Escolar Documentos

Profissional Documentos

Cultura Documentos

Effect of Aggregate Quality on Concrete Properties

Enviado por

Elakkiya KarthicTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Effect of Aggregate Quality on Concrete Properties

Enviado por

Elakkiya KarthicDireitos autorais:

Formatos disponíveis

See

discussions, stats, and author profiles for this publication at: http://www.researchgate.net/publication/265060255

EFFECT OF AGGREGATE QUALITY ON THE

PROPERTIES OF CONCRETE

ARTICLE

CITATION

READS

162

4 AUTHORS, INCLUDING:

M. Maslehuddin

Alfarabi Sharif

King Fahd University of Petroleum and Min

King Fahd University of Petroleum and Min

128 PUBLICATIONS 1,163 CITATIONS

31 PUBLICATIONS 449 CITATIONS

SEE PROFILE

SEE PROFILE

Available from: M. Maslehuddin

Retrieved on: 29 October 2015

Construction and Building Materials 17 (2003) 97103

Effect of coarse aggregate quality on the mechanical properties of high

strength concrete

H. Beshrb,1, A.A. Almusallama, M. Maslehuddinb,*

a

Department of Civil Engineering, King Fahd University of Petroleum & Minerals, Dhahran 31261, Saudi Arabia

b

Research Institute, King Fahd University of Petroleum & Minerals, Dhahran 31261, Saudi Arabia

Received 25 February 2001; received in revised form 15 June 2002; accepted 28 August 2002

Abstract

This paper reports results of a study conducted to evaluate the effect of four types of coarse aggregates, namely calcareous,

dolomitic, quartzitic limestone, and steel slag, on the compressive and tensile strength, and elastic modulus of high strength

concrete. The highest and lowest compressive strength was obtained in the concrete specimens prepared with steel slag and

calcareous limestone aggregates, respectively. Similarly, the split tensile strength of steel slag aggregate concrete was the highest,

followed by that of dolomitic and quartzitic limestone aggregate concretes. The lowest split tensile strength was noted in the

calcareous limestone aggregate concrete. The type of coarse aggregate also influences the modulus of elasticity of concrete.

Weaker aggregates tend to produce a more ductile concrete than stronger aggregates do.

2002 Elsevier Science Ltd. All rights reserved.

Keywords: Coarse aggregate; Compressive and tensile strengths; High strength concrete; Modulus of elasticity

1. Introduction

The term high strength concrete is used for concrete

with a compressive strength in excess of 41 MPa, as

defined by the ACI Committee 363 w1x. Others define

high strength concrete as that possessing a uniaxial

compressive strength greater than that which is ordinarily obtained in a region, because the maximum strength

of concrete which is currently being produced varies

considerably from region to region w2x. Use of high

strength concrete leads to smaller cross-sections and

hence, the reduced dead load of a structure. This helps

engineers to build taller buildings and bridges with

longer spans.

In conventional concrete (compressive strength -41

MPa), the properties of coarse aggregates seldom

become strength-limiting, because this type of concrete

mixtures typically correspond to a watercement ratio

*Corresponding author. Tel.: q966-3860-2853; fax: q966-38603996.

E-mail address: muddin@kfupm.edu.sa (M. Maslehuddin).

1

Former Graduate Student, King Fahd University of Petroleum &

Minerals, Dhahran 31261, Saudi Arabia.

(wyc) in the range of 0.50.7. Within this range, the

weakest components in concrete are the hardened cement

paste and the transition zone between the cement paste

and the coarse aggregate, rather than the coarse aggregate itself w37x. Similarly, when designing conventional

concrete mixtures, the mineralogy of coarse aggregate

is rarely of concern unless the aggregate contains some

constituents, such as opal which is a reactive silica

mineral that could have a deteriorating effect on concrete

durability w8x, while for a high strength (compressive

strength )41 MPa) concrete, researchers have noted

that the hardened cement paste and the transition zone

are no longer strength-limiting, but it is the mineralogy

and the strength of the coarse aggregate that control the

ultimate strength of concrete.

The importance of the mineralogical characteristics

of coarse aggregates on the quality of concrete has been

pointed out by Farran w9x, Maso w10x, Alexander and

Davis w11x, Baalbaki et al. w12x, and Giaccio et al. w13x.

The effect of the coarse aggregate on elastic properties

of high performance concrete (HPC) was also pointed

out by Aitcin and Mehta w8x, Baalbaki et al. w12x, and

Aitcin w14x. These authors observed some significant

0950-0618/03/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 9 5 0 - 0 6 1 8 0 2 . 0 0 0 9 7 - 1

98

H. Beshr et al. / Construction and Building Materials 17 (2003) 97103

Table 1

Chemical composition of Portland cement

Table 3

Grading of coarse aggregate

Constituent

Wt.%

SiO2

Al2O3

Fe2O3

CaO

MgO

SO3

K 2O

Na2O

L.O.I.

C 3S

C 2S

C 3A

C4AF

19.92

6.54

2.09

64.70

1.84

2.61

0.56

0.28

0.73

55.90

19.00

7.50

9.80

Sieve

opening

(mm)

Percentage

passing

19.00

12.50

9.50

4.75

2.36

100

90

30

10

0

strain characteristics. Some studies w1,18,19x conducted

to date have generally indicated that the empirical

relationships between compressive strength and other

properties, such as tensile strength, flexural strength,

and modulus of elasticity, established for normal concretes cannot always be utilized for high strength concretes. Generally, it is noted that cracking of HSC is

more localized and approaches a homogeneous material

behavior as compared to normal strength concrete. Also,

HSC exhibits more linear elastic behavior and is more

brittle than normal strength concrete. Therefore, it is

essential to develop data on the mechanical properties

of hardened concrete, particularly its strength, in relation

to the properties of the aggregates.

This paper reports the results of a study conducted to

investigate the influence of coarse aggregate quality on

the compressive and split tensile strength and elastic

properties of high strength concrete.

differences in the elastic modulus and hysteresis loop in

the case of HPCs prepared with different coarse aggregates, but with the same water-to-cement ratio w8,14x.

Aitcin et al. w15x investigated the effect of three different

coarse aggregates in superplasticized concrete mixtures

with identical materials and properties (wycs0.24).

They found that for a calcareous-limestone aggregate

(85% calcite), a dolomitic-limestone aggregate (80%

dolomite), and a quartzitic-gravel aggregate containing

schist, the 91 day compressive strengths were 93, 103

and 83 MPa, respectively. Moreover, they concluded

that the aggregatecement paste bond was stronger in

the limestone aggregate concrete than in the gravel

concrete due to the interfacial reaction effect w15x. Zhang

and Gjorv w16x investigated the effect of four coarse

aggregate types, available in north California, on the

compressive strength and elastic behavior of a very high

strength concrete mixture. Based on their study, some

significant differences in the elastic moduli and hysteresis loop were observed. A formula was derived by

Chang and Su w17x from the theory of granular mechanics to estimate the compressive strength of coarse

aggregate to be used in high strength concrete. This

study w17x showed that there is a good correlation

between the compressive strength of aggregates and

some of the engineering properties of concrete.

With increasing use of high strength concrete (HSC)

as a structural material, further information on its

mechanical properties is required, especially its stress

ASTM C150 Type I Portland cement, with the chemical composition shown in Table 1, was utilized in

preparing the concrete specimens. Four types of coarse

aggregates, namely calcareous limestone (CC), dolomitic limestone (DL), quartzitic limestone (QZ), and steel

slag (SS), were utilized to prepare the concrete mixtures.

The physical properties of the coarse aggregates selected

for this study and their grading are shown in Tables 2

and 3, respectively, while the quantity of clay lumps in

the selected coarse aggregates are shown in Table 4.

Table 2

Absorption and specific gravity of coarse aggregates

Table 4

Clay lumps in coarse aggregates

2. Experimental program

2.1. Materials and test specimens

Type of aggregate

Absorption

(%)

Bulk

specific

gravity

Source of aggregates

Clay

lumps

(%)

ASTM C

142 limit

(%)

Calcareous limestone

Dolomitic limestone

Quartzatic limestone

Steel slag

4.95

2.20

1.60

0.85

2.39

2.54

2.70

3.51

Calcareous limestone

Dolomitic limestone

Quartzitic limestone

Steel slag

0.78

0.65

0.41

0.12

H. Beshr et al. / Construction and Building Materials 17 (2003) 97103

99

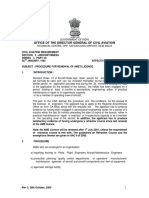

Fig. 1. Experimental setup utilized to evaluate the stress-strain characteristics of concrete.

Same aggregate grading was used in all the concrete

mixtures. Dune sand with a bulk specific gravity of 2.54

and water absorption of 0.65% was used as fine aggregate. All the concrete mixtures were prepared with a

water-to-cement ratio of 0.35 and a cement content of

450 kgym3, and a coarse aggregate to fine aggregate

ratio of 1.63. A naphthalene-based superplasticizer was

used to improve the workability of the concrete mixtures.

Cylindrical concrete specimens, 75 mm in diameter

and 150 mm high, were prepared for determining the

compressive strength, split tensile strength, and modulus

of elasticity. Mixing was done in a revolving drum type

mixer for approximately 35 min to obtain uniform

consistency. After mixing, the concrete was filled in the

cylindrical moulds in two layers and consolidated on a

vibrating table to remove entrapped air. After casting,

the specimens were covered with a wet burlap and cured

in the laboratory at a temperature of 20"2 8C for 24 h

prior to demolding and then cured under calcium

hydroxide solution till the time of test.

2.2. Test techniques

2.2.1. Compressive strength

The compressive strength of concrete prepared using

the selected coarse aggregates was determined by loading the specimens in uniaxial compression according to

ASTM C 39 at a constant loading rate of 3.3 kNys

using a servo-controlled hydraulic testing machine of

3000 kN capacity. The compressive strength was determined after 3, 7, 14, 28 and 180 days of curing.

2.2.2. Split tensile strength

The tensile strength of concrete can be experimentally

determined by w20x: (1) uniaxial tensile test; (2) split

cylinder test; and (3) beam test in flexure. The first

method of obtaining the tensile strength is referred to as

a direct test for determining the tensile strength, while

the second and third methods are indirect tests. The

indirect method of applying tension in the form of

splitting was suggested by Fernando Cerneiro, a Brazilian engineer w20x, and the test is often referred to as the

Brazilian test, although it was also developed independently in Japan.

In this study, the split tensile strength of concrete

specimens prepared with the selected coarse aggregates

was determined according to ASTM C 496.

2.2.3. Modulus of elasticity

The static modulus of elasticity was determined

according to ASTM C 469. The specimens were tested

in uniaxial compression at a constant rate of loading of

approximately 3.3 kNys using a servo-controlled hydraulic testing machine. A portable data logger was used to

record the load and strain readings. Longitudinal strains

were measured using a compressometer that was fixed

parallel to the direction of the applied load. The compressometer was centered at mid-height of the specimen

and the compressive deformation was measured using

two LVDTs located at diametrically opposite locations

on the surface of the specimen. Fig. 1 shows the

experimental set up utilized to evaluate the stressstrain

characteristics of the concrete specimens prepared using

the selected aggregates.

3. Results and discussion

3.1. Effect of aggregate quality on compressive strength

of concrete

The effect of aggregate quality on the compressive

strength of concrete was evaluated by testing concrete

100

H. Beshr et al. / Construction and Building Materials 17 (2003) 97103

specimens prepared with CC, DL, QZ and SS aggregates. Fig. 2 shows the variation of compressive strength

with age for the concrete specimens prepared with the

four types of aggregates selected for this study. As

expected, the compressive strength increased with age

in all the concrete specimens. Further, the data in Fig.

2 indicate that the type of coarse aggregate has a

significant effect on the compressive strength of concrete. The highest compressive strength was measured

in the concrete specimens prepared with the steel slag

aggregates while the lowest compressive strength was

noted in the concrete specimens prepared with calcareous limestone aggregates. After 28 days of curing, the

compressive strength of concrete specimens prepared

with calcareous, dolomitic, and quartzitic limestone and

steel slag aggregates was 43, 45, 47 and 54 MPa,

respectively.

The data developed in this study indicate that in a

high strength concrete, i.e. concrete prepared with a low

water-to-cement ratio and a high cement content, the

compressive strength is dependent on the quality of

coarse aggregate. In such concrete, the bulk of the

compressive load is borne by the aggregates rather than

the cement paste alone. The failure in such concretes is

often through the aggregates. Since the calcareous limestone aggregates are known to be weaker than the

Table 5

Loss on abrasion in the coarse aggregates

Type of aggregate

Loss on

abrasion

(%)

Calcareous limestone

Dolomitic limestone

Quartzitic limestone

Steel slag

34.4

24.2

19.2

11.6

dolomitic and quartzitic limestone aggregates the low

load carrying capacity of concrete prepared with calcareous limestone aggregates is understandable. Similarly,

the dolomitic limestone aggregates are weaker than the

quartzitic limestone aggregates, as such marginally lower

compressive strength of concrete prepared with former

coarse aggregates compared to that prepared with the

latter coarse aggregates is comprehensible.

The data on loss on abrasion summarized in Table 5

of these aggregates provide ample evidence of the weak

nature of the calcareous and dolomitic limestone aggregates compared to the quartzitic limestone and steel slag

aggregates. The compressive strength of steel slag aggregate concrete was more than that of the quartzitic

limestone aggregate concrete. This indicates that this

Fig. 2. Compressive strength development of concrete specimens prepared with the selected aggregates.

H. Beshr et al. / Construction and Building Materials 17 (2003) 97103

aggregate is very suitable for producing high strength

concrete.

When concrete is subjected to compressive loads,

failure takes place at one or more of the following

locations: (i) within the paste matrix; (ii) at the paste

aggregate interface; or (iii) within the aggregate. In a

rich concrete mix, as the one utilized in this study, the

possibility of failure within the paste matrix, alone, is

very rare, since this phase is very strong. Therefore, the

failure plain has to pass through the pasteaggregate

interface or through the aggregate. In both modes of

failure, the quality of aggregate significantly influences

the mode of failure of concrete under compression.

Another point to be noted is that the porous aggregates, such as calcareous and dolomitic limestone aggregates, are capable of absorbing a significant amount of

water. Hence, the cementaggregate bond in such aggregates is better than that of quartzitic limestone and steel

slag aggregates. Therefore, the failure of concretes prepared with the calcareous and dolomitic limestone aggregates is presumed to be within the aggregates since the

interface in these concrete specimens is strong due to a

good bond between the aggregate and the cement paste.

Such a failure was noted in the concrete specimens on

visual inspection after testing in compression. Higher

compressive strength of steel slag and quartzitic limestone aggregate concretes compared with calcareous and

dolomitic limestone aggregate concretes may thus be

attributed to the quality of the aggregates. As shown in

Table 5, the loss on abrasion of calcareous and dolomitic

limestone aggregates was more than that in the quartzitic

limestone and steel slag aggregates. The higher strength

of quartzitic limestone and steel slag aggregates, contributes to increased compressive strength of concrete

prepared with these aggregates.

According to Wasserman and Bentur w21x, the physical process that occurs at an early age is governed by

the absorption of water into the aggregate. Higher

absorption eliminates the accumulation of water in the

fresh matrix in the vicinity of the aggregate; as a result,

the interfacial transition zone in the aggregates with

higher absorption is denser. Aitcin and Mehta w8x noted

that in a high-strength concrete the hardened cement

paste and the transition zone are no longer strength

limiting. On the other hand, the mineralogy and the

strength of coarse aggregates may control the ultimate

strength of concrete, particularly in a high strength

concrete.

Baalbaki et al. w12x investigated the influence of three

different types of crushed coarse aggregates (dolomitic

limestone, quartzite, and sandstone) on the elastic properties of high strength concrete. They found that the

highest and lowest compressive strength was of the

sandstone and quartz aggregate concretes, respectively

w12x. The low compressive strength of quartz concrete

may be explained by the relative incompressibility of

101

Fig. 3. Split tensile strength of concrete specimens prepared with the

selected aggregates.

the aggregates that improves the rigidity of concrete and

decreases the strength. On the other hand, the capacity

of the sandstone aggregate to deform in one direction

allows the stress to be more uniformly distributed;

thereby, the whole section contributes to strength, as

opposed to the rigid aggregates that tend to concentrate

stresses on certain regions of the section, therefore

creating premature ruptures w12x.

The average rate of strength development, as shown

in Fig. 2, was higher at early ages, where the ratio of

728 days strengths, ranged from 0.74 to 0.80, compared with 0.73 to 0.82 reported by Berke et al. w22x.

Also, the ratio of 28180 days strength was in the range

0.880.93 compared with 0.850.95 reported by Berke

et al. w22x. This observation is in good agreement with

that reported by Carette and Malhotra w23x and also by

Slate et al. w18x. According to Carrasquillo et al. w24x,

the ratio of 728 days strengths is between 0.60 and

0.65 in the case of normal strength concrete. The higher

rate of strength gain of HSC compared to normal

strength concrete is attributed to the high internal curing

temperature developed during hydration w18x. The high

heat of hydration is associated with the high cement

content in HSC mixes. Differences in the rate of strength

gain, however, becomes negligible at later ages w18x.

3.2. Effect of aggregate quality on split tensile strength

of concrete

The split tensile strength was determined after 14, 28

and 90 days of curing. Fig. 3 shows the split tensile

strength of concrete specimens prepared with the four

102

H. Beshr et al. / Construction and Building Materials 17 (2003) 97103

Fig. 4. Modulus of elasticity of the concrete specimens prepared with

the selected aggregates.

types of aggregates investigated in this study. The split

tensile strength increased with age in all the concrete

specimens. As can be seen in Fig. 3 the split tensile

strength of steel slag aggregate concrete was the highest,

followed by that of quartzitic and dolomitic limestone

aggregate concretes. The least split tensile strength was

noted in the concrete specimens prepared with calcareous limestone aggregates. However, the split tensile

strength of concrete specimens prepared with quartzitic

and dolomitic limestone aggregates was almost similar

after 28 days of curing. After this age, the split tensile

strength of steel slag aggregate concrete was 164% of

that of calcareous limestone aggregate concrete. Similarly, the split tensile strength of concrete prepared with

the dolomitic and quartzitic limestone aggregates was

129 and 130%, respectively, of that prepared with the

calcareous limestone aggregates.

3.3. Effect of aggregate quality on the static modulus of

elasticity of concrete

aggregates. A more ductile failure results in the concrete

specimens prepared with these aggregates.

The importance of coarse aggregate quality on elastic

properties of high strength concrete was also pointed by

Aitcin w14x, and Aitcin and Mehta w8x. Some significant

differences in the elastic modulus and hysteresis loop

were noted in high strength concrete prepared with

different coarse aggregates. Baalbaki et al. w12x also

evaluated the effect of coarse aggregates on the elastic

properties of high strength concrete. The elastic modulus

of high strength concrete was noted to be strongly

influenced by the elastic properties of coarse aggregates

w12x. Similarly, Giaccio et al. w13x noted that the highest

modulus of elasticity of concrete was achieved in basaltic-HSC, followed by limestone-HSC and granitic-HSC.

They w13x stated that this could be attributed to a higher

percentage of microcracking in limestone-HSC during

the first loading applied to measure the modulus of

elasticity.

As is apparent from the data in Fig. 4, the static

modulus of elasticity was higher for the concretes

containing steel slag aggregates and quartzatic limestone

aggregate concretes, than for concrete prepared with

calcareous and dolomitic limestone aggregates. For higher compressive strength concretes, the modulus of elasticity was higher because of the mortar stiffness and

improved mortaraggregate bond. Hooton w25x, Luther

and Hanse w26x, and Khatri and Sirivivatnanon w27x also

found that elastic modulus is primarily a function of

compressive strength. Based on the previous discussion,

it can be concluded that the effect of the type of coarse

aggregate is more significant on the modulus of elasticity

as compared to the compressive strength. According to

Aitcin and Mehta w8x, and Baalbaki et al. w12x, the

nature of coarse aggregate significantly affects the modulus of elasticity of high strength concrete. This influence was attributed to the highly dense paste structure

and pasteaggregate bond, which causes the concrete to

behave like a composite material. Therefore, aggregate

characteristics could be important in determining the

elastic properties of high strength concrete.

4. Conclusions

Fig. 4 shows the measured values of the modulus of

elasticity of concrete specimens prepared with the selected coarse aggregates. These data indicate that the type

of coarse aggregate has a significant effect on the

modulus of elasticity of concrete. After 28 days of

curing, the modulus of elasticity of calcareous, dolomitic

and quartzitic limestone and steel slag aggregate concretes was 21.6, 24.5, 28.8 and 29.6 GPa, respectively.

The modulus of elasticity of steel slag aggregate concretes was the highest, while that of calcareous limestone

aggregate concrete was the lowest. The lower values of

modulus of elasticity of calcareous limestone aggregate

concrete may be attributed to the soft nature of these

The quality of coarse aggregate has a significant

effect on the compressive strength of high strength

concrete. The compressive strength of steel slag aggregate concrete was more than that of crushed limestone

aggregate concrete. The compressive strength of concrete prepared with calcareous limestone aggregate was

the least. These data indicate that in a high strength

concrete, i.e. concrete prepared using a low water

cement ratio and high cement content, the compressive

strength is dependent on the quality of aggregate. In

such concrete, the bulk of the compressive load is borne

by the aggregate rather than the cement paste alone.

H. Beshr et al. / Construction and Building Materials 17 (2003) 97103

The failure in such concretes is often through the

aggregates. Since the calcareous limestone is known to

be weaker than the dolomitic and quartzitic limestone

aggregates, its low load carrying capacity is

understandable.

Split tensile strength increased with age in all the

concrete specimens. The type of aggregate also influences the split tensile strength of concrete. The split

tensile strength of steel slag aggregate concrete was

more than that of limestone aggregate concrete. The

least split tensile strength was noted in the calcareous

limestone aggregate concretes.

The quality of coarse aggregate also influences the

modulus of elasticity of concrete. Weaker aggregates

tend to produce a more ductile concrete than strong

aggregates do.

Acknowledgments

The authors acknowledge the support provided by the

Department of Civil Engineering and the Research

Institute at King Fahd University of Petroleum and

Minerals, Dhahran, Saudi Arabia.

References

w1x ACI Committee 363. State-of-the-art report on high strength

concrete. High strength concrete seminar course manualySCM

(87)-ACI, 1987.

w2x Hester WT. Field testing HSC: a critical review of the stateof-the-art.Concrete International, 1980. p. 27 38.

w3x Mehta PK. Concrete: structure, properties and materials. Englewood Cliffs: Prentice-Hall, 1986. p. 36 40.

w4x Yuan CZ, Guo WJ. Bond between marble and cement paste.

Cem Concr Res 1987;17:544 52.

w5x Kaplan MF. Flexural and compressive strength of concrete as

affected by the properties of coarse aggregates. ACI J Proc

1959;55(11):1193 208.

w6x Larrard F, Belloc A. Are small aggregates really better for

making high-strength concrete? Cem Concr Aggregates

1992;14(1):62 6.

w7x Zia P. International workshop on high performance concrete.

ACI SP-159, Detroit. 1994. p. 215 23.

w8x Aitcin PC, Mehta PK. Effect of coarse-aggregate characteristics

on mechanical properties of high-strength concrete. ACI Mater

J 1990;87(2):103 7.

w9x Farran J. Contribution mineralogique

a` letude

de ladherence

des ciments et les materiaux

entre les constituants hydrates

Thesis, Toulouse, 1956.

enrobes.

103

w10x Maso JC. Nature mineralogigue

des agregats

facteur essentiel

de la resistance

des betons

et laction du gel. Thesis, Toulouse,

1969.

w11x Alexander MG, Davis DE. Properties of aggregates in concrete.

South Africa: Hippo Quarries Technical Publication, 1989.

w12x Baalbaki W, Benmokrane B, Challal O, Aitcin PC. Influence

of coarse aggregate on elastic properties of high performance

concrete. ACI Mater J 1991;88(5):499 503.

w13x Giaccio G, Rocco C, Violini D, Zappitelli J, Zerbino R. HSC

incorporating different coarse aggregates. ACI Mater J

1992;89(3):242 6.

w14x Aitcin PC. From gigaPascals to nanometers. Engineering Foundation Conference, Potosi, Missouri, August 1988.

w15x Aitcin PC, Sarkar SL, Yaya D. Microstructural study of

different types of very HSC. Proc Mater Res Soc 1987;85:261

72.

w16x Zhang MH, Gjorv OE. Mechanical properties of high-strength

lightweight concrete. ACI Mater J 1991;88(3):122 6.

w17x Chang TP, Su NK. Estimation of coarse aggregate strength in

HSC. ACI Mater J 1996;93(1):3 8.

w18x Slate FO, Nilson AH, Martinez S. Mechanical properties of

high-strength lightweight concrete. High strength concrete seminar course manualySCM-15(87)-ACI.

w19x Swamy RN. High-strength concrete-material properties and

structural behavior. SP-87. Detroit: American Concrete Institute, 1991. p. 113 9.

w20x Neville AM. Properties of concrete. A Pitman International

Text, 1978.

w21x Wasserman R, Bentur A. Interfacial interactions in lightweight

aggregate concretes and their influence on the concrete

strength. Cem Concr Compos 1996;18:67 76.

w22x Berke NS, Dallaire MP, Hicks MC. Plastic, mechanical, corrosion and chemical resistance properties of silica fume concretes. ACI SP-132, Detroit. 1992. p. 1125 50.

w23x Carette GG, Malhotra VM. Long-term strength development

of silica fume concrete. ACI SP-132, Detroit. 1992. p. 1017

44.

w24x Carrasquillo RL, Nilson AH, Slate FO. Microcracking and

engineering properties of high-strength concrete. Structural

engineering, report no. 80-1. Ithaca, New York: Cornell University, 1980.

w25x Hooton RD. Influence of silica fume replacement of cement

on physical properties and reactivity. ACI Mater J

1993;90(2):143.

w26x Luther MD, Hanse W. Proceedings of the Third International

Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, Trondheim, Norway, ACI Special Publication SP 114-27, 1989:573.

w27x Khatri RP, Sirivivathnanon V. Effect of different supplementary

cementitious materials on mechanical properties of high performance concrete. Cem Concr Res 1995;25(1):209 20.

Você também pode gostar

- Lecture Notes on Reinforced Concrete DesignNo EverandLecture Notes on Reinforced Concrete DesignAinda não há avaliações

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessAinda não há avaliações

- Designing, Proposing and Comparing The Methods Predicting The Compressive Strength of The Ferrocement MortarDocumento10 páginasDesigning, Proposing and Comparing The Methods Predicting The Compressive Strength of The Ferrocement MortarAnis ShatnawiAinda não há avaliações

- Improvement in Durability of Ferrocement Using Fly Ash and Silica Fume Modified MortarDocumento4 páginasImprovement in Durability of Ferrocement Using Fly Ash and Silica Fume Modified MortarijsretAinda não há avaliações

- Investigating The Abrasion Resistance of Interlocking Blocks Incorporating Steel Slag AggregateDocumento13 páginasInvestigating The Abrasion Resistance of Interlocking Blocks Incorporating Steel Slag Aggregatemido_20067581Ainda não há avaliações

- Investigation of Shear Transfer Between Vibrated and Self-Consolidating Concrete in Precast Reinforced Concrete ConstructionsDocumento9 páginasInvestigation of Shear Transfer Between Vibrated and Self-Consolidating Concrete in Precast Reinforced Concrete ConstructionsRohan ReddyAinda não há avaliações

- J Cemconcomp 2003 09 003Documento10 páginasJ Cemconcomp 2003 09 003shaik chandiniAinda não há avaliações

- Construction and Building Materials: Kazim TurkDocumento9 páginasConstruction and Building Materials: Kazim TurkTarek ChikerAinda não há avaliações

- Testing Abrasion Resistance of High-Strength ConcreteDocumento11 páginasTesting Abrasion Resistance of High-Strength ConcreteKeerti BonguAinda não há avaliações

- Effect of fly ash and silica fume on compressive strength of self-compacting concreteDocumento8 páginasEffect of fly ash and silica fume on compressive strength of self-compacting concretegeostaterAinda não há avaliações

- Ultra-High-Performance Concrete Impacts of Steel Fibre Shape and Content On Flowability, Compressive Strength and Modulus of RuptureDocumento7 páginasUltra-High-Performance Concrete Impacts of Steel Fibre Shape and Content On Flowability, Compressive Strength and Modulus of RuptureShaker QaidiAinda não há avaliações

- EffectofpozzolanicmaterialsandcuringmethodsontheelasticmodulusofHPC Nassif Et Al 2005Documento10 páginasEffectofpozzolanicmaterialsandcuringmethodsontheelasticmodulusofHPC Nassif Et Al 2005omar heshamAinda não há avaliações

- Determination_of_rectangular_stress_blocDocumento6 páginasDetermination_of_rectangular_stress_blocKorrapati Pratyusha 19PHD0497Ainda não há avaliações

- An Experimental Study On Bond Strength of Reinforced Steel in High Volume Fly Ash ConcreteDocumento14 páginasAn Experimental Study On Bond Strength of Reinforced Steel in High Volume Fly Ash Concretemohamed ellithyAinda não há avaliações

- Al-Fahdawi 2020 IOP Conf. Ser. Mater. Sci. Eng. 881 012179Documento10 páginasAl-Fahdawi 2020 IOP Conf. Ser. Mater. Sci. Eng. 881 012179Saif LlAinda não há avaliações

- Ultra High Strength Concrete1Documento34 páginasUltra High Strength Concrete1rangarajAinda não há avaliações

- Effects of Various Fineness Moduli of FineDocumento12 páginasEffects of Various Fineness Moduli of FineGeomanjeriAinda não há avaliações

- Cementitious FlooringDocumento11 páginasCementitious FlooringMarjorie Dulay DumolAinda não há avaliações

- Proportioning of Fly Ash Concrete MixesDocumento6 páginasProportioning of Fly Ash Concrete Mixesjignesh shahAinda não há avaliações

- Role of Water Cement Ratio On The Cement MortarDocumento7 páginasRole of Water Cement Ratio On The Cement MortarPankaj Munjal100% (1)

- Axial Shortening MendisDocumento6 páginasAxial Shortening Mendisjoaobarbosa22Ainda não há avaliações

- Self-Compacting Concrete Literature Review ChapterDocumento27 páginasSelf-Compacting Concrete Literature Review ChapterPutu DidikAinda não há avaliações

- Influence of Sand Grain Size Distribution and Supplementary Cementitious Materials On The Compressive Strength of Ultrahigh-Performance ConcreteDocumento9 páginasInfluence of Sand Grain Size Distribution and Supplementary Cementitious Materials On The Compressive Strength of Ultrahigh-Performance ConcreteShaker QaidiAinda não há avaliações

- Correlation between compressive strength and durability indices of cement concretesDocumento5 páginasCorrelation between compressive strength and durability indices of cement concretesrajasekhar.cheruvu8635Ainda não há avaliações

- Two-Stage Concrete As A Sustainable Production: CMSS-2017Documento7 páginasTwo-Stage Concrete As A Sustainable Production: CMSS-2017Bishowkumar ShresthaAinda não há avaliações

- Comparative Study of Fly Ash and Pond Ash On Compressive and Flexural Strength of ConcreteDocumento4 páginasComparative Study of Fly Ash and Pond Ash On Compressive and Flexural Strength of Concretediwakar prasadAinda não há avaliações

- Compliance criteria for quality concrete mixesDocumento8 páginasCompliance criteria for quality concrete mixesrajasekhar.cheruvu8635Ainda não há avaliações

- Production of High Strength Concrete in SudanDocumento8 páginasProduction of High Strength Concrete in SudanInternational Organization of Scientific Research (IOSR)Ainda não há avaliações

- A Study On Durability Properties of High-PerformanceDocumento15 páginasA Study On Durability Properties of High-PerformanceBenharzallah KrobbaAinda não há avaliações

- The Effect of Shrinkage Cracks On The Load Bearing Capacity of Steel-Fibre-Reinforced Roller-Compacted - Concrete PavementsDocumento27 páginasThe Effect of Shrinkage Cracks On The Load Bearing Capacity of Steel-Fibre-Reinforced Roller-Compacted - Concrete PavementsLouis KiwaAinda não há avaliações

- Development of Mix Design for High Strength ConcreteDocumento5 páginasDevelopment of Mix Design for High Strength ConcretesooricivilAinda não há avaliações

- Mechanical Properties of Cement Mortar With Al O NanoparticlesDocumento4 páginasMechanical Properties of Cement Mortar With Al O NanoparticlesSridhar DineshAinda não há avaliações

- 1 s2.0 S2949891023010333 MainDocumento23 páginas1 s2.0 S2949891023010333 Mainmyak33802Ainda não há avaliações

- Investigation of Abrasion Test and Mechanical Properties of Concrete Using Fly Ash As A Partial Replacement of CementDocumento11 páginasInvestigation of Abrasion Test and Mechanical Properties of Concrete Using Fly Ash As A Partial Replacement of CementIJRASETPublicationsAinda não há avaliações

- Performance of Ferrocement Panels in Different EnvironmentsDocumento8 páginasPerformance of Ferrocement Panels in Different EnvironmentsSulaiman Mohsin AbdulAzizAinda não há avaliações

- Effect of Mineral Admixtures On Mechanical Properties of High Strength Concrete Made With Locally Available MaterialsDocumento13 páginasEffect of Mineral Admixtures On Mechanical Properties of High Strength Concrete Made With Locally Available MaterialsSahriil AffandiAinda não há avaliações

- Jalal Et Al PDFDocumento12 páginasJalal Et Al PDFreginaldovirgilioAinda não há avaliações

- Construction and Building Materials: Ali Reza Khaloo, Amin Esrafili, Masoud Kalani, Mohammad Hosein MobiniDocumento7 páginasConstruction and Building Materials: Ali Reza Khaloo, Amin Esrafili, Masoud Kalani, Mohammad Hosein MobiniMohamed YagoubAinda não há avaliações

- 1-s2.0-S1018363923000284-main (1) (1)Documento11 páginas1-s2.0-S1018363923000284-main (1) (1)RidwanAinda não há avaliações

- Influence of Truck Drum Revolution Count On Fresh and Hardened Concrete CharacteristicsDocumento11 páginasInfluence of Truck Drum Revolution Count On Fresh and Hardened Concrete CharacteristicsEvana LarasatiAinda não há avaliações

- Effect of Quarry Rock Dust On The Exural Strength of ConcreteDocumento8 páginasEffect of Quarry Rock Dust On The Exural Strength of Concreteadeoye adebayoAinda não há avaliações

- 7.prediction of Models On UhpcDocumento36 páginas7.prediction of Models On UhpcDarssni RavichandranAinda não há avaliações

- The Use of Blast Furnace Slag As A Supplementary CDocumento13 páginasThe Use of Blast Furnace Slag As A Supplementary CCivil manAinda não há avaliações

- The Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsDocumento11 páginasThe Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsTarek ChikerAinda não há avaliações

- Brief: Reducing The Specimen Size of Concrete Flexural Strength Test For Safety and Ease of HandlingDocumento12 páginasBrief: Reducing The Specimen Size of Concrete Flexural Strength Test For Safety and Ease of HandlinganbertjonathanAinda não há avaliações

- Brief: Reducing The Specimen Size of Concrete Flexural Strength Test For Safety and Ease of HandlingDocumento12 páginasBrief: Reducing The Specimen Size of Concrete Flexural Strength Test For Safety and Ease of HandlinganbertjonathanAinda não há avaliações

- In Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteDocumento9 páginasIn Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteA M Yasin ArmanAinda não há avaliações

- Effect of Tension Lap Splice On The Behavior of High Strength Self Compacted Concrete BeamsDocumento10 páginasEffect of Tension Lap Splice On The Behavior of High Strength Self Compacted Concrete BeamsMaruf MuhammadAinda não há avaliações

- Effect of Aggregate Type On Compressive Strength of ConcreteDocumento10 páginasEffect of Aggregate Type On Compressive Strength of ConcreteamelialoritaAinda não há avaliações

- J Cemconres 2004 11 003Documento8 páginasJ Cemconres 2004 11 003BhuvanAinda não há avaliações

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Documento8 páginasIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationAinda não há avaliações

- Effects of hydroxyethyl cellulose and oxalic acid on cement propertiesDocumento11 páginasEffects of hydroxyethyl cellulose and oxalic acid on cement propertiesRoberto MuselliAinda não há avaliações

- Effect of Fly Ash On Durability of Leightweight ConcreteDocumento10 páginasEffect of Fly Ash On Durability of Leightweight ConcreteRadna kurniasariAinda não há avaliações

- Impact Test On Geopolymer Concrete Slabs: T Kiran, Sadath Ali Khan Zai, Srikant Reddy SDocumento7 páginasImpact Test On Geopolymer Concrete Slabs: T Kiran, Sadath Ali Khan Zai, Srikant Reddy SAce NovoAinda não há avaliações

- A Review On Recycled Aggregate Concrete Reinforced With FibersDocumento6 páginasA Review On Recycled Aggregate Concrete Reinforced With FibersIJRASETPublicationsAinda não há avaliações

- Materials: Engineering Properties and Correlation Analysis of Fiber Cementitious MaterialsDocumento13 páginasMaterials: Engineering Properties and Correlation Analysis of Fiber Cementitious MaterialsDaniel GiraldoAinda não há avaliações

- Parative Study of Strength and Corrosion Resistant Properties of Plain and Blended Cement Concrete TypesDocumento14 páginasParative Study of Strength and Corrosion Resistant Properties of Plain and Blended Cement Concrete TypeszeeAinda não há avaliações

- 10.1007@978 3 030 22034 119Documento7 páginas10.1007@978 3 030 22034 119Ahmed EsamAinda não há avaliações

- Relation Between Density and Compressive Strength of Hardened ConcreteDocumento9 páginasRelation Between Density and Compressive Strength of Hardened ConcreteMohd NasimAinda não há avaliações

- Properties of Concrete Influenced by Aggregate Shape and TextureDocumento9 páginasProperties of Concrete Influenced by Aggregate Shape and TexturebinodAinda não há avaliações

- IBPS Clerk Question PaperDocumento16 páginasIBPS Clerk Question PaperjagdishAinda não há avaliações

- Clerk Model Paper Computer by (WWW - Questionpaperz.in)Documento5 páginasClerk Model Paper Computer by (WWW - Questionpaperz.in)Elakkiya KarthicAinda não há avaliações

- Ibps Po Cwe: Test-I: Reasoning AbilityDocumento24 páginasIbps Po Cwe: Test-I: Reasoning AbilityBalu RahulAinda não há avaliações

- The 5 Generations of ComputersDocumento14 páginasThe 5 Generations of ComputersVehleSinghAinda não há avaliações

- Adjectives PDFDocumento3 páginasAdjectives PDFManoj KbAinda não há avaliações

- Car 16 PDFDocumento7 páginasCar 16 PDFElakkiya KarthicAinda não há avaliações

- IBPS CWE PO/MT 2012 Question Paper With Answer KeyDocumento29 páginasIBPS CWE PO/MT 2012 Question Paper With Answer KeysachinAinda não há avaliações

- SBI Clerk Examination Mock Model Question PaperDocumento12 páginasSBI Clerk Examination Mock Model Question Paperanon_82618091Ainda não há avaliações

- Clerk Model Paper 1 AnswersDocumento4 páginasClerk Model Paper 1 AnswersElakkiya KarthicAinda não há avaliações

- Ibps Clerk 2011Documento38 páginasIbps Clerk 2011rajwants921620Ainda não há avaliações

- IBPS Clerk 2012 16.12.2012Documento33 páginasIBPS Clerk 2012 16.12.2012Elakkiya KarthicAinda não há avaliações

- IBPS Common Written Exam PO / MT: Test - I: Reasoning AbilityDocumento46 páginasIBPS Common Written Exam PO / MT: Test - I: Reasoning AbilitysachinAinda não há avaliações

- Overhaul Approvals for Aircraft ComponentsDocumento21 páginasOverhaul Approvals for Aircraft ComponentschelliboyanaAinda não há avaliações

- Solar Tracking System Project ReportDocumento12 páginasSolar Tracking System Project ReportSrinivas MudhirajAinda não há avaliações

- Design & Development of A Two-Jaw Parallel Pneumatic GripperDocumento49 páginasDesign & Development of A Two-Jaw Parallel Pneumatic Gripperengr_faheemAinda não há avaliações

- Train ProjectDocumento74 páginasTrain ProjectElakkiya KarthicAinda não há avaliações

- Abirami AnthathiDocumento24 páginasAbirami Anthathijekay2ab92% (12)

- PROCEDURE FOR RENEWAL OF AME'S LICENCEDocumento4 páginasPROCEDURE FOR RENEWAL OF AME'S LICENCEElakkiya KarthicAinda não há avaliações

- Auto Cad MechtrncsDocumento41 páginasAuto Cad MechtrncsElakkiya KarthicAinda não há avaliações

- Belajar Autocad 3DDocumento15 páginasBelajar Autocad 3DMuhammad SyawalAinda não há avaliações

- Conveyer For Quality ControlDocumento2 páginasConveyer For Quality ControlElakkiya KarthicAinda não há avaliações

- (Unless Otherwise Specified, Dimensions Are in Inches.) 1.: Autocad Tutorial: 2D Fundamentals Add-1Documento10 páginas(Unless Otherwise Specified, Dimensions Are in Inches.) 1.: Autocad Tutorial: 2D Fundamentals Add-1shaikhaziz84Ainda não há avaliações

- Automatic Foot Dust CleanerDocumento2 páginasAutomatic Foot Dust CleanerElakkiya Karthic100% (1)

- Engine Oil Level and Temperature Monitoring SystemDocumento3 páginasEngine Oil Level and Temperature Monitoring SystemElakkiya KarthicAinda não há avaliações

- Piezo Electric Power Generation Using Shock AbsorberDocumento1 páginaPiezo Electric Power Generation Using Shock AbsorberElakkiya KarthicAinda não há avaliações

- ME582 Chapter 3 Micromechanical AnalysisDocumento26 páginasME582 Chapter 3 Micromechanical AnalysisElakkiya KarthicAinda não há avaliações

- Dress Wasing Attachments in Gym CycleDocumento2 páginasDress Wasing Attachments in Gym CycleElakkiya KarthicAinda não há avaliações

- Compression Air EngineDocumento1 páginaCompression Air EngineElakkiya KarthicAinda não há avaliações

- Aerodrome Data, Physical Characteristics and Obstacle RestrictionDocumento19 páginasAerodrome Data, Physical Characteristics and Obstacle RestrictionElakkiya Karthic100% (1)

- 16 Mark QuestionDocumento3 páginas16 Mark QuestionElakkiya Karthic100% (1)

- MINING AND EXTRACTIVE TECHNOLOGYDocumento68 páginasMINING AND EXTRACTIVE TECHNOLOGYKiran JojiAinda não há avaliações

- Management of Solid Waste For Sustainability of Steel IndustryDocumento7 páginasManagement of Solid Waste For Sustainability of Steel IndustryAtika syafawiAinda não há avaliações

- Luminescent Materials and ApplicationsDocumento34 páginasLuminescent Materials and ApplicationsfreeroamAinda não há avaliações

- Characteristics and Cementitious Properties of Ladle Slag Fines From Steel ProductionDocumento4 páginasCharacteristics and Cementitious Properties of Ladle Slag Fines From Steel Productionneetika tiwariAinda não há avaliações

- 2017.02 POV M.C.natarajaDocumento2 páginas2017.02 POV M.C.natarajasmishra2222Ainda não há avaliações

- Norma ASTM C125Documento9 páginasNorma ASTM C125Jony GutiérrezAinda não há avaliações

- METALLURGICAL TREATMENT DUCTILE IRONin ProgressDocumento78 páginasMETALLURGICAL TREATMENT DUCTILE IRONin ProgressVishal MaliAinda não há avaliações

- Label Welding DefectsDocumento54 páginasLabel Welding DefectsMuthuKumarAinda não há avaliações

- Lecture 3 Casting Surface DefectsDocumento72 páginasLecture 3 Casting Surface DefectsLuis Arturo RamirezAinda não há avaliações

- Project Reports ListDocumento266 páginasProject Reports ListSrikanth ChandaAinda não há avaliações

- CEMENTDocumento77 páginasCEMENTLeecel CalugayAinda não há avaliações

- Masonry and Concrete: Practical Guide Book SeriesDocumento168 páginasMasonry and Concrete: Practical Guide Book SeriesMirajAinda não há avaliações

- 166 Q 1 D 1916Documento84 páginas166 Q 1 D 1916subhansamuelsAinda não há avaliações

- Guide to Metallurgy, Welding and TestingDocumento41 páginasGuide to Metallurgy, Welding and Testingolp757Ainda não há avaliações

- Lecture 07 - CUPOLA AND CHARGE ESTIMATION FOR CUPOLADocumento9 páginasLecture 07 - CUPOLA AND CHARGE ESTIMATION FOR CUPOLAManan GuptaAinda não há avaliações

- New Microsoft Word DocumentDocumento15 páginasNew Microsoft Word DocumentSK Abdul KaiumAinda não há avaliações

- SW ManualDocumento663 páginasSW ManualAnil Amrawanshi100% (1)

- Manufacture of SteelDocumento10 páginasManufacture of SteelBGSSAP 2017Ainda não há avaliações

- Chapter 13, 14 - Metals PDFDocumento9 páginasChapter 13, 14 - Metals PDFAarush SharmaAinda não há avaliações

- Reactivity and PerformanceDocumento6 páginasReactivity and Performancepabloa19Ainda não há avaliações

- Understanding Domestic Work Exploring Issues, Literature, and Policy PerspectivesDocumento4 páginasUnderstanding Domestic Work Exploring Issues, Literature, and Policy PerspectivesEditor IJTSRDAinda não há avaliações

- BF Alkali ProblemDocumento6 páginasBF Alkali ProblemSuresh BabuAinda não há avaliações

- PROSES EKTRAKSI Au (GOLDDocumento46 páginasPROSES EKTRAKSI Au (GOLDNanda Rizky0% (1)

- Lecture 21 PDFDocumento14 páginasLecture 21 PDFMehmet Arvasi100% (1)

- Metallurgy Notes For IIT JEE PDFDocumento17 páginasMetallurgy Notes For IIT JEE PDFADIL RIZVIAinda não há avaliações

- Group IndustriesDocumento43 páginasGroup IndustriesDevanathan ChinnasamyAinda não há avaliações

- Alternatives of Sand PDFDocumento27 páginasAlternatives of Sand PDFRaviteja100% (1)

- Fluxes Used in SAWDocumento21 páginasFluxes Used in SAWTrushar ParmarAinda não há avaliações

- Steel Making ProcessDocumento19 páginasSteel Making ProcessHari sadu100% (1)

- Steel Making: Basic Oxygen ProcessDocumento1 páginaSteel Making: Basic Oxygen ProcessPablo GomesAinda não há avaliações