Escolar Documentos

Profissional Documentos

Cultura Documentos

Multigraphics 1450/1650 Heavy-Duty Drive Motor Conversion Kit

Enviado por

porqTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Multigraphics 1450/1650 Heavy-Duty Drive Motor Conversion Kit

Enviado por

porqDireitos autorais:

Formatos disponíveis

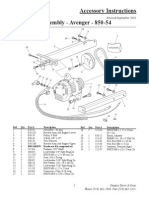

MULTIGRAPHICS 1450/1650 HEAVY-DUTY DRIVE MOTOR

CONVERSION KIT (PART NO. 43866)

43866i.08

5/1/96

INSTALLING THE MULTIGRAPHICS 1450/1650 HEAVY-DUTY

DRIVE MOTOR CONVERSION KIT (PART NO. 43866)

Read through these INSTALLATION INSTRUCTIONS once briefly to familiarize yourself with the various

parts that are required to install your motor kit. Follow the instructions and the installation will be a relatively

simple operation. If you need additional information, please call Townsend Industries at 1-800-247-2262,1515-967-4261, or FAX 1-515-967-7519.

WARNING: Unplug the parent press.

1. Locate the parent press serial number plate (QG) and affix the adhesive replacement electrical current

plate (QH) designating AMPS 14/13 over the original AMPS 12/11 rating. The serial number plate is usually

on the cabinet door.

2. Place the adhesive replacement electrical rating plate (QI) designating F4 10A 250V Slo-Blo over the

original F4 7A 250V Slo-Blo rating on the control box cover. Remove the original 7A fuse and install the

provided 10A fuse (QJ). Keep the extra 10A fuse inside the control box.

WARNING: BE SURE ALL GUARDS, COVERS, AND SAFETY DEVICES ARE INSTALLED

AND PROPERLY ADJUSTED BEFORE OPERATING THIS UNIT. IF THE T-51 IS REMOVED

FROM THE PARENT PRESS, THE ORIGINAL GUARDING MUST BE REPLACED BEFORE

OPERATING THE PRESS. WHEN THE T-51 IS SWUNG OFF TO THE SIDE, THE REPLACEMENT SAFETY GUARD MUST BE USED BEFORE OPERATING THE PRESS.

43866i.08

5/1/96

INSTALLING THE MULTIGRAPHICS 1450/1650 HEAVY-DUTY

DRIVE MOTOR CONVERSION KIT (PART NO. 43866)

3. Take off the non-operator side cabinet cover and unplug the fan.

4. Remove the four bolts that secures the motor to the mounting plate and slip the drive belt off of the motor

drive pulley. Lift the motor off of the plate and set it onto the floor.

5. Remove the power cord from the motor by unplugging it from the two wires inside the motor wiring

compartment and removing the ground wire screw. Take the drive pulley (WA) off of the motor. Slide the

pulley onto the replacement motor assembly intermediate shaft so that it is even with the end of the shaft.

Tighten the locking set screw that is oriented toward the inside of the pulley. Set the original motor aside.

6. If the motor vibration isolators are not the current design (WC) and (WD), update the parent press with the

necessary conversion kit (part number 43936) before proceeding. The kit can be ordered by calling Townsend

Industries at 1-800-247-2262, 1-515-967-4261, or FAX 1-515-967-7519.

7. Remove the motor mounting plate by taking off the nuts on the threaded rods (WB) and bolts (WC1)

protruding through the vibration isolators. Remove the bracket and vibration isolator assembly (WD) from

the plate.

8. Take off the plate (WN). Insert the power cord through the strain relief clamp (WH). Plug the brown cord

wire (WI) onto the black motor wire (WK) and the blue cord wire (WJ) onto the red motor wire (WL). Secure

the green / yellow ground wire (WM) to the motor using the ground screw. Tighten the screws on the strain

relief clamp (WH) to secure the power cord. Replace the plate (WN).

9. Position 3 or 4 pieces of the styrofoam packing material directly under the motor mounting area as an aid

to installing the replacement motor assembly (WE). Set the replacement motor assembly onto the bolts

(WC1) and finger tighten the parent press star washers and nuts. Slip the parent press drive belt (WF) onto

the drive pulley. The belt will help support the motor as the nuts are completely tightened.

10. Mount the bracket and vibration isolator assembly (WD) using the parent press star washers and nuts.

Thread the parent press nuts onto the threaded rods (WB) and adjust the drive belt tension so that it deflects

1/4 - 1/2 inch (6 - 13 mm). To ensure that the replacement motor assembly is level, be certain that the

dimension (WG) is the same for each threaded rod when the belt tension is correct.

WARNING: BE SURE ALL GUARDS, COVERS, AND SAFETY DEVICES ARE INSTALLED

AND PROPERLY ADJUSTED BEFORE OPERATING THIS UNIT. IF THE T-51 IS REMOVED

FROM THE PARENT PRESS, THE ORIGINAL GUARDING MUST BE REPLACED BEFORE

OPERATING THE PRESS. WHEN THE T-51 IS SWUNG OFF TO THE SIDE, THE REPLACEMENT SAFETY GUARD MUST BE USED BEFORE OPERATING THE PRESS.

43866i.08

5/1/96

INSTALLING THE MULTIGRAPHICS 1450/1650 HEAVY-DUTY

DRIVE MOTOR CONVERSION KIT (PART NO. 43866)

11. Remove the 4 screws that secures the control board (QA) to the control box. Leave the wires connected

to the board. Thoroughly clean the back side of the control board, heat sink (QB), and mounting surfaces of

the control box with alcohol. Completely coat the back side of the board and heat sink with the provided

Silicone Heat Sink Compound (QC). Install the board and heat sink using the provided

screws, washers, and nuts.

12. Mount the non-operator side cabinet cover being certain that the fan is plugged into the circuit.

13. Recalibrate the TORQUE (QF) limiting potentiometer as follows:

WARNING: The recalibration procedure should only be done by authorized technicians. Also, if the IR

COMP (QK), MIN SPEED (QL), or MAX SPEED (QM) potentiometers need to be adjusted, refer to the

Multigraphics manual section entitled Safety, Drive, Control 21-3. HOWEVER, THE TORQUE (I-LIM)

POTENTIOMETER MUST BE ADJUSTED ACCORDING TO THE FOLLOWING INSTRUCTIONS TO

PREVENT EQUIPMENT DAMAGE.

Open the cabinet doors and take off the control box cover.

Connect the terminals of a millivolt meter to the resistor at the locations (QD) and (QE). Set the meter to

read millivolts.

Turn the speed control to the position 10 so that the speed is 10000 impressions per hour. Plug in the

parent press.

WARNING: When performing the following step, do not adjust the meter reading above 95mV since the

handwheel cannot always be held above this reading. If the correct mV meter readings cannot be

achieved, the IR COMP (QK), MIN SPEED (QL), or MAX SPEED (QM) potentiometers may need to be

adjusted by referring to the Multigraphics manual section entitled Safety, Drive, Control 21-3.

Use the Multigraphics safety interlock by-pass key so that the parent press can be operated. While 1

technician stalls the motor by holding the handwheel, another technician must turn the screw (QF1) on

the potentiometer so that the meter reading is 95mV and then turn the screw the opposite direction to

decrease the reading to 92mV. Use the provided screwdriver to perform this adjustment.

14.WARNING: Remove the by-pass key. Install the control box cover and close the cabinet doors.

WARNING: BE SURE ALL GUARDS, COVERS, AND SAFETY DEVICES ARE INSTALLED

AND PROPERLY ADJUSTED BEFORE OPERATING THIS UNIT. IF THE T-51 IS REMOVED

FROM THE PARENT PRESS, THE ORIGINAL GUARDING MUST BE REPLACED BEFORE

OPERATING THE PRESS. WHEN THE T-51 IS SWUNG OFF TO THE SIDE, THE REPLACEMENT SAFETY GUARD MUST BE USED BEFORE OPERATING THE PRESS.

43866i.08

5/1/96

Você também pode gostar

- Subaru - Impreza - Workshop Manual - 1999 - 2002Documento8.373 páginasSubaru - Impreza - Workshop Manual - 1999 - 2002bart3omiej3boguszewiAinda não há avaliações

- 194 Funny and Interesting FactsDocumento6 páginas194 Funny and Interesting Factsporq100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- Drive Belt Inspection and Testing ProcedureDocumento13.111 páginasDrive Belt Inspection and Testing ProcedureJuan Harmond Bambang WirawanAinda não há avaliações

- Actuator Variable Geometry Turbocharger ReplacementDocumento11 páginasActuator Variable Geometry Turbocharger ReplacementZoltán Szecsődi100% (1)

- Excel Instructions Using Excel 2010: CAUTION: Read Appendix B For Specific Instructions Relating To These TemplatesDocumento71 páginasExcel Instructions Using Excel 2010: CAUTION: Read Appendix B For Specific Instructions Relating To These TemplatesMelissaGuerra10% (10)

- Survive & Thrive with Brand ThinkingDocumento7 páginasSurvive & Thrive with Brand Thinkingporq100% (5)

- 11 Sex Secrets From The Experts That Will Set Your Bed On FireDocumento4 páginas11 Sex Secrets From The Experts That Will Set Your Bed On Fireporq100% (1)

- Test Transmision 420E CatDocumento8 páginasTest Transmision 420E CatEdin Raul Yalle RafaelAinda não há avaliações

- Replace Rocker Arm Cover Gasket - ctm415 - Service ADVISOR™Documento5 páginasReplace Rocker Arm Cover Gasket - ctm415 - Service ADVISOR™Fernando Aguilar100% (1)

- Brand Extension by Marty NeumeierDocumento15 páginasBrand Extension by Marty NeumeierporqAinda não há avaliações

- State of California Security Evaluation ES&S EVS 5210Documento12 páginasState of California Security Evaluation ES&S EVS 5210Christopher GleasonAinda não há avaliações

- Behavior Based Safety ChecklistDocumento5 páginasBehavior Based Safety Checklistvictor100% (1)

- 21 Things To Look For in A Boyfriend by Chelsea FaganDocumento2 páginas21 Things To Look For in A Boyfriend by Chelsea Faganporq100% (1)

- 3054 Engine Valve Lash - InspectAdjustDocumento5 páginas3054 Engine Valve Lash - InspectAdjusthenry lavieraAinda não há avaliações

- Caja Reductora de EngranajeDocumento32 páginasCaja Reductora de EngranajeJesùs AmèsquitaAinda não há avaliações

- Her Deepest, Darkest Sex Secrets RevealedDocumento4 páginasHer Deepest, Darkest Sex Secrets RevealedporqAinda não há avaliações

- The Strategic Pyramid: Steal This IdeaDocumento6 páginasThe Strategic Pyramid: Steal This IdeaporqAinda não há avaliações

- The Originality Scale by Marty NeumeierDocumento12 páginasThe Originality Scale by Marty NeumeierporqAinda não há avaliações

- Installation, Maintenaince and Service Braden PD15B, PD12C, PD17ADocumento39 páginasInstallation, Maintenaince and Service Braden PD15B, PD12C, PD17ALázaro ConcepcionAinda não há avaliações

- Installation and Parts Manual D6R - D6TDocumento23 páginasInstallation and Parts Manual D6R - D6TJUAN CARLOS PAZ100% (3)

- Braden PD Series Hydraulic WinchDocumento39 páginasBraden PD Series Hydraulic WinchKOKAinda não há avaliações

- AUMA Valve ActuatorDocumento14 páginasAUMA Valve ActuatorSellappan MuthusamyAinda não há avaliações

- Brand Messaging by Marty NeumeierDocumento14 páginasBrand Messaging by Marty Neumeierporq50% (2)

- Brand Messaging by Marty NeumeierDocumento14 páginasBrand Messaging by Marty Neumeierporq50% (2)

- 15 Ways To Become A Better PersonDocumento3 páginas15 Ways To Become A Better Personporq100% (1)

- Student Guide - CFP 270 - Brocade 8 GB/s Introduction To Administration and Theory LabDocumento74 páginasStudent Guide - CFP 270 - Brocade 8 GB/s Introduction To Administration and Theory LabemcviltAinda não há avaliações

- George Bacovia Plumb ComentariuDocumento32 páginasGeorge Bacovia Plumb ComentariuFlorinel Alex11% (18)

- VTC Actuator FixDocumento11 páginasVTC Actuator FixthemummraAinda não há avaliações

- 0133900061Documento15 páginas0133900061GiacomoDemoniac50% (2)

- Manual pl0495503 PDFDocumento12 páginasManual pl0495503 PDFfelipesaraabrilcarolAinda não há avaliações

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- Governador para Motor PerkinsDocumento4 páginasGovernador para Motor Perkinsacere18Ainda não há avaliações

- The Brand Flip - SampleDocumento33 páginasThe Brand Flip - Sampleporq100% (1)

- Principia Ketogenica 2014082901Documento289 páginasPrincipia Ketogenica 2014082901erixsparhawk50% (2)

- II Field Force Vietnam Lessons Learned 12 January 1968Documento71 páginasII Field Force Vietnam Lessons Learned 12 January 1968Robert ValeAinda não há avaliações

- 004 Headlines Headlines More Headlines PDFDocumento23 páginas004 Headlines Headlines More Headlines PDFporqAinda não há avaliações

- Breakthrough Advertising PrefaceDocumento1 páginaBreakthrough Advertising PrefaceporqAinda não há avaliações

- Face Recognition Report PDFDocumento16 páginasFace Recognition Report PDFTeja ReddyAinda não há avaliações

- Leverage Design Thinking at Every LevelDocumento5 páginasLeverage Design Thinking at Every LevelporqAinda não há avaliações

- Atv71 Installation Manual EngDocumento43 páginasAtv71 Installation Manual EngArun SudarsanAinda não há avaliações

- Auma ManualDocumento17 páginasAuma ManualAhmed EldosokyAinda não há avaliações

- Flex Sys Cable ReelerDocumento38 páginasFlex Sys Cable ReelerAngel Sanchez VilcaAinda não há avaliações

- Scissors Paper Rock BY MARTY NEUMEIERDocumento13 páginasScissors Paper Rock BY MARTY NEUMEIERporqAinda não há avaliações

- Instalacion Marcha NeumaticaDocumento36 páginasInstalacion Marcha Neumaticaacere18Ainda não há avaliações

- APTA Standards Booklet 2013 PDFDocumento56 páginasAPTA Standards Booklet 2013 PDFFelora MangawangAinda não há avaliações

- Brand Illustrated by Marty NeumeierDocumento10 páginasBrand Illustrated by Marty NeumeierporqAinda não há avaliações

- 8013 Instruction Manual For Camflex and VarimaxDocumento10 páginas8013 Instruction Manual For Camflex and Varimaxtoche33Ainda não há avaliações

- Vlaim029 - Position Pac Iom 07-2000Documento8 páginasVlaim029 - Position Pac Iom 07-2000rodrurenAinda não há avaliações

- Pole Position 14 VKMC 01250 1 EN Highres PDFDocumento6 páginasPole Position 14 VKMC 01250 1 EN Highres PDFRita PcomputerAinda não há avaliações

- 25F-PRCServ PDFDocumento38 páginas25F-PRCServ PDFsindelu60Ainda não há avaliações

- Ar 40Documento6 páginasAr 40jose maria machin sanchezAinda não há avaliações

- 07 - Power DrivetrainDocumento20 páginas07 - Power DrivetrainVictor RamirezAinda não há avaliações

- 950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationDocumento12 páginas950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationMohamed ZohierAinda não há avaliações

- Alternator Installation Instructions for Avenger 850-54Documento6 páginasAlternator Installation Instructions for Avenger 850-54cristi_stoiciucAinda não há avaliações

- Installation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)Documento23 páginasInstallation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)aliAinda não há avaliações

- Hydrostatic Test 5FZDocumento26 páginasHydrostatic Test 5FZGuido Emanuel SteinbachAinda não há avaliações

- Enertork TQ020Documento48 páginasEnertork TQ020evilolao50% (2)

- Parking Brake System: SectionDocumento8 páginasParking Brake System: Sectionfrank1220uAinda não há avaliações

- Data Anchor Windlass ManualDocumento23 páginasData Anchor Windlass ManualccnbtAinda não há avaliações

- Actuador Electrico AutomaxDocumento12 páginasActuador Electrico AutomaxLuis Guerra VegaAinda não há avaliações

- 2 Installation Maintenance - FantechDocumento12 páginas2 Installation Maintenance - FantechLoi Chan TuAinda não há avaliações

- Hydrostatic TestDocumento22 páginasHydrostatic TestGuido Emanuel SteinbachAinda não há avaliações

- Belgravia Supreme IOM GuideDocumento12 páginasBelgravia Supreme IOM GuidePaul KwongAinda não há avaliações

- HKS EVC V Boost Controller Setup InstructionsDocumento7 páginasHKS EVC V Boost Controller Setup InstructionsDave_B100% (2)

- Retrofit Transmission Shifter for Increased ReliabilityDocumento6 páginasRetrofit Transmission Shifter for Increased ReliabilityJose Miguel Oyola Coronado0% (1)

- Assembly Compression AirDocumento3 páginasAssembly Compression Airaqshal candraAinda não há avaliações

- 980a3578 PDFDocumento49 páginas980a3578 PDFMichael Davenport100% (1)

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDocumento12 páginasInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146Ainda não há avaliações

- Replace Governor ActuatorDocumento8 páginasReplace Governor ActuatorSteven ManuputtyAinda não há avaliações

- AFC Sensor de Presion PDFDocumento10 páginasAFC Sensor de Presion PDFCharlie BrownAinda não há avaliações

- YTC SPTM-6V Series Position Transmitter User ManualDocumento14 páginasYTC SPTM-6V Series Position Transmitter User ManualcuongnammuAinda não há avaliações

- Installation and Service Instructions For 180-210 C-Face MotorsDocumento4 páginasInstallation and Service Instructions For 180-210 C-Face MotorsAnonymous gMMbTAQlAinda não há avaliações

- Valve Adjustment PDFDocumento34 páginasValve Adjustment PDFlilo6romeroAinda não há avaliações

- MSD Pulse Ignition For Harley-DavidsonDocumento12 páginasMSD Pulse Ignition For Harley-DavidsonFabio MachadoAinda não há avaliações

- Manual Markon NAC160 NAC190Documento23 páginasManual Markon NAC160 NAC190Sajjad HussainAinda não há avaliações

- Cook INSTALLATION, OPERATION, AND MAINTENANCE MANUALDocumento12 páginasCook INSTALLATION, OPERATION, AND MAINTENANCE MANUALtylerdurdaneAinda não há avaliações

- Variable Speed Drives for Asynchronous Motors Installation ManualDocumento43 páginasVariable Speed Drives for Asynchronous Motors Installation ManualsilvaroneAinda não há avaliações

- Max power Installation Manual CT100_CT125_EN_01Documento19 páginasMax power Installation Manual CT100_CT125_EN_01554x95pq54Ainda não há avaliações

- Coleman Generator L0807053Documento12 páginasColeman Generator L0807053Jody WoodenAinda não há avaliações

- Pump and Governor Tool Groups (650, 1250) e Inyeccion 4Documento13 páginasPump and Governor Tool Groups (650, 1250) e Inyeccion 4Jose A. Basanta H.Ainda não há avaliações

- Installation and Maintenance Information: Turbine Powered StartersDocumento12 páginasInstallation and Maintenance Information: Turbine Powered StartersAbdelkader AbdelkaderAinda não há avaliações

- BC-244 NewDocumento5 páginasBC-244 NewLuis Alberto Lopez100% (1)

- TT Bearing Insp Proc v3Documento7 páginasTT Bearing Insp Proc v3Rino AdityaAinda não há avaliações

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationAinda não há avaliações

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationAinda não há avaliações

- 5-How To Eliminate The Dentist From Your Life Using Selfhelp MetodsDocumento4 páginas5-How To Eliminate The Dentist From Your Life Using Selfhelp MetodsjpaAinda não há avaliações

- 82 Mind-Blowing Movies Facts You Probably Didn't KnowDocumento5 páginas82 Mind-Blowing Movies Facts You Probably Didn't KnowporqAinda não há avaliações

- 42 Incredibly Weird Facts You'Ll Want To Tell All Your FriendsDocumento2 páginas42 Incredibly Weird Facts You'Ll Want To Tell All Your FriendsporqAinda não há avaliações

- The Basics of Metaphors A Metaphor Is A BridgeDocumento2 páginasThe Basics of Metaphors A Metaphor Is A Bridgeporq100% (1)

- 25 Science-Backed Ways To Feel HappierDocumento11 páginas25 Science-Backed Ways To Feel HappierporqAinda não há avaliações

- Your Checklist For Dating SuccessDocumento2 páginasYour Checklist For Dating SuccessporqAinda não há avaliações

- How To Find The BEST Therapist For YouDocumento4 páginasHow To Find The BEST Therapist For YouporqAinda não há avaliações

- The Boyfriend List Does He Meet The 12 Checkmarks by Kristen Dalton WolfeDocumento2 páginasThe Boyfriend List Does He Meet The 12 Checkmarks by Kristen Dalton WolfeporqAinda não há avaliações

- The 15 Habits of Incredibly Happy PeopleDocumento7 páginasThe 15 Habits of Incredibly Happy PeopleporqAinda não há avaliações

- Raising A Well Mannered DogDocumento1 páginaRaising A Well Mannered DogporqAinda não há avaliações

- Raising A Well Mannered DogDocumento1 páginaRaising A Well Mannered DogporqAinda não há avaliações

- Cyberbad Where Spam Is Leading To: Phillip Hallam-BakerDocumento28 páginasCyberbad Where Spam Is Leading To: Phillip Hallam-BakerPraveen ChintuAinda não há avaliações

- Denial of Service Attacks: RadwareDocumento20 páginasDenial of Service Attacks: RadwareAnbu VananAinda não há avaliações

- Security in Practice: Examining The Collaborative Management of Sensitive Information in Childcare Centers and Physicians' OfficesDocumento386 páginasSecurity in Practice: Examining The Collaborative Management of Sensitive Information in Childcare Centers and Physicians' OfficesLaurian VegaAinda não há avaliações

- AMA 2005 Electronic Monitoring & Surveillance SurveyDocumento13 páginasAMA 2005 Electronic Monitoring & Surveillance Surveymailinator23Ainda não há avaliações

- Lab No 2Documento4 páginasLab No 2Obaid Ur RehmanAinda não há avaliações

- Cce-Edusat Session For Computer FundamentalsDocumento37 páginasCce-Edusat Session For Computer FundamentalsGemark AlmacenAinda não há avaliações

- Land Allotment Scheme GOMS No 225 Application FormDocumento2 páginasLand Allotment Scheme GOMS No 225 Application FormYenda LakshmanAinda não há avaliações

- Smokeping Cacti OverviewDocumento25 páginasSmokeping Cacti OverviewsigoisetteAinda não há avaliações

- Splendid CRM 2.1 Deployment GuideDocumento23 páginasSplendid CRM 2.1 Deployment GuideAncient MarinerAinda não há avaliações

- Network Traffic Anomaly DetectionDocumento5 páginasNetwork Traffic Anomaly Detectionm1ndwerkAinda não há avaliações

- 7 Golden Safety Rules For Working in HV LaboratoryDocumento4 páginas7 Golden Safety Rules For Working in HV LaboratoryPierre Enrique Carrasco FuentesAinda não há avaliações

- ORACLE-BASE - Oracle Enterprise Manager Cloud Control 12c Release 1 Installation On Oracle Linux 5.7 and 6Documento10 páginasORACLE-BASE - Oracle Enterprise Manager Cloud Control 12c Release 1 Installation On Oracle Linux 5.7 and 6h_sniper551772Ainda não há avaliações

- Reverse Engineering Windows AFD.sys: Uncovering Bugs in the Kernel Networking StackDocumento19 páginasReverse Engineering Windows AFD.sys: Uncovering Bugs in the Kernel Networking Stackjames wrightAinda não há avaliações

- Dubai Customs New Registration PDFDocumento46 páginasDubai Customs New Registration PDFSundara MoorthyAinda não há avaliações

- Auto Key Cipher and Hill CipherDocumento6 páginasAuto Key Cipher and Hill CipherDamam SakethAinda não há avaliações

- TINYPPT presentation template for PowerPointDocumento1 páginaTINYPPT presentation template for PowerPointDiptoDCastleAinda não há avaliações

- ALSTOM Micom P443: Line 2 LineDocumento8 páginasALSTOM Micom P443: Line 2 LineSenthilkumaran VenkatasamyAinda não há avaliações

- The Definitive Guide To Securing Kubernetes: Liz Rice Brendan BurnsDocumento7 páginasThe Definitive Guide To Securing Kubernetes: Liz Rice Brendan BurnsmkafghanAinda não há avaliações

- Epsilon BrochureDocumento8 páginasEpsilon BrochureAbdul Bijur VallarkodathAinda não há avaliações

- EFSIS-2 2P Packaging Application FormDocumento6 páginasEFSIS-2 2P Packaging Application FormjamiegormanAinda não há avaliações

- Quiz 2Documento21 páginasQuiz 2adityavarshaAinda não há avaliações

- RC4 Encryption Algorithm: Computer Network LaboratoryDocumento12 páginasRC4 Encryption Algorithm: Computer Network LaboratoryDivyakant MevaAinda não há avaliações