Escolar Documentos

Profissional Documentos

Cultura Documentos

Sulph PDF

Enviado por

marraezDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sulph PDF

Enviado por

marraezDireitos autorais:

Formatos disponíveis

SULPH.

F/COVER 25/1/2001 4:55 pm Page 1

January February 2001

Number 272

The Magazine for the World Sulphur and Sulphuric Acid Industries

Ensuring uniform heat distribution in sulphur

vapour lines

SULPH.P44-46 16/3/2001 6:04 pm Page 44

SULPHUR PROCESSING

Ensuring uniform heat

distribution in sulphur

vapour lines

Uniform temperature distribution in sulphur pipeline walls can be

achieved by applying heating elements which are strategically positioned using

accurate thermodynamic process modelling software. A well-designed system protects

the process from interruptions caused by corrosion or blockage of the pipeline.

David R. Hornbaker of Controls Southeast, Inc. reports on a typical case in point.

ertain hot process piping services require thermal maintenance devices to keep stream

temperatures within design limits. In

such cases conventional pipe jacketing has been regarded as sufficient

but often too expensive. An alternative to pipe jacketing, tube tracing,

does not effectively prevent problems caused by temperature variations along the process pipe wall.

Frequently, tube tracing is used as an

economical way to try and compensate for heat loss. In low temperature

applications with broad temperature

envelopes, steam tracing can be effective. However, in those applications,

the position of the tracers, and the

temperature distribution in the pipe

material are not considered important. A new system for process temperature maintenance or uniform

pipe wall temperatures, comparable

in price to tube tracing, consists of

contoured, bolt-on trace elements.

These elements are strategically positioned after modelling heat dynamics

in the operating piping system. In

dealing with the actual problems

caused by unwanted heat variation,

frequently the key principle is assuring uniform pipe wall temperature.

To assure uniformity, it is necessary

Sulphur

No 272

to manage the heat distribution in

the pipe wall. Proper management of

heat distribution depends on the

number and placement of heating

elements. This placement in turn

depends on accurate modelling of

process thermodynamics. Therefore,

the heating element vendor should

apply accurate process modelling

software to assure uniform pipe wall

temperature. An example of the

result of this type of modelling is

shown in Figure 1. Heat from steam

at 159C is applied from a contoured

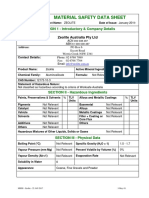

Fig. 1: Calculated pipe wall temperatures for an Alberta-based SRU

30 in. process pipe

4 control trace heating elements

gas=130C

midpoint between

control trace elements

132C

133C

136C

141C

147C

steam=159C

Source: CSI

January . February 2001

SULPH.P44-46 16/3/2001 6:05 pm Page 45

SULPHUR PROCESSING

year lifetime of the original pipe to be

economically unsound, plant management sought to find a better way to

maintain pipe temperature. They

reviewed the experience of similar

plants equipped with ControTrace

systems. In some instances, these systems had been effective in comparable

service for over ten years.

The gas plant operator analysed

the various parameters involved in

heating and cooling the pipe. They

used a proprietary finite-difference

computer model developed by

Controls Southeast, Inc. (CSI), the

manufacturer of the ControTrace system.They created a model for gas flow

through the pipe and generated temperature profiles of the piping system

under various operating conditions.

Conventional trace sizing programs simply deal with the pipe sizes,

temperature, insulation and ambient

conditions. These programs calculate

total heat loss from the pipe and determine the number of heating tracers

needed to replace that amount of heat.

No consideration is given to how the

heat gets distributed to all parts of the

pipe. Adding more heat than is being

lost does not assure that all points on

the pipe will operate above the condensation temperature.

heating element to a pipe wall at

defined intervals. Directly under the

element, the wall temperature is

147C. Note the decrease in wall

temperature as the distance from the

element increases, until a minimum

of 132C is reached.

At this point heat conducted

through the wall from another heating element causes the wall temperature to rise again. The wall temperature varies within a defined range and

the warmest and coolest points can

also be readily identified.

Application of contoured pipe

tracing after thermal analysis prevents

problems of condensation and associated pipe corrosion caused by mixed

vapours in sulphur processing.

Case history:

sulphur recovery

Sulphur recovery units in refineries or

gas plants usually include tail gas or

degas vapour lines. These lines are

commonly heated to prevent the condensation of either sulphur or water.

In most cases, the gas in the line is at

an elevated temperature and can be

assumed to be at or above dew point

temperatures. There are two dew

points, one for water and one for sulphur. It has been common practice to

employ conventional tube tracing (or

in some cases electric tracing) to heat

the line. Despite this practice, condensation and resulting corrosion are

often still a problem. The cause is

uneven or inadequate heating of the

pipe.

A gas plant operator can achieve

more uniform heating of the pipe. It is

necessary to conduct a detailed thermal analysis of the pipe, gas, heating

elements and insulation. Then the

operator installs an innovative bolt-on

temperature management system.

Thermal analysis reveals that the flowing process gas may actually be cooling the pipe wall. Conventional steam

or electric tracings are usually not

heating the pipe uniformly, resulting in

cold spots where condensation occurs.

Condensation can be prevented

by using high-performance bolt-on

steam tracing material, properly distributed around the pipe. This case

describes an installation at a natural

gas plant sulphur degassing unit in

central Alberta, Canada.

Sulphur

No 272

Fig 2: ControTrace installation.

Steam tracing allows

corrosion

The degas vent piping at the Alberta

plant had been in place for about six

years and had suffered serious corrosion, particularly in and around the

low spots. The original steam tracing

had been done with conventional

5 in. tube tracing employing 500

/8

kPag saturated steam. Vent line sizes

were 20in., 24in., and 30in. diameter,

running about 55 meters from the

degas pit to the incinerator. They had

been installed with 10 tracing tubes on

the 20in. line and as many as 13 tubes

on the 30in. line.The tracing was generally located around the bottom of

the pipe in horizontal runs and on a

convenient side on vertical runs. The

analysis model showed that 13 tubes

was the very minimum that could be

used if they were spaced at equal intervals around the 30in. pipe.

Because they considered the six-

Better analytical tool

The more comprehensive analytical

tool provided by CSI models shows

how much heat is going into the pipe.

It measures how that heat is distributed by conduction along the pipe

wall, through the insulation, and by

convection, to the process itself. The

analysis uses the following data sets:

pipe size; wall thickness and material

properties; insulation thickness and

properties; worst-case ambient temperature; wind conditions; process gas

properties; and flow rates.

From all of these properties and flow

conditions, CSI was able to calculate a

heat transfer coefficient specific to the

Alberta plant.

By applying the model, plant management and CSI determined detailed

temperature profiles for various conditions. Variables included heating elements and their spacing, steam temperature, insulation thickness, and

flow conditions (from maximum

expected to zero flow). They deterJanuary . February 2001

SULPH.P44-46 16/3/2001 6:05 pm Page 46

SULPHUR PROCESSING

Fig 3: ControTrace on an elbow.

mined the optimum number of elements and their placement so that pipe

wall temperatures would prevent

process condensation.

Plant management then conducted

a material cost and installation

expense analysis specific to the Alberta

plant. It revealed that even though the

material cost for ControTrace was

higher than for tube tracing, the

installed cost was expected to be significantly less. Because the management of the Alberta plant expected

longer pipe lifetime with the

ControTrace system, both the performance and economic criteria were theoretically met. Management awarded

a contract to CSI for the necessary

thermal modelling/design and fabrication of the new bolt-on tracing system.

Installation was done by the plant and

plant contract personnel.

results in improved and more predictable performance. Not only does

the ControTrace system use fewer elements (tubes) than the traditional

round tubing, it is significantly more

mechanically stable.

The sulphur pipeline continued to

operate during the installation of the

ControTrace system. In spite of this,

the actual installation cost was less

than originally predicted. Most of the

installation was done from scaffolding,

although some of the bolt-on tracing

was shop mounted prior to pipe hanging. The ControTrace is supplied pre-

fabricated into rings and headered

panels. (See figure 2: photo for typical

straight run.)

During installation, the non-hardening heat transfer mastic was applied

to the trace surface. Then the individual panels and ring halves were bolted

together. It was necessary that the

panels and rings be pulled snugly

against the pipe and flanges. Meeting

this requirement was not difficult

because the ControTrace is very

rugged and can withstand large bolting pressures. The installation crew

said that the ControTrace product

was easier to install than tube tracing.

(See figures 3 and 4: two photos show

installations around an elbow and at

a pipe support.)

Following installation the system

was insulated. Insulating over the

ControTrace was no more difficult

than insulating pipe of similar size

with tube tracing. Trapping of the

steam system was based on plant

standards and steam loads taken

from the thermal modeling program.

Interconnection of steam between

individual components was done

with hard piping in accordance with

plant standards.

At startup, pipe wall temperatures

were checked with a surface pyrometer. Temperatures quickly came to

values in the expected range. Since

then, periodic pipe wall temperature

measurements have been made with

all values falling in the expected

S

range.

Effective heat transfer

ControTrace heating elements are

drawn from SA178 carbon steel into a

rectangular shape. One side is curved

to fit the outside contour of the pipe.

The ControTrace elements used on

the sulphur pipeline are nominally

25mm by 50mm. They are registered

in Canada with a pressure rating of

2380 kPag at 340C. Heat exchange

between the steam and the pipe is

greatly enhanced by the use of a thin

film of heat transfer mastic. This

January . February 2001

Fig 4: ControTrace at a pipe support.

Sulphur

No 272

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Musculoskeletal 20,000 Series CPT Questions With Answers-CpcDocumento16 páginasMusculoskeletal 20,000 Series CPT Questions With Answers-Cpcanchalnigam25100% (7)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Answers To Competency Assessment SectionDocumento16 páginasAnswers To Competency Assessment Sectionapi-209542414100% (1)

- LPG Plant ReportDocumento104 páginasLPG Plant Reportmsh_jaazAinda não há avaliações

- Paracetamol DegradationDocumento9 páginasParacetamol DegradationTruyền Phạm MinhAinda não há avaliações

- A Crude Distillation Unit Model Suitable Foronline ApplicationsDocumento21 páginasA Crude Distillation Unit Model Suitable Foronline ApplicationsNông DânAinda não há avaliações

- PSV PDFDocumento35 páginasPSV PDFJagan BoseAinda não há avaliações

- Tom Kenyon - ImmunityDocumento9 páginasTom Kenyon - ImmunityDren Hoti100% (2)

- Atomic Structure Worksheet: Name PeriodDocumento4 páginasAtomic Structure Worksheet: Name Periodapi-496534295100% (1)

- Zeolite MsdsDocumento6 páginasZeolite MsdsmarraezAinda não há avaliações

- Five Best PracticesDocumento10 páginasFive Best PracticesAntHony K-ianAinda não há avaliações

- MechReaction Liu 2016Documento26 páginasMechReaction Liu 2016marraezAinda não há avaliações

- MD AlkyClean v2Documento4 páginasMD AlkyClean v2marraezAinda não há avaliações

- US20220144724A1Documento24 páginasUS20220144724A1marraezAinda não há avaliações

- MSDS Zeolite 25 JAN 2019Documento4 páginasMSDS Zeolite 25 JAN 2019marraezAinda não há avaliações

- US8105968Documento24 páginasUS8105968marraezAinda não há avaliações

- Sulfuric Acid Alkylation Technology: Dr. Girish K. Chitnis Mr. Ron D. Mcgihon Mr. Aneesh Prasad Mr. Christopher M. DeanDocumento18 páginasSulfuric Acid Alkylation Technology: Dr. Girish K. Chitnis Mr. Ron D. Mcgihon Mr. Aneesh Prasad Mr. Christopher M. DeanmarraezAinda não há avaliações

- SNG Symp2019 KBR 2 K SAATDocumento30 páginasSNG Symp2019 KBR 2 K SAATmarraezAinda não há avaliações

- World RefiningDocumento7 páginasWorld RefiningmarraezAinda não há avaliações

- DuplicateDocumento134 páginasDuplicatemarraezAinda não há avaliações

- K-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsDocumento17 páginasK-SAAT - A Break-Through Solid Acid Alkylation Technology: Edward GriffithsmarraezAinda não há avaliações

- AZ Cover Sheet For SummaryDocumento1 páginaAZ Cover Sheet For SummarymarraezAinda não há avaliações

- Refining K-Saat 2022marDocumento4 páginasRefining K-Saat 2022marmarraezAinda não há avaliações

- E04413040 PDFDocumento11 páginasE04413040 PDFjoseAinda não há avaliações

- Crude and Vacuum Unit Design ChallengesDocumento24 páginasCrude and Vacuum Unit Design Challengesumeshchandra yadavAinda não há avaliações

- CHEMICAL ENGINEERING Interview QuestionsDocumento28 páginasCHEMICAL ENGINEERING Interview QuestionsNikunj PatelAinda não há avaliações

- Lo Que AprenderásDocumento2 páginasLo Que AprenderásmarraezAinda não há avaliações

- Petroleum Fraction at Ion OverviewDocumento35 páginasPetroleum Fraction at Ion Overviewphobos2000Ainda não há avaliações

- Thermodynamic Analysis: Yaşar DemirelDocumento31 páginasThermodynamic Analysis: Yaşar DemirelmarraezAinda não há avaliações

- Modification of Outlet Stream of The AtmDocumento9 páginasModification of Outlet Stream of The AtmADEOLAAinda não há avaliações

- Refractory Nitrogen Compounds in Hydrocr PDFDocumento6 páginasRefractory Nitrogen Compounds in Hydrocr PDFmarraezAinda não há avaliações

- Process Profits W SimulationDocumento4 páginasProcess Profits W SimulationmarraezAinda não há avaliações

- Process Profits W SimulationDocumento4 páginasProcess Profits W SimulationmarraezAinda não há avaliações

- Hydro Cracking For Maximizing Middle Dis PDFDocumento9 páginasHydro Cracking For Maximizing Middle Dis PDFmarraezAinda não há avaliações

- Some Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilDocumento22 páginasSome Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilmarraezAinda não há avaliações

- Ordouei Mohammad HosseinDocumento159 páginasOrdouei Mohammad HosseinmarraezAinda não há avaliações

- Polymer ProDocumento25 páginasPolymer ProJeerisuda KingklangAinda não há avaliações

- Physical Fitness TestDocumento1 páginaPhysical Fitness TestGiessen Fran RamosAinda não há avaliações

- PS Ebook BagsPouches2 1116 HRDocumento58 páginasPS Ebook BagsPouches2 1116 HRGovindarajulu RAinda não há avaliações

- Kora 3T 09Documento1 páginaKora 3T 09Vаleriy шефAinda não há avaliações

- Beta CaroteneDocumento2 páginasBeta CaroteneValeria MarcuțăAinda não há avaliações

- Trash Chute-Compliance Sheet Sangir)Documento5 páginasTrash Chute-Compliance Sheet Sangir)Li LiuAinda não há avaliações

- Nuclear Over Hauser Enhancement (NOE)Documento18 páginasNuclear Over Hauser Enhancement (NOE)Fatima AhmedAinda não há avaliações

- Pediatric Medication Dosing GuildelinesDocumento2 páginasPediatric Medication Dosing GuildelinesMuhammad ZeeshanAinda não há avaliações

- Cell Organelles 2Documento13 páginasCell Organelles 2Sadeeq ur RahmanAinda não há avaliações

- Organic Facial Remedies Versus Inorganic Facial RemediesDocumento13 páginasOrganic Facial Remedies Versus Inorganic Facial Remediesapi-271179911Ainda não há avaliações

- Nitrile Butadiene Rubber (NBR), Synthetic Latex: ApplicationDocumento2 páginasNitrile Butadiene Rubber (NBR), Synthetic Latex: ApplicationbobAinda não há avaliações

- Elasticity, Plasticity Structure of Matter: by DR R. HouwinkDocumento9 páginasElasticity, Plasticity Structure of Matter: by DR R. HouwinkKhlibsuwan RAinda não há avaliações

- Ws - Mea Millennium Ecosystem AssessmentDocumento3 páginasWs - Mea Millennium Ecosystem Assessmentapi-305791685Ainda não há avaliações

- Eaton BECOPAD P Range TechnicalDataSheet enDocumento4 páginasEaton BECOPAD P Range TechnicalDataSheet enEsteban Fernando Meza IbacetaAinda não há avaliações

- Geographical Perspective On Selected Issues and Problems #ToppersnotesDocumento16 páginasGeographical Perspective On Selected Issues and Problems #ToppersnotesParidhi JainAinda não há avaliações

- Ir33+ Range: ... Continuity, Innovation and DesignDocumento4 páginasIr33+ Range: ... Continuity, Innovation and DesignbenAinda não há avaliações

- Bachelor of Physiotherapy (BPT) 2nd YearDocumento17 páginasBachelor of Physiotherapy (BPT) 2nd YearMOHD TAUSIF0% (1)

- Genomics and Crop ImprovementDocumento56 páginasGenomics and Crop Improvementsenguvelan100% (6)

- Park Ch. 1 - A1000 - Spring13Documento21 páginasPark Ch. 1 - A1000 - Spring13lingyeeAinda não há avaliações

- Urie BronfenbrennerDocumento27 páginasUrie Bronfenbrennerapi-300862520100% (1)

- Notes About BurnsDocumento11 páginasNotes About BurnsMichelle Ann GacudAinda não há avaliações

- of Biology On Introductory BioinformaticsDocumento13 páginasof Biology On Introductory BioinformaticsUttkarsh SharmaAinda não há avaliações

- Mercury II 5000 Series Encoders: High Performance Encoders With Digital OutputDocumento21 páginasMercury II 5000 Series Encoders: High Performance Encoders With Digital OutputRatnesh BafnaAinda não há avaliações

- P13Documento21 páginasP13Saeful AzizAinda não há avaliações

- Sikament®-4101 NS: Product Data SheetDocumento2 páginasSikament®-4101 NS: Product Data SheetShihab AhamedAinda não há avaliações