 - Decision Making and LoopingDocumento94 páginasChapter 5 - Decision Making and LoopingAcapSuiAinda não há avaliações

- Set 2 Unit 2 PDF FreeDocumento13 páginasSet 2 Unit 2 PDF FreeASHWATH G (RA2111018010045)Ainda não há avaliações

- HOF - To PrasannaDocumento3 páginasHOF - To PrasannahishamndtAinda não há avaliações

- Original Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwDocumento32 páginasOriginal Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwnikosvitalAinda não há avaliações

- BOQ For Interior WorkDocumento2 páginasBOQ For Interior WorkSudhanshu MandlikAinda não há avaliações

- DPP Series 1 PDFDocumento1 páginaDPP Series 1 PDFsukainaAinda não há avaliações

- TIA Workshop ITBDocumento48 páginasTIA Workshop ITBFirman Suhendra100% (1)

- Redesigning Boilers Solves Problems and Saves MoneyDocumento9 páginasRedesigning Boilers Solves Problems and Saves MoneyfelramAinda não há avaliações

- Conversion of A Scroll Compressor To An Expander For Organic Rankine Cycle: Modeling and AnalysisDocumento162 páginasConversion of A Scroll Compressor To An Expander For Organic Rankine Cycle: Modeling and Analysisdr_kh_ahmed100% (1)

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocumento1 página4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFRonald ValenciaAinda não há avaliações

- (H-EP) Expanded Perlite: Low Temperature and Cryogenic InsulationDocumento2 páginas(H-EP) Expanded Perlite: Low Temperature and Cryogenic InsulationKamesh KalgiAinda não há avaliações