Escolar Documentos

Profissional Documentos

Cultura Documentos

WPS Api 1104

Enviado por

miguelTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

WPS Api 1104

Enviado por

miguelDireitos autorais:

Formatos disponíveis

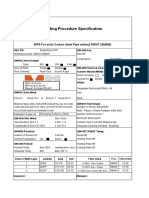

API WELDING PROCEDURE SPECIFICATION

WPS:

API 1000-12

REV. NO.:

PROCESS:

0.187 thru 0.750

Thickness:

SMAW

API-1104 QUALIFIED RANGES

Filler Metal Group:

Diameter: 2.375 o.d. thru 12.75 o.d.

Mate rial:

DATE:

9/9/2004

API Group 1

Butt

Joint Type:

Yield greater than 42 kip to equal to or less than 65 kip

Positions:

Fixed:

N/A

Rolled:

Down

Progression:

NOTE: This WPS shall be used in conjunction with the applicable sections of the Los Alamos National

Laboratories Welding Standards Manual (GWS)

Butt

WELD JOINT:

Type:

Joint Description:

Open Butt single V- welded from one side only.

FILLER MATERIALS:

Sizes (s): 1/8

ASTM A53 or A 106 A/B

Spec:

0.187 - 0.750

Thickness Welded:

2.375 o.d. thru 12.75 o.d. pipe

Pipe Diame ter:

1

Fixed:

to

Group:

5/32

N/A

Rolled:

API 5L X42 /X52

to

Spec:

to

0.187 - 0.750

2.375 o.d. thru 12.75 o.d. pipe

Pipe Diameter

to

Down

PREHEAT:

5/32

See pg. 2 for typical number and of beads

BASE MATERIALS:

POSITIONS:

E-6010

AWS Class:

F No.:

Number of Beads:

Progression:

API Group No.:

5.1

ASME P No.:

Full Penetration

See pg. 2 for typical sketch and bead sequence.

Sketch Number:

SFA Class:

Class:

P No.: 1

PWHT:

Group:

70

N/A

Time @ F Temp.:

N/A

Temperature Range F:

Minimum Temp F:

GAS:

Shielding:

NOTE:

See time between passes.

Composition:

INTERPASS TEMP.:

N/A

Flow Rate:

N/A

Backing: N/A

N/A

CFH

N/A

ELECTRICAL CHARACTERISTICS:

Current:

DC

Polarity:

Trans fer Mode: N/A

Electrode size and Type

EP

WFS/IPM:

See pg. 2

MAX. TIME BETWEEN PASSES:

Ranges Amps:

N/A

See pg. 2

Volts:

Travel/IPM

See pg. 2

See pg. 2

5 minutes between root pass and second pass.

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

WPS No.:

API-1000-12

Rev. No.:

Date:

9/9/2004

WELDING TECHNIQUE:

Line-Up Clamp:

Optional, if used line-up clamp shall be left until 50% of root bead is complete.

Stringer or Weave Bead: (S)

(W)

Single Pass

N/A

Multi Pass

Cleaning and/or Grinding:

PROCEDURE QUALIFIED FOR:

Maximum K/J Heat Input:

Charpy V Notch

N/A

NDTT

N/A

D.T.

N/A

N/A

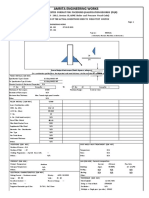

JOINT SKETCH AND BEAD NUMBER AND SEQUENCE

37.5 Bevel

t thickness varies

0 3/32 land

1/16 3/32 gap

NOTE: Weld layers are representative only actual number of passes and layer sequence may vary

due to variation in joint design, thickness and fit-up.

TYPICAL WELDING PARAMETERS

Travel Speed

Amps

Volts

in/min.

70 -100

22 - 26

9 12

Pass

Filler/ Electrode

Number

E-6010

1

Size

1/8

E-6010

5/32

125 132

22 - 26

9 13

E-6010

5/32

125 132

22 - 26

9 13

E-6010

5/32

125 132

22 - 26

9 13

E-6010

5/32

125 132

22 - 26

9 13

E-6010

5/32

125 132

22 - 26

9 13

E-6010

5/32

125 132

22 - 26

9 13

E-6010

5/32

125 132

22 - 26

9 13

Other

PREPARED BY:

Kelly Bingham

Signature on File

DATE:

9/9/2004

APPROVED BY:

Tobin Oruch

Signature on File

DATE:

9/9/2004

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

API-1000-12

REV.: 0

PAGE 3 OF 3

DATE: 9/9/2004

API WELDING SPECIFICATION PROCEDURE

TEST PARAMETERS

Point Type:

Full Penetration Single V Butt

Diameter: 8.644 o.d.

Thickness:

0.322 wall

Filler:

1/8 & 5/32

Material:

API 5L X42 /X52 to ASTM A53

Preheat:

70*F

Position:

5G Fixed

Current:

DCEP

Volts:

22-26

Progression: Down

E-6010

Amps: 70-125

No.

1.

Type

Face

GUIDED BEND TESTS

Result

No.

Type Result

Accept no indications

5.

N/A

2.

Root

Accept no indications

6.

N/A

3.

Face

Accept no indications

7.

N/A

4.

Root

Accept no indications

8.

N/A

No.

Specimen

Type

Area

Sq./ in

Applied

Load

1.

Figure 4

.3051

23,619

77,408

Base metal cup and cone

2.

Figure 4

.3213

23,232

72,305

Base metal cup and cone

3.

N/A

4.

N/A

No.

TENSILE TESTS

Ultimate

Tensile

Character of failure and location

NICK-BREAK TESTS

Remarks on Nick-Break tests

Type

1.

Figure 5

Acc. Break is clean.

2.

Figure 5

Acc. Break is clean

3.

N/A

N/A

4.

Welders Name: Scott Simonich

Tests Conducted By: Brett McNeil

Z No.: 200360

Stamp: SC002

We certify that the statements herein are correct and that the tests were conducted in accordance with

API-1104.

Authorized By: Kelly Bingham ___________________

Date: 10/30/03

Signature on File

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

Você também pode gostar

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerNo EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerNota: 5 de 5 estrelas5/5 (1)

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocumento3 páginasEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Sample API 1104 WpsDocumento6 páginasSample API 1104 Wpsjacquesmayol100% (2)

- WPS PQR PDFDocumento23 páginasWPS PQR PDFtomj9104Ainda não há avaliações

- Wps Aws d1.1 NEWDocumento2 páginasWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocumento1 páginaAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipAinda não há avaliações

- QW-484A (WPQ) GTAW 4MM FilletDocumento2 páginasQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPSDocumento2 páginasWPSAlam MD Sazid100% (1)

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocumento4 páginas170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraAinda não há avaliações

- 004 Gtaw P5aDocumento16 páginas004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- WPS 2014-002 006 - 6G PipeDocumento3 páginasWPS 2014-002 006 - 6G PipejeswinAinda não há avaliações

- Aws d1.1 Tubular Vs Non TubularDocumento1 páginaAws d1.1 Tubular Vs Non TubularrendraAinda não há avaliações

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 páginas(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkDocumento1 páginaWelder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkMahendra singhAinda não há avaliações

- Aws d1.5 PQRDocumento2 páginasAws d1.5 PQRjacquesmayolAinda não há avaliações

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Documento3 páginasWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Qualification Record: Shipyard LogoDocumento4 páginasWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocumento1 páginaTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014Ainda não há avaliações

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Documento8 páginasQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanAinda não há avaliações

- Wps 1010 IfrDocumento28 páginasWps 1010 IfrSyed Mahmud Habibur RahmanAinda não há avaliações

- NSH-DALM-JERP-WPS-11-P2 Rev.00Documento10 páginasNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidAinda não há avaliações

- PhuBia-WPS-AWS D1.1-8-6-2011Documento2 páginasPhuBia-WPS-AWS D1.1-8-6-2011poulmackAinda não há avaliações

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 páginasIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocumento3 páginasWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniAinda não há avaliações

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocumento5 páginasWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- WPS Format For AWS D1.1 - WPS - FCAWDocumento1 páginaWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityAinda não há avaliações

- 19403955-WPS M.S. Is 2062Documento10 páginas19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Documento3 páginasHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnAinda não há avaliações

- PQR A106 HAL-1Documento1 páginaPQR A106 HAL-1Budi Setia RahmanAinda não há avaliações

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 páginas163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraAinda não há avaliações

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Documento2 páginasWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniAinda não há avaliações

- Asme PQR DemoDocumento3 páginasAsme PQR DemoMuthusamy AyyanapillaiAinda não há avaliações

- Pwps Jo Wps Asme 016 Rev.001Documento2 páginasPwps Jo Wps Asme 016 Rev.001Bagandi ManurungAinda não há avaliações

- Welding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Documento1 páginaWelding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Lipika Gayen100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocumento1 páginaAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityAinda não há avaliações

- SMAW DuniDocumento4 páginasSMAW DuniMuhammad Fitransyah Syamsuar PutraAinda não há avaliações

- Qw-482 Welding Procedure Specification (WPS)Documento4 páginasQw-482 Welding Procedure Specification (WPS)Aldeline SungahidAinda não há avaliações

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocumento1 páginaWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavAinda não há avaliações

- Welding Proposed Pwps For Our Jubail WorkDocumento2 páginasWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocumento6 páginasWPS Resrvoire Sous Pression Smaw SawDanem HalasAinda não há avaliações

- Format WPQDocumento2 páginasFormat WPQAkash Singh TomarAinda não há avaliações

- WPS For A333 ADocumento1 páginaWPS For A333 ARamzi BEN AHMED100% (1)

- Welding Procedure SpecificationDocumento27 páginasWelding Procedure SpecificationGopakumar K100% (2)

- PWPS For Piping-API 1104Documento6 páginasPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Documento3 páginasAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyAinda não há avaliações

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocumento2 páginasASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaAinda não há avaliações

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocumento1 páginaPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarAinda não há avaliações

- For Fillet Weld Joint Project:Production ManifoldDocumento1 páginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Documento1 páginaQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasAinda não há avaliações

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocumento3 páginasVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnAinda não há avaliações

- WPS D1.6 Annex m1 PDFDocumento1 páginaWPS D1.6 Annex m1 PDFbollascribdAinda não há avaliações

- 6GR RequirementsDocumento1 página6GR Requirementswalitedison100% (1)

- Proposed WPSDocumento2 páginasProposed WPSChisom Ikengwu100% (2)

- Sample API 1104 WpsDocumento1 páginaSample API 1104 Wpsippon_osoto100% (1)

- Welding Procedure Specification For GTAW & GMAWDocumento4 páginasWelding Procedure Specification For GTAW & GMAWanh thoAinda não há avaliações

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocumento3 páginasSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013Ainda não há avaliações

- WPS MS 01C Rev. 0Documento1 páginaWPS MS 01C Rev. 0alinor_tnAinda não há avaliações

- API-1000-11 Rev 0Documento3 páginasAPI-1000-11 Rev 0Mahesh MishraAinda não há avaliações

- API Welding Procedure Specification PDFDocumento3 páginasAPI Welding Procedure Specification PDFBob LeeAinda não há avaliações

- Asnt MT Level IIDocumento431 páginasAsnt MT Level IImiguelAinda não há avaliações

- Lista VTDocumento6 páginasLista VTmiguelAinda não há avaliações

- Renewal ApplicationDocumento6 páginasRenewal ApplicationmiguelAinda não há avaliações

- Ramones GT Installaton Guide IC-001145 PDFDocumento88 páginasRamones GT Installaton Guide IC-001145 PDFmiguelAinda não há avaliações

- Pqr-Hoja 2 IsoDocumento2 páginasPqr-Hoja 2 IsomiguelAinda não há avaliações

- Form N9Documento1 páginaForm N9cal2_uniAinda não há avaliações

- 1-Outokumpu-Welding Stainless-Steel-Handbook PDFDocumento36 páginas1-Outokumpu-Welding Stainless-Steel-Handbook PDFTuTuy AnAinda não há avaliações

- English GrammarDocumento81 páginasEnglish GrammarmiguelAinda não há avaliações

- API 6d Pipeline ValvesDocumento8 páginasAPI 6d Pipeline ValvesmiguelAinda não há avaliações

- Internship Report PDFDocumento71 páginasInternship Report PDFNafiz FahimAinda não há avaliações

- Papalia Welcome Asl 1 Guidelines 1 1Documento14 páginasPapalia Welcome Asl 1 Guidelines 1 1api-403316973Ainda não há avaliações

- Java Edition Data Values - Official Minecraft WikiDocumento140 páginasJava Edition Data Values - Official Minecraft WikiCristian Rene SuárezAinda não há avaliações

- L5T-112 Manual - 2007 - Issue 1.1 PDFDocumento16 páginasL5T-112 Manual - 2007 - Issue 1.1 PDFfluidaimaginacionAinda não há avaliações

- Dash8 200 300 Electrical PDFDocumento35 páginasDash8 200 300 Electrical PDFCarina Ramo LakaAinda não há avaliações

- Paper 4 Material Management Question BankDocumento3 páginasPaper 4 Material Management Question BankDr. Rakshit Solanki100% (2)

- Exercise-3 (B) : Linear EquationsDocumento3 páginasExercise-3 (B) : Linear EquationsVRUSHABHAinda não há avaliações

- Steve JobsDocumento18 páginasSteve JobsVibhor AggarwalAinda não há avaliações

- Under Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisDocumento13 páginasUnder Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisMahmud RahmanAinda não há avaliações

- Full Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFDocumento42 páginasFull Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFtimothy.mees27497% (39)

- Certificate of Attendance: Yosapat NashulahDocumento2 páginasCertificate of Attendance: Yosapat NashulahStrata WebAinda não há avaliações

- MMB & DFT 2012 Workshop ProceedingsDocumento44 páginasMMB & DFT 2012 Workshop ProceedingsFelipe ToroAinda não há avaliações

- (Kazantzakis Nikos) Freedom or DeathDocumento195 páginas(Kazantzakis Nikos) Freedom or DeathTarlan FisherAinda não há avaliações

- Earth and Life Science, Grade 11Documento6 páginasEarth and Life Science, Grade 11Gregorio RizaldyAinda não há avaliações

- Region: South Central State: Andhra PradeshDocumento118 páginasRegion: South Central State: Andhra PradeshpaulinAinda não há avaliações

- Rate If Iodine and PropanoneDocumento3 páginasRate If Iodine and Propanoneshareef1Ainda não há avaliações

- The Chassis OC 500 LE: Technical InformationDocumento12 páginasThe Chassis OC 500 LE: Technical InformationAbdelhak Ezzahrioui100% (1)

- Albert-Einstein-Strasse 42a, D-63322 Roedermark, Germany Tel.: 0049 (0) 6074-7286503 - Fax: 0049 (0) 6074-7286504Documento19 páginasAlbert-Einstein-Strasse 42a, D-63322 Roedermark, Germany Tel.: 0049 (0) 6074-7286503 - Fax: 0049 (0) 6074-7286504Ilias Asimakis100% (1)

- HYDRAULIC WINCH-MS1059 - Operation & Maintenance Manual Rev ADocumento33 páginasHYDRAULIC WINCH-MS1059 - Operation & Maintenance Manual Rev Azulu80Ainda não há avaliações

- Ep Docx Sca SMSC - V2Documento45 páginasEp Docx Sca SMSC - V290007Ainda não há avaliações

- Visual Inspection ReportDocumento45 páginasVisual Inspection ReportKhoirul AnamAinda não há avaliações

- You're reading a free preview. Pages 4 to 68 are not shown in this preview. Leer la versión completa You're Reading a Free Preview Page 4 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 5 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 6 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 7 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 8 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 9 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 10 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 11 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 12 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 13 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 14 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 15 is notDocumento9 páginasYou're reading a free preview. Pages 4 to 68 are not shown in this preview. Leer la versión completa You're Reading a Free Preview Page 4 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 5 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 6 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 7 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 8 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 9 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 10 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 11 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 12 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 13 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 14 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 15 is notFernando ToretoAinda não há avaliações

- 5000-5020 en PDFDocumento10 páginas5000-5020 en PDFRodrigo SandovalAinda não há avaliações

- PRINCIPLES OF TEACHING NotesDocumento24 páginasPRINCIPLES OF TEACHING NotesHOLLY MARIE PALANGAN100% (2)

- Rwamagana s5 Mathematics CoreDocumento4 páginasRwamagana s5 Mathematics Coreevariste.ndungutse1493Ainda não há avaliações

- Wood ReportDocumento36 páginasWood Reportメルヴリッ クズルエタAinda não há avaliações

- DILG Opinion-Sanggunian Employees Disbursements, Sign Checks & Travel OrderDocumento2 páginasDILG Opinion-Sanggunian Employees Disbursements, Sign Checks & Travel OrderCrizalde de DiosAinda não há avaliações

- MotorsDocumento116 páginasMotorsAmália EirezAinda não há avaliações

- NOV23 Nomura Class 6Documento54 páginasNOV23 Nomura Class 6JAYA BHARATHA REDDYAinda não há avaliações

- King Saud UniversityDocumento10 páginasKing Saud UniversitypganoelAinda não há avaliações