Escolar Documentos

Profissional Documentos

Cultura Documentos

Wind Turbine Manual

Enviado por

Victor BiacoloDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Wind Turbine Manual

Enviado por

Victor BiacoloDireitos autorais:

Formatos disponíveis

Wuxi NaiEr Wind Power Technology Development Co.

, Ltd

600 WATTS WIND

TURBINE GENERATOR

INSTALLATION MANUAL

NO:2014040202

Date:2014-04-02

-1-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

Contents

1. Important Safety Instructions3

2. Technical Specifications 4

3. Wind Turbine Assembly5

3-1 Torque Specifications5

3-2 Assembly Procedure 5

4. Sitting6

5. Towers 7

6. Wiring Options 7

6-1 Hybrid System Wiring 9

6-2 Multiple Wiring 10

6-3 Wire Size11

6-4 Fuses, Circuit Breakers, Ammeter13

6-5 Batteries13

6-6 Wind Turbine Grounding13

6-7 Tower Grounding14

6-7-1 Electrodes Driven In Soil 14

7. Installation16

7-1 Wire Connection 16

7-2 Mounting On Tower16

7-3 Final Connections17

8. Operation 17

8-1 Operational Summary17

8-2 Operating Modes19

8-3 Using An Alternate Charge Controller19

9. Maintenance20

10. Trouble Shooting 20

11. Exploded Views & Parts List21

-2-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

1. Important Safety Instructions

Read these instructions before assembling, installing and

operating SF-series wind turbine.

1) Keep this manual. This manual contains important instructions that must be

followed during assembly, installation and maintenance.

2) Read, understand and respect all warnings.

3) Do not install our wind turbine on windy day.

4) If unusual noise or status is experienced, turn off machine and contact

authorized technician.

5) Properly torque all fasteners during assembly and installation.

6) Only use proper grounding techniques as established by the NEC (National

Electrical Codes).

7) Properly fill in and return warranty Registration Card.

8) Our wind turbine must be installed in accordance with this manual and local

related stipulation. Failure to comply with this manual and local related

stipulation may affect and void your warranty.

9) Rotating blades are a serious mechanical hazard. Ensure that nobody comes

into contact with blades while installing our wind turbine.

10) Comply with the stipulation about wiring, including wire size and fuse

recommendations.

-3-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

2. Technical Specifications

Model

SF-600-3

SF-600-5

Weight

8KG

9.3KG

Blades

Rotor diameter

1.22M

Start up wind speed

3.0M/S

2.5M/S

Kilowatt hours/month

30kph

42kph

Maximum wind speed

50M/S

Rated power

400W

Max Capacity

600W

Condition

-2080

*Power generation per mouth refers to 3.5m/s avg. wind speed throughout the

year

Wind Turbine Dimension

-4-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

3. Wind turbines Assembly

Your wind turbine is delivered partially assembled. Assembly requires mounting

the blades on the blade hub, securing the hub to the turbine body and

installing the nosecone on the blade hub. The necessary hex key (Allen)

wrenches are furnished with wind turbine.

3-1 Torque Specifications:

Blade to hub bolts,1/4-201.25 inch, Socket Head Bolt,7.0lb-ft(13.6Nm)

Hub to rotor nut,5/8-18inch,Jam nut,50-lb-ft(68Nm)

Yaw Clamp Bolts,M535mm,Socket Head Bolt,4.0lb-ft(5.4 Nm)

3-2 Assembly Procedure

3-2-1 Start the assembly by examining how the blades mount to the hub, refer

to Fig.1.

1. Coating the hub and blades with Tef-Gel place a nylock nut (Item 4) in the

detent on the back of the blade hub while positioning a blade on the hub.

2. Pass a bolt through the blade and screw it into the nylock nut do not fully

tighten the bolt yet.

3. Install the second bolt and nylock nut and torque both bolts to 7

ft-lbs(9.4Nm).

4. Install the remaining two blades following the same procedure.

Fig.1 Blade Attachment Detail

-5-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

3-2-2 Wind turbine is to be installed on a tilt-up tower

If wind turbine is to be installed on a tilt-up tower, here is the step

1. Mount the blade/hub assembly to the turbine now.

2. Start the 5/8-18 hub nut on shaft threads spin the hub completely onto the

turbine alternator shaft.

3. Fully tighten the hub to 50 ft-lbs(68Nm) by inserting a 5/16 inch hex key

wrench in the turbine alternator shaft and turning the shaft while turning the

blades.

3-2-3 Snap the nosecone into position over the outside edges of the blade hub.

Make sure all three edges of the nosecone snap over the edge of the blade

hub.

After installation tug on the nosecone to make sure it is securely attached

4. Sitting

Small changes in wind speed can have a dramatic effect on power production.

The sitting of your wind turbine should be carefully considered. Each

installation is different and is often a compromise among tower height,

distance from the battery bank, local zoning requirements and obstacles such

as buildings and trees.

In general the higher the tower, the greater the wind speed and ultimately

power production. However, towers are expensive and can easily exceed the

cost of the turbine.

Our wind turbine recommended tower height is 25ft (7.6m)on open ground or

20 ft(6m) above nearby obstructions.(Fig.2)Try to locate the wind turbine in

the cleanest turbulent free air as possible. Turbulence will reduce the

efficiency of the wind turbine and may accelerate wear on rotating

components.

Safety must be the primary concern when selecting the mounting location.

Install our wind turbine so there is no possibility of accidental contact with

rotating blades even if it requires installing the wind turbine in a less than ideal

location. Safety has precedence over efficiency.

WARNING: Install wind turbine so there is no Possibility of

accidental contact with rotating blades even if it requires installing

the wind turbine in a less than ideal location.

-6-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

Fig.2 Optimal location

5 Towers

Wind turbine is designed to mount on tubing or pipe with a nominal

1.875-1.900 inch outside diameter. This dimension enables constructing a

tower from a range of readily available materials including 1 1/2 inch Schedule

40 steel pipe and 2 inch SS-20 galvanized fence tubing (0.090 inch wall

thickness). Under no circumstances should plastic pipe be used to construct a

tower.

6 Wiring Options

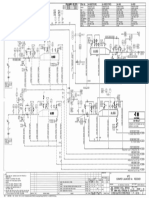

Fig.3 Single Turbine Installation

-7-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

Fig.3 represents a single turbine installation. Higher input voltages from

additional wind generators, solar panels, fuel-powered generators etc., can

trick the wind generators controller into sensing the battery in full charge, and

the controller will prematurely stop charging. It will not harm the wind

generator, just cause to slow down or stop spin. Please disconnect the other

charging sources to determine the possible interference source.

You can wire the wind generator through most power centers. However, if

you experience interference, you must bypass it and wire the wind generator

directly to the battery bank to its own set of battery posts. Allow the wind

generator to operate independently, monitor the battery and charge is

necessary.

CAUTION:DO NOT CONNECT WIND GENERATOR POSITIVE

TO BATTERY NEGATIVE AND WIND GENERATOR NEGATIVE

TO BATTERY POSITIVE FOR EVEN A SECOND,OR ELSE WILL

DAMAGE THE WIND GENERATORS CONTROLLER AND VOID

YOUR WARRANTY.(IF YOU ARE UNCERTAIN OF THE

POLARLTY OF THE WIRES,SIMPLY SPIN THE ROTOR SHAFT

AND MEASURE THE VOLTAGE DIRECTION WITH A VOLT

METER.)

NOTE: One bad battery can create high voltages (16-18

volts) and stop the Wind Generator from charging, check

the condition of each individual battery.

Consult the battery manufacturer for testing individual

batteries or cells.

-8-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

Fig.4 Single Turbine Installation with Up-Tower Junction Box

Fig.4 represents a system with an Up Tower Junction Box. The junction box

may be installed close to the top of the tower to ease installing a Lightning

Arrestor. Typically installing the box will require drilling holes in the tower to

install the box-be careful not to compromise the tower strength.

6-1 Hybrid System Wiring

Fig.5 represents a typical hybrid system with solar panels. Some charging

sources (solar panels, fuel-powered generators, additional wind generators,

etc.) connected to the same system may cause interference with our wind

turbine internal electronic and result in pre-regulation. The interference will not

harm the turbine; it will just cause it to spin slowly as if braked or it may stop

the turbine. If this occurs, test for possible interference by disconnecting the

-9-

Wuxi NaiEr Wind Power Technology Development Co., Ltd

other charging sources to determine the possible cause. If possible wire the

turbine and PV panels to their own set of battery posts.

TIP: In figure5. the wind turbine internal regulator is used. A diversion

type external regulator could also have been used

Fig.5 Hybrid System with Solar Panels

6-2 Multiple Wiring

It is possible to wire multiple wind turbines together. A typical multi-turbine

system is depicted in figure 6.

There are two methods used to accomplish this task.

Method One:

Each wind turbine is treated separately. Each turbine will have its own wires,

- 10 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

stop switch and fuse and will connect directly to battery using the internal

regulator to control charging.

Method Two:

Wire each turbine is a bus and then run one set of wires from the bus to the

battery. Each turbines internal regulator or an external diversion type regulator

may be utilized.

A bus system typically results in reduced wire costs.

Fig.6 Multiple wind turbine Wiring

6-3 Wire Size

All electrical systems lose energy due to resistance in conductors.

Large wires have less resistance but can be considerably more costly..

Resistance losses will also increase with increasing current; therefore, if yours

is a high wind site, it may be worthwhile to go with a larger size wire to take

advantage of the greater energy production potential of your site.

Conversely, in low wind sites it may not be cost effective to increase the wire

- 11 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

size since power production will be low.

The following wiring sizes provide maximum annual energy losses of 5% or

Less for sites with a 12 mph average wind speed (assuming the standard

Rayleigh distribution of wind speeds) which is sufficient for most sites.

To determine the size wire, measure the distance from the batteries to your

wind turbine. Be sure to include height of the tower, Refer to the appropriate

chart for your system voltage and number of turbines and select the wire size.

We recommend these as the minimum wire sizes; for optimal performance use

the largest wires that are practical and affordable. Local, state, and national

electrical codes have precedence over these recommendations and must be

followed to ensure the safety of your system.

Note: Wiring Resistance and Regulation

Depending on your exact system configuration including other charging

sources in your system, wiring resistance may affect the regulation set point of

the turbine. Higher wiring resistance (smaller wires) will tend to lower the

voltage at which the turbine enters regulation and stops charging. The

recommended wiring sizes should provide little effect on the regulation set

point, but all installations should be observed over time to ensure that the

12 Volt Systems, AWG/Metric Wire Size mm2

Wind

0-9M

9-10M

18-27M

27-46M

46-58M

Turbine

1

4mm2

6mm2

10mm2

16mm2

90mm2

2

10mm2

16mm2

25mm2

25mm2

25mm2

3

10mm2

16mm2

25mm2

35mm2

50mm2

**** If your system requires this length of wire, consider using parallel wires.

24 Volt Systems, AWG/Metric Wire Size mm2

Wind

0-9M

9-10M

18-27M

Turbine

1

2.5mm2

4mm2

6mm2

2

4mm2

10mm2

16mm2

3

6mm2

10mm2

16mm2

- 12 -

27-46M

46-58M

10mm2

25mm2

25mm2

16mm2

25mm2

35mm2

Wuxi NaiEr Wind Power Technology Development Co., Ltd

6-4 Fuses, Circuit Breakers and Ammeter

Our wind turbine is capable of producing high amperages. As with all electrical

installations, you must protect each of your turbines with a fuse or circuit

breaker. Wire wind turbine with an appropriate sizeslow-blow fuse or circuit

breaker between it and the batteries. Refer to installation figures at the start of

Section 5. If a stop switch is used, the fuse or circuit breaker should be placed

between the switch and the batteries.

Recommended Sizes for Circuit Breakers or Slow-Blow Fuses

12-volt model:40 amp DC, part number 3-ELOT -1147-04

24-volt model:20 amp DC, part number 3-ELOT -1147-03

Circuit Breakers can be bought by your own.

While not necessary, an ammeter (sometimes called an Amp Meter) is an

excellent addition to any system. The Amp Meter allows you to monitor the

current output of your turbine. Place it in between your turbine and the battery

on the positive lead. It will give you instantaneous reading of output in amps.

6-5 Batteries

There are many battery choices available-flooded lead acid, absorbed glass

mat (AGM), gel cell and Nicad. The type of Battery utilized will depend largely

on the battery bank location and cost. For battery installations where fumes

can be safely ventilated and the potential for acid leakage accommodated, the

flooded lead acid battery is typically the most economical choice.

Mini recommended battery bank size:

12-Volt systems -400 Amp-hours

24-Volt systems -200 Amp-hours

6-6 Wind Turbine Grounding

Proper grounding of the wind turbine provides protection to individuals and

equipment by elimination the possibility of dangerous voltage potentials.

There are two aspects to grounding any electrical system-grounding one of the

- 13 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

conductors of the electrical system and grounding all metal structures in the

system that may have a voltage potential caused by an electrical failure.

In a typical wind turbine installation grounding one of the conductors is

accomplished by connecting the wind turbine negative (black) conductor to an

earth ground close to the battery bank. Installation and connection to

grounding rods is described in the following section on Tower Grounding.

Grounding the metal structures in the system-typically this includes the tower

and turbine-is accomplished by connecting the structures together using

conductors of the same size as the positive and negative conductors and then

routing a conductor to an earth ground.

6-7 Tower grounding

Every wind turbine and turbine tower should be grounded at the tower base

even though the system may be grounded at the battery bank or service panel

by means of the yaw ground lead. Grounding the tower at its base may prevent

shocks to persons touching the tower due to lightning or electrical faults.

The following sections are provided as a guide to properly grounding the tower

and should not be considered completely comprehensive. You are encouraged

to reference the National Electrical Code (NEC) and local building and zoning

regulations for complete requirements. Relevant sections of the National

Electrical Code are referenced.

Tower grounding may be accomplished in several ways; the most common

method is a copper clad steel electrode(s) driven into the soil and connected to

the tower using a wire conductor.

6-7-1 Electrodes Driven In Soil

Electrodes should to a minimum of 8ft (2.5m)in length and free of

non-conductive coatings such as paint. Hollow electrodes of pipe or conduit

should not be smaller than trade size 3/4(metric designator 21) and must be

galvanized or otherwise protected from corrosion. Solid rod electrodes must be

at least 5/8 inch (16mm) diameter. Stainless steel rods less than 5/8 inch

diameter, nonferrous rods or their equivalent less than 1/2 inch diameter shall

be listed by an organization having jurisdiction in the area. For example: UL

- 14 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

in the USA and CSA in Canada.

Electrodes shall be installed such that 8ft (2.5m) is in contact with the soil.

They should be driven into undisturbed soil within 1ft of the tower foundation.

Electrodes should be driven to a depth of 8 ft (2.5m) except where rock is

encountered; then the electrode may be driven at an angle not to exceed 45

degrees from vertical. Some local authorities permit burial of the electrode in a

trench that is a minimum of 30inch (76cm)deep.

The upper and of the electrode and its connection to the grounding conductor

should be below grade or if above ground, must be protected from damage.

Bonding the grounding conductor to the electrode and to the tower may be

accomplished by exothermic weld or by a listed mechanical connector. Solder

connections are not permitted. Most local authorities require a minimum

grounding conductor size of 6 AWG for copper and 4AWG for aluminum (if

aluminum is permitted).

The grounding conductor may be buried directly or contained in conduit; in

either case it is important that it have no sharp bends to keep its inductance

low.

The accompanying figure depicts a typical tower grounding technique and the

following sections of the NEC are listed for reference.

FIG.7

- 15 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

7. Installation

The following are general guidelines for the installation of wind turbine.

Because each wind turbine installation is unique, specific step-by-step

installation instructions cannot be provided. However, before attempting final

installation the following basic steps should be completed.

Completely review the Owners Manual

Select tower and site and install tower. See sections 4.0 and 5.0 and 6.0

Determine wire size. See section 6.3.

Design system including batteries, switches, circuit breakers-draw wiring

diagram.

Obtain required components.

Assemble turbine See Section 3.0 Turbine Assembly.

Once these steps are completed, final assembly is fairly simple and consists

primarily of making good electrical connections according to the wiring

diagram and mounting wind turbine on the tower.

7-1 Wire Connections

Connect wire leads from wind turbine to wires to be run down the tower using

split bolt or solder connectors. Follow good practice and use color coded

wires-red for battery positive, black for battery negative, and yellow for earth.

wires must be sized based on turbine to battery bank distance. Refer to Section

5.Insulate connections with heat shrink tubing or good quality electrical tape.

Leave sufficient service loop in the wires to accommodate removal of the

turbine from the tower.

Follow system wiring diagram and run wires to disconnect switch, fuse or

circuit breaker and ammeter. If a stop switch is utilized (highly recommended)

turn switch to OFF until all connections are completed.

- 16 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

7-2 Mounting on Tower

After wires are connected to wind turbine, route the wires down the tower and

slide the turbine yaw over tower top. After the yaw is completely lowered onto

tower top, lift the yaw approximately 1/8 inch (3mm)to 1/4 inch (6mm) so that

the only contact between the yaw and tower top is through the rubber isolation

pad. This will reduce noise and vibration transmission to the tower.

Once the yaw is positioned on the tower, secure the yaw clamp screws using

the supplied 5/32 inch hex key wrench. Torque to 5 ft lbs (6.8Nm).

If blade/hub assembly is not already installed on turbine, it may be installed

now. Position the 5/8-18 nut in the hexagonal detent at the center of the hub.

Coat the shaft threads and blade hub bore with Tef-Gel and spin the hub

completely onto the turbine alternator shaft. Fully tighten hub to 50lb-ft by

inserting a 5/16 inch hex key wrench in the turbine alternator shaft and

attempting to turn the shaft while holding the blades.

Snap the nosecone into position over the outside edges of the blade hub. Make

sure all three edges of the nosecone snap over the edge of the blade hub. After

installation tug on the nosecone to make sure it is securely attached.

7-3 Final Connections

Before making final connections to the batteries, make sure circuit breakers

and stop switch are in the OFF position. Attach wires to battery; red to positive

battery terminal and black to negative battery terminal.

The installation is now complete.

ARNING: If the battery connections are reversed, wind turbine

electronics will be damaged. The polarity of wind turbines wires

may be checked by connecting a volt-meter to the wires and

spinning the rotor by hand.

- 17 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

8. Operation

8-1Operational Summary

Wind turbines operate by capturing the kinetic energy of moving air: the wind.

They convert it to rotational motion to turn an alternator that produces

electrical power. The electrical power must be regulated to a voltage to charge

the system batteries, and there must be a system to prevent over-charging the

batteries and resume charging as the battery voltage drops.

The A means to protect the wind turbine from extreme wind damage must also

be provided.

Our wind generator accomplishes all these goals by incorporating a three

phase brushless permanent magnet alternator and microprocessor controlled

electronic to optimize its power production capability. The microprocessor

continuously adjusts the loading of the alternator to keep the blades operating

at their optimal angle of attack. The result:

high power production;

high blade efficiency; and

lower blade noise

8-2 Operating Modes

Charging: With our wind turbine connected to batteries with the voltage

below the voltage regulation set point, the blades will spin in response to the

wind. With an available wind, the blades will continue to spin until the battery

voltage matches the regulation set point.

Note that our wind turbine requires a minimum battery bank voltage

(approximately 10.5 volts on a 12-volt system) or the controller will behave as

if an open circuit condition exists. Refer to open circuit/Free spinning section.

Stall Mode: stall mode is marked by a dramatic reduction in turbine speed to

approximately 500-700rpm.Our wind turbine will enter stall mode when a wind

speed to 35 mph (15.6m/s)is sensed, and it will remain in stall mode until the

speed drops to 32mph(14m/s), If a wind speed of 50mph (22 m/s)is

detected ,the turbine will completely shut down for 5 minutes.

- 18 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

Braking Mode: our wind turbine may be placed in braking mode by directly

shorting the turbine positive and negative wires together or by the use of a

stop switch. The stop switch first disconnects the turbine from the battery and

then shorts the positive and negative wires. In very strong winds the blades

may rotate slowly even with the switch activated,

No load Operation /Open Circuit /Free Spinning: our wind turbine will

spin freely if disconnected from an electrical load. These results in a cycle of

rapid blade speed followed by rapid breaking this mode of operation may

accelerate wear of the turbine and is also non-productive.

8-3 Using an Alternate Charge Controller

There are some conditions under which our wind turbine internal regulator is

not appropriate as the primary regulator. These conditions include:

Systems where battery temperature varies widely

Battery charge efficiency varies in extreme temperatures. If these conditions

exist an external regulator with a temperature compensation sensor should be

used to optimize the charge rate. There are several regulators available that

adjust the charge rate based on ambient battery temperature.

Batteries that is extremely sensitive to charge voltage

Follow the recommendations of the battery manufacturer. For most battery

systems our wind turbine internal voltage regulator is completely adequate.

Multiple turbines with a bus system

Multiple turbine installations will typically function best using a single voltage

regulator close to the battery bank. This is particularly true if the wire lengths

connecting each turbine to the bus vary by distance or wire gauge.

If a charge controller other than our mind turbine internal controller is utilized,

it must be a diversion style regulator. A diversion style regulator charges the

batteries, and as the batteries become charged, the excess power is diverted

to a resistive load. This technique allows for the capture of full turbine power

even after the batteries are charged.

- 19 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

CAUTION: Most controllers designed to work with solar panels

are not suitable for use with our wind turbine .These controllers

disconnect the solar panels or in this case our mind turbine from

the battery bank when the batteries are charged, allowing our

wind turbine

9. Maintenance

Although your wind turbine has been designed to run for long periods without

requiring any maintenance, reliability and performance will be enhanced if you

periodically inspect your system.

After one month and every six months thereafter:

Check blades for chips or nicks. Replace blades if damaged. Do not operate

the turbine with chipped or unbalanced blades. This can cause severe wear,

damage, and possible failure. Do not install individual blades. The blades

are balanced as a set.

Check the blade bolts and the hub nut for tightness.

Check nosecone for cracks and proper fit.

Wash off any built-up dirt or debris from the blades.

Check all electrical connections to make sure they are tight and free from

corrosion.

As with all charging systems, check your battery water levels and add

distilled water in accordance with manufacturers recommendation.

Our wind turbine suggests replacing the blades and bearings every five

years for optimal performance.

10. Trouble shooting

Three quick bench tests can verify if your wind turbine is working correctly.

Test 1 does not require any equipment. For tests 2 and 3you will need a battery

bank and a power drill.

- 20 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

Test 1

1). Remove the blade/hub assembly from the turbine and place in a safe

location. Replace the rotor hub nut on the rotor shaft.

2). Attempt to quickly spin the rotor shaft with your fingers while connecting

and disconnecting the red and black wires (turbine must not be connected to

batteries).A second person may be helpful to perform this test.

3). With the red and black wires connected to each other, the shaft should be

more difficult to turn. Replace the rotor hub nut on the rotor shaft. With the

yaw wires disconnected it should spin freely. Spinning the shaft quickly makes

difference easier to detect. If these conditions do not exist, you should contact

your turbine dealer.

11. Exploded Views &Parts List

FIG.8 BODY ASSSEMBLY EXPLODED VIEW

Item

Description

1

2

3

4

5

6

Nose Cone

Blade

Hub

Motor

Wind turbine body

Yaw Assembly

QTY

SF-600-3

SF-600-5

1

5

1

1

1

1

- 21 -

Wuxi NaiEr Wind Power Technology Development Co., Ltd

Company Profile

Wuxi NaiEr wind power technology development Co., Ltd. is a research and

development, manufacturing, sales of wind turbines and technology enterprises. The

company is located in Wuxi City, Jiangsu Province, located in the scenic Taihu Lake,

railway, highway, airport nearby. Here, beautiful scenery and convenient transportation,

pleasant climate, in fact, commerce, an ideal place for tourism.

The company owns a number of professional personnel, advanced production

equipment and testing facilities, has formed a set design, manufacture, installation,

commissioning, marketing and after-sales service system integration services, mainly

produces 200W, 300W, 500W, 1KW, 2KW,

3KW, 5KW, 10KW, 20KW, 30KW, 50KW series of wind turbines, most of our products

occupy the domestic market and exported to the United States, France, Canada,

Norway, Australia and other countries, are popular and well received.

Working Environment

Contact Information

Name: Viola Yi

Email: violayi@wxnaier.com

Msn: violayi@outlook.com.cn

Tel: +86 133 9513 1902

- 22 -

Você também pode gostar

- Transport Manual V90Documento28 páginasTransport Manual V90cungondaAinda não há avaliações

- VesselsDocumento34 páginasVesselskush149Ainda não há avaliações

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNo Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNota: 4 de 5 estrelas4/5 (1)

- Angolan Offshore ProjectsDocumento70 páginasAngolan Offshore ProjectsDPR007100% (1)

- Safety of Wind SystemsDocumento36 páginasSafety of Wind SystemsNemanja KomatinovicAinda não há avaliações

- Wind TurbineDocumento42 páginasWind TurbineAlaeddineAinda não há avaliações

- Specification Guide For Wind Turbines (UK)Documento56 páginasSpecification Guide For Wind Turbines (UK)Vinoth Kumar100% (2)

- Wind Turbine MaintenanceV47Documento4 páginasWind Turbine MaintenanceV47سامح الجاسمAinda não há avaliações

- Turbine SpecificationsDocumento7 páginasTurbine SpecificationsFaouzi TlemcenAinda não há avaliações

- Maintenance of Offshore Wind TurbineDocumento3 páginasMaintenance of Offshore Wind TurbineSamuel TanAinda não há avaliações

- Offshore Wind Operations and MaintenanceDocumento55 páginasOffshore Wind Operations and MaintenanceNenad IlicAinda não há avaliações

- Alstom T1693enDocumento169 páginasAlstom T1693enNathaniel DizonAinda não há avaliações

- User Manual - MSIMMA - Rev5 PDFDocumento130 páginasUser Manual - MSIMMA - Rev5 PDFiuliiulianAinda não há avaliações

- Guidelines For Onshore and Offshore Wind FarmsDocumento114 páginasGuidelines For Onshore and Offshore Wind Farmsjackiepallo100% (1)

- OHSE ManualDocumento119 páginasOHSE Manualadrian0% (2)

- Safety Catalog SOFAMEL 2011Documento80 páginasSafety Catalog SOFAMEL 2011antegeia2222100% (3)

- EON Offshore FactbookDocumento60 páginasEON Offshore FactbookvijaypshindeAinda não há avaliações

- Wind Turbine Installation VesselsDocumento30 páginasWind Turbine Installation Vesselsyoler478Ainda não há avaliações

- 518 STD Usa Centrifuge Manual Part 90 90 061 Reva21 PDFDocumento109 páginas518 STD Usa Centrifuge Manual Part 90 90 061 Reva21 PDFChemist - Aban DD8Ainda não há avaliações

- 8 Wind Turbine Lecture NCDocumento45 páginas8 Wind Turbine Lecture NCali381Ainda não há avaliações

- DBU Technical & InstallationDocumento42 páginasDBU Technical & InstallationManguishAinda não há avaliações

- Offshore WindDocumento36 páginasOffshore WindWangwen Zhao100% (1)

- Offshore Wind Cost Reduction Pathways StudyDocumento88 páginasOffshore Wind Cost Reduction Pathways StudyCarlos ManuelAinda não há avaliações

- Lifting Operations HandbookDocumento80 páginasLifting Operations Handbookzaur baimuratovAinda não há avaliações

- ALSPA MV3000e: Safety InstructionsDocumento115 páginasALSPA MV3000e: Safety Instructionsleebjb100% (1)

- Guide To Offshore WindfarmDocumento72 páginasGuide To Offshore WindfarmJoe Dagner100% (1)

- Offshore Wind Turbine Installation VesselDocumento45 páginasOffshore Wind Turbine Installation VesselJACK100% (1)

- SLB LiftingDocumento98 páginasSLB Liftingbilo1984100% (8)

- Offshore Wind: Cable Installation Cable Trenching Survey & Seabed Mapping IMRDocumento8 páginasOffshore Wind: Cable Installation Cable Trenching Survey & Seabed Mapping IMRsenthil_5100% (1)

- VestaDocumento18 páginasVestaKonstantinos Chr.Ainda não há avaliações

- Manriding Winch Requirements DNV-OS-E101 Drilling PlantDocumento2 páginasManriding Winch Requirements DNV-OS-E101 Drilling PlantDayde6950% (2)

- Chinese WTG ManufacturesDocumento9 páginasChinese WTG ManufacturesSpark NetworkAinda não há avaliações

- Back Presure Valve in PCP or SRPDocumento15 páginasBack Presure Valve in PCP or SRPShubham GuptaAinda não há avaliações

- Derrick Escape Descender - Instruction ManualDocumento12 páginasDerrick Escape Descender - Instruction ManualSteve WatsonAinda não há avaliações

- Rules and Classification For Well Control EquipmentDocumento22 páginasRules and Classification For Well Control EquipmentShaikh Sabir HussainAinda não há avaliações

- 2481spm subSEA L02 1 PDFDocumento76 páginas2481spm subSEA L02 1 PDFSanat KumarAinda não há avaliações

- ROSA Field TotalDocumento18 páginasROSA Field TotalWaldemarAinda não há avaliações

- Peter Tavner Durham University Whats Hot in University Offshore Renewable ResearchDocumento33 páginasPeter Tavner Durham University Whats Hot in University Offshore Renewable ResearchadepomaAinda não há avaliações

- Brochure Wind Farm Management enDocumento26 páginasBrochure Wind Farm Management envikasAinda não há avaliações

- Offshore Wind Farm Electrical Systems DNV - Plymouth UniDocumento49 páginasOffshore Wind Farm Electrical Systems DNV - Plymouth UniaojgbengaAinda não há avaliações

- D392004720 MKT 001 PDFDocumento28 páginasD392004720 MKT 001 PDFsorangel_123Ainda não há avaliações

- BX Elevator Lock Tab Washer TO17311Documento5 páginasBX Elevator Lock Tab Washer TO17311mohamed hamed100% (1)

- Rig Stacking StrategiesDocumento14 páginasRig Stacking StrategiesJeril PhilipAinda não há avaliações

- Wind Turbine Rotor Balance Static V Dynamic Rev4 ExtDocumento14 páginasWind Turbine Rotor Balance Static V Dynamic Rev4 ExtmlenzAinda não há avaliações

- Threaded Lifting Systems-UkDocumento24 páginasThreaded Lifting Systems-UkCristi AndoneAinda não há avaliações

- Albers TUDelft Introduction, Heave CompensationDocumento17 páginasAlbers TUDelft Introduction, Heave Compensationnvkurup100% (1)

- Well Control and Subsea Drilling EquipmentDocumento48 páginasWell Control and Subsea Drilling EquipmentYunita SelonikaAinda não há avaliações

- Gustomsc Brochure Jack Ups.r08 12Documento12 páginasGustomsc Brochure Jack Ups.r08 12anhlhAinda não há avaliações

- Winch, Manrider (FA150KGi) Product InstructionsDocumento16 páginasWinch, Manrider (FA150KGi) Product InstructionsTonyAinda não há avaliações

- IMO Test Reports LSADocumento12 páginasIMO Test Reports LSAMd AmirulAinda não há avaliações

- Offshore Wind Turbine DesignDocumento47 páginasOffshore Wind Turbine DesignJeEJyZa100% (1)

- Offshore WindDocumento38 páginasOffshore WindMDAinda não há avaliações

- Electrician's Guide To The Building Regulations (3rd Edition)Documento2 páginasElectrician's Guide To The Building Regulations (3rd Edition)fopoku2k2100% (1)

- 500W Wind Generator ManualDocumento18 páginas500W Wind Generator ManualNicolae ȘoituAinda não há avaliações

- Wind Air403 ManualDocumento41 páginasWind Air403 ManualSebastian Lobos OpitzAinda não há avaliações

- ZH 750 ManualDocumento15 páginasZH 750 ManualCesar MoraAinda não há avaliações

- User Manual of Wind GeneratorsDocumento7 páginasUser Manual of Wind GeneratorsSmithAinda não há avaliações

- ARE110-48V Owners Manual Mechanical Ver5.0Documento23 páginasARE110-48V Owners Manual Mechanical Ver5.0Karthik PalaniswamyAinda não há avaliações

- TOR Electric Utility Annual Preventive MaintenanceDocumento10 páginasTOR Electric Utility Annual Preventive MaintenanceVictor BiacoloAinda não há avaliações

- Genset Base PadDocumento1 páginaGenset Base PadVictor BiacoloAinda não há avaliações

- Inter Company Employee Transfer Letter FormatDocumento2 páginasInter Company Employee Transfer Letter FormatVictor Biacolo100% (1)

- Weekly Timesheet With Payslip Excel TemplateDocumento4 páginasWeekly Timesheet With Payslip Excel TemplateVictor BiacoloAinda não há avaliações

- Receipt ExpensesDocumento4 páginasReceipt ExpensesVictor BiacoloAinda não há avaliações

- WP20Documento8 páginasWP20Victor BiacoloAinda não há avaliações

- For AccreditationDocumento1 páginaFor AccreditationVictor BiacoloAinda não há avaliações

- Receipt ExpensesDocumento2 páginasReceipt ExpensesVictor BiacoloAinda não há avaliações

- Water Quality AnalyzerDocumento1 páginaWater Quality AnalyzerVictor BiacoloAinda não há avaliações

- Plam - TDSDocumento1 páginaPlam - TDSVictor BiacoloAinda não há avaliações

- June 2021 ExpensesDocumento2 páginasJune 2021 ExpensesVictor BiacoloAinda não há avaliações

- IBS Training ModuleDocumento58 páginasIBS Training ModuleAkhtar Khan100% (1)

- Fice Solution Cons Inc: Organizational ChartDocumento1 páginaFice Solution Cons Inc: Organizational ChartVictor BiacoloAinda não há avaliações

- Continuity/Insulation Resistance Test FormDocumento1 páginaContinuity/Insulation Resistance Test FormVictor BiacoloAinda não há avaliações

- Data SheetDocumento1 páginaData SheetVictor BiacoloAinda não há avaliações

- PVC Foam Data Sheet: Property Test Method Unit Q80Documento1 páginaPVC Foam Data Sheet: Property Test Method Unit Q80Victor BiacoloAinda não há avaliações

- 5 Adca Training - Part 3 5d72288d3b8cfDocumento48 páginas5 Adca Training - Part 3 5d72288d3b8cfVictor BiacoloAinda não há avaliações

- AdcaTraining-2-Rev 02 53b126afc413aDocumento40 páginasAdcaTraining-2-Rev 02 53b126afc413ajoaquin torrano veraAinda não há avaliações

- 6 Adca Training - Part 4 5d7228a93513fDocumento31 páginas6 Adca Training - Part 4 5d7228a93513fVictor BiacoloAinda não há avaliações

- 3 Adca Training - Part 1 5d722ade5d2acDocumento30 páginas3 Adca Training - Part 1 5d722ade5d2acVictor BiacoloAinda não há avaliações

- Pre-Commissioning and CommissioningDocumento25 páginasPre-Commissioning and CommissioningVictor BiacoloAinda não há avaliações

- Large Scale Commercial Solution: Three Phase Grid-Tied Solar InverterDocumento4 páginasLarge Scale Commercial Solution: Three Phase Grid-Tied Solar InverterVictor BiacoloAinda não há avaliações

- Scrapper LAuncher M-840 & Receivers M-850Documento1 páginaScrapper LAuncher M-840 & Receivers M-850Victor BiacoloAinda não há avaliações

- Date GE Tag Description LearningDocumento3 páginasDate GE Tag Description LearningVictor BiacoloAinda não há avaliações

- MaterialsDocumento3 páginasMaterialsVictor BiacoloAinda não há avaliações

- Vibration StudyDocumento2 páginasVibration StudyVictor BiacoloAinda não há avaliações

- Brochure Explosion Protection enDocumento45 páginasBrochure Explosion Protection enpramodtryAinda não há avaliações

- Motor PartsDocumento27 páginasMotor PartsVictor BiacoloAinda não há avaliações

- 200ah 12VDocumento2 páginas200ah 12VVictor BiacoloAinda não há avaliações

- Introduction To Marine MachineriesDocumento13 páginasIntroduction To Marine MachineriessrcattozziAinda não há avaliações

- Master Cyilinder Actuation Package CO Pneumatic Release ActuatorDocumento2 páginasMaster Cyilinder Actuation Package CO Pneumatic Release ActuatorEliud RodriguezAinda não há avaliações

- WattmeterDocumento13 páginasWattmeterGovindaraju RajuAinda não há avaliações

- PB PDFDocumento95 páginasPB PDFMisha KulibaevAinda não há avaliações

- Catalog - Regent RSV Ed 3Documento14 páginasCatalog - Regent RSV Ed 3Nyu123456Ainda não há avaliações

- X2 / 275 and 300 Vac: B 32 92 EMI Suppression CapacitorsDocumento6 páginasX2 / 275 and 300 Vac: B 32 92 EMI Suppression CapacitorsDimas ScrewAinda não há avaliações

- CSB-F: Three-Phase Power Capacitor With Fuse ProtectionDocumento2 páginasCSB-F: Three-Phase Power Capacitor With Fuse ProtectionAbdul RafaeAinda não há avaliações

- 09 MaschinenfabrikReinhausen On LoadTap ChangerDocumento28 páginas09 MaschinenfabrikReinhausen On LoadTap Changerhardian syaputraAinda não há avaliações

- IC ENGINES NOTES Unit 2Documento41 páginasIC ENGINES NOTES Unit 2Satya NarayanaAinda não há avaliações

- Impressed Current Cathodic Protection Design For Eleme Petrochemical 6 and 8'' Pipeline PDFDocumento16 páginasImpressed Current Cathodic Protection Design For Eleme Petrochemical 6 and 8'' Pipeline PDFobuseAinda não há avaliações

- JSW SteelDocumento44 páginasJSW Steelauttyhubli100% (1)

- PWMcircuit 08Documento10 páginasPWMcircuit 08kcarringAinda não há avaliações

- Load Flow - CompleteDocumento24 páginasLoad Flow - CompleteJohn Cristouv CortezAinda não há avaliações

- 1.2 Substation Components, Functions & RatingsDocumento57 páginas1.2 Substation Components, Functions & Ratings021804Ainda não há avaliações

- Pe Final Ex SS 2010-2011Documento8 páginasPe Final Ex SS 2010-2011Saif Uddin100% (1)

- G7Documento21 páginasG7Maame Ama FrempongAinda não há avaliações

- Chemical Engg Basic IndiabixDocumento123 páginasChemical Engg Basic IndiabixRishikesh Awale100% (3)

- RippleTankSE Key PDFDocumento10 páginasRippleTankSE Key PDFYesi Setyo Ningrum100% (1)

- Design of Water SystemDocumento18 páginasDesign of Water Systempolaris100% (1)

- 8.13 - Glycol Heat Tracing 11Documento1 página8.13 - Glycol Heat Tracing 11Greg EverettAinda não há avaliações

- ABB - OPR Lightning - p31-p31Documento1 páginaABB - OPR Lightning - p31-p31Indra WanAinda não há avaliações

- Fuel, Lubricants and Fluids: en-GBDocumento59 páginasFuel, Lubricants and Fluids: en-GBRuanAinda não há avaliações

- Sowinkumar Namel A/l Nagarajan (Ee095367) Raneej A/l Sukumaran (Ee095356) Section 4 Bench 05Documento2 páginasSowinkumar Namel A/l Nagarajan (Ee095367) Raneej A/l Sukumaran (Ee095356) Section 4 Bench 05Sowin HustleAinda não há avaliações

- 0111 SunSwitch - OFFER FOR - 1 KVA TO 8 KVA Solar Hybrid PCUDocumento8 páginas0111 SunSwitch - OFFER FOR - 1 KVA TO 8 KVA Solar Hybrid PCUGaurav KhannaAinda não há avaliações

- Vimp Question Chem: A) 8,8 B) 4,4 C) 6,6 D) 8,4Documento3 páginasVimp Question Chem: A) 8,8 B) 4,4 C) 6,6 D) 8,4Ankit SinghAinda não há avaliações

- LGP4247 11SPLDocumento11 páginasLGP4247 11SPLViorel CioataAinda não há avaliações

- Cooling by Underground Earth TubesDocumento4 páginasCooling by Underground Earth TubesNaava BasiaAinda não há avaliações

- Reinforcement Learning-Based Intelligent Maximum Power Point Tracking Control For Wind Energy Conversion SystemsDocumento10 páginasReinforcement Learning-Based Intelligent Maximum Power Point Tracking Control For Wind Energy Conversion SystemsBook4AllAinda não há avaliações

- Sugar ManufacturingDocumento55 páginasSugar Manufacturingamrialifa100% (3)

- Sustainability 09 02214Documento11 páginasSustainability 09 02214dictussAinda não há avaliações

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsNo EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsNota: 3.5 de 5 estrelas3.5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeNo EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeNota: 4.5 de 5 estrelas4.5/5 (9)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialNo EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialNota: 3.5 de 5 estrelas3.5/5 (3)

- Teach Yourself Electricity and Electronics, 6th EditionNo EverandTeach Yourself Electricity and Electronics, 6th EditionNota: 3.5 de 5 estrelas3.5/5 (15)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesNo EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesNota: 5 de 5 estrelas5/5 (1)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosNo EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosNota: 5 de 5 estrelas5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)

- Analog Design and Simulation Using OrCAD Capture and PSpiceNo EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceAinda não há avaliações

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonNo EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonNota: 5 de 5 estrelas5/5 (2)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)No EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Nota: 4.5 de 5 estrelas4.5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesNo EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesNota: 5 de 5 estrelas5/5 (1)

- Heat Transfer Engineering: Fundamentals and TechniquesNo EverandHeat Transfer Engineering: Fundamentals and TechniquesNota: 4 de 5 estrelas4/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsNo EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovAinda não há avaliações

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionNo EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionNota: 4.5 de 5 estrelas4.5/5 (543)

- Power Electronics Diploma Interview Q&A: Career GuideNo EverandPower Electronics Diploma Interview Q&A: Career GuideAinda não há avaliações

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Ainda não há avaliações