Escolar Documentos

Profissional Documentos

Cultura Documentos

Chevron Turbine Oil

Enviado por

corsini999Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chevron Turbine Oil

Enviado por

corsini999Direitos autorais:

Formatos disponíveis

GST OIL

32, 46, 68, 100

PRODUCT DESCRIPTION

FEATURES

GST Oils are formulated with premium base oil

technology designed to meet the critical demands of:

GST Oils are formulated with premium

base oil technology and an ashless,

zinc-free formulation that provides

exceptional oxidation stability, water

separability, and protection against rust and corrosion.

non-geared gas, steam, and hydroelectric turbine

bearing lubrication

reduction gear lubrication in marine operations

They are an excellent recommendation for many other

industrial applications including air compression where

R&O type oils are recommended.

CUSTOMER BENEFITS

GST Oils deliver value through:

Exceptional oxidation stability for long service

life at elevated temperatures. Formulated with

premium base oil technology and an ashless, zincfree formulation.

Rust and corrosion protection

High viscosity index helps ensure minimum

viscosity change when variations in temperature

occur.

Minimum foam helps prevent sump overflow or

erratic governor operation.

Fast air release minimizes possibility of pump

cavitation in systems with high circulation rates and

small reservoirs.

Higher temperatures in advanced gas and steam

turbines require circulating system oil with exceptional

high temperature stability. GST Oils have outstanding

thermal and oxidation stability.

Nonvolatile oxidation inhibition minimizes the

evaporative loss of the inhibitors, a common problem

with turbine oils where bearing temperatures are high

and system capacities are limited. With retained

oxidation resistance for long periods under high

temperature conditions, GST Oils will promote long oil

service life and help minimize turbine down time.

Corrosion inhibition protects costly turbine shafts

and gears from corrosion and rusting.

GST Oils have excellent demulsibility characteristics

which allow these oils to maintain a high film strength

coating on critical wear points of bearings and gear

reducers and assure fast removal of water

contamination.

Foam inhibition helps prevent sump overflow and

erratic governor operation.

Exceptional thermal stability minimizes deposit

formation.

Rapid water separation keeps water in oil to a

minimum.

Hydraulic fluid service GST Oils 32, 46, and

68 are excellent hydraulic fluids in low pressure

systems up to 1000 psi.

Air compressor lubricant when OEM recommends

R&O type oil.

Product(s) manufactured in the USA.

Always confirm that the product selected is consistent with the original equipment manufacturer's recommendation for the

equipment operating conditions and customer's maintenance practices.

A Chevron company product

26 June 2015

IO-85

2007-2015 Chevron U.S.A. Inc. All rights reserved.

Chevron, the Chevron Hallmark and GST are trademarks owned by Chevron Intellectual Property LLC. All other trademarks are

property of their respective owners.

13-43

GST Oil Continued

APPLICATIONS

GST Oil 68

GST Oils are formulated to meet the critical demands

of non-geared gas, steam, and hydroelectric turbine

bearing lubrication, and reduction gear lubrication in

marine operations. They are an excellent

recommendation for many other industrial applications

including air compression where R&O type oils are

recommended.

meets

ASTM D4304 Type I, British Standard

489, and DIN 51515 standard organization

requirements for new lubricants used in gas and

steam turbines and auxiliary equipment

MAG Cincinnati, Cincinnati Machine P-54

The following viscosity grades are formulated to meet

the specified OEM requirements:

suitable for use in hydroelectric turbines, land and

marine steam turbines, and associated reduction

gears when OEM recommends R&O type oil.

GST Oil 32

GST Oil 100

meets and exceeds

meets

ASTM D4304 Type I, British Standard

489, and DIN 51515 standard organization

requirements for new lubricants used in gas and

steam turbines and auxiliary equipment

General Electric GEK-32568j, GEK 28143A,

GEK-46506D, GEK-27070

Solar ES 9 224 requirements for gas turbine oils

meets

MAG Cincinnati, Cincinnati Machine P-38

is approved by

Alstom Power HTGD 90117 (for non-geared

turbines)

Siemens TLV 901305

Siemens Westinghouse M spec 55125Z3

GST Oil 46

meets

ASTM D4304 Type I, British Standard

489, and DIN 51515 standard organization

requirements for new lubricants used in gas and

steam turbines and auxiliary equipment

MAG Cincinnati, Cincinnati Machine P-55

Solar ES 9 224 requirements for gas turbine oils

ASTM D4304 Type I, British Standard

489, and DIN 51515 standard organization

requirements for new lubricants used in gas and

steam turbines and auxiliary equipment

suitable for use in hydroelectric turbines, land and

marine steam turbines, and associated reduction

gears when OEM recommends R&O type oil.

GST Oils 32, 46, 68, and 100 are registered by NSF

and are acceptable as lubricants where there is no

possibility of food contact (H2) in and around food

processing areas. The NSF Nonfood Compounds

Registration Program is a continuation of the USDA

product approval and listing program, which is based

on meeting regulatory requirements of appropriate

use, ingredient review and labeling verification.

Do not use in high pressure systems in the vicinity of

flames, sparks and hot surfaces. Use only in well

ventilated areas. Keep container closed.

Do not use in breathing air apparatus or medical

equipment.

is approved by

Alstom Power HTGD 90117 (for non-geared

turbines)

Siemens TLV 901305

successfully used in some reactor coolant pump

motor bearings.

Always confirm that the product selected is consistent with the original equipment manufacturer's recommendation for the

equipment operating conditions and customer's maintenance practices.

26 June 2015

IO-85

13-44

GST Oil Continued

TYPICAL TEST DATA

ISO Grade

Product Number

SDS Number

32

46

68

100

253026

253027

253028

253029

6710

6710

6710

6710

AGMA Grade

API Gravity

32.7

32.0

31.7

31.4

Viscosity, Kinematic

cSt at 40C

cSt at 100C

32.0

5.4

43.7

6.6

68.0

8.8

100.0

11.4

Viscosity, Saybolt

SUS at 100F

SUS at 210F

165

44.4

225

48.2

352

55.9

520

65.4

Viscosity Index

102

101

102

100

Flash Point, C(F)

222(432)

224(435)

245(473)

262(504)

Pour Point, C(F)

-36(-33)

-36(-33)

-33(-27)

-30(-22)

Oxidation Stability

ASTM D943a

ASTM D2272b

17,000

1700

12,000

1400

11,000

1400

11,000

1400

a Hours to 2.0 mg KOH/g acid number modified D943, allowed to run beyond 10,000 h.

b Minutes to 25 psi pressure drop.

Minor variations in product typical test data are to be expected in normal manufacturing.

Always confirm that the product selected is consistent with the original equipment manufacturer's recommendation for the

equipment operating conditions and customer's maintenance practices.

26 June 2015

IO-85

13-45

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Steam Conservation Guide 101Documento59 páginasSteam Conservation Guide 101Arun KumarAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- HEI 2623 04 Standards For Power Plant Heat Ex Changers 4thDocumento88 páginasHEI 2623 04 Standards For Power Plant Heat Ex Changers 4thArun Kumar100% (2)

- Chimney Sizing Calculation-R1Documento3 páginasChimney Sizing Calculation-R1Arun Kumar67% (3)

- Chimney Sizing Calculation-R1Documento3 páginasChimney Sizing Calculation-R1Arun Kumar67% (3)

- Chimney Sizing Calculation-R1Documento3 páginasChimney Sizing Calculation-R1Arun Kumar67% (3)

- Fan Sizing VENTILATIONDocumento1 páginaFan Sizing VENTILATIONArun KumarAinda não há avaliações

- CastableDocumento8 páginasCastableManindra SinghAinda não há avaliações

- Mathesh - Meaning - Baby Name Mathesh Meaning and AstrologyDocumento4 páginasMathesh - Meaning - Baby Name Mathesh Meaning and AstrologyArun KumarAinda não há avaliações

- Feed Water Inter Connection SchemeDocumento1 páginaFeed Water Inter Connection SchemeArun KumarAinda não há avaliações

- Stainless Steel 422 Round BarDocumento2 páginasStainless Steel 422 Round BarArun KumarAinda não há avaliações

- Memo StyleDocumento3 páginasMemo StyleArun KumarAinda não há avaliações

- Expansion JointsDocumento10 páginasExpansion JointsArun KumarAinda não há avaliações

- Casting Material CF8M DATA SHEETDocumento9 páginasCasting Material CF8M DATA SHEETArun KumarAinda não há avaliações

- PID-0002 Heater SystemDocumento1 páginaPID-0002 Heater SystemArun KumarAinda não há avaliações

- Not For SaleDocumento1 páginaNot For SaleArun KumarAinda não há avaliações

- Fundamentals of Orifice Measurement Techwpaper PDFDocumento9 páginasFundamentals of Orifice Measurement Techwpaper PDFartletAinda não há avaliações

- IS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StorageDocumento98 páginasIS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StoragePankaj DhimanAinda não há avaliações

- Sno Service Pipe Material: 4. Non Ibr PipingsDocumento1 páginaSno Service Pipe Material: 4. Non Ibr PipingsArun KumarAinda não há avaliações

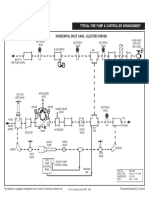

- ARM STRONG PUMP INTERLOCK HSC ElectricDocumento1 páginaARM STRONG PUMP INTERLOCK HSC ElectricArun KumarAinda não há avaliações

- Construction of Electric Plants - 2009Documento153 páginasConstruction of Electric Plants - 2009balwant singh negi100% (2)

- Construction of Electric Plants - 2009Documento153 páginasConstruction of Electric Plants - 2009balwant singh negi100% (2)

- Route Map PDFDocumento1 páginaRoute Map PDFArun KumarAinda não há avaliações

- Consolidated Startup CurvesDocumento3 páginasConsolidated Startup CurvesArun KumarAinda não há avaliações

- IS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StorageDocumento98 páginasIS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StoragePankaj DhimanAinda não há avaliações

- Flange Table ASME BS As ANSI DN200mmDocumento2 páginasFlange Table ASME BS As ANSI DN200mmArun KumarAinda não há avaliações

- Underground Fire Supply GuideDocumento11 páginasUnderground Fire Supply GuideArun KumarAinda não há avaliações

- Route MapDocumento1 páginaRoute MapArun KumarAinda não há avaliações

- Is 10221Documento31 páginasIs 10221Vinoth P50% (2)

- 5822Documento16 páginas5822rambinodAinda não há avaliações