Escolar Documentos

Profissional Documentos

Cultura Documentos

Power Line Communication

Enviado por

nipunkhatriDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Power Line Communication

Enviado por

nipunkhatriDireitos autorais:

Formatos disponíveis

AN NJAH NATIONAL UNIVERSITY

FACULTY OF ENGINEERING

ELECTRICAL ENGINEERING DEPARTMENT

Power line

communication

Remote control of electrical equipment

Prepared by; Amani Shelbayeh, Lara Nasser, Sawsan Salah

2009

Power line communication

This project is about control the electrical equipment remotely, by using the

FSK signal through the power line. We managed to control two devices in our

project.

Page

2

Power line communication

Table of Contents

1. Team and Acknowledgements

........................................................................... 3

1.1. Team

Members................................................................................................ 3

1.2.

Acknowledgements....................................................................................

...... 3

2.

Introduction................................................................................................

........ 3

2.1. Project

objective............................................................................................... 4

2.2. System

concept................................................................................................. 4

2.3. Transmitter

section.......................................................................................... 6

2.3.1. Control

panel................................................................................................. 7

2.3.2. Trigger

circuit

.. 7

2.3.3.

Microcontroller

8

2.3.4. VCO-Voltage Controlled Oscillator

............................8

2.3.5. Line Interface

Transformer 9

2.4. Receiver

section..............................................................................................11

2.4.1. Line Interface

Transformer..........................................................................12

2.4.2. Phase locked loop

12

2.4.3.

Microcontroller

.13

2.4.4. Relay

circuit

.13

Page

3

Power line communication

3. Source

codes......................................................................................................14

3.1. Transmitter

code............................................................................................14

3.2. Receiver code

................................................................................................17

4.

Conclusions................................................................................................

.......19

5. Further

scope....................................................................................................19

6.

Limitations..................................................................................................

......20

7. Circuits

schematics

21

7.1 transmitter

schematic.21

7.1.1. Trigger

circuit..

22

VCO .7.1.2

circuit

.23

MCU FSK Supervisor. .7.1.3

..24

line interface ..7.1.4

transformer.25

Receiver .7.2

side

26

Line interface .7.2.1

transformer27

Phase locked .7.2.2

loop28

MCU FSK .7.2.3

Supervisor.29

Project .8

hardware

.30

Appendix 1: list of

components..

Page

4

Power line communication

1. Team and Acknowledgements

1.1. Team Members

Our group for this project consisted of three undergraduate electrical

engineering students.

Amani Shelbayeh

Lara Nasser

Sawsan Salah

1.2. Acknowledgements

We would like to acknowledge the efforts and contributions made by the

lab technicians in the Electrical and Computer Engineering department

at the university. Namely: eng. Manar Qamheyeh and eng. Alaa AlDeen

Bani Odeh, eng. Nuha Odeh.

We would also like to thank Dr. Mazen Rasekh for his time and for

agreeing to take on this project. Thank you for your support in making

this project a success.

2. Introduction

Power line communication system can be defined as is a system for

carrying data on a conductor also used for electric power transmission.

Our project is based on the concept of digital transmission over ACpower lines.

This concept enables the remote control of electrical equipments via the

power line. In Industries, remote control by wireless control is very

difficult due the presence of high Electromagnetic interference.

Control by Optical means needs line of sight communication, which will

not be possible all the time.

Under circumstances, control by data transmission over power lines will

be the best option.

This concept will have applications in process control industries and in

places where the equipments to be controlled are many and are widely

spaced.

Moreover, this concept uses existing power lines for transmission of data

and thus does not involve any expenditure for the transmission medium.

This Project aims at implementation of such a Microcontroller based

remote control system by transmission of control data over the power

Page

5

Power line communication

lines. FSK line carrier modems are used for transmission of data over the

power line. The digital data to be transmitted modulates an FSK

generator for onward transmission over the power lines.

Line carrier modems transmits and receives digital data via electric

power lines instead of telephone lines or dedicated lines. The FSK

modems are interfaced to the power line via high frequency isolation

transformers.

Selective remote control means selection and operation of remotely

placed equipments from a common transmitter.

Some application areas of such a system

1) Industrial Controls

2) Domestic appliance Control

3) Street Light Control

4) Security system Control

2.1 PROJECT OBJECTIVE:

The project involves the design and development of selective remote

control system over AC power lines as the communication channel. The

system will be designed around the microcontroller AT89C2051. The

system will be designed to operate with single phase power line. For

interface with Three- phase power lines, only the line interface circuit

needs to be modified using three phase transformer.

2.2. System Concept

Selective remote control means, selecting one of the remotely placed

equipments and operating it from another centralized location.

In our project, two remotely placed equipments will be used; we will

express them by using two lamps.

To identify these remotely placed units, an address has to be assigned to

each of the units. Any eight bit word ranging from 00h to FFh can be

used as addresses for these remote units. This eight bit word is used as

address for the transmission from the transmitter to the receiver.

Asynchronous serial communication protocol is used in the system.

UART port of the microcontroller is used for this purpose.

To operate the remotely placed units, a selector switch at the

transmitter selects one of the units. This selector switch enables one of

the port pins of the microcontroller. When the Push to Start switch is

operated, a serial data communication process is initiated by the

Page

6

Power line communication

microcontroller, wherein the address of the unit selected is transmitted

as FSK signal over the power line. Once this data is transmitted, it will be

available at all points wherever the power lines runs.

The FSK signal is generated using a voltage controlled oscillator-VCO.

The input to the VCO is from the serial output port of the MCU.

The VCO generates two distinct frequencies corresponding to 1s and 0s

of the input data. A 60 kHz signal is generated for logic0 and 75 kHz

for logic 1.

This FSK data is coupled to the power line through a high frequency

transformer after suitable amplification.

The receiver at the remote location receives this FSK information

through a line interface circuit coupled to the power line. The output of

the interface circuit is fed to a Phase Locked Loop. The PLL demodulates

the FSK signal. The output will be a serial digital bit stream

corresponding to the one transmitted at the transmission end.

The recovered serial data is fed to the serial communication input port

of the MCU. The MCU decodes the received data and recovers the

transmitted address. This address is compared with all the addresses of

the units to be controlled. When a match is found, that particular unit is

switched ON using a relay circuit. The output of the MCU toggles the

relay circuit. Hence the address transmitted for the first time switches

ON the selected unit, and the same address transmitted second time

switches OFF the unit

.

Page

7

Power line communication

2.3. Transmitter Section

Page

8

Power line communication

2.3.1. Control Panel

The control panel has the following controls

1) System on/ off switch

2) Selector switches to select the equipment to be controlled.

3) Push switch to switch on / off the selected unit.

4) LEDs to indicate the various operating modes.

2.3.2. Trigger Circuit

A monostable circuit is used for generating trigger pulse for the MCU.

Whenever the Push switch is operated, this circuit generates the trigger

pulse.

This pulse is sensed by the Microcontroller and acts upon it as

programmed.

This circuit generates a negative going pulse to trigger the MCU.

The monostable used is IC CD4047.

The output is fed to the Microcontroller through the 2-position selector

switch on the front panel.

The output of monostable circuit also toggles a D- flip flop to drive a

LED. Whenever the Microcontroller is triggered, this LED glows.

Page

9

Power line communication

Figure- The output from the trigger circuit

2.3.3. Microcontroller

The microcontroller accepts input from the control panel. The output of

the control panel has two output points. These two outputs correspond

to the two units to be controlled & are connected to two input ports of

the microcontroller. The control panel outputs a pulse signal for each of

the unit selected. Whenever the MCU senses this pulse, it selects the

proper address and converts it to serial format for transmission through

its serial port.

Microcontroller Circuit

The system incorporates the Microcontroller AT89C2051 for controlling

the serial communication over the power line.

Port pins P1.0 and P1.1 are used as input port pins for two units to be

remote controlled. The selector switch is connected to the port pins

referred above.

The serial output data from the MCU is available at connector J5. The

output at J5 is connected to the VCO circuit to generate the FSK signal.

The MCU circuit is same for Tx and Rx. In the Tx section only that portion

applicable to the transmitter is used.

Page

10

Power line communication

2.3.4. VCO-Voltage Controlled Oscillator

The VCO accepts serial data as input and outputs FSK signal. When logic

0 is present at the input, it generates 60 kHz signal.

When logic 1 is present at its input, it generates 75 kHz signal.

Hence the output of VCO will be serial FSK data. The IC CD4046 is used

for this purpose.

VCO Circuit

This circuit generates the FSK signal. The input to this circuit is from the

MCU in the form of serial data.

The VCO is built around the IC U6, CD 4046. The output from MCU is fed

to the control input of the VCO

The free running frequency of the VCO is decided by the combination of

C10, R18, R19, R20 and R21. The output of the VCO is buffered by the

emitter follower Q4 .

The output of the VCO feeds the line interface circuit.

Figure : the output from VCO

2.3.5. Line Interface Transformer

-

Line Interface Amplifier

Page

11

Power line communication

The FSK signal generated by the VCO is amplified by a linear amplifier to

increase the level to suitable amplitude for interface.

-Transformer

This is a high frequency ferrite transformer which will interface the FSK

signal to the power line. It provides the basic isolation due to the use of

separate windings for primary and secondary.

There will be no reverse coupling from the power line to the system,

since the high frequency transformer will not develop any magnetic field

at 50 Hz, which is the line frequency.

Line Interface Circuit

This circuit performs the function of interfacing the output of VCO to the

mains power line. The basic interfacing is done through a high frequency

isolation transformer.

The FSK from VCO is fed to base of Q1 through R1. Capacitor C1 is used

to decrease the switching time of Q1. Transistor Q1 is driver stage. R2 is

used for discharging the base stored charge which in turn will reduce the

switch off time of Q1. R3 is the load resistor. The amplified output at Q1

collector is fed to the base of power transistor Q2. R5, D1 and D2 are

used to provide discharge path for the base stored charge. Transformer

T1 is the driver and isolation transformer for the FSK signal. C4 is the

tuning capacitor and also removes any spurious signal. The induced

signal in the secondary of the transformer is coupled to the mains line

through the coupling capacitors C5 and C6. These capacitors provide a

low impedance path for the high frequency FSK signal. At the same time

these capacitors presents high impedance to the 50Hz mains frequency.

Moreover, the secondary of T1 acts as a short for 50Hz mains frequency

and as a normal secondary for the high frequency FSK signal. Thus no

reverse voltage from mains line is induced into the circuit. The mains

line is connected to J3.C2, C3, C15, C16 are supply bypass capacitors.

After coupling the FSK signal to the power line, the FSK signal will be

available at all points wherever the power line runs and the receiver can

be connected at any convenient point.

Page

12

Power line communication

2.4. Receiver Section

Page

13

Power line communication

2.4.1. Line Interface Transformer

Page

14

Power line communication

The line interface transformer at the receiver detects the FSK signal and

feeds it the receiver section. This transformer will be exactly the same

as used at the transmitter end.

Receiver Line Interface

Refer to the LINE INTERFACE schematic diagram.

The FSK signal received from mains power line. This signal is fed to the

primary of the isolation Transformer T2 through coupling capacitors C8

and C9.The induced signal at the secondary of T2 is fed to the amplifier

transistor Q3 through C10. R8, R9 and C9 form an attenuating network

to reduce the signal to a lower level to prevent over loading of Q3. R10,

R11, R12 and R13 are the biasing resistors for Q3. The amplified output

at collector of Q3 is fed to base of Q4 through R14 and C11. A square

wave signal of about 2v-pp of frequency of the incoming FSK signal will

be available at collector of Q4. Resistor R15 and R17 are used as

potential divider for the output signal to limit the level to 2v-pp. The final

output of the circuit is available at connector J4. C12 and C13 are supply

bypass capacitors.

2.4.2. Phase Locked Loop

The PLL decodes the FSK signal output of the pulse shaper and produces

a serial data corresponding to the one transmitted at the transmitter

end. When 60 kHz signal is received, the output will be logic 0. When 75

kHz signal is received, the output will be logic 1. This serial data output

is fed to the receive microcontroller for further decoding.

IC LM567 is the PLL

The free running frequency of the PLL is tuned to 75 khz. The

combination of C17, R25 and preset P2 decides this frequency. In the

absence of valid input frequency. The output of the PLL is logic high.

When the valid frequency is received, the output will go from high to

low. The output from the PLL will be an exact replica of serial output at

the transmitter MCU.

The output of the PLL decoder is fed to the MCU circuit via an opto

isolator. The opto isolator used to prevent interference to the MCU via

the power line.

Page

15

Power line communication

2.4.3. Microcontroller

The output of the PLL is fed to serial receive input port of microcontroller

AT89C2051. The received serial data is stored in one of the registers of

the MCU. The MCU holds the addresses of the units to be controlled. The

received data is compared with these addresses. One of the stored

address matches with the received data. When this match is found, the

particular port of MCU assigned to that particular unit will drive an opto

coupler, which in turn will drive the selected unit.

MCU Receiver

Refer to the schematic MCU FSK Supervisor.

This circuit receives the serial data from the decoder and drives the

proper Relay circuits to operate the remotely placed units.

The circuit receives the data at connector J5, which is the serial input

COM port of the MCU.

In the receive section port P1 is the output port. The output port drives

three relay circuits corresponding to the three units. The received data

is decoded by the MCU and it compares the received data with the local

addresses of the three units. When the match is found, that particular

relay is switched ON. The output contacts of the relay switches ON

the selected unit to the power line. The output port pins also drives

LEDs DS3, DS4 and DS5 to the activation of relays K1, K2 and K3.

The output port of the MCU is connected to the relay circuits through

opto isolators to prevent interference from relay circuit back into the

MCU circuit. The output of port pins will be high normally. This in turn

will ensure logic high at the input of relay drive buffer IC CD 4049, circuit

reference U7. The output of U7 will be low and the relay is not operated.

When a valid data is received, the output of MCU will go low and this in

turn will make the output of the buffers high. This high level will switch

ON the relay through transistors Q1, Q2 and Q3.

2.4.4. Relay Circuit

Page

16

Power line communication

Relay circuits provide drive to the relays. Discrete transistors are used

for this purpose. The NO (normally open) contact of relays is connected

to the power socket of different units. Whenever a relay operates, the

respective socket is switched on, and the connected unit is controlled.

3. Source Codes

The source code is in assembly language and used for transmitter and

receiver microcontrollers are given in this chapter.

3.1. Transmitter Code

;Program for FSK-Tx remote controller.Rev01

;Will have four switches at transmitter end

org 0000h

sjmp 0030h ;Clear vector table

org 0030h

mov a,#00h ;clear acc

mov p1,#0ffh ;make port p1 an input port

mov scon,#40h ;serial mode1, receive disabled

mov tmod,#20h ;timer1.mode2, 8 bit autoreload

mov th1,#-240 ;baud rate 150

setb tr1 ;start timer

begin:

jb p1.3,next1 ;check SW3 for logic low at pin 14

acall delay1 ;wait for a short period

jb p1.3,next1 ;if p1.2 has gone high, goto next1

mov a,#2ah ;move code 2A to acc, SW3-code

mov sbuf,a ; start sending SW3-code

wait1:

Page

17

Power line communication

jnb ti,wait1 ;wait for end of transmission

clr ti ;clear TI bit

acall delay2 ; delay before sensing next switch

sjmp begin ;go back to beginning

next1:

jb p1.4,next2 ;check SW4 at pin 15 for logic low

acall delay1 ;monitor low level for some time

jb p1.4,next2 ;if p1.3 is high goto next SW 5

mov a,#3bh ;load code 3B to acc, code for SW4

mov sbuf,a ;start sending SW4 code

wait2:

jnb ti,wait2 ;wait till end of transmission

clr ti ;clear TI flag

acall delay2

sjmp begin

next2:

jb p1.5,begin ;check SW5 at pin 16for logic low

acall delay1

jb p1.5,begin

mov a,#4ch ; 4C is the code for SW5

mov sbuf,a ;start sending SW5 code

wait3:

jnb ti,wait3 ;wait for end of transmission

clr ti

acall delay2

sjmp begin ;go to begin

Page

18

Power line communication

; DELAY SUB ROUTINES

delay1:

mov r2,#40 ;outer loop counter

again:

mov r3,#250 ;inner loop counter

stay: djnz r3,stay

djnz r2,again

ret

delay2:

mov r4,#05 ;outer loop2 counter

once: mov r5,#255 ;outer loop1 counter

back: mov r6,#255 ;inner most loop counter

hold: djnz r6,hold

djnz r5,back

djnz r4,once

ret

end

Page

19

Power line communication

3.2. Receiver Code

;ASM program Line FSK remote receiver

org 0000h

sjmp 0030h ;bypass vector lookup table

org 0030h

mov a,#00h ;clear acc

mov p1,#0ffh ;make all port-1 pins high

mov scon,#50h ;serial mode1,receive enable

mov tmod,#20h ;timer1, mode2, auto reload

mov th1,#-240 ;select baud rate-150

setb tr1 ;start timer

begin:

clr ri ;clear RI initially

here:

jnb ri,here ;monitor RI for received data

mov a,sbuf ;copy Rx data to acc

cjne a,#2ah,next1 ;If not equal check next code

cpl p1.0 ; if equal toggle p1.0, relay K1

; operates and unit U1 switches ON

cpl p1.3 ;p1.3 is low and DS3 glows

clr ri ;clear receive interrupt, ri should

;not be cleared till all codes

;are checked

sjmp begin

next1:

Page

20

Power line communication

cjne a,#3bh,next2 ;if not equal check next code

cpl p1.1 ; if equal, toggle p1.1,relay K2

; operates and U2 switches ON

cpl p1.4 ;make p1.4 low,DS4 glows

clr ri ;clear ri to receive next byte

sjmp begin

next2:

cjne a,#4ch,begin ;if not equal check next code

cpl p1.2 ;if equal, toggle p1.2, relay K3

; operates and U3 switches ON

cpl p1.5 ;make p1.5 low,DS5 glows

clr ri

sjmp begin

;delay sub-routine

delay: mov r2,#250 ;load outer loop counter

back: mov r3,#250 ;load inner loop counter

stay: djnz r3,stay

djnz r2,back

ret

end

Page

21

Power line communication

4. Conclusion

This project simply demonstrates the capability of transmission of digital

data over power lines which have been traditionally used to transmit low

frequency analog signals. This is achieved by modulating the digital

signal using FSK modulation technique and thus transmitting digital data

at higher frequencies. This project thus just demonstrates the basic idea

which can be further improved upon so as to be used in various

applications.

The limitation of this project is that it will successfully transmit data only

over a single same phase power line thus restricting the range of

transmission. With some additional hardware, we can achieve data

transmission over all three phases of power lines thus enabling the

transmission over a greater range. Once that is achieved, this concept

can be used in various applications like home automation, home

networking, street lighting, security system control, control of various

remote devices in industry and even internet access.

5. Further Scope

Greater research in the area of transmission of digital signals over power

lines will definitely enable us to come up with various applications of the

concept. The biggest application of this concept though could be

Internet Access over the Power Lines. In todays world where access to

information on the move has become an essential part of life to survive

in the world which moves at cut throat pace, digital transmission over

power lines might enable us this access through any of the millions of

power socket in the world. This would enable us to access the internet

from any location with power supply. The device to be used to access

the internet could be simply plugged into the power socket for ready to

use Plug and Play Internet access. This will of course require us to

update the hardware associated with the power lines as now we will

have to include routers at transformer sections. Besides this we will

have to connect these power lines to the servers. Protocols and

standards for the same will have to be developed if this technology has

to be implemented on a commercial scale.

Internet access could also be made possible by the setting up of Wi-Fi

Hot spots at areas close to transformers. Thus diligent effort in this field

just might enable us to access information through the internet in a

whole new way and Cable and DSL technologies just might become

Page

22

Power line communication

completely redundant as the ubiquitous power lines itself will provide us

the gateway to the warehouse of information-the Internet.

6. Limitations

Although the prospects for the implementation and use of this

technology seem bright but there are a few limitations with this concept

which would have to be dealt with before its commercial application.

1) The biggest problem that digital data transmission over power lines

encounters is the radio interference. Since the power lines are usually

uncovered, unshielded and untwisted, they might act as antennas and

would thus radiate a large amount of radio energy. This would lead to

great interference with the other radio signals being transmitted at the

same time. The reverse process would also be affecting the signals

being sent over the power lines and thus lead to interference in the data

transmission.

2) The power line cable, unlike any other broadband medium (copper

twisted pair, fiber, coaxial cable), is inherently unsuited for carrying the

frequencies BPL uses. Power lines, copper twisted pair, and coaxial cable

all act like natural low pass filters, meaning higher frequencies are

attenuated more than lower frequencies when attempting to transmit

them through the medium.

Power lines are designed to carry electrical power. They were not

designed to carry radio signals. They do this very poorly, loosing much of

the signal to losses. Another major problem would be faced when data

will have to be sent over the numerous transformers. The transformers

being high inductance devices will act as low pass filters allowing only

the low frequency components to pass through while blocking the higher

frequency signals. We will thus have to use greater number of repeaters

in the communication channel.

3) The last problem to be faced would be the same faced by all new

technologies the absence of any standard protocols. For the technology

to a success and for large scale implementation, a body such as IEEE

Page

23

Power line communication

would have to come forward with a set of rules or standards for digital

data transmission over power lines.

This would allow various equipment manufacturing companies to

produce equipment conforming to the standard valid over all countries

and the service providers to transmit and receive data as per a fixed

protocol.

Once solutions to these limitations are found, this technology can be

used for various commercial applications as mentioned in the section

above.

7. Circuits Schematics:

TRANSMITTER

SIDE

CIRCUIT

SCHEMATICS

Page

24

Power line communication

TRIGGER CIRCUIT

VCC

C1

VC C

R2

1

R4

14

SW 1

1

11

10

13

12

7414

R6

2

3 RX

13

6 RCC OSC

-T

12

RET

4

8 AST

+T

VCC

10

Q 11

Q

14

9

RST 5

AST 7

GND

3

R5

C3

C LK

R

6

5 S

D

4013

VDD

J1

1

Page

25

D1

LED

2

Q1

R7

4047

R3

C4

U3

CX

U 2A

14

U1

C2

VD D

VC C

R1

Power line communication

VCO CIRCUIT

J1

1

2

C1

CAP NP

6

5

4

M C T2E

CONN PCB 4

C2

C AP

R1

U2

R E S IS T O R

9

3

14

R3

U3

6

5

C3

CAP NP R4

R5

4

M C T2E

R8

R

R 10

R E S IS T O R

R 11

Q5

1R 1001

Page

26

6

7

11

12

5

16

U1

V C O IN V C O U T

VD D

C IN

S IN

C

C

R

R

P1

P2

P3

PP

1A

1B

1

2

DEMO

IN H

vss

1

2

3

R9

R

4046

J2

4

2

13

15

1

10

J3

Q6

1R 1001

C4

R6

R

R7

R CAP NP

1

2

C ONN PCB 4

Power line communication

MCU FSK SUPERVISOR

J4

1

2

C5

R 12

R 13

R 14

R 15

CON2

C6

J5

D1 D3

1

2

3

J6

D2

D4

U3

1

2

3

VCC

R S T/V P P

J7

1

2

3

4

5

6

J8

4

3

2

1

XTA L2

XTA L1

11

9

8

7

6

3

2

P

P

P

P

P

P

P

3 .7

3 .5 /T 1

3 .4 /T 0

3 .3 /IN T 1

3 .2 /IN T 0

3 .1 /T XD

3 .0 /R XD

P 1 .7

P 1 .6

P 1 .5

P 1 .4

P 1 .3

P 1 .2

P 1 .1 /A IN 1

P 1 .0 /A IN 0

20

C7

1

4

5

19

18

17

16

15

14

13

12

C8

R 16

5v

J9

C9

4

3

2

1

C O N N TR BLK 4

AT89C 2051

CON4

Page

27

Power line communication

LINE INTERFACE CIRCUIT

J1

2

1

C 1

C 2

J2

VC C

1

2

C 4

R 2

C 5

C 9

C 6

C 7

R 3

R 4

1

2

U 2

D 1

D 2

R 5

R 6

D 3

0

0

Page

28

T1

C 3

2

6

TR N SF M R 29873

U 1

J4

J3

2

1

R 1

C 8

Power line communication

RECEIVER

SIDE

CIRCUIT

SCHEMATICS

Page

29

Power line communication

LINE INTERFACE CIRCUIT

VCC

C1

R2

R4

C4

1

2

R8

C7

C5

T1

J2

R3

0

C3

R1

J1

R5

2

1

U1

C6

U2

R9

C2

R 10

R7

R 11

R 12

TR N SF M R 67109510

R 13

C8

0

0

0

Page

30

C O N N TR B LK 2

R6

Power line communication

PHASE LOCKED CIRCUIT

J4

HI

1

2

V IN

VOUT

CON2

GND

U1

J2

R8

+

R E S IS T O R

C 14

CAP NP

C 13

CAP POL

C 10

CAP NP

+ C 12

CAP POL

R2

R E S IS T O R

1

6

5

LM 567

R7

R E S IS T O R

R6

C 16

CAP NP

4

M C T2E

O U T F IL

R4

POT

TC

O U TPU T

TR

+V C C

IN P U T

GND

CAP NP

LF IL

R 11

R E S IS T O R

1

2

CON2

U3

C1

J3

U2

C 17

CAP NP

C 18

C AP NP

C2

CAP NP

Page

31

1

2

3

CON2

Power line communication

MCU FSK SUPERVISOR

3

4

1

2

R3

1

R2

U3

G 6 R N -S P D T _ 1

R4

6

5

U 2A

U4

4049

1

2

3

5v

R5

J2

M C T2

J5

3

2

1

5v

R L6

R7

12v

5v

4

R8

U6

6

5

J20

1

2

3

4

5

U7

1

2

R9

U 2B

5

G 6 R N - S P D T _ 1J 4

3

2

1

R 10

4049

M C T2

C8

C O N N TR BLK 5

D5

R 11

R 12

R 13 R 14

C9

J7

D7 D9

1

2

3

J9

D8

D 10

J8

1

2

3

U8

1

2

3

VCC

R S T /V P P

J10

XTA L2

XTA L1

1

2

3

4

5

6

11

9

8

7

6

3

2

P

P

P

P

P

P

P

3 .7

3 .5 /T1

3 .4 /T0

3 .3 /IN T 1

3 .2 /IN T 0

3 .1 /TXD

3 .0 /R XD

P 1 .7

P 1 .6

P 1 .5

P 1 .4

P 1 .3

P 1 .2

P 1 .1 /A IN 1

P 1 .0 /A IN 0

20

C 10

4

5

19

18

17

16

15

14

13

12

R L5

vcc

1

C 11

R 15

4

5v

1

2

12v

0

C 12

AT89C 2051

R 16

U9

R 17

6

5

4049

M C T2

Page

32

U 2C

G 6 R N -S P D T _ 1

D 11

R 18

6

R 19

U 10

Power line communication

Project

hardware

Page

33

Power line communication

Appendix

LIST OF

COMPONENTS

Page

34

Power line communication

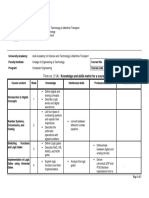

Trigger MCU

Sl No.

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

capacitor

capacitor

capacitor

capacitor

resistor

resistor

resistor

resistor

resistor

resistor

resistor

18

LED

Connector

junction

switch

Circuit

reference

C1

C2

C3

C4

R1

R2

R3

R4

R5

R6

R7

U1

U2

U3

Q1

D1

J1

Value

1000uF

0.22uF

10uF

0.1uF

470 ohms

470 ohms

6K8

820K

47K

470 ohms

22K

4047

4013

7414

BC547

Sw1

VCO

Sl. No.

Description

1

2

3

4

capacitor

capacitor

capacitor

capacitor

Circuit

Reference

C1

C2

C3

C4

Page

35

Value

0.1uF

100uF

1000pF

s.c

Power line communication

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

resistor

resistor

resistor

resistor

resistor

resistor

resistor

resistor

resistor

R1

R2

R3

R4

R5

R6

R7

R8

R9

U1

U2

U3

J2

Jumper

Connector

Jumper

Connector

Potentiometer

15K

12K

s.c

12K

1K

47K

6K8

12K

1K

MCT2E

MCT2E

4046

J1

P1

Q

5K preset

PLL: Receiver

Sl. No.

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

capacitor

capacitor

capacitor

capacitor

resistor

resistor

resistor

resistor

resistor

14

15

16

Jumper

Connector

Jumper

Connector

Jumper

Connector

Potentiometer

Circuit

Reference

C1

C2

C3

C4

R1

R2

R3

R4

R5

U1

U2

U3

J2

J1

J3

P1

Page

36

Value

0.1uF

100 uF

47uF

0.1uF

120K

10K

1K

47K

120K

78L05

MCT2E

8PIN-567

Power line communication

MCU FSK Transmitter

Sl. No.

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

capacitor

capacitor

capacitor

capacitor

capacitor

Resistor

Resistor

Resistor

Resistor

Resistor

Red LED

Red LED

Red LED

Red LED

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

crystal

microcontroller

16

17

18

19

20

21

22

Circuit

Reference

C5

C6

C7

C8

C9

R12

R13

R14

R15

R16

D1

D2

D3

D4

J4

Value

47uF

0.1uF

2.2pF

3.3pF

3.3pF

470 ohms

470 ohms

470 ohms

470 ohms

47K

2pins

J5

3pins

J6

3pins

J7

6pins

J8

4pins

J9

4pins

20 pin

ZIF

Line Interface Circuit: Transmitter

Page

37

Power line communication

Sl. No.

Description

1

2

3

capacitor

capacitor

capacitor

4

5

6

7

capacitor

capacitor

capacitor

capacitor

C4

C5

C6

C7

capacitor

C8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Circuit

Reference

C1

C2

C3

capacitor

resistor

resistor

resistor

resistor

resistor

resistor

Jumper Connector

Jumper Connector

Jumper Connector

Jumper Connector

diode

diode

diode

Pulse transformer

Transistor

Transistor

C9

R1

R2

R3

R4

R5

R6

J1

J2

J3

J4

D1

D2

D3

1002C

U1

U2

Value

0.1uF

100uF

0.22/400v(Oran

ge)

100uF

0.1uF

0.01uF

22KGreen(223K)

0.22/400v(Oran

ge)

1000uF

12K

1K5

47 ohm

12K

47K

12K

2pins

2pins

2pins

2pins

4148

4148

4148

MJE3055

BC 547

Line Interface Receiver

Sl. No.

Description

1

2

3

4

5

6

7

8

9

10

11

12

capacitor

capacitor

capacitor

capacitor

capacitor

capacitor

capacitor

resistor

resistor

resistor

resistor

resistor

Circuit

Reference

C1

C2

C3

C4

C5

C6

C7

R1

R2

R3

R4

R5

Page

38

Value

100uF

0.1uF

0.01uF

0.22uF

o.c

0.01uF

0.22uF

5K6

4K7

6K8

5K6

3K9

Power line communication

13

14

15

16

17

18

19

20

21

22

23

24

25

resistor

resistor

resistor

resistor

resistor

resistor

resistor

resistor

Jumper

Connector

Jumper

Connector

Pulse

transformer

Transistor

Transistor

R6

R7

R8

R9

R10

R11

R12

R13

J1

J2

47K

4K7

2K7

2K2

12K

2K7

2K2

2K2

2pins

2pins

1002C

U1

U2

BC 547

BC 547

MCU FSK Receiver

Sl. No.

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

capacitor

capacitor

capacitor

capacitor

capacitor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Red LED

Red LED

Red LED

Red LED

Circuit

Reference

C5

C6

C7

C8

C9

R2

R3

R4

R5

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

D1

D2

D3

D4

Page

39

Value

47uF

0.1uF

2.2pF

3.3pF

3.3pF

12K

470 ohm

10K

47K

470 ohm

12K

10K

47K

12K

470 ohms

470 ohms

470 ohms

470 ohms

47K

470 ohm

10K

47K

Power line communication

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Jumper

Connectors

Relay Sugar

Cube

Relay Sugar

Cube

Relay Sugar

Cube

J2

3pins

J7

3pins

J9

3pins

J10

6pins

J8

3pins

J4

3pins

J5

3pins

J20

5pins

16 Pin 4049

crystal

microcontroller

U8

41

42

43

44

45

46

U3

U6

U9

U4

U6

U10

Page

40

20 pin

ZIF

6 Pin MCT2

6 Pin MCT2

6 Pin MCT2

100N

100N

100N

Power line communication

Page

41

Você também pode gostar

- Power Line Communication TechniqueDocumento6 páginasPower Line Communication TechniqueVikas AsodariyaAinda não há avaliações

- Transient Stability Analysis Transient Stability Analysis: by Prof. C. Radhakrishna by Prof. C. RadhakrishnaDocumento32 páginasTransient Stability Analysis Transient Stability Analysis: by Prof. C. Radhakrishna by Prof. C. RadhakrishnaakemaladinAinda não há avaliações

- Sew Motor EurodriverDocumento361 páginasSew Motor EurodriverJosma IseaAinda não há avaliações

- Energetski Pretvaraci 1 13E013EP1Documento127 páginasEnergetski Pretvaraci 1 13E013EP1Zoran LalkovicAinda não há avaliações

- Master RadDocumento68 páginasMaster Radzlajaar4081Ainda não há avaliações

- Line Distance Protection 511Documento38 páginasLine Distance Protection 511sayedmhAinda não há avaliações

- Biopotential AmplifiersDocumento15 páginasBiopotential AmplifiersJesus PeñaAinda não há avaliações

- Monte Carlo Simulation of Solar CellsDocumento12 páginasMonte Carlo Simulation of Solar Cellsmani_vlsiAinda não há avaliações

- Chap1 2 3Documento14 páginasChap1 2 3reza_powerAinda não há avaliações

- Electronics Measurements and Instrumentation Ebook & NotesDocumento94 páginasElectronics Measurements and Instrumentation Ebook & NotesGunjan JhaAinda não há avaliações

- Understanding Servo Motors and Their ApplicationsDocumento14 páginasUnderstanding Servo Motors and Their ApplicationselecenggAinda não há avaliações

- Kompenzacija Reaktivne Snage - Uticaj Visih Harmonika Na Kondenzatorske BaterijeDocumento14 páginasKompenzacija Reaktivne Snage - Uticaj Visih Harmonika Na Kondenzatorske BaterijeMahir Muratovic100% (2)

- Course Outline: 1. Introduction To WECC 2. Fundamentals of ElectricityDocumento51 páginasCourse Outline: 1. Introduction To WECC 2. Fundamentals of ElectricityWoldemariam WorkuAinda não há avaliações

- Experiment 4 - Three Phase Uncontrolled RectifierDocumento13 páginasExperiment 4 - Three Phase Uncontrolled RectifierAaaa DdddAinda não há avaliações

- Novel Switching Sequences For A Space Vector Modulated Three Level Inverter-LibreDocumento11 páginasNovel Switching Sequences For A Space Vector Modulated Three Level Inverter-LibreHollie RosaAinda não há avaliações

- Seminarski Rad (Aidm) v2 KomentariDocumento52 páginasSeminarski Rad (Aidm) v2 KomentariRebecca Bradford0% (1)

- Variable Frequency Drive : Ravikumar .M M.Tech 3 SEM C.A.I.DDocumento22 páginasVariable Frequency Drive : Ravikumar .M M.Tech 3 SEM C.A.I.Davi013Ainda não há avaliações

- Using PIC Microcontrollers to Control Triacs PhaseDocumento22 páginasUsing PIC Microcontrollers to Control Triacs PhaseMarko Lukic100% (1)

- Electrical Technology Chapter SummariesDocumento200 páginasElectrical Technology Chapter Summariesmjaji khulehAinda não há avaliações

- SVPWM PDFDocumento5 páginasSVPWM PDFmauricetappaAinda não há avaliações

- Estimation of Enob of A D Converter Using Histogram Test TechniqueDocumento8 páginasEstimation of Enob of A D Converter Using Histogram Test TechniqueIAEME PublicationAinda não há avaliações

- Basics of FACTS DevicesDocumento16 páginasBasics of FACTS Devicesbrijendra21Ainda não há avaliações

- Baldor Basics PDFDocumento6 páginasBaldor Basics PDFSHUBHAM SINHAAinda não há avaliações

- Ec 2252 Communication Theory Lecture NotesDocumento120 páginasEc 2252 Communication Theory Lecture NotesAnonymous G4srxwO3jIAinda não há avaliações

- 5 Paper - Load BlinderDocumento9 páginas5 Paper - Load BlindermubarakkirkoAinda não há avaliações

- Multi-Motor DrivesDocumento6 páginasMulti-Motor DrivessriabolfazlAinda não há avaliações

- Universal Motor - WikipediaDocumento27 páginasUniversal Motor - WikipediaAlejandro ReyesAinda não há avaliações

- Real European Low Voltage Test Network For Smart Grid ApplicationsDocumento100 páginasReal European Low Voltage Test Network For Smart Grid ApplicationsDavid Jose Poma GuillenAinda não há avaliações

- ANFISDocumento19 páginasANFISShimaa Barakat100% (1)

- VSB: Vestigial Sideband ModulationDocumento5 páginasVSB: Vestigial Sideband Modulationi1019117Ainda não há avaliações

- Lec 13 PDFDocumento15 páginasLec 13 PDFkapil chander100% (1)

- Emf Equation of AlternatorDocumento2 páginasEmf Equation of AlternatorThe Engineers EDGE, CoimbatoreAinda não há avaliações

- ISIP Skripta - Asinhroni Prenos RS232 I RS485Documento14 páginasISIP Skripta - Asinhroni Prenos RS232 I RS485Dragan LazicAinda não há avaliações

- SCR and Thyristor Triggering Methods and Commutation TechniquesDocumento14 páginasSCR and Thyristor Triggering Methods and Commutation TechniquesmalathynarayaniAinda não há avaliações

- Vsi Csi With Various LoadsDocumento56 páginasVsi Csi With Various LoadsDeependra RastogiAinda não há avaliações

- OkanDocumento20 páginasOkanGökhan YüksekAinda não há avaliações

- Microconverter 12-Bit Adcs and Dacs With Embedded High Speed 62-Kb Flash Mcu Aduc841/Aduc842/Aduc843Documento88 páginasMicroconverter 12-Bit Adcs and Dacs With Embedded High Speed 62-Kb Flash Mcu Aduc841/Aduc842/Aduc843qhan90100% (1)

- Chapter 12Documento23 páginasChapter 12sachin235Ainda não há avaliações

- Maintaining the Measurement CellDocumento31 páginasMaintaining the Measurement CellBryan Navarro Ojeda100% (1)

- Sime Format 24 System Boiler InstDocumento36 páginasSime Format 24 System Boiler InstJer CotterAinda não há avaliações

- Circuit Breaker Characteristics in Medium Voltage EquipmentDocumento121 páginasCircuit Breaker Characteristics in Medium Voltage EquipmentquangspktAinda não há avaliações

- Circuit BreakerDocumento86 páginasCircuit BreakerShashidhar KasthalaAinda não há avaliações

- Fuzzy Logic Control of Three Phase Induction Motor: A ReviewDocumento3 páginasFuzzy Logic Control of Three Phase Induction Motor: A ReviewInternational Journal of Innovative Science and Research Technology100% (1)

- Module 1 Lecture 1 - 4Documento17 páginasModule 1 Lecture 1 - 4ukassyahAinda não há avaliações

- MT831 Installation ManualDocumento92 páginasMT831 Installation ManualmamijatoAinda não há avaliações

- Practical ExamDocumento2 páginasPractical ExamIrfan AliAinda não há avaliações

- Major ReportDocumento43 páginasMajor ReportPrashant BaliaAinda não há avaliações

- V25 GB PDFDocumento143 páginasV25 GB PDFStefan CiobotariuAinda não há avaliações

- Power Line Communication - PDFDocumento268 páginasPower Line Communication - PDFAzamkhon Saidilakhanov100% (1)

- Electronic Circuits (Unit 3) - Feedback Amplifiers Handwritten Notes Material Uploaded byDocumento45 páginasElectronic Circuits (Unit 3) - Feedback Amplifiers Handwritten Notes Material Uploaded bySri watsa JiAinda não há avaliações

- Fault Detection On Radial Power DistributionDocumento15 páginasFault Detection On Radial Power DistributionJuan CarlosAinda não há avaliações

- Solid State Drives Short BookDocumento48 páginasSolid State Drives Short BookGomathi Raja MAinda não há avaliações

- Motion Sensors: BY:Abdulaziz Moosa & Peshkaft Hussein Superviced By: JawahirDocumento20 páginasMotion Sensors: BY:Abdulaziz Moosa & Peshkaft Hussein Superviced By: Jawahirabdulazizmoosa93Ainda não há avaliações

- MASTER RAD Ivan Subotic PDFDocumento82 páginasMASTER RAD Ivan Subotic PDFpero1111Ainda não há avaliações

- NETWORK ANALYSIS Chap.8 TWO PORT NETWORK & NETWORK FUNCTIONS PDFDocumento34 páginasNETWORK ANALYSIS Chap.8 TWO PORT NETWORK & NETWORK FUNCTIONS PDFsudarshan poojaryAinda não há avaliações

- Seminarski SksDocumento34 páginasSeminarski SksEdinBandović100% (1)

- Real-Time Simulation Technology for Modern Power ElectronicsNo EverandReal-Time Simulation Technology for Modern Power ElectronicsAinda não há avaliações

- Power Line Communication: Remote Control of Electrical EquipmentDocumento39 páginasPower Line Communication: Remote Control of Electrical Equipmentsana parveen kAinda não há avaliações

- Substation Monitoring System: Prof. Kunal V.Ranvir, Mayuri A. Solanke, Rohit P. Ratnaparkhi, Ashvini N. SableDocumento3 páginasSubstation Monitoring System: Prof. Kunal V.Ranvir, Mayuri A. Solanke, Rohit P. Ratnaparkhi, Ashvini N. SableerpublicationAinda não há avaliações

- Communication Antenna Switching System Based On Micro ControllerDocumento4 páginasCommunication Antenna Switching System Based On Micro ControllerAjay Kumar YadavAinda não há avaliações

- Triack OffDocumento1 páginaTriack OffnipunkhatriAinda não há avaliações

- Micro Radio Schematic OverviewDocumento2 páginasMicro Radio Schematic Overviewnipunkhatri100% (1)

- DatasheetDocumento9 páginasDatasheetnipunkhatriAinda não há avaliações

- HT12EDocumento13 páginasHT12Eapi-3700809100% (2)

- 10 1 1 124 4401Documento3 páginas10 1 1 124 4401nipunkhatriAinda não há avaliações

- Aveyond Player GuideDocumento23 páginasAveyond Player GuideMickey WordAinda não há avaliações

- St. Joseph's High School Computer Class Chapter 1 NetworkDocumento6 páginasSt. Joseph's High School Computer Class Chapter 1 NetworkAishveer BrarAinda não há avaliações

- LS Data Director User GuideDocumento38 páginasLS Data Director User GuideMelhem SalehAinda não há avaliações

- Kodak I1200 I1300Documento118 páginasKodak I1200 I1300אליהו אסתי אנדרד100% (2)

- 3m Locator&MarkingDocumento16 páginas3m Locator&Markingzein mubarakAinda não há avaliações

- Sjzl20090609-Unitrans ZXONM E300 (V3.19R2) Maintenance Manual - 516854Documento129 páginasSjzl20090609-Unitrans ZXONM E300 (V3.19R2) Maintenance Manual - 516854CROIX ROUGEAinda não há avaliações

- Stryker 1188 HD User ManualDocumento21 páginasStryker 1188 HD User ManualBiomedical E. Equipos Medicos y Servicios.Ainda não há avaliações

- SecureDoc SES Server 7.1 SR6 InstructionDocumento3 páginasSecureDoc SES Server 7.1 SR6 Instructionmatrixit0% (1)

- MegaPointer4 HelpDocumento71 páginasMegaPointer4 HelpAureoSoft EditoraAinda não há avaliações

- VipDocumento8 páginasVipManiVinoAinda não há avaliações

- SynopsisDocumento8 páginasSynopsisTina ShahAinda não há avaliações

- ICTICT501 SlideshowDocumento61 páginasICTICT501 Slideshowyazdan kundiAinda não há avaliações

- Profibus and Profinet For Grundfos MP 204: Functional Profile and User ManualDocumento28 páginasProfibus and Profinet For Grundfos MP 204: Functional Profile and User ManualAlvaro Medina100% (1)

- Computer Specifications: Hardware RequirementsDocumento2 páginasComputer Specifications: Hardware RequirementsOdellien SajaAinda não há avaliações

- Inventory Voucher Kya He, Stock Journal Voucher - Tally Seekhe Tally Learn in HindiDocumento9 páginasInventory Voucher Kya He, Stock Journal Voucher - Tally Seekhe Tally Learn in Hindipreeti gahlotAinda não há avaliações

- PMAC Catalogue 2012Documento33 páginasPMAC Catalogue 2012Milton VladimirAinda não há avaliações

- Fast Dormancy and Enhanced Cell FACH V1 - OLNDocumento49 páginasFast Dormancy and Enhanced Cell FACH V1 - OLNMatthew BarnettAinda não há avaliações

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocumento32 páginasEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- cm6800 32x16Documento82 páginascm6800 32x16vijayakumar3661Ainda não há avaliações

- 160kva Spec SheetDocumento3 páginas160kva Spec SheetGodfrey James MachotaAinda não há avaliações

- Maintain Training FacilitiesDocumento4 páginasMaintain Training FacilitiesRuth ValAinda não há avaliações

- Principal Electrical Hardware Engineer in Los Angeles CA Resume Robel BorjaDocumento2 páginasPrincipal Electrical Hardware Engineer in Los Angeles CA Resume Robel BorjaRobelBorjaAinda não há avaliações

- English 002 An Essay About Computer GamesDocumento2 páginasEnglish 002 An Essay About Computer Gamesshenyang28Ainda não há avaliações

- A Generic High Bandwidth Data Acquisition Card For Physics ExperimentsDocumento9 páginasA Generic High Bandwidth Data Acquisition Card For Physics ExperimentsekaAinda não há avaliações

- Exam Exam Exam Exam::::: Cisco Cisco Cisco Cisco 640-802 640-802 640-802 640-802Documento17 páginasExam Exam Exam Exam::::: Cisco Cisco Cisco Cisco 640-802 640-802 640-802 640-802dmbowie89Ainda não há avaliações

- CC442 NAQAA Form 11Documento3 páginasCC442 NAQAA Form 11MuhamdA.BadawyAinda não há avaliações

- GKL Audio GKit BabyPreV4.1 AssemblyGuideDocumento7 páginasGKL Audio GKit BabyPreV4.1 AssemblyGuidecrackintheshatAinda não há avaliações

- Preturi Panouri FotovoltaiceDocumento106 páginasPreturi Panouri FotovoltaiceramonadoniciAinda não há avaliações

- Oxygen ManualDocumento2 páginasOxygen ManualntovasAinda não há avaliações

- Eng DS Epp-2314 1410Documento2 páginasEng DS Epp-2314 1410MarkusAldoMaquAinda não há avaliações