Escolar Documentos

Profissional Documentos

Cultura Documentos

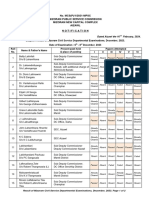

WSM 0000848 01

Enviado por

hatelTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

WSM 0000848 01

Enviado por

hatelDireitos autorais:

Formatos disponíveis

05:01-04

Issue 1

Gearbox

GRS890

GRS900

GRS920

GRSH900

GRSO900

Shafts

Work Description

1 714 660

Scania CV AB 2005, Sweden

en

Contents

Contents

Input shaft

Exploded view drawings .......................................... 3

Dismantling .............................................................. 4

Assembly .................................................................. 7

Mainshaft

Exploded view drawing .......................................... 10

Dismantling ............................................................ 12

Renewing bearing races for splitter gearwheel....... 15

Assembly ................................................................ 17

Layshaft

Exploded view drawing .......................................... 24

Dismantling ............................................................ 25

Assembly ................................................................ 29

Specifications

Materials ................................................................. 33

Tightening torques .................................................. 33

Scania CV AB 2005, Sweden

05:01-04

Input shaft

Input shaft

Exploded view drawings

GRS890, GRS/GRSH900

4

5

3

1

2

3

4

5

6

7

8

9

Shaft

Snap ring

Bearing

Gear

Needle bearing

Sealing ring

Piston ring

Spacing ring

Pipe

1

2

3

4

5

6

7

8

Shaft

Snap ring

Bearing

Gear

Needle bearing

Sealing ring

Piston ring

Pipe

136 218

GRS920, GRSO900

7

4

5

3

136 219

05:01-04

Scania CV AB 2005, Sweden

Input shaft

Dismantling

Special tools

Description

87 596

Slide hammer

99 136

Hollow drift

99 141

Support ring

Illustration

Tool board

D2

87 596

00 1610

Number

P1

00 1622

99 136

P1

00 1623

99 141

Other tools

Description

587 312

Snap ring pliers

Illustration

587 312

111 445

Number

Scania CV AB 2005, Sweden

05:01-04

Input shaft

1 Remove the two piston rings by hand.

Earlier gearboxes may have a spacing ring

between the piston rings.

2 Remove the snap ring. Use snap ring pliers

587 312. It may be necessary to tap the

bearing inner race with something first, such

as a drift and hammer.

3 Place the shaft on hollow drift 99 136 and

support ring 99 141. Press out the bearing

and gear. Place something soft underneath

to protect the shaft when it comes loose.

05:01-04

Scania CV AB 2005, Sweden

Input shaft

4 Remove the bearing and the gear. Remove

the bearing shells.

If the input shaft is the old type, i.e. with the

oil pipe pressed into the input shaft, remove

as follows.

5 Tap the oil pipe using an M10 pilot tap.

6 Pull out the oil pipe using an M10 bolt with

welded-on washer and slide hammer

87 596. Clean the oilway.

Scania CV AB 2005, Sweden

05:01-04

Input shaft

Assembly

Special tools

Description

98 224

Pressplate

98 334

Counterholding tube

98 450

Shank

Illustration

Tool board

G1

98 224

110 065

Number

G3

110 120

98 334

00 1633

R2, AD2, AM1

98 450

Assembly drift

99 136

Hollow drift

99 141

Support ring

G1

98 636

110 815

98 636

P1

00 1622

99 136

P1

00 1623

99 141

Other tools

Description

587 312

Snap ring pliers

Illustration

587 312

111 445

Number

05:01-04

Scania CV AB 2005, Sweden

Input shaft

If the input shaft is the old type, i.e. with the oil

pipe pressed into the shaft, fit as described in

steps 1-2.

1 Place the shaft in pressplate 98 224.

2 Press in the oil pipe using shank 98 450.

Press in the pipe so that it protrudes at least

21.5 mm (dimension A). Check that the

lubricating holes are clear. The pipe must

not be upset.

3 Fit the bearing shells and the gear with the

splines downwards.

4 Press on the bearing using counterholding

tube 98 334 and assembly drift 98 636.

Scania CV AB 2005, Sweden

05:01-04

Input shaft

5 Fit the snap ring using snap ring pliers

587 312. Select a snap ring which provides

the least possible clearance between the ring

and bearing. Check that the snap ring goes

down into the groove.

6 Place the shaft on hollow drift 99 136 and

support ring 99 141. Press the bearing

against the snap ring using a press force of

70 kN max. (7 tonnes).

7 Fit the two piston rings. Earlier versions

also have a spacing ring between the piston

rings.

05:01-04

Scania CV AB 2005, Sweden

Mainshaft

Mainshaft

Exploded view drawing

10

Scania CV AB 2005, Sweden

05:01-04

Mainshaft

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Mainshaft

Bearing

Nut

Roller bearing

Spacing ring

Shim

Gear

Gear

Needle bearing

Gear

Snap ring

Needle bearing

Gear

Slide bearing

Driver

Coupling sleeve

Gear

Slide bearing

Slide bearing

Nozzle

Shim

Spacing ring

Shift sleeve

Snap ring

Sun wheel

Spacing washer

Shim

Nut

05:01-04

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

Cone

Driver

Compression spring

Plunger

Clevis pin

Shift sleeve

Latch cone

Cone

Synchromesh cone

Driver

Compression spring

Plunger

Clevis pin

Shift sleeve

Latch cone

Coupling disc

Spring pin

Snap ring

Synchromesh

Intermediate cone

Latch cone

Driver plate

Compression spring

Plunger

Clevis pin

Washer

Shift sleeve

Driver

Scania CV AB 2005, Sweden

11

Mainshaft

Dismantling

Special tools

Number

Description

Illustration

87 237

Support drift

98 322

Lifting handle

98 575

Support drift

99 136

Hollow drift

99 140

Support ring

99 202

Split support ring

Tool board

G2

G2

109 805

98 322

G2

00 1621

98 575

P1

00 1622

99 136

P1

111 007

99 140

P1

111 022

99 201

Other tools

Description

587 318

Puller plate

587 319

Puller

587 600

Socket

Illustration

114 693

Number

D

Di

00 1890

12

Scania CV AB 2005, Sweden

05:01-04

Mainshaft

1 Pull off the front bearing. Use support drift

87 237, puller plate 587 318 and puller

587 319.

WARNING!

Wear protective goggles. There is a risk

of flying fragments if the bearing breaks.

2 Remove the round nut, use socket 587 600.

3 Fit lifting handle 98 322 and lift the shaft

onto the press.

05:01-04

Scania CV AB 2005, Sweden

13

Mainshaft

4 Lower the shaft into hollow drift 99 136.

When the shift sleeve is down in the hollow

drift, fit the split support ring 99 202. Centre

carefully. Place, for example, a rubber cloth

in the drift to cushion the fall.

99 202

99 136

133 794

5 Press out the rear bearing, reverse shaft gear,

crawl and first gears. Protect the ends of the

shaft using support drift 98 575. Remove the

bearing, gears and synchromesh assembly.

Keep the synchromesh assembly as a unit.

Mark the parts and place the assembly to

one side.

98 575

6 Turn the shaft and place it in hollow drift

99 136. Use support ring 99 140. Protect the

ends of the shaft using support drift 98 575.

7 Press out the shaft. Remove the second gear

and splitter gear with their corresponding

synchromesh assembly. Mark the splitter

gearwheel so that it faces in the same

direction during assembly. Keep the

synchromesh assembly as a unit. Mark the

parts and place the assembly to one side.

14

Scania CV AB 2005, Sweden

05:01-04

Mainshaft

Renewing bearing races for splitter gearwheel

Special tools

Description

87 446

Drift

87 758

Drift

Illustration

Tool board

AD2

87 446

00 1581

Number

G1

00 1611

87 758

Other tools

Description

587 316

Counterhold

587 530

Puller

Illustration

115 110

114 058

Number

05:01-04

Scania CV AB 2005, Sweden

15

Mainshaft

1 Mount the gearwheel in a vice with soft

jaws. Use puller 587 530 and counterhold

587 316 to pull out one bearing race. Use a

separator plate made of e.g. aluminium

sheet.

2 Press out the other bearing race using drift

87 758.

3 Press in new bearing races using drift

87 446.

16

Scania CV AB 2005, Sweden

05:01-04

Mainshaft

Assembly

Special tools

Description

Illustration

87 089

Drift

87 089

87 550

Drift

87 550

87 932

Drift

88 292

Pull rod

98 075

Dial gauge

Tool board

AM2, D3

110 283

Number

00 1628

AD2

D3, G1

00 1636

87 932

G2

00 1848

88 292

D2

98 075

0

90

10

10

90

80

20

20

80

15

30

5

10

70

70

30

40

60

60

40

50

00_1637

50

98 568

Drift

98 575

Support drift

98 575

99 127

Drift

99 127

99 136

Hollow drift

AM1

00_1618

98 568

00 1621

G2

00 1629

AM1

P1

00 1622

99 136

05:01-04

Scania CV AB 2005, Sweden

17

Mainshaft

Description

99 140

Support ring

99 190

Drift

99 191

Drift

99 199

Counterhold

Illustration

Tool board

P1

99 140

111 007

Number

G4

00 1638

99 190

G4

109 785

99 191

99 199

111 021

G4

Other tools

Description

Illustration

587 250

Indicator stand with magnetic

base

587 600

Socket

102350

Number

D

Di

00 1890

1 Fit the needle bearing.

2 Fit the second gear with the spline flange

upwards.

18

Scania CV AB 2005, Sweden

05:01-04

Mainshaft

05_3289

3 Fit the synchromesh assembly for second

and third gears with the longer neck of the

driver downwards. Guide onto the splines

and press if necessary.

4 Press one bearing onto the splitter

gearwheel, use drifts 99 190 and 99 191.

5 Fit the spacing ring first and then the shims.

When measuring the clearance, you should

start with too much clearance. Therefore fit

one shim more than before.

6 Fit the splitter gearwheel. Fit it onto the

splines on the synchromesh cone.

05:01-04

Scania CV AB 2005, Sweden

19

Mainshaft

7 Press on the other bearing using drift 99 190

and 99 191. Rotate the gear while pressing.

Stop pressing if it is hard to rotate the wheel

and change to a thicker shim. See step 11.

8 Fit the round nut. Use counterhold 99 199,

pull rod 88 292 and socket 587 600.

Tightening torque 400 Nm.

9 Check the splitter gearwheel clearance.

Leave the shaft on counterhold 99 199, or

clamp the shaft in a press with 10 - 20 kN.

Fit dial gauge 98 075 and indicator stand

587 250.

10 Rotate the gear a few turns, always in the

same direction. Prise the gear upwards using

two screwdrivers. Rotate the gear and

perform at least three measurements, mark

the gear so that the measurements are

carried out at the same position. Take the

average. Correct clearance: 0.03 - 0.09 mm.

20

Scania CV AB 2005, Sweden

05:01-04

Mainshaft

11 Adjusting the clearance: Press up the shift

sleeve to gear position 3. Place the shaft in

hollow drift 99 136 with support rings

99 140 and press out the bearing using drift

98 575. Fit new shims and begin again from

step 6.

122 564

12 Lock the nut on the two recesses provided

for the purpose and remove counterhold

99 199.

13 Turn the mainshaft over. Use drift 98 568 as

a support under the shaft if the front bearing

is pressed on.

14 Lubricate and fit the needle bearing.

05:01-04

Scania CV AB 2005, Sweden

21

Mainshaft

15 Line up the synchromesh assembly and

place it in position on the first gear. Then fit

the gear with the synchromesh assembly on

the shaft.

16 Lubricate and press on the inner ring for the

crawl gear needle bearing. Use drifts 87 550

and 99 127. Fit the needle bearing.

17 Fit the crawl gear with the coupling teeth

upwards. Fit the driver, press if necessary.

Use drifts 87 550 and 99 127.

18 Fit the shift sleeve.

22

Scania CV AB 2005, Sweden

05:01-04

Mainshaft

19 Lubricate and press on the inner ring for the

reverse gear needle bearing. Use drifts

87 932 and 99 127.

20 Fit the reverse gear needle bearing and the

gear with the coupling teeth downwards.

21 Lubricate the rear bearing and press it on

using drift 87 932.

22 Turn the shaft and press on the front

bearing, use drift 87 089.

05:01-04

Scania CV AB 2005, Sweden

23

Layshaft

Layshaft

Exploded view drawing

All versions of GRS gearboxes have a layshaft

which is designed in the same way, what differs

is, for example, the number of teeth and the

strength of the gearwheels.

1

2

3

4

5

6

7

8

9

10

11

24

Scania CV AB 2005, Sweden

Shaft

Retaining ring

Bearing

Gear

Gear

Spacing sleeve

Gear

Bearing

O-ring

Shim

Retaining ring

05:01-04

Layshaft

Dismantling

Special tools

Description

98 575

Support drift

98 647

Support drift

99 136

Hollow drift

99 140

Support ring

99 142

Support ring

99 143

Split support ring

99 450

Split support ring

Illustration

Tool board

G2

98 575

00 1621

Number

G2

P1

00 1622

99 136

P1

111 007

99 140

P1

00 1624

99 142

P1

111 008

99 143

128 352

PT1

05:01-04

Scania CV AB 2005, Sweden

25

Layshaft

Other tools

Description

587 312

Snap ring pliers

587 318

Puller plate

587 319

Puller

Illustration

587 312

114 693

111 445

Number

1 Pull off the rear bearing using puller plate

587 318 and puller 587 319. Use support

drift 98 647. If the bearing breaks, split it.

WARNING!

Wear protective goggles.

2 Pull off the front bearing using puller plate

587 318 and puller 587 319. Use support

drift 98 647. Loosen the bearing slightly

first, then grasp it again. If the bearing

breaks, split it.

26

Scania CV AB 2005, Sweden

05:01-04

Layshaft

3 Remove the snap ring. Use snap ring pliers

587 312.

4 Place the layshaft in a press. Centre

carefully.

GRSO900: Press off the layshaft high split

gearwheel. Use hollow drift 99 136 with

split support ring 99 450 and support drift

98 575.

OTHERS: Press off the layshaft low split

gearwheel. Use hollow drift 99 136 with

split support ring 99 143 and support drift

98 575.

GRSO900

Place, for example, a rubber cloth in the

hollow drift to cushion the fall of the shaft

when it drops down.

Other gearboxes

5 Press off the next splitter gearwheel. Use

hollow drift 99 136 with support ring

99 140. Remove the spacing ring.

05:01-04

Scania CV AB 2005, Sweden

27

Layshaft

6 Press out the second gear. Use hollow drift

99 136, support ring 99 142 and support

drift 98 575.

28

Scania CV AB 2005, Sweden

05:01-04

Layshaft

Assembly

Special tools

Description

98 575

Support drift

98 638

Assembly drift

99 136

Hollow drift

99 142

Support ring

99 190

Drift

99 191

Drift

99 450

Split support ring

Illustration

Tool board

G2

98 575

00 1621

Number

G3

110 816

98 638

P1

00 1622

99 136

P1

00 1624

99 142

G4

00 1638

99 190

G4

109 785

99 191

128 352

PT1

Other tools

Description

587 312

Snap ring pliers

Illustration

587 312

111 445

Number

05:01-04

Scania CV AB 2005, Sweden

29

Layshaft

All gears are bonded onto the layshaft. Before

the gears are bonded onto the shaft, the surfaces

must be carefully cleaned with degreasing

solvent. Then use locking compound 584 075

(Loctite 16 705) which is spread evenly over

both surfaces for good adhesion.

IMPORTANT! To guarantee the strength of the

locked joint, the press force when fitting must

reach at least 300 kN (30 tonnes) just before the

gears reach the bottom. If the force is not

attained, the shaft and/or gear should be

scrapped. The reason for this is that if you do

not use the correct locking compound and attain

the correct press force, the gears will rotate on

the shaft.

1 Place the second gear on support ring

99 142 and press in the shaft.

Note: Protect the ends of the shaft using support

drift 98 575. The press force must reach at least

300 kN (30 tonnes) before the gear reaches the

bottom.

30

Scania CV AB 2005, Sweden

05:01-04

Layshaft

2 Place the high split gear (low split gear for

GRSO900) on support ring 99 142. Fit the

spacing ring on the shaft and press on the

gear.

Note: Protect the ends of the shaft using support

drift 98 575. The press force must reach at least

300 kN (30 tonnes) before the gear reaches the

bottom.

3 GRSO900: Place the high split gear on

support ring 99 450 and press in the shaft.

OTHERS: Place the low split gear on

support ring 99 142 and press in the shaft.

Note: Protect the ends of the shaft using support

drift 98 575. The press force must reach at least

300 kN (30 tonnes) before the gear reaches the

bottom.

99 450

GRSO900

Other gearboxes

4 Press on the rear bearing. Use drift 99 190

and drift 99 191.

05:01-04

Scania CV AB 2005, Sweden

31

Layshaft

5 Turn the shaft in the press. Fit the snap ring.

6 Place the shaft on drift 99 191. Press on the

front bearing. Use assembly drift 98 638.

32

Scania CV AB 2005, Sweden

05:01-04

Specifications

Specifications

Materials

Sealing agent part No.

584 010

Locking compound

561 200

Tightening torques

Round nut on mainshaft

400 Nm + locking

compound

Lock bolt for reverse gear shaft

50 Nm + locking

compound

Pressure relief valve

45 Nm

Oil pipe

26 Nm

Oil nozzle in shaft

80 Nm

Oil pump bolts

10 Nm

Clutch housing retaining bolts

210 Nm

Support sleeve retaining bolts

26 Nm

Round nut, end yoke

600 Nm

Drain and level plugs

100 Nm

05:01-04

Scania CV AB 2005, Sweden

33

34

Scania CV AB 2005, Sweden

05:01-04

05:01-04

Scania CV AB 2005, Sweden

35

36

Scania CV AB 2005, Sweden

05:01-04

Você também pode gostar

- We Move You. With Passion.: YachtDocumento27 páginasWe Move You. With Passion.: YachthatelAinda não há avaliações

- Diesel EngineDocumento42 páginasDiesel EngineMadhu KiranAinda não há avaliações

- Engine 4 StrokeDocumento16 páginasEngine 4 Strokeelsoukkary100% (2)

- Lecture 1Documento11 páginasLecture 1hatelAinda não há avaliações

- Lecture 2Documento26 páginasLecture 2hatelAinda não há avaliações

- 3 حقن الوقودDocumento138 páginas3 حقن الوقوداشرينكيل مسونكيلAinda não há avaliações

- الباب الأولDocumento39 páginasالباب الأولhatelAinda não há avaliações

- SAE J1939 TrainingDocumento80 páginasSAE J1939 TrainingDiego Vargas83% (6)

- Hello Youtybe HatelDocumento1 páginaHello Youtybe HatelhatelAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- AudiDocumento21 páginasAudiapi-281175594Ainda não há avaliações

- Courts Tribunals TrackerDocumento42 páginasCourts Tribunals TrackerLegal CheekAinda não há avaliações

- W20 - Character SheetDocumento4 páginasW20 - Character SheetWilliam PenroseAinda não há avaliações

- Common Patterns of Cortisol Imbalance: Patient HandoutDocumento2 páginasCommon Patterns of Cortisol Imbalance: Patient HandoutCorey EasleyAinda não há avaliações

- Unit 12 - BT MLH Lop 12 - KeyDocumento6 páginasUnit 12 - BT MLH Lop 12 - KeyThao NguyenAinda não há avaliações

- GX Annular Blowout PreventerDocumento2 páginasGX Annular Blowout PreventerCarlos Munizaga100% (1)

- Tennis and Archery Ahead: As Shown Island Resort Cagbalete Mr. Kevin K. WongDocumento1 páginaTennis and Archery Ahead: As Shown Island Resort Cagbalete Mr. Kevin K. WongMarkJosephRamosAinda não há avaliações

- Smit Estian 2012 Mark Singletons Yoga Body The Origins of Modern Posture Practice A Synopsis Review and Personal Perspective PDFDocumento57 páginasSmit Estian 2012 Mark Singletons Yoga Body The Origins of Modern Posture Practice A Synopsis Review and Personal Perspective PDFJosé Alberto FernándezAinda não há avaliações

- Gameweek 2 28 September 2021 PSG Manchester CityDocumento24 páginasGameweek 2 28 September 2021 PSG Manchester CityBen SaadAinda não há avaliações

- Physical Therapy Intervention For Individuals With Osteoporosis (W)Documento2 páginasPhysical Therapy Intervention For Individuals With Osteoporosis (W)Tahsinur RahmanAinda não há avaliações

- Intramurals 2023Documento5 páginasIntramurals 2023Evangeline BaisacAinda não há avaliações

- Ingles Febrero 6to PrimariaDocumento26 páginasIngles Febrero 6to PrimariaVitia Arely Zuñiga RivasAinda não há avaliações

- Lab Aula2 ParametrosDocumento1 páginaLab Aula2 ParametrosMarcoAinda não há avaliações

- Major Global Company LogosDocumento37 páginasMajor Global Company LogosVinod KumarAinda não há avaliações

- Result of Mcs Departmental Examination December 2023Documento2 páginasResult of Mcs Departmental Examination December 2023Destiny AroraAinda não há avaliações

- RMAX Instruction ManualDocumento40 páginasRMAX Instruction ManualGuille Gimeno100% (1)

- Five Nights at FreddyDocumento46 páginasFive Nights at Freddyapi-28960625675% (4)

- Horses in Europe: by Carolina LiljenstolpeDocumento32 páginasHorses in Europe: by Carolina LiljenstolpeMilos StojanovicAinda não há avaliações

- Despiece Ensobradora Pitney Bowes Di380 PDFDocumento132 páginasDespiece Ensobradora Pitney Bowes Di380 PDFLuis GuerreroAinda não há avaliações

- 5 ĐỀ THI HK 1 - Tiếng Anh 3 Global có đáp ánDocumento18 páginas5 ĐỀ THI HK 1 - Tiếng Anh 3 Global có đáp ánNhàn BeeAinda não há avaliações

- Shop Crue Product DataDocumento7.232 páginasShop Crue Product DataMehul DasAinda não há avaliações

- Biology IGCSE Human Circulatory SystemDocumento17 páginasBiology IGCSE Human Circulatory SystemNiharika100% (1)

- Assignment 2.2 ForcesDocumento4 páginasAssignment 2.2 Forcespanghua tanAinda não há avaliações

- Monster Hunter, DND 5.0. - Guild MonsterDocumento2 páginasMonster Hunter, DND 5.0. - Guild MonsterJuan Daniel EcheverriAinda não há avaliações

- Case StudyDocumento4 páginasCase StudyBabilash KBAinda não há avaliações

- NEBRASKA TRACTOR TEST 1956 JOHN DEERE 5065E DIESELDocumento2 páginasNEBRASKA TRACTOR TEST 1956 JOHN DEERE 5065E DIESELChoudhary Vikrant GurjarAinda não há avaliações

- Yamaha Wr125 Service Manual PDFDocumento372 páginasYamaha Wr125 Service Manual PDFTudor Miclăuș67% (6)

- Shekhar ResumeDocumento1 páginaShekhar Resumemurali2007krishnaAinda não há avaliações

- Gsxr-600 k6-k7 Full ListDocumento137 páginasGsxr-600 k6-k7 Full ListAttila SzemesAinda não há avaliações

- 04 The Big Book of Madness RulebookDocumento12 páginas04 The Big Book of Madness RulebookYordan GinovAinda não há avaliações