Escolar Documentos

Profissional Documentos

Cultura Documentos

Installation Manual Series ED124: Power Amplifier For Pressure Valves

Enviado por

mehdi810Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Installation Manual Series ED124: Power Amplifier For Pressure Valves

Enviado por

mehdi810Direitos autorais:

Formatos disponíveis

Bulletin 5715-505

Installation Manual

Series ED124

Power Amplifier for

Pressure Valves

Parker Hannifin GmbH

Hydraulic Controls Division

Gutenbergstr. 38

41564 Kaarst, Germany

Tel.:

(+) 2131-513-0

Fax:

(+) 2131-513-230

www.parker.com

Copyright 2000, Parker Hannifin GmbH

Contents

Power Amplifier for Pressure Valves

Series ED124

Installation Manual

Note

This document and other information from Parker Hannifin GmbH, its

subsidiaries, sales offices and authorized distributors provide product

or system options for further investigation by users having technical

expertise. Before you select or use any product or system it is important

that you analyse all aspects of your application and review the

information concerning the product or system in the current product

catalogue. Due to the variety of operating conditions and applications

for these products or systems, the user, through his own analysis and

testing, is solely responsible for making the final selection of the

products and systems and assuring that all performance and safety

requirements of the application are met. The products are subject to

change by Parker Hannifin GmbH at any time without notice.

IA ED124 UK A5.PM6.5 MM

Hydraulics

Home

Parker Hannifin GmbH

Hydraulic Controls Division

Power Amplifier for Pressure Valves

Series ED124

Installation Manual

Electronic module for the control of proportional

pressure relief valves. The pressure values and the

changing sequence are determined by externally

applied command signals as well as internal limit and

ramp potentiometers. The pressure is measured by

a pressure sensor and controlled by a closed loop

circuit.

Features

Processing and amplification of the externally

supplied positive commands into output signals

for the required pressure values.

Can be combined with EZ150 or external

programmable control.

DIP switch from internal ramp generation to

external ramp settings.

MAX limiter for matching the working range to the

full command range.

Pulsed low loss amplifier power stage with

supporting constant current control for constant,

temperature-independant, solenoid forces.

Dither generator with applied frequency to

improve static characteristics.

Diagnosis by means of diagnostic sockets as

well as LEDs for indicating working conditions.

Characteristics

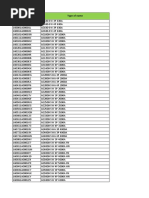

Connection

Power supply

Command voltage

Ramp disable voltage

Power required

Reference output

Max. solenoid output current

Ambient temperature

Ramp time

Shielded cable connections

48-pole male conn., DIN 41612F

regulated: 22-38V

0 to +10V DC

5 to 30V DC

40VA

+10V DC 10mA

1.3A

0 to 70C

0-5 seconds adjustable

Supply connection + valve: AWG15

Commands: AWG20

2A medium lag, DIN 41571/5x20mm

Fuse

Ordering Code

ED

Electronic

module

pressure

relief valve

ventile

Operating

pressure

Valve

size

124

10

Module

type

Design

series

Code

bar

Code

Valve size

Module type

2

3

210

350

0

1

2*

3

4

5

6

DSAEB NG06

DSAEB NG16

DSAEB NG25

DSAEB NG32

DSAEB NG40

DSAEB NG50

DSAEB NG63

Amplifier for use

with pressure

sensor,

adjustable

MAX.-limit,

UP/DOWN ramps

* for DSAEB "P"

and DSAEB "R"

use onlyCode 2

IA ED124 UK A5.PM6.5 MM

Hydraulics

Home

Parker Hannifin GmbH

Hydraulic Controls Division

Power Amplifier for Pressure Valves

Series ED124

Installation Manual

EMC

EN 50081-2

EN 50082-2

EN 55011

ENV 50140

EN 61000-4-4

ENV 50204

EN 61000-4-5

EN 61000-4-2

EN 61000-4-6

Block Diagram

Connector

(Elevation B)

z8

z10

z12

b14

Diff.-Input 0V

Diff.-Input (+) 0...10 V

Output (+) 10 V reference

Diagnosis output 1 V ^ 100 bar

z18

z20

z22

z24

z26

z28

z30

z32

Output sensor signal (4-20mA)

Input sensor supply

Input 24 V DC supply

Output Control Solenoid

Output Control Solenoid

Reference potential 0 V sensor

Reference potential 0 V set value

Reference potential 0 V Supply

IA ED124 UK A5.PM6.5 MM

Hydraulics

Home

Parker Hannifin GmbH

Hydraulic Controls Division

Power Amplifier for Pressure Valves

Series ED124

Installation Manual

Operating and Diagnostic Elements

(Elevation A)

1 (MIN.-limiting is not used here)

2 MAX.-limiting for matching

the max. pressure

3 (B-values are not used here)

4 Red socket for current

diagnostic

5 Black socket for current

diagnostic (0V potential)

6 Red LED (A) for:

function indicator pressure

(B not used)

7 Yellow LED for:

correct transducer installation

correct voltage supply

8 Red grip strip with

reference information for

measured values on the

diagnostic sockets

9 UP ramp-potentiometer

10 DOWN ramp potentiometer

Notes:

Turn off the electrical power

to this board whenever the

hydraulic supply to the valve

is not on.

Always turn off the power to this

board before removing it from

the card holder.

Dimensional Drawing

(Eurocard)

IA ED124 UK A5.PM6.5 MM

Hydraulics

Home

Parker Hannifin GmbH

Hydraulic Controls Division

Power Amplifier for Pressure Valves

Series ED124

Installation Manual

INSTALLATION GUIDE TO ELECTRONIC MODULES

TO PROVISION OF ELECTROMAGNETIC COMPATIBILITY.

Power Supply

The utilized power supply has to comply with the EMC-standards (CE-sign, certificate of conformity).

Parker is offering the following power supplies:

EX00-N01

EX00-N04

EX00-N08

( 2.5 Amp.)

( 5.0 Amp.)

(10.0 Amp.)

Relais and solenoids operating from the same supply circuit as the valve electronics have to be fitted

by surge protection elements.

Wiring Cable

The wires between the installation site of the module and the peripheral units, as power supply, valve

solenoids, command signal source have to be shielded. The following wire sizes must be reached:

power supply AWG 16, other connections AWG 20. The capacity should not exceed a value of approx.

130 pF/m (wire/wire). The maximum cable length is 50 m. No power current lines may be placed within

the wired shielded cables to the electronic module. The cable shield has to be connected to ground

at both ends (see also chapter Grounding). Please be aware of ground loops.

Installation

The module has to be mounted within a conductive, shielded enclosure. Usable is i.e. an EMCapproved control cabinet. A perfect grounding of the enclosure is mandatory (see also chapter

"Grounding).

Grounding

The mounting plate of the valve has to be connected to the grounded metal machine frame. The cable

shields must be tied to ground at the control cabinet. A low-ohmic potential compensation wire has

to be provided between the control cabinet and the machine frame (cable wire >AWG 7 cross section)

to prevent ground loops.

IA ED124 UK A5.PM6.5 MM

Hydraulics

Home

Parker Hannifin GmbH

Hydraulic Controls Division

Você também pode gostar

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsNo EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsNota: 3.5 de 5 estrelas3.5/5 (6)

- SI 580E - Sehwa PDFDocumento75 páginasSI 580E - Sehwa PDFrudiAinda não há avaliações

- CS 7600 Image Plate System: SPCX726 CS 7600 Roller KitDocumento4 páginasCS 7600 Image Plate System: SPCX726 CS 7600 Roller KitpacoAinda não há avaliações

- RE50214 Nivometer PDFDocumento16 páginasRE50214 Nivometer PDFCaspar Heerkens100% (1)

- User's Manual: AD/DA Conversion UnitDocumento194 páginasUser's Manual: AD/DA Conversion Unitmgkso706Ainda não há avaliações

- Manual Pi130Documento129 páginasManual Pi130Denis ChitoragaAinda não há avaliações

- Siemens Micromaster Eco ManualDocumento181 páginasSiemens Micromaster Eco ManualMohammad Imtiaz ChowdhuryAinda não há avaliações

- Ds Acopos1022 1045 1090Documento19 páginasDs Acopos1022 1045 1090Simon DrumsAinda não há avaliações

- SKIIP09NAC125IT45Documento1 páginaSKIIP09NAC125IT45Charoon SuriyawichitwongAinda não há avaliações

- 133R0228 HLP-SK180 Series English Operating Manual V2013-04Documento147 páginas133R0228 HLP-SK180 Series English Operating Manual V2013-04salesiano05Ainda não há avaliações

- Catalogo Botoes EatonDocumento348 páginasCatalogo Botoes EatonxixiaucamruAinda não há avaliações

- MP36 DataSheet US PDFDocumento2 páginasMP36 DataSheet US PDFCesar Augusto Arriaga ArriagaAinda não há avaliações

- E-Series CableOverviewDocumento8 páginasE-Series CableOverviewXithuAinda não há avaliações

- Robin KMP4120 Loop TesterDocumento12 páginasRobin KMP4120 Loop Testert0nt0Ainda não há avaliações

- CNCmakers-EP100 B QuickGuide-EN - EP100Documento14 páginasCNCmakers-EP100 B QuickGuide-EN - EP100Angelica PeñarandaAinda não há avaliações

- Data SheetDocumento16 páginasData SheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣAinda não há avaliações

- Participants ManualDocumento62 páginasParticipants ManualaaaaaAinda não há avaliações

- BLDC 5015aDocumento5 páginasBLDC 5015aroozbehxoxAinda não há avaliações

- Components Keystone CatalogueDocumento102 páginasComponents Keystone Catalogueamit64007Ainda não há avaliações

- 2013 Zippy Guide BookDocumento238 páginas2013 Zippy Guide BookDaniel Lang0% (1)

- 915Documento9 páginas915Jorge CotzomiAinda não há avaliações

- Manual VDF EN600 CompletoDocumento283 páginasManual VDF EN600 CompletoManuel galleguillosAinda não há avaliações

- Challenger Lc2201sb Lc26sb Lc2601sb SMDocumento40 páginasChallenger Lc2201sb Lc26sb Lc2601sb SMAntonioCésarUtreraAinda não há avaliações

- Mac Valves CatalogeDocumento359 páginasMac Valves CatalogeEnano Herrera100% (1)

- Electromagnetic Flowmeter User Manual: SHM "Gives You Trust"Documento22 páginasElectromagnetic Flowmeter User Manual: SHM "Gives You Trust"Rudi SetiawanAinda não há avaliações

- R230 Manual Macfarlane GeneratorsDocumento7 páginasR230 Manual Macfarlane Generatorsabuzer1981Ainda não há avaliações

- SKK Gearmotor MFG500 Series A Series CataloqDocumento128 páginasSKK Gearmotor MFG500 Series A Series Cataloqyb7knv100% (2)

- Pe 194802B Philips Manual DatasheetDocumento14 páginasPe 194802B Philips Manual DatasheetMárcio FernandesAinda não há avaliações

- Operation Manual: SINUS/VTC 4 - 160 KW SINUS/VTCV 5.5 - 200 KWDocumento113 páginasOperation Manual: SINUS/VTC 4 - 160 KW SINUS/VTCV 5.5 - 200 KWTainan ReichertAinda não há avaliações

- Atv312 Quick Start en S1a10942 01Documento4 páginasAtv312 Quick Start en S1a10942 01Auliya UrrochmanAinda não há avaliações

- 8200 MotecDocumento3 páginas8200 Motecyera1Ainda não há avaliações

- Panasonic TX-25lk1p TX-28lk1p Chassis z8Documento22 páginasPanasonic TX-25lk1p TX-28lk1p Chassis z8drrebyAinda não há avaliações

- On-Off Valve Actuator: (GEA-20A, 35A, 55A, 100A, 250A)Documento5 páginasOn-Off Valve Actuator: (GEA-20A, 35A, 55A, 100A, 250A)Quang PhanAinda não há avaliações

- Yamaha DXR8,10,12,15Documento114 páginasYamaha DXR8,10,12,15boroda2410100% (5)

- Pioneer sc-89 sc-87 rrv4550 Av Receiver PDFDocumento89 páginasPioneer sc-89 sc-87 rrv4550 Av Receiver PDFAlexandru PădeanuAinda não há avaliações

- PL 50 P 5 HXDocumento120 páginasPL 50 P 5 HXalvhann_1100% (1)

- Product Catalogue For WUHAN HUAYING ELECTRIC POWER TECH&SCIENCE CO.,LTDDocumento37 páginasProduct Catalogue For WUHAN HUAYING ELECTRIC POWER TECH&SCIENCE CO.,LTDhayanellAinda não há avaliações

- Mov (Varistor)Documento488 páginasMov (Varistor)saeidraminaAinda não há avaliações

- Calibrating Zero Water On A Micro 20 BoardDocumento3 páginasCalibrating Zero Water On A Micro 20 Boardeduardo_barreto_54Ainda não há avaliações

- Vivace Service Manual AQV12VBDocumento100 páginasVivace Service Manual AQV12VBEmerson SantosAinda não há avaliações

- Onkyo HT-R570 Service ManualDocumento90 páginasOnkyo HT-R570 Service Manualmaximadigital100% (1)

- NOVA Servo CatalogueDocumento7 páginasNOVA Servo CatalogueDip Narayan BiswasAinda não há avaliações

- (002, 003, 701, 743) Air Dryer, Screw Compressors ATLAS COPCO VorläufigDocumento572 páginas(002, 003, 701, 743) Air Dryer, Screw Compressors ATLAS COPCO VorläufigBata ZivanovicAinda não há avaliações

- Detectomat Katalog 2011Documento226 páginasDetectomat Katalog 2011Milica LolićAinda não há avaliações

- Spellman PDFDocumento254 páginasSpellman PDFLê HoàngAinda não há avaliações

- DS2 Series 220V Servo DriverDocumento59 páginasDS2 Series 220V Servo Driverspectra-tw100% (1)

- VCB 2C Vector - GBDocumento117 páginasVCB 2C Vector - GBppeanut70100% (1)

- Installation and Maintenance: This Manual Is To Be Given To The End UserDocumento12 páginasInstallation and Maintenance: This Manual Is To Be Given To The End UserHoang GiangAinda não há avaliações

- Bang Gia Thiet Bi Dien Mitsubishi 01-04-2020Documento422 páginasBang Gia Thiet Bi Dien Mitsubishi 01-04-2020Kien Nguyen TrungAinda não há avaliações

- PAMIO 4enc4a enDocumento2 páginasPAMIO 4enc4a enRicardo AlvaradoAinda não há avaliações

- UT-2506 User ManualDocumento22 páginasUT-2506 User ManualBayanaka TehnikAinda não há avaliações

- Sinamics Common Error CodesDocumento5 páginasSinamics Common Error CodesSuzanne DickersonAinda não há avaliações

- Etg101-151 1 UkDocumento114 páginasEtg101-151 1 UkJUANAinda não há avaliações

- Service Manual: CX-BK7Documento160 páginasService Manual: CX-BK7Frank ElizaldeAinda não há avaliações

- Installation Manual Series ED105: Power Amplifier For Pressure ValvesDocumento6 páginasInstallation Manual Series ED105: Power Amplifier For Pressure Valvesmehdi810Ainda não há avaliações

- Y11 Ee104Documento6 páginasY11 Ee104mehdi810Ainda não há avaliações

- Installation Manual Series ED101: Power Amplifier For Pressure ValvesDocumento6 páginasInstallation Manual Series ED101: Power Amplifier For Pressure Valvesmehdi810Ainda não há avaliações

- Installation Manual Series ET154: Power Amplifier For Flow ValvesDocumento6 páginasInstallation Manual Series ET154: Power Amplifier For Flow Valvesmehdi810Ainda não há avaliações

- Installation Manual Series ED104: Power Amplifier For Pressure ValvesDocumento6 páginasInstallation Manual Series ED104: Power Amplifier For Pressure Valvesmehdi810Ainda não há avaliações

- Neutral Strategies - Option AlphaDocumento4 páginasNeutral Strategies - Option Alphamehdi810Ainda não há avaliações

- Y04 DFH31Documento20 páginasY04 DFH31mehdi810Ainda não há avaliações

- HowToWin FYST EbookDocumento12 páginasHowToWin FYST Ebookmehdi810Ainda não há avaliações

- 9 Tons CO2 Waste TBBDocumento1 página9 Tons CO2 Waste TBBmehdi810Ainda não há avaliações

- Y03 DFTDocumento8 páginasY03 DFTmehdi810Ainda não há avaliações

- Rld90 ManualDocumento179 páginasRld90 Manualmehdi810Ainda não há avaliações

- Form Manual700Documento37 páginasForm Manual700mehdi810100% (1)

- Y15 Ew101Documento6 páginasY15 Ew101mehdi810Ainda não há avaliações

- Installation Manual Series ET101: Power Amplifier For Flow ValvesDocumento6 páginasInstallation Manual Series ET101: Power Amplifier For Flow Valvesmehdi810Ainda não há avaliações

- Installation Manual Series ED105: Power Amplifier For Pressure ValvesDocumento6 páginasInstallation Manual Series ED105: Power Amplifier For Pressure Valvesmehdi810Ainda não há avaliações

- Installation Manual Series EW104: Power Amplifier For DC ValvesDocumento6 páginasInstallation Manual Series EW104: Power Amplifier For DC Valvesmehdi810Ainda não há avaliações

- Y16 Ew102Documento6 páginasY16 Ew102mehdi810Ainda não há avaliações

- Installation Manual Series ET104: Power Amplifier For Flow ValvesDocumento6 páginasInstallation Manual Series ET104: Power Amplifier For Flow Valvesmehdi810Ainda não há avaliações

- Installation Manual Series ET102: Power Amplifier For Flow ValvesDocumento6 páginasInstallation Manual Series ET102: Power Amplifier For Flow Valvesmehdi810Ainda não há avaliações

- Installation Manual Series EZ 305: Auxiliary ModuleDocumento6 páginasInstallation Manual Series EZ 305: Auxiliary Modulemehdi810Ainda não há avaliações

- Installation Manual Series NC: Digital Axis ControllerDocumento47 páginasInstallation Manual Series NC: Digital Axis Controllermehdi810Ainda não há avaliações

- Installation Manual Series EZ 305: Auxiliary ModuleDocumento6 páginasInstallation Manual Series EZ 305: Auxiliary Modulemehdi810Ainda não há avaliações

- Installation Manual Series ET154: Power Amplifier For Flow ValvesDocumento6 páginasInstallation Manual Series ET154: Power Amplifier For Flow Valvesmehdi810Ainda não há avaliações

- Installation Manual Series ET154: Power Amplifier For Flow ValvesDocumento6 páginasInstallation Manual Series ET154: Power Amplifier For Flow Valvesmehdi810Ainda não há avaliações

- Installation Manual Series EZ 305: Auxiliary ModuleDocumento6 páginasInstallation Manual Series EZ 305: Auxiliary Modulemehdi810Ainda não há avaliações

- Installation Manual Series EQ104: Power Amplifier For Hydraulic Pump PVDocumento6 páginasInstallation Manual Series EQ104: Power Amplifier For Hydraulic Pump PVmehdi810Ainda não há avaliações

- Installation Manual Series EC106: Power Amplifier For Pressure-/ Flow ValvesDocumento8 páginasInstallation Manual Series EC106: Power Amplifier For Pressure-/ Flow Valvesmehdi810Ainda não há avaliações

- Installation Manual Series EC106: Power Amplifier For Pressure-/ Flow ValvesDocumento8 páginasInstallation Manual Series EC106: Power Amplifier For Pressure-/ Flow Valvesmehdi810Ainda não há avaliações

- Installation Manual Series EQ104: Power Amplifier For Hydraulic Pump PVDocumento6 páginasInstallation Manual Series EQ104: Power Amplifier For Hydraulic Pump PVmehdi810Ainda não há avaliações

- Installation Manual EX-M02: Test Unit For Electronic ModulesDocumento4 páginasInstallation Manual EX-M02: Test Unit For Electronic Modulesmehdi810Ainda não há avaliações

- Installation Manual Series EQ104: Power Amplifier For Hydraulic Pump PVDocumento6 páginasInstallation Manual Series EQ104: Power Amplifier For Hydraulic Pump PVmehdi810Ainda não há avaliações

- Installation Manual VS111 Series: Plug-In Amplifier For Proportional ValvesDocumento7 páginasInstallation Manual VS111 Series: Plug-In Amplifier For Proportional Valvesmehdi810Ainda não há avaliações

- Installation Manual EX-M02: Test Unit For Electronic ModulesDocumento4 páginasInstallation Manual EX-M02: Test Unit For Electronic Modulesmehdi810Ainda não há avaliações

- Installation Manual EX-M03: Test Unit For Proportional Valves With Integrated ElectronicsDocumento4 páginasInstallation Manual EX-M03: Test Unit For Proportional Valves With Integrated Electronicsmehdi810Ainda não há avaliações

- Inverter 1 KW ManualDocumento44 páginasInverter 1 KW ManualLeonardoAinda não há avaliações

- Women EmpowermentDocumento7 páginasWomen EmpowermentJessica Glenn100% (1)

- The Case - Lijjat PapadDocumento16 páginasThe Case - Lijjat Papadganesh572Ainda não há avaliações

- SanMilan Inigo Cycling Physiology and Physiological TestingDocumento67 páginasSanMilan Inigo Cycling Physiology and Physiological Testingjesus.clemente.90Ainda não há avaliações

- BMJ 40 13Documento8 páginasBMJ 40 13Alvin JiwonoAinda não há avaliações

- Installing Touareg R5 CamshaftDocumento1 páginaInstalling Touareg R5 CamshaftSarunas JurciukonisAinda não há avaliações

- ArticleDocumento5 páginasArticleJordi Sumoy PifarréAinda não há avaliações

- Women and ViolenceDocumento8 páginasWomen and ViolenceStyrich Nyl AbayonAinda não há avaliações

- SGT PDFDocumento383 páginasSGT PDFDushyanthkumar DasariAinda não há avaliações

- CXC - Past - Paper - 2022 Solutions PDFDocumento17 páginasCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- Basics of Fire SprinklerDocumento21 páginasBasics of Fire SprinklerLeo_1982Ainda não há avaliações

- Answers To Your Questions About Circumcision and HIV/AIDSDocumento2 páginasAnswers To Your Questions About Circumcision and HIV/AIDSAlex BrownAinda não há avaliações

- Method Statement (RC Slab)Documento3 páginasMethod Statement (RC Slab)group2sd131486% (7)

- Starkville Dispatch Eedition 9-10-20Documento12 páginasStarkville Dispatch Eedition 9-10-20The DispatchAinda não há avaliações

- 3 Activities For Adults To Practice Modeling SELDocumento10 páginas3 Activities For Adults To Practice Modeling SELDavid Garcia PerezAinda não há avaliações

- Alugbati Plant Pigment Extraction As Natural Watercolor SourceDocumento6 páginasAlugbati Plant Pigment Extraction As Natural Watercolor SourceMike Arvin Serrano100% (1)

- Flame Retardant and Fire Resistant Cable - NexansDocumento2 páginasFlame Retardant and Fire Resistant Cable - NexansprseAinda não há avaliações

- A Comprehensive Review of Cementitious Grouts - Composition, Properties, Requirements and Advanced PerformanceDocumento16 páginasA Comprehensive Review of Cementitious Grouts - Composition, Properties, Requirements and Advanced PerformanceiporrasAinda não há avaliações

- AtelectasisDocumento37 páginasAtelectasisSandara ParkAinda não há avaliações

- Chapter 2 and 3 ImmunologyDocumento16 páginasChapter 2 and 3 ImmunologyRevathyAinda não há avaliações

- Wisconsin Humane Society To Acquire Kenosha's Safe Harbor Humane Society - Press ReleaseDocumento3 páginasWisconsin Humane Society To Acquire Kenosha's Safe Harbor Humane Society - Press ReleaseTMJ4 NewsAinda não há avaliações

- Village Survey Form For Project Gaon-Setu (Village Questionnaire)Documento4 páginasVillage Survey Form For Project Gaon-Setu (Village Questionnaire)Yash Kotadiya100% (2)

- OPSS1213 Mar98Documento3 páginasOPSS1213 Mar98Tony ParkAinda não há avaliações

- Neuro M Summary NotesDocumento4 páginasNeuro M Summary NotesNishikaAinda não há avaliações

- Rules For State Competitions and Iabf Approved TournamentsDocumento56 páginasRules For State Competitions and Iabf Approved TournamentsQuality management systems documentsAinda não há avaliações

- Jun Judging ClinicDocumento1 páginaJun Judging Cliniccsponseller27Ainda não há avaliações

- How To Import Medical Devices Into The USDocumento16 páginasHow To Import Medical Devices Into The USliviustitusAinda não há avaliações

- How McDonald'sDocumento2 páginasHow McDonald'spratik khandualAinda não há avaliações

- What Is A VolcanoDocumento2 páginasWhat Is A VolcanonatachaAinda não há avaliações

- 41403A - Guide - Rev - 12-20-17 - With Edits - 2-16-18Documento167 páginas41403A - Guide - Rev - 12-20-17 - With Edits - 2-16-18Ronald KahoraAinda não há avaliações