Escolar Documentos

Profissional Documentos

Cultura Documentos

Michaud

Enviado por

madhuDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Michaud

Enviado por

madhuDireitos autorais:

Formatos disponíveis

PHARMACEUTICALS

JACQUES MICHAUD

Cerestar

Application Centre Pharma & Chemical

Vilvoorde, Belgium

Starch based

excipients for

pharmaceutical tablets

n todays pharmaceutical

softening it for fast disintegration.

industry, excipients must have

Pregelatinised or cold water soluble

more functional properties than

starches act as strong binders resulting

being just inert filler. Excipients

in stronger, but also slower,

are now essential parts of the drug

disintegrating tablets.

delivery system in pharmaceutical

Both starches can be used in wet

tablets. They are generally used as

granulation and direct compression

diluent, binder, disintegrant, gliding

processes, although granulation is

agent, lubricant or release control

frequently favored, due to their poor

agent. At a time when synthetic

compressibility (1).

polymers and animal-based products

The way starch acts in a tablet

are creating some

formulation is

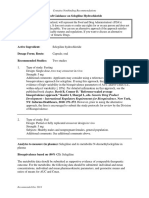

Figure 1 - Scanning electron

concerns amongst the

related to different

microscope picture of CPharm

users, the need for

starch

DC 93000

natural excipients that

characteristics.

are safe and versatile

Among these

becomes more acute.

parameters, the

Starch is one of the

crystalline structure

most traditional

or crystallinity of

excipients used for solid

the starch plays an

dosage formulations.

important role.

Depending on the

Native starch has a

application, maize

crystallinity of

starch acts as a diluent,

approximately

disintegrant or binder.

45%. By

Native starch is a classic tablet

gelatinisation of the starch the crystal

disintegrant whereas pregelatinised

structure is melted, resulting in a

starch is often used as a binder. Starch

crystallinity of barely 5% (2). Maize

also offers a wide range of possibilities

starch with an increased amorphous

and can be one of the preferred

structure will have a larger tendency to

functional excipients of the future. It

solubilise, i.e. reduced tablet

can undergo a wide range of physical

disintegration, and the higher its

or chemical modification in order to

binding strength, the stronger tablets

modify its properties (Table I).

will be.

The specific advantages

Table I

brought by special starches

can be better illustrated by

Chemical modification

Physical modification

three examples.

DIRECTLY

COMPRESSIBLE

STARCH

Tablets containing regular

maize starch easily allow water

to penetrate into the tablet,

42

JUNE 2002

- Oxidation

- Substitution

- Cross-bonding

- Extrusion

- Roll drying

- Spray drying

- Granulation / agglomeration

Advantages:

- New functionality

- Innovation

Advantages:

- Versatility

- Existing monographs

PHARMACEUTICALS

case with osmotic systems where the

One of the other very

release is governed by the

interesting properties of directly

permeability of the drug through a

compressible starch is its

porous membrane. Ion exchange

aptitude to demonstrate

systems are also used when ionic

synergies with other excipients

active is embedded in a matrix

such as lactose and microcapable of exchanging ions. Another

crystalline cellulose. These two

solution is multi-layer coating the

products are certainly some of

tablets. In this case, the delivery of an

the most widely used excipients

active ingredient is delayed by the

in pharmaceutical formulations

respective dissolution time of the

besides starch (5).

different layers.

Partly-pregelatinised starch

A more recent development

and MCC will deform chiefly

involves the encapsulation of an active

plastically whereas lactose will

fragmentise (6). Both

Figure 3 - The influence of the composition of the mixture on

kinds of deformation

the disintegration time.

will aid tablet

Tablets made with a compression force of 25 kN.

formation and will

Type of fit: Special cubic smoothing (R2 = 0.8502)

increase the tablet

hardness. The synergy

becomes more visible

when disintegration

time of a ternary blend

is investigated

(Figure 3). Tablets that

are made with both

lactose and MCC keep

very high disintegration times.

A direct compressible starch that

Only when CPharm DC

has to be both a binder and a

93000 is added to either

disintegrant, therefore needs to

lactose or MCC or for

possess the correct ratio of both a

mixtures containing all three

crystalline to amorphous structure.

excipients, a lower

As direct compression is a shorter,

disintegration time is

less complex and also cheaper

obtained.

production process, the interest to

The fastest disintegration time is

ingredient in a modified starch matrix

provide a starch which is suitable for

achieved when the formulation

like a modified pregelatinised high

direct compression is high (3).

contains 35% to 70% directly

amylose maize starch (9). In the case

CPharm DC 93000 combines the two

compressible starch (7).

of Contramid (10) a cross-linked

main properties of both pregelatinised

amorphous high amylose starch

Figure 4 - Classic release versus controlled release

forms a strong gelly/rubbery

layer at the surface of the tablet

on contact with water or gastric

juice. This layer acts as an

osmotic membrane that does

not allow enzymes to penetrate

and thus prevents the amylose

network from being disrupted.

At the same time the active

ingredient can slowly diffuse

through (Figure 5).

This product is being launched on

and native starch: strong binding and

the market and is likely to help in the

fast disintegration (4). This new directly

design of many slow-release

SLOW-RELEASE TABLETS

compressible starch appears as a white

formulations.

free-flowing powder composed of partly

The immediate and fast

gelatinised agglomerated starch granules

delivery of an active

(Figure 1).

Figure 5 - Drug release properties.

ingredient is not always

When evaluated in a standard

Dissolution profile of standard tablets of Contramid 92450

recommended. Delayed or

with 5% diclofenac Na as a model drug

formulation with 0.25% silicon dioxide

prolonged release may be

and 0.5% magnesium stearate, this

more effective or better

starch shows outstanding

tolerated in, for instance, the

performances compared to those of

case of permanent treatment

native and pregelatinised starch and

or when high peak dosage

also compared to those of standard

could have an adverse effect

compressible starches. The properties

(Figure 4).

of the tablets produced at different

There are several systems

compression forces show a very high

known to do this but they are

resistance to crushing at the same

complex and rather

time as a very fast disintegration in

expensive (8). This is the

water (Figure 2).

Figure 2 - Compression profile of CPharm 93000

PHARMACEUTICALS

JUNE 2002

43

Figure 6 Concentrations of salivary miconazole after

administration of oral gel and of bio-adhesive tablet.

Mean (SD; n=15) salivary miconazole concentrations

after

A) repeated applications of 60 mg miconazole nitrate

as Daktarin gel;

B) administration of 10 mg miconazole nitrate as

bio-adhesive tablet

amount of drug

administered, which might

improve patient compliance.

The bio-adhesive tablet

formulation contained

pregelatinised waxy maize

starch. The salivary miconazole

nitrate concentrations after

administration of the bioadhesive tablet and of oral

gels were compared

(Figure 6).

Although the amount

of drug administered via

the bio-adhesive tablet

was six fold lower than

when the gel was used,

the salivary miconazole

levels were higher and

remained above the MIC

value of Candida albicans

for more than 10 hrs. The

mean adhesive time of the

tablet was 586 min. The

gingiva seemed to be the

best site for application of

the buccal bioadhesive

system (12).

magnetic starch micro-spheres or

starch based micro-capsules.

REFERENCES

1)

2)

3)

4)

5)

6)

7)

8)

BIO-ADHESIVE TABLETS

CONCLUSION

9)

Buccal gels containing miconazole

nitrate are usually used for the

treatment of conditions such as oral

candidiasis. They must be applied

several times a day. In order to

increase the buccal residence time

of miconazole, a bioadhesive buccal

tablet with slow-release properties

can be applied (11). The main

advantages of this delivery system

are a reduction in the frequency and

Starch and modified starches are

safe and well established excipients.

It can be physically modified to

enhance its properties and to

improve its performances. It can also

be chemically modified to obtain a

very wide range of new properties

that can play an important role in the

formulation of complex delivery

systems. Additional example (13) of

such systems could be given as

10)

44

JUNE 2002

11)

12)

13)

WADE, A. et al. Starch and pregelatinised

starch in Handbook of Pharmaceutical

excipients, 2nd Edn, 1994

WISTLER, R.L. et al. Gelatinisation of starch

and mechanical properties of starch pastes in

Starch Chemistry and Technology, 2nd

Edn, Chapter II and III, 1984

SWARBRICK, J. et al., Direct compression

tabletting in Encyclopedia of

Pharmaceutical Technology; Vol.4, 1991

MICHAUD, J. et al.; Free-flowable, directly

compressible starch as binder, disintegrant

and filler for compression tablets and hard

gelatine capsules; EP 0 933 079 A1 (1999)

SWARBRICK, J. et al. Direct compression

tabletting in Encyclopedia of

Pharmaceutical Technology, Vol.4, 1991

LIEBERMAN, H.A. et al., Pharmaceutical

Dosage Forms: Tablets; Vol.1, 2nd Edn,

revised and expanded, 1989, Chapter 4

MICHAUD, J. et al.; Directly compressible

starch as enhancer of properties of excipients

when used as a binder and disintegrant for

compression tablets; EP 1 062 945 A1, 2000

CARAMELLA, C. et al. Pharmaceutical

Technology Europe 1995, Feb, 18-26

LENAERTS, V. et al. Journal of Controlled

Release 1998, 53, 225-234

LENAERTS, V. et al.; Cross-linked high

amylose starch use in controlled release

formulation and processes for its manufacture;

US 09/606,399, 2000

BOUCKAERT, S. et al.; J. Pharm. Pharmacol.

1993, 45, 504-507

BOUCKAERT, S. et al. Eur. J. Clin.

Pharmacol. 1993, 44, 331-335

REMON, J.P. et al., Starch based drug delivery

systems; Symposium Chemical Aspects of

Drug Delivery Systems, Salford University,

April 17-18, 1996

PHARMACEUTICALS

Você também pode gostar

- Novel Excipients As Different Polymers ADocumento6 páginasNovel Excipients As Different Polymers AsandraAinda não há avaliações

- Direct Compression ExcipientsDocumento10 páginasDirect Compression ExcipientsAzhar DkAinda não há avaliações

- Functionality 4Documento6 páginasFunctionality 4Cesar Rodolfo Angulo DelgadoAinda não há avaliações

- 10.4103 0975-1483.51868 PDFDocumento7 páginas10.4103 0975-1483.51868 PDFAbhiAinda não há avaliações

- Influence of Different Excipients On The Properties of Hard Gelatin Capsules With Metamizole SodiumDocumento4 páginasInfluence of Different Excipients On The Properties of Hard Gelatin Capsules With Metamizole SodiumGERALDINE IVONNE Y. BOBADILLA PASTORAinda não há avaliações

- Sustained Release Dosage FormsDocumento9 páginasSustained Release Dosage FormsJasdeep KaurAinda não há avaliações

- Modern Pharmaceutics 4th Edition Chapter 10Documento47 páginasModern Pharmaceutics 4th Edition Chapter 10Faysal MasoodAinda não há avaliações

- Added Functionality Excipients:: An Answer To Challenging FormulationsDocumento7 páginasAdded Functionality Excipients:: An Answer To Challenging FormulationsDATIBEAinda não há avaliações

- Abstract:: Extended Release Tablet With Active CoatingDocumento10 páginasAbstract:: Extended Release Tablet With Active Coatingiloveit52252Ainda não há avaliações

- 1 s2.0 S1773224720312752 Main PDFDocumento10 páginas1 s2.0 S1773224720312752 Main PDFGabriella MagalineAinda não há avaliações

- Compaction and Compression of PowderDocumento23 páginasCompaction and Compression of Powderjabed sarkar100% (1)

- Direct Compressible and Co-Processed Excipients - A ReviewDocumento6 páginasDirect Compressible and Co-Processed Excipients - A ReviewIJAR JOURNALAinda não há avaliações

- Chitosan ReviewDocumento20 páginasChitosan ReviewkarthikAinda não há avaliações

- Powders For InjectionDocumento11 páginasPowders For InjectionAbigail Mayled LausAinda não há avaliações

- Tablet FormulationDocumento9 páginasTablet FormulationChintan Deepakkumar Kabir100% (2)

- Spray Dryer-EncapsulationDocumento6 páginasSpray Dryer-EncapsulationhhkkllAinda não há avaliações

- (Vinesia, 2010: Importance of CapsuleDocumento8 páginas(Vinesia, 2010: Importance of CapsuleFarzana ShantaAinda não há avaliações

- Polymers in Pharmaceutical ProductsDocumento14 páginasPolymers in Pharmaceutical Productsstudent910112Ainda não há avaliações

- pc-12810 Nutraceutical Dietary Supplements PDFDocumento12 páginaspc-12810 Nutraceutical Dietary Supplements PDFMartin CelestinoAinda não há avaliações

- 24 12v2i2 2Documento10 páginas24 12v2i2 2Khyati ChourasiaAinda não há avaliações

- Jchps 6 (4) 15 Page 286-292 MsreddyDocumento7 páginasJchps 6 (4) 15 Page 286-292 MsreddydwahyusafriAinda não há avaliações

- Direct Compression - An Overview: - ReviewDocumento4 páginasDirect Compression - An Overview: - ReviewJim ColinsAinda não há avaliações

- High Functionality Excipients (HFE) - Prosolv SMCC As An Effective Strategy For Generic Drug FormulationDocumento4 páginasHigh Functionality Excipients (HFE) - Prosolv SMCC As An Effective Strategy For Generic Drug FormulationCesar Rodolfo Angulo DelgadoAinda não há avaliações

- Tablets TextDocumento18 páginasTablets TextarunbaskaranjAinda não há avaliações

- Compaction 0r Pre - CompresionDocumento7 páginasCompaction 0r Pre - CompresionADVOCATE ASHUTOSH SHARMAAinda não há avaliações

- Cole 1999 Liquid Filled and Sealed Hard Gelatin CapsulesDocumento12 páginasCole 1999 Liquid Filled and Sealed Hard Gelatin CapsulesZirrus GlassAinda não há avaliações

- Emulsions in Health Care Applications-An Overview: Journal of Dispersion Science and Technology May 2002Documento24 páginasEmulsions in Health Care Applications-An Overview: Journal of Dispersion Science and Technology May 2002Quốc ThắngAinda não há avaliações

- TabletsDocumento46 páginasTabletsSai SharathAinda não há avaliações

- 6 Challenges in Technology of Bilayer and Multi-Layer Tablets - A Mini-ReviewDocumento7 páginas6 Challenges in Technology of Bilayer and Multi-Layer Tablets - A Mini-ReviewANGELY MELISSA OVIEDO ROMEROAinda não há avaliações

- A Formulation Strategy For Solving Over-Granulation Problem inDocumento2 páginasA Formulation Strategy For Solving Over-Granulation Problem inBinh NguyenAinda não há avaliações

- Pharmaceutical Technology-Ii: Lecture Notes ONDocumento27 páginasPharmaceutical Technology-Ii: Lecture Notes ONTouquir Alam100% (1)

- The Role of Disintegrants in Solid Oral Dosage ManufacturingDocumento17 páginasThe Role of Disintegrants in Solid Oral Dosage ManufacturingRhosuna Aina0% (1)

- Formulation and Evaluation of Cefixime Trihydrate Dispersible TabletsDocumento10 páginasFormulation and Evaluation of Cefixime Trihydrate Dispersible TabletsEditor IJTSRDAinda não há avaliações

- Siow 2020Documento10 páginasSiow 2020vishal makadiaAinda não há avaliações

- The Role of Disintegrants in Solid Oral Dosage ManufacturingDocumento5 páginasThe Role of Disintegrants in Solid Oral Dosage ManufacturingMoonstruck ApuAinda não há avaliações

- Sample PageDocumento4 páginasSample PageRahma SantosoAinda não há avaliações

- Pickering Emulsions - Preparation Processes, Key Parameters Governing Their Properties and Potential For Pharmaceutical ApplicationsDocumento31 páginasPickering Emulsions - Preparation Processes, Key Parameters Governing Their Properties and Potential For Pharmaceutical ApplicationsEsteban MalamboAinda não há avaliações

- Formulation and Standardization of NutraceuticalsDocumento10 páginasFormulation and Standardization of Nutraceuticalssudhindra kini100% (3)

- Fundamental Aspects of Solid Dispersion Technology For Poorly Water Soluble DrugsDocumento8 páginasFundamental Aspects of Solid Dispersion Technology For Poorly Water Soluble DrugsUday BaruahAinda não há avaliações

- 52 Vol. 9 Issue 12 Dec 2018 IJPSR RA 10816Documento13 páginas52 Vol. 9 Issue 12 Dec 2018 IJPSR RA 10816amirsuryahidayahAinda não há avaliações

- Review 4.2 PDFDocumento5 páginasReview 4.2 PDFEditor IjprtAinda não há avaliações

- Review ArticleDocumento20 páginasReview Articleaishwarya bodkeAinda não há avaliações

- Advance Granulation TechnologyDocumento81 páginasAdvance Granulation TechnologysyeedAinda não há avaliações

- Recent Advancement in Tablet Coating TechnologyDocumento16 páginasRecent Advancement in Tablet Coating TechnologyAdhi WicaksonoAinda não há avaliações

- Design Dan EvaluasiDocumento8 páginasDesign Dan EvaluasiDiiva MaulidinaAinda não há avaliações

- Chapter 1. IntroductionDocumento30 páginasChapter 1. Introductionlweon37Ainda não há avaliações

- Formulation Optimization For Tabletting Applications: Technical FeatureDocumento3 páginasFormulation Optimization For Tabletting Applications: Technical FeatureParthMairAinda não há avaliações

- Oral Disintegrating Tablets A Future CompactionDocumento10 páginasOral Disintegrating Tablets A Future CompactionArifin I. OputuAinda não há avaliações

- International Journal of Pharmtech ResearchDocumento9 páginasInternational Journal of Pharmtech ResearchTabare CostaAinda não há avaliações

- V. Deva Prasad V. Deva Prasad V. Deva PrasadDocumento15 páginasV. Deva Prasad V. Deva Prasad V. Deva PrasadAhmad RazaAinda não há avaliações

- International Research Journal of Pharmacy: Processing Technologies For Pharmaceutical Tablets: A ReviewDocumento4 páginasInternational Research Journal of Pharmacy: Processing Technologies For Pharmaceutical Tablets: A ReviewBella Puspita HapsariAinda não há avaliações

- Formulation and Optimization of Immediate Release Tablet of An Anti Hypertensive Drug by Dry Granulation MethodDocumento9 páginasFormulation and Optimization of Immediate Release Tablet of An Anti Hypertensive Drug by Dry Granulation MethodEDI SAPUTRAAinda não há avaliações

- Physics of Tablet CompressionDocumento60 páginasPhysics of Tablet CompressionSagar FirkeAinda não há avaliações

- Avicel PH 101 & PH 102 - Microcrystalline Cellulosa PH 101 & PH 102 (p.129-133) 158-162Documento5 páginasAvicel PH 101 & PH 102 - Microcrystalline Cellulosa PH 101 & PH 102 (p.129-133) 158-162Marsha Fendria PrastikaAinda não há avaliações

- Celulosa MicrocristalinaDocumento4 páginasCelulosa MicrocristalinaEva Maria RamosAinda não há avaliações

- Compression Physics in The Formulation DevelopmentDocumento65 páginasCompression Physics in The Formulation DevelopmentharishsushilAinda não há avaliações

- Encapsulation and Controlled Release Technologies in Food SystemsNo EverandEncapsulation and Controlled Release Technologies in Food SystemsDr Jamileh M. LakkisAinda não há avaliações

- Design and Manufacture of Pharmaceutical TabletsNo EverandDesign and Manufacture of Pharmaceutical TabletsNota: 3.5 de 5 estrelas3.5/5 (6)

- New Polymers for Encapsulation of Nutraceutical CompoundsNo EverandNew Polymers for Encapsulation of Nutraceutical CompoundsJorge Carlos Ruiz RuizAinda não há avaliações

- Drug Delivery Strategies for Poorly Water-Soluble DrugsNo EverandDrug Delivery Strategies for Poorly Water-Soluble DrugsAinda não há avaliações

- Hydrocortisone TabletsDocumento2 páginasHydrocortisone TabletsmadhuAinda não há avaliações

- Torrent PDFDocumento36 páginasTorrent PDFmadhubabu6183Ainda não há avaliações

- Selegiline Hydrochloride 5mg TabletsDocumento2 páginasSelegiline Hydrochloride 5mg TabletsmadhuAinda não há avaliações

- Torrent PDFDocumento36 páginasTorrent PDFmadhubabu6183Ainda não há avaliações

- United States Patent (19) : Marttila Et Al. (11) Patent NumberDocumento3 páginasUnited States Patent (19) : Marttila Et Al. (11) Patent NumbermadhuAinda não há avaliações

- SPC SelegilineDocumento11 páginasSPC SelegilinemadhuAinda não há avaliações

- Selegiline HCL CapsuleDocumento2 páginasSelegiline HCL CapsulemadhuAinda não há avaliações

- SelegilineDocumento19 páginasSelegilinemadhu100% (1)

- Drugs in InformationDocumento11 páginasDrugs in InformationmadhuAinda não há avaliações

- SpectroDocumento7 páginasSpectromadhuAinda não há avaliações

- Stability Study of Lipoic Acid in The Presence of Vitamins ADocumento13 páginasStability Study of Lipoic Acid in The Presence of Vitamins AmadhuAinda não há avaliações

- CAS OlonDocumento2 páginasCAS OlonmadhuAinda não há avaliações

- Lipoic AcidDocumento33 páginasLipoic AcidmadhuAinda não há avaliações

- Pharm Exam AgianDocumento7 páginasPharm Exam AgianyalahopaAinda não há avaliações

- Metoprolol (Lopressor) - Beta BlockerDocumento2 páginasMetoprolol (Lopressor) - Beta Blockerjustjesko0lAinda não há avaliações

- (Lecture 2) Vice, Drug Education and ControlDocumento24 páginas(Lecture 2) Vice, Drug Education and ControlJohnpatrick DejesusAinda não há avaliações

- Apteka - Participants - Profile1Documento26 páginasApteka - Participants - Profile1Gurukrushna PatnaikAinda não há avaliações

- Medical and Pharmacy Abbreviations (Sig Codes)Documento3 páginasMedical and Pharmacy Abbreviations (Sig Codes)SolCharmerAinda não há avaliações

- PKPD For BeginnersDocumento31 páginasPKPD For Beginnerstanty_ukAinda não há avaliações

- Pharmacology Step 1 For USMLEDocumento3 páginasPharmacology Step 1 For USMLEraj_1041100% (1)

- Drugs Interaction Basic & Clinical Pharmacology (PDFDrive) - 1170-1187Documento18 páginasDrugs Interaction Basic & Clinical Pharmacology (PDFDrive) - 1170-1187Ismail Ali إسماعيل عليAinda não há avaliações

- Hisstory of PharmacyDocumento31 páginasHisstory of PharmacyIka Widiawati100% (1)

- Or Drug StudyDocumento7 páginasOr Drug StudyNikki M. ArapolAinda não há avaliações

- Natural Product Chemistry For Drug DiscoveryDocumento458 páginasNatural Product Chemistry For Drug DiscoveryUğur ÇiğdemAinda não há avaliações

- General Anaesthesia 1Documento46 páginasGeneral Anaesthesia 1Karuna DewalwarAinda não há avaliações

- Praziquantel in TurtlesDocumento1 páginaPraziquantel in TurtlesMara Hernández FresnilloAinda não há avaliações

- Last QU 24-8-2017Documento21 páginasLast QU 24-8-2017ahmed masoudAinda não há avaliações

- Admission Committee For Professional CouresesDocumento11 páginasAdmission Committee For Professional CouresesRohit patelAinda não há avaliações

- Clinic Medicine Inventory: Quantit Y Unit Description Expiration DateDocumento3 páginasClinic Medicine Inventory: Quantit Y Unit Description Expiration DateANGELICA RIVERAAinda não há avaliações

- Drug Distribution System in HospitalDocumento22 páginasDrug Distribution System in HospitalRana EhtishamAinda não há avaliações

- Test Bank For Pharmacology 9th Edition MccuistionDocumento3 páginasTest Bank For Pharmacology 9th Edition MccuistionKenneth Maestas100% (31)

- Pharmacological Approaches To Pregnancy Termination in Dogs and Cats Including The Use of Prostaglandins, Dopamine Agonists, and Dexamethasone - IVISDocumento18 páginasPharmacological Approaches To Pregnancy Termination in Dogs and Cats Including The Use of Prostaglandins, Dopamine Agonists, and Dexamethasone - IVISDai AnaAinda não há avaliações

- Inotropes and Vasopressors FinalDocumento71 páginasInotropes and Vasopressors Finalankur100% (1)

- MetabolismDocumento21 páginasMetabolismNagendra NayakAinda não há avaliações

- KARNATAKA Pharma Companies With Mail IdsDocumento10 páginasKARNATAKA Pharma Companies With Mail IdsGanesh67% (3)

- Ranitidine Hydrochloride PDFDocumento9 páginasRanitidine Hydrochloride PDFDanisha LailaAinda não há avaliações

- Cadila Pharmaceuticals LTDDocumento6 páginasCadila Pharmaceuticals LTDPau GajjarAinda não há avaliações

- Formulation and Evaluation of Sustained Release Matrix Tablets of GliclazideDocumento3 páginasFormulation and Evaluation of Sustained Release Matrix Tablets of Gliclazidequangoanh12042001Ainda não há avaliações

- Pharma PrelimDocumento8 páginasPharma PrelimNom NomAinda não há avaliações

- Biochemical and Molecular Toxicology: Principles of Toxicokinetics/ToxicodynanicsDocumento70 páginasBiochemical and Molecular Toxicology: Principles of Toxicokinetics/Toxicodynanicskiki rawitriAinda não há avaliações

- Pediatric Drug FormulationsDocumento14 páginasPediatric Drug FormulationsJürgen FleischerAinda não há avaliações

- Percobaan 2 FarmakokinetikDocumento12 páginasPercobaan 2 FarmakokinetikTaufik HidayatAinda não há avaliações

- (PORSOLT) Comparative Anticonvulsant Activity of Carbamazepine Lamotrigine and Valproate in The Mouse and in The RatDocumento1 página(PORSOLT) Comparative Anticonvulsant Activity of Carbamazepine Lamotrigine and Valproate in The Mouse and in The RatBestka ZaushaAinda não há avaliações