Escolar Documentos

Profissional Documentos

Cultura Documentos

Fault Location of Overhead Transmission Line

Enviado por

Sandeep HnayakDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Fault Location of Overhead Transmission Line

Enviado por

Sandeep HnayakDireitos autorais:

Formatos disponíveis

Seminar Report 2013

SEMINAR REPORT

A NOVEL APPROACH FOR FAULT LOCATION

OF OVERHEAD TRANSMISSION LINE WITH

NONCONTACT MAGNETIC-FIELD

MEASUREMENT

Presented by:

YELSIN AY

DEPARTMENT OF

ELECTRICAL AND ELECTRONICS ENGINEERING

2013

Seminar Report 2013

ABSTRACT

Fault location and correction are important in case of any power systems. This process

has to be prompt and accurate so that system reliability can be improved, outage time can be

reduced and restoration of system from fault can be accelerated. The traditional systems

adopted for fault location (travelling-wave-based approach and impedance-measurementbased approach) result in complexity, lack of economy, non-homogeneity and sometimes

even cause unacceptable location errors.

The method for fault location explained here is one in which non-contact magnetic

field measurement is utilized. In this, magnetic field is measured along transmission line

using a highly sensitive, low-cost magneto resistive magnetic sensor, and fault span is

located. The collected data can be utilized for identifying fault location within the fault span

as well as the type of fault. The simulations carried out validate this scheme of fault locating.

Seminar Report 2013

CHAPTER 1

INTRODUCTION

Fault location and correction are important in case of any power systems. This

process has to be prompt and accurate so that system reliability can be improved, outage

time can be reduced and restoration of system from fault can be accelerated. The

traditional systems adopted for fault location are travelling-wave-based approach and

impedance-measurement-based approach. The travelling-wave-based approach requires

detection devices to connect to the high-voltage transmission line, making the solution

complex and costly. And the impedance-measurement-based approach is highly

dependent on the quality of the signal and affected by fault resistance, ground resistance

and non-homogeneity in line configuration. Hence, these approaches may cause a

location error that is unacceptable in certain operation cases.

The new method of locating of fault utilizes the new technology of magneto

sensors which are used for finding the fault in transmission lines. It is a low-cost highprecision solution, which does not need to connect the device to the HV transmission line

and is highly sensitive for fault location.

We all know that the fault is a condition causes abnormal flow of electric current. Faults

are mainly two types

Symmetrical fault

e.g.; 3 to ground fault

Unsymmetrical fault

e.g.; L-G fault, L-L fault, L-L-G fault

CHAPTER 2

Seminar Report 2013

CURRENT METHODS

Several methods are currently used for fault locating. Some of them are

2.1 Impedance-based fault location

In the impedance-measurement-based technique, the voltage and current during

prefault and post fault are acquired and analysed. The line parameters can then be calculated

with the transmission-line model and the fault can be located.

Impedance-based methods require the following approach

Measure the voltage and current phasors

Extract the fundamental components

Determine the phasors and fault type

Apply impedance algorithm

One-ended impedance methods of fault location are a standard feature in most

numerical relays. One-ended impedance methods use a simple algorithm, and communication

channels and remote data are not required. One-ended impedance-based fault locators

calculate the fault location from the apparent impedance seen by looking into the line from

one end. To locate all fault types, the phase-to-ground voltages and currents in each phase

must be measured.Impedance algorithm calculation is complex in nature. In certain cases

error may reach 5% or even more. The installed system may cause an error of 3 km in 500kV transmissionlines. The maintenance crew may have to walk 6 km in a rough terrain to

determine the exact location of the fault point

Two-ended methods can be more accurate but require data from both terminals. Data

must be captured from both ends before an algorithm can be applied.

2.2 Travelling-wave-based fault location

Fault occurring on a power cable will generate both voltage and current traveling

waves with wideband signals which cover the entire frequency range. These different

frequency components will travel along the line until they meet a discontinuity on the line,

such as the fault point or busbar. At this point, both a reflection and a refraction of the wave

will occur. This generates additional waves which will propagate through the power system.

In the travelingwave technique, either the transient created by a fault is captured or

impulses are injected into the line, and the reflected travelling wave is detected with timedomain reflectometery (TDR). The fault location is then determined by timing analysis of the

Seminar Report 2013

travelling wave. As the faulted signal obtained at the end of the transmission line is highly

mingled with noise, some modern signal processing techniques, such as the wavelet are used

for fault location.In the traveling-wave based approach, the accuracy of the location is highly

dependent on the performance of the costly high-speed data-acquisition system.

Furthermore, these methods fully depend on an assumption that the parameters of the

transmission line are uniform. Considering the fact that the transmission lines are distributed

over a large geographical area, this assumption is generally not entirely true. For example, the

non-uniform spacing of the phase conductors may affect the inductance (although phase

conductors are transposed to reduce the effect), temperature may affect the resistance, and

sag may affect the capacitance in different transmission-line segments.

Operation experience shows that most of the systems can limit the fault-location error

within12% of the monitored line length. In certain cases, the error may reach 5% or even

more. The accuracy factor becomes even more important for long transmission lines because

even a relatively small error would result in an uncertainty of a few kilometers, causing

significant delay for the maintenance crew to find the fault location. Especially in areas over

rough terrain (e.g., mountain area, forest area), the installed system may cause a large error.

For nonpermanent faults, such as flashover caused by sag of stressed lines, considering their

temporary nature, it may take even more effort to locate the fault point with these systems

because the fault is not permanent and the system may have already resumed its normal

condition by the time the maintenance crew arrives.

CHAPTER 3

DRAWBACKS OF CURRENT METHODS

But both of these techniques have many problem associated with them. Some of them are

Seminar Report 2013

The parameters of the lines are to be known

Have to consider that the line is homogenous in nature, while in fact it is not

The relative location error is very large many times

Error occur when fault reactance is there

Performance is highly dependent on signal processing techniques

Have to connect instruments to the live line, which increases the cost of

instruments needed

Hard to map the electrical distance to actual geographical location

Affected by CT saturation

Have to assume uniform wave speed

High speed data acquisition

High cost

CHAPTER 4

MAGNETORESISTANCE SENSOR

The MR magnetic sensor, based on the magnetoresistance effect is used in this

application. Magnetoresistance is the property of a material to change the value of its

Seminar Report 2013

electrical resistance when an external magnetic field is applied to it. The strength, direction,

and distribution of the magnetic field emanated from the conductors contain information

about the electric power parameters, such as amplitude, frequency, and phase of the electric

current.

Recently, the anisotropic magnetoresistance (AMR), giant magnetoresistance

(GMR), and tunneling magnetoresistance (TMR) materials are discovered and integrated into

commercial magnetic-field sensors successfully. These sensors in general have high

sensitivity, large temperature range, and wide frequency bandwidth (from dc to several

megahertz). The recent advances in MR sensors make it possible to fabricate low-cost chipscale magnetometers for detecting the 3-D vector magnetic field.

4.1 Anisotropic magneto resistance sensor

AMR sensors use materials, such as permalloy (an alloy containing about 80%

nickel and 20% iron), whose resistance depends on the angle between the magnetization and

the direction of current flow. The resistance changes roughly as the square of the cosine of

the angle between the magnetization and the direction of current flow.

Permalloy is the most common material for AMR sensors because it has a

relatively large magnetoresistance and because its characteristics are compatible with the

fabrication techniques employed to make silicon integrated circuits. The magnetoresistance

of permalloy is less than 4%.

Anisotropic magnetoresistance (AMR) sensor: (a) resistance versus angle between the magnetization and the

direction of current flow, (b) change in due to the application of a magnetic field.

4.2 Giant magneto resistance sensor

Seminar Report 2013

Larger changes in magnetoresistance were observed in planar structures of metals.

The effect was named giant magnetoresistance or GMR. In its simplest form, called a spin

valve, GMR is achieved by using a four layer structure that consists of two thin ferromagnets

separated by a conductor. The fourth layer is an antiferromagnet that is used to pin (inhibit

the rotation) the magnetization of one the ferromagnetic layers. The ferromagnet layer that is

being pinned is between the conductor and the antiferromagnet. The pinned ferromagnet is

called the hard ferromagnet and the unpinned ferromagnet is called the soft ferromagnet.

Electrons can travel more easily either parallel to the layers or perpendicular to the

layers if the magnetizations of the two ferromagnets are parallel to one another. The reason

for this is that when the magnetizations are parallel, electrons suffer less scattering in going

from an electronic band structure state in one of the ferromagnets into a similar or identical

electronic band structure state in the other ferromagnet. The difference in resistivity between

the case when the magnetizations are parallel and when they are antiparallel can be as large

as 12.8% at room temperature. To optimize the effect, the layers must be very thin, about a

nanometre thick.

Orientation of the magnetization of the ferromagnetic layers in a GMR spin valve for different external fields H.

(a) H = 0, the magnetization of the free ferromagnetic layer is perpendicular to the magnetization of pinned

ferromagnet, R = R(0). (b) Low resistant state, H parallel to the magnetization of the pinned ferromagnet,

Seminar Report 2013

R <R(0). (c) High resistant state, H directed opposite to the magnetization of the pinned ferromagnet, R >R(0).

(d) H large enough to unpin the pinned ferromagnet, R <R(0).

4.3 Tunneling magneto sensor

Magnetic tunnel junctions (MTJ) or spin dependent tunneling (SDT) sensors, first

fabricated in 1995, have a structure similar to the four layer structure described above in

GMR sensors. Again there are two ferromagnets separated by an intervening layer and the

magnetoresistance is a function of orientation of the two ferromagnets, but in this case the

intervening layer is an insulator. In MTJ sensors, the conduction occurs by tunneling of

electrons through the insulator.

Based on a spin-polarized tunnelling model the magnetoresistance ratio MR or R/R is given

by

=

Where Rp and Ra are the resistances when the two ferromagnets are parallel and

antiferromagnetic, respectively, and P1 and P2 are the spin polarizations of the two

ferromagnets.

Seminar Report 2013

CHAPTER 5

PROPOSED METHOD

This method of locating of fault utilizes the new technology of magneto sensors

which are used for finding the fault in transmission lines. It is a a low-cost high-precision

solution, which does not need to connect the device to the HV transmission line and is highly

sensitive for fault location

The sensors are placed on the tower, and the data are transmitted to a dataprocessing centre where analysis software can determine which span the fault location

belongs to. The collected magnetic-field data can also be used to identify the fault type and

even locate within the fault span.

This method utilizes fast advancement of the microelectromechanical systems

(MEMS) packaging technology and magnetoresistance material technology. The MR

magnetic sensor, based on the magnetoresistance effect is used in this application.

Magnetoresistance is the property of a material to change the value of its electrical resistance

when an external magnetic field is applied to it. The strength, direction, and distribution of

the magnetic field emanated from the conductors contain information about the electric

power parameters, such as amplitude, frequency, and phase of the electric current.

Recently, the anisotropic magnetoresistance (AMR), giant magnetoresistance

(GMR), and tunneling magnetoresistance (TMR) materials are discovered and integrated into

commercial magnetic-field sensors successfully. These sensors, in general, have high

sensitivity, large temperature range, and wide frequency bandwidth (from dc to several

Seminar Report 2013

megahertz). The recent advances in MR sensors make it possible to fabricate low-cost chipscale magnetometers for detecting the 3-D vector magnetic field.

CHAPTER 6

STRUCTURE OF PROPOSED METHOD

The monitoring terminal is a small device integrated on a printed-circuit board

(PCB) board. The entire system is composed of a microprocessor (CPU) and its peripheral

devices [sensor module, data-acquisition (DAQ) module, storage module, communication

module, signal preconditioning module, and power supply]. The microprocessor controls the

entire system and performs DAQ of the magnetic signal continuously. The information in the

signal can be extracted by simple analysis (e.g., amplitude calculation).

Once a certain change in the signal is detected, the data are stored and sent to the

centre station through the communication channel. Since the system aims at serving a

mountainous area, a radio station communication solution (i.e., not dependent on commercial

service) is preferable. The sensor module is composed of a magnetic sensor chip capable of

measurement in the x, y and z axes and its amplifying and filtering circuits.

The sensor is designed to be independent of the disturbance coming from the

power supply of the monitoring unit by separating it from the main board. The entire system

can be powered by a solar power module which is composed of a solar panel, a charger, and a

battery, or alternatively, it can be powered through coupling with the transmission lines.

For the long span, an additional monitoring terminal can be added in the middle

since the devices of a terminal are cheap and they can work at a place far away from the

current-carrying conductors. The data collected from the remote monitoring terminals can be

visualized in client software with the aid of the geographical information system (GIS) to

help the operating crew locate the fault position promptly.

Seminar Report 2013

Overall scheme of the proposed solution for fault location in HV transmission lines. (The circles indicate the

positions of sensors.)

6.1 3-D VECTOR MAGNETIC FIELD

The three components of the magnetic field in the 3-D space can be separately

measured by MR sensors, they can be used to derive the change in the three-phase current.

The magnetic field of current-carrying transmission-line conductors can be calculated by

Maxwells equations. Under certain assumptions, an analytical expression about the relative

position between the measured point and the conductors can be formed.

Seminar Report 2013

=

= (

Where

and

+

+(

+

+ ) cos )+ ((

- ) sin )+

are the magnetic-field components generated by phase

currents iA, iB and iC respectively, and

and

are the unit vectors along the x, y and z

axes respectively.

If the system is not symmetric, the magnetic field should be calculated

according to the BiotSavart law. However, for simple estimation, the effect of conductor

sag is neglected and the line is assumed to be of infinite length, then Ba , Bb and Bc can be

calculated as

where is the magnetic constant, and rA, rB and rC are defined in Figure below

Calculation of the magnetic field at the point of sensor head. The direction of current is assumed to be along the

z-axis, which is pointing toward the observer.

For a radial transmission system, in which only the sending end has power sources, it

is simple to locate the fault point by simply checking where short-circuit current exists in the

Seminar Report 2013

transmission lines. The output of the terminal closest to the fault point can only be used for

qualitative analysis because its output may be affected by the fault.

CHAPTER 7

LOCATION OF FAULT

Typical faults on transmission lines include single-phase short circuit, doublephase short circuit, and three- phase short circuit. In the impedance-based approach, the effect

of the fault resistance and ground resistance must be considered. In the proposed scheme,

these effects do not affect the accuracy of the location.

When the three-phase short circuit occurs, the measured magnetic field is increased.

The ratio of the magnetic field during the fault to that during the normal situation is the same

as the ratio of the short-circuit current to the current at normal condition, provided that the

transient process is not considered. The transient generally further increases the value of the

magnetic field. In order to obtain a full view of the transient process along the entire

transmission line to help find the fault point, the magnetic field measured at every tower

along the transmission line, which connects two systems, is plotted

Distribution of the magnetic field along the transmission line under3- short-circuit condition (m =100 km).

Seminar Report 2013

In the figure, the axis represents the evolution of time (during the lifecycle of a fault,

that is, prefault, fault, and postfault), the axis represents the distribution along the

transmission line (0 to the length of the line), and the axis represents the measured magnetic

field. Note that the high magnitude at the beginning of the fault is caused by the decaying dc

components in the three-phase currents. The magnitude of the magnetic field at steady state

under fault condition is determined by the short-circuit levels of the two systems connected at

two sides. The difference in the short-circuit level can help locate the fault to a span by

simply comparing the value of the measured magnetic field. If the fault occurs at a point

where the short-circuit level at two sides is almost the same, making the magnitude of the

magnetic field at two sides very close, then the direction of the magnetic field may be a good

indicator of determining the fault span in this case.

System diagram of the test system in the numerical simulation (l: the total length of the transmission line and m:

distance from the sending end to the fault location).

CHAPTER 8

Seminar Report 2013

IDENTIFICATION OF THE FAULT TYPE

The measured magnetic field can be used for not only locating the fault but also for

identifying the fault type. When a fault occurs, the type of fault can be identified according to

the magnitude and direction of the measured magnetic field. Since the short-circuit current is

generally much larger than the normal current, the magnetic field caused by current flowing

in the unfaulted phase can be neglected.

8.1 LINE TO GROUND FAULT

When a single-phase fault occurs, the measured magnetic field satisfies the

following conditions

= tan

fault at phase A

fault at phase B

= -tan

fault at phase C

8.2 LINE TO LINE FAULT

When a double-phase fault occurs, one should distinguish the difference between

line-to-line fault and double-line-to-ground fault. When the line-to-line fault is considered

(transient neglected), the relation among the measured magnetic-field components

AB line to line fault

AC line to line fault

BC line to line fault

8.3 DOUBLE LINE TO GROUND FAULT

Seminar Report 2013

When a double-line-to-ground fault occurs, there is no such simple relation

among the components. However, by incorporating the estimation of the short-circuit current

(since the fault point is known), the fault type can be identified.

In double line-to-ground fault the field strength is medium.When double phase lineto-ground fault occurs

1) AB line to ground fault - By is 1/3 of that in three phase fault and By/Bx> 0

2) AC line to ground fault - By is as large as in three phase fault

3) BC line to ground fault - By is 1/3 of that in three phase fault and By/Bx < 0

8.4 THREE PHASE FAULT

When three phase faults occurs, there is no such simple relation among the

components. In the case of three phase fault all the magnetic components and field strength

are large

8.5 FAULT IDENTIFICATION PROCEDURE

The identification procedure may consist of the following steps

1) Locating the fault according to the data sent back from the terminal installed along the

transmission line

2) Approximately estimating the short-circuit current level with the fault distance

determined by Step 1)

3) Comparing the measured magnetic field and the calculated value to determine

whether the fault belongs to single-phase fault, double-phase fault, or three-phase

fault

4) Further determine the actual type of the fault.

5) Locating within the fault span according to the result of previous location and

identification

CHAPTER 9

LOCATION WITHIN FAULT SPAN

Seminar Report 2013

The fault span can be obtained by the earlier steps. It is observed that the measured

magnetic fields have no significant

difference

along

the

faulted

transmission line. However, the

measured magnetic fields at the two

sides of the fault span are different.

This difference can be used to

estimate the distance between the

fault point and the tower. Figure

shows the model for estimation of the distance to a tower in a faulted span for a single

conductor. Assuming that the sensor is installed under a faulted conductor on which a current

i(t) is flowing through at a distance of a. If a is far less than the length of a span, according to

Biot-Savart law, the ratio of the measured magnetic field beside the fault point to the other

measured magnetic field is

Where Bx and By are assumed to be the measured magnetic field components far away from

the fault span.

For double-phase and three-phase faults, it is more complex because a simple

analytical expression cannot be found due to the difference in phase angle in the three phases.

However, once the type of the fault is determined, the location within the fault span can be

accomplished using the

or

component

CHAPTER 9

CONCLUSION

Seminar Report 2013

As the MEMS packaging technology and magnetoresistance material

technology are progressing rapidly, MR sensors based on the magnetoresistance effect, which

can carry out the point measurement of the magnetic field, may bring revolutionary change

for measurement techniques in power systems. In this, a novel approach based on the

noncontact measurement of magnetic field is proposed for the fault location of overhead

transmission lines. By checking whether the short-circuit current exists in the transmission

line at the position of an installed monitoring terminal, the fault span can be located which

may greatly reduce the uncertainty in searching for fault location and, hence, improve the

efficiency. Moreover, the solution is low-cost and more effective for finding the exact fault

location even for non-permanent faults. After the fault span is located, the measured magnetic

field can be used to further identify the fault type and locate within the fault span. In future,

other types of tower configurations or their combinations should be considered to extend the

applications. Moreover, the configuration of the sensor array can be further modified and

improved in order to extend the application into the fault location for double or multi-circuit

transmission lines.

Você também pode gostar

- Trilogy of Wireless Power: Basic principles, WPT Systems and ApplicationsNo EverandTrilogy of Wireless Power: Basic principles, WPT Systems and ApplicationsAinda não há avaliações

- Underground Cable Fault Detection Using GSMDocumento50 páginasUnderground Cable Fault Detection Using GSMSiva Raj100% (1)

- Report of Seminar On Underground Cable Detection TechnologyDocumento34 páginasReport of Seminar On Underground Cable Detection TechnologyAnand Krishnan67% (3)

- Detection of Transmission Line Faults Using Discrete Wavelet TransformDocumento6 páginasDetection of Transmission Line Faults Using Discrete Wavelet Transformwvargas926Ainda não há avaliações

- Lightning ArresterDocumento18 páginasLightning ArresterDinesh Prasad SenapatiAinda não há avaliações

- Comparative of Islanding Detection Passive Methods For Distributed Generation Applications PDFDocumento8 páginasComparative of Islanding Detection Passive Methods For Distributed Generation Applications PDFJhonatan Paucara PradoAinda não há avaliações

- XLPE CableDocumento69 páginasXLPE CableS.M.Touhidur Rahman100% (1)

- Electronic Circuit BreakerDocumento13 páginasElectronic Circuit BreakerAbhishek Agarwal100% (4)

- CIGRE Green Books: Series Editor Cigre International Council On Large Electric Systems (CIGRE) Paris, FranceDocumento45 páginasCIGRE Green Books: Series Editor Cigre International Council On Large Electric Systems (CIGRE) Paris, FranceEsel DimapilisAinda não há avaliações

- Polymer InsulatorsDocumento34 páginasPolymer InsulatorsAbraiz Khan KhattakAinda não há avaliações

- Indian Wind Grid Code: Draft Report OnDocumento54 páginasIndian Wind Grid Code: Draft Report OnRamesh NaiduAinda não há avaliações

- Over Under Voltage and Over Current Protection SystemDocumento8 páginasOver Under Voltage and Over Current Protection SystemHassan AliAinda não há avaliações

- Cigre Study Committee Minutes 2010 100510id31ver108Documento233 páginasCigre Study Committee Minutes 2010 100510id31ver108Julio VergaraAinda não há avaliações

- Presentation by Pgcil Development of Transmission System in India Foir Workshop at Goa 21 10 2013Documento36 páginasPresentation by Pgcil Development of Transmission System in India Foir Workshop at Goa 21 10 2013Rahul RockonAinda não há avaliações

- Ee6002 Power System Transients Unit 1Documento18 páginasEe6002 Power System Transients Unit 1FLOWERAinda não há avaliações

- Detailed Report On Manufacturing of Turbo Generators at BHEL HaridwarDocumento40 páginasDetailed Report On Manufacturing of Turbo Generators at BHEL HaridwarPradip GoswamiAinda não há avaliações

- Transmission Lines - PresentationDocumento24 páginasTransmission Lines - PresentationMadanasekhar TadimarriAinda não há avaliações

- Unit-I Transmission Line Parameters: Conductor MaterialsDocumento53 páginasUnit-I Transmission Line Parameters: Conductor Materialsirshad224Ainda não há avaliações

- Seminar Report On Air Insulated and Gas Insulated SubstationDocumento22 páginasSeminar Report On Air Insulated and Gas Insulated Substationrajpate213775% (4)

- HVDC TransmissionDocumento14 páginasHVDC TransmissionAxay ShahAinda não há avaliações

- WBN028 - B1.47 - Mar21Documento63 páginasWBN028 - B1.47 - Mar21E PenaAinda não há avaliações

- Development of EPRI TL WorkstationDocumento258 páginasDevelopment of EPRI TL WorkstationBlakeAinda não há avaliações

- Overhead Transmission Line FaultsDocumento8 páginasOverhead Transmission Line FaultsQaisar_mastAinda não há avaliações

- UHV AC Transmission SystemsDocumento5 páginasUHV AC Transmission SystemsHemang TailorAinda não há avaliações

- Prospects of Bulk Power EHV and UHV Transmission (PDFDrive)Documento20 páginasProspects of Bulk Power EHV and UHV Transmission (PDFDrive)Prashant TrivediAinda não há avaliações

- 2.1 History and Development of Facts DevicesDocumento22 páginas2.1 History and Development of Facts DevicesmianAinda não há avaliações

- Parameter Identification and Comparision of An Induction Motor ModelsDocumento11 páginasParameter Identification and Comparision of An Induction Motor ModelsJUAN4201Ainda não há avaliações

- Report On Radial Feeder ProtectionDocumento15 páginasReport On Radial Feeder ProtectionHarshit SharmaAinda não há avaliações

- POWERGRID Experience On Life Assessment of EHV Current TransformersDocumento7 páginasPOWERGRID Experience On Life Assessment of EHV Current TransformersOm BhaskarAinda não há avaliações

- Lightning Arrester ReportDocumento15 páginasLightning Arrester ReportantoAinda não há avaliações

- (REPORT) - Automatic Sun Tracking SystemDocumento14 páginas(REPORT) - Automatic Sun Tracking SystemPrashant Kumar100% (1)

- SIEMENS Manfred Pohl 20120523cigre2012Documento23 páginasSIEMENS Manfred Pohl 20120523cigre2012suraiyya begumAinda não há avaliações

- Insulation Coordination of Ultra High VoDocumento38 páginasInsulation Coordination of Ultra High Voupenderaits100% (1)

- Advancements in Transmission Line Fault LocationDocumento143 páginasAdvancements in Transmission Line Fault LocationtunghtdAinda não há avaliações

- Design of Transmission Tower For A Sub Station of 132 KVDocumento11 páginasDesign of Transmission Tower For A Sub Station of 132 KVIJRASETPublicationsAinda não há avaliações

- Transmission Line Foult SafetyDocumento23 páginasTransmission Line Foult SafetyParv Choudhary0% (1)

- Inverter-Based Resource Performance Guideline NERCDocumento97 páginasInverter-Based Resource Performance Guideline NERCSubhadeep PaladhiAinda não há avaliações

- 2019 CIGRE-IEC 2019 ConferenceDocumento10 páginas2019 CIGRE-IEC 2019 ConferencetdropulicAinda não há avaliações

- Operation and Mantance of Substation 220/132/33kv SubstationDocumento109 páginasOperation and Mantance of Substation 220/132/33kv SubstationUmla Naik Nenavath100% (1)

- Transmission Line PrincipleDocumento9 páginasTransmission Line PrincipletamsideAinda não há avaliações

- 000000000001001846Documento361 páginas000000000001001846Dante Filho100% (1)

- 24 - 400 - 220 - KV - SS HW PDFDocumento28 páginas24 - 400 - 220 - KV - SS HW PDFgaurang1111Ainda não há avaliações

- Seminar Report On PLCCDocumento25 páginasSeminar Report On PLCCanon_946814792Ainda não há avaliações

- Major Project 2 (Faults in Transmission Line)Documento31 páginasMajor Project 2 (Faults in Transmission Line)Khaja SameeduddinAinda não há avaliações

- CIGRÉ 2001 TUTORIAL On Types and Uses of High Temperature ConductorsDocumento42 páginasCIGRÉ 2001 TUTORIAL On Types and Uses of High Temperature ConductorsAlexis de Jesus Fernandez CordovaAinda não há avaliações

- PowerPoint Presentation PDFDocumento46 páginasPowerPoint Presentation PDFNhất Nguyễn Văn100% (1)

- 765kV TrainingDocumento38 páginas765kV TrainingSumit MondalAinda não há avaliações

- Project Report Transmission Line Fault MonitoringDocumento34 páginasProject Report Transmission Line Fault Monitoringkra_amAinda não há avaliações

- Condition Based Maintenance of Underground Cable Systems: A Seminar Report OnDocumento20 páginasCondition Based Maintenance of Underground Cable Systems: A Seminar Report OnChethan PintoAinda não há avaliações

- PDFDocumento382 páginasPDFEdu Daryl MacerenAinda não há avaliações

- Power TheftDocumento16 páginasPower TheftSreenu vasuAinda não há avaliações

- Substations-Pdf Parte3 PDFDocumento76 páginasSubstations-Pdf Parte3 PDFCopr'esunaestafa EditorialdemierdaAinda não há avaliações

- Seven Year Electricity Planning Statement-Main-reportDocumento85 páginasSeven Year Electricity Planning Statement-Main-report2003vinayAinda não há avaliações

- Code of Practice For Design, Installation and Maintenancefor Overhead Power LinesDocumento22 páginasCode of Practice For Design, Installation and Maintenancefor Overhead Power LinesStarla HillAinda não há avaliações

- DR - Babasaheb Ambedkar Technological University, Lonere-RaigadDocumento25 páginasDR - Babasaheb Ambedkar Technological University, Lonere-RaigadAdeel ArshadAinda não há avaliações

- Transmission Line Tower Design ConceptsDocumento28 páginasTransmission Line Tower Design ConceptsDiego Cobo del ArcoAinda não há avaliações

- T&D (Compatibility Mode) (Repaired)Documento211 páginasT&D (Compatibility Mode) (Repaired)VanaVihari DasAinda não há avaliações

- Ijeet: International Journal of Electrical Engineering & Technology (Ijeet)Documento7 páginasIjeet: International Journal of Electrical Engineering & Technology (Ijeet)IAEME PublicationAinda não há avaliações

- Cable Fault Monitoring and Indication: A ReviewDocumento5 páginasCable Fault Monitoring and Indication: A Reviewijcsn100% (1)

- Effective Two-Terminal Single Line To Ground Fault Location AlgorithmDocumento6 páginasEffective Two-Terminal Single Line To Ground Fault Location AlgorithmLikhitha KukkalaAinda não há avaliações

- Ae 2014 PDFDocumento15 páginasAe 2014 PDFSandeep HnayakAinda não há avaliações

- Transistors Study Notes For RRB Alp Stage 2 Part B For Electronic Mechanic 2018 PDFDocumento5 páginasTransistors Study Notes For RRB Alp Stage 2 Part B For Electronic Mechanic 2018 PDFSandeep HnayakAinda não há avaliações

- Block ElectricalDocumento1 páginaBlock ElectricalSandeep HnayakAinda não há avaliações

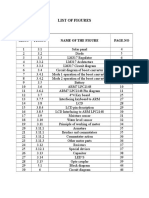

- List of Figures: SL - No Fig - No Name of The Figure Page - NoDocumento2 páginasList of Figures: SL - No Fig - No Name of The Figure Page - NoSandeep HnayakAinda não há avaliações

- Synopsis: The Features of The Project AreDocumento3 páginasSynopsis: The Features of The Project AreSandeep HnayakAinda não há avaliações

- Solar PanelDocumento61 páginasSolar PanelSandeep Hnayak0% (1)

- US6362718 Meg Tom Bearden 1Documento15 páginasUS6362718 Meg Tom Bearden 1Mihai DanielAinda não há avaliações

- Computer Shortcut Keys SystemDocumento5 páginasComputer Shortcut Keys SystemNo RebelAinda não há avaliações

- NRC RG 1.99 Rev. 2 PDFDocumento10 páginasNRC RG 1.99 Rev. 2 PDFlalitAinda não há avaliações

- Design Guide Fichtner PDFDocumento246 páginasDesign Guide Fichtner PDFAnonymous knICax100% (1)

- Sand ControlDocumento12 páginasSand ControlNIRAJ DUBEYAinda não há avaliações

- Tundish RefractoryDocumento15 páginasTundish RefractoryMashiur RahmanAinda não há avaliações

- SimulatorHW MidSize dSPACE Catalog 2008Documento4 páginasSimulatorHW MidSize dSPACE Catalog 2008Ram Krishan SharmaAinda não há avaliações

- TomatoDocumento19 páginasTomatoaravind kishanAinda não há avaliações

- Grade 10: Mathematics Structuring Competencies in A Definitive Budget of WorkDocumento2 páginasGrade 10: Mathematics Structuring Competencies in A Definitive Budget of Worksher blasAinda não há avaliações

- Micr Code Meaning of ChequeDocumento3 páginasMicr Code Meaning of Chequeमन्नू लाइसेंसीAinda não há avaliações

- Proceedings of Spie: Design and Simulation Analysis of A Magnetic Shielding Box For Ring Laser GyroscopeDocumento9 páginasProceedings of Spie: Design and Simulation Analysis of A Magnetic Shielding Box For Ring Laser GyroscopeTanzil ZaidiAinda não há avaliações

- FMS 304 Research Methodology - 0 PDFDocumento188 páginasFMS 304 Research Methodology - 0 PDFvicky100% (2)

- Motion 2000 Hydraulic v8 42-02-1P20 B7Documento248 páginasMotion 2000 Hydraulic v8 42-02-1P20 B7ElputoAmo XD100% (1)

- Experimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustDocumento13 páginasExperimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustPerarasan MAinda não há avaliações

- Registro Evaluacion Ergonomica ROSADocumento6 páginasRegistro Evaluacion Ergonomica ROSAEryade Grace ValenzuelaAinda não há avaliações

- Solow Model Extension-Human CapitalDocumento16 páginasSolow Model Extension-Human CapitalQusay Falah Al-dalaienAinda não há avaliações

- IBM PVM Getting Started GuideDocumento104 páginasIBM PVM Getting Started GuideNoureddine OussouAinda não há avaliações

- G. Measurement of Angles and DirectionsDocumento3 páginasG. Measurement of Angles and DirectionsJasleneDimarananAinda não há avaliações

- SB Erv Arvu123zea2 03 20Documento2 páginasSB Erv Arvu123zea2 03 20Mohammed Tausif AhmedAinda não há avaliações

- Consumer Perception On MatrimonyDocumento41 páginasConsumer Perception On Matrimonydeepak1818Ainda não há avaliações

- Mining Engineering Syllabus PDFDocumento5 páginasMining Engineering Syllabus PDFihateu1Ainda não há avaliações

- Summit X670 Series: Product OverviewDocumento10 páginasSummit X670 Series: Product OverviewAlex KramerAinda não há avaliações

- Reference BookDocumento313 páginasReference BooknirdeshAinda não há avaliações

- Advanced PHP ManualDocumento246 páginasAdvanced PHP Manualkennedy onuzulikeAinda não há avaliações

- Numpy For Matlab UserDocumento17 páginasNumpy For Matlab Userreza khAinda não há avaliações

- Mech CVTDocumento15 páginasMech CVTsachin guptaAinda não há avaliações

- External Interface (XINTF)Documento38 páginasExternal Interface (XINTF)AlonsoAinda não há avaliações

- Name: Edwin D. Bagos Jr. Date: Course, Year §ion: BSIT 1-E Rating: Contact Number: 09755276308 Subject: Computer Programming 1-JAVADocumento5 páginasName: Edwin D. Bagos Jr. Date: Course, Year §ion: BSIT 1-E Rating: Contact Number: 09755276308 Subject: Computer Programming 1-JAVAMonalyn Señaris100% (2)

- Danyar Et Al., 2020 - FinalDocumento24 páginasDanyar Et Al., 2020 - FinalSardar SaleemAinda não há avaliações

- SortDocumento174 páginasSortPeter CampellAinda não há avaliações