Escolar Documentos

Profissional Documentos

Cultura Documentos

MicroSlice Standard Laser Kit

Enviado por

Marius BuneaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

MicroSlice Standard Laser Kit

Enviado por

Marius BuneaDireitos autorais:

Formatos disponíveis

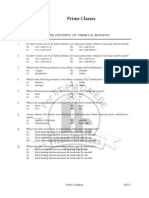

Standard

Laser Module Kit

Issue Date: 4-2014

The standard laser module kit uses a 3.8mm 200mW Mitsubishi laser diode in a

12mm module case that also houses the laser driver. The driver has adjustable

output current and can either be operated continuously or optionally TTL modulation

can be used to switch the output e.g. for PWM power control.

COMPONENT PHOTOGRAPHS

Fitting the Driver Board

Caution! The laser diode is sensitive to static until it is connected to the driver board.

The laser diode is supplied pre-inserted in the front part of the diode case:

Use the diagram above to identify the laser diode pins. Cut off the Not Used pin.

Bend the LD- pin slightly apart from the LD+ pin so the driver board can sit between them.

Place the driver board between the LD+ pin and LD- pins, bend and trim the pins as required to align with the

appropriate solder pads on the driver board. Make sure the driver board is centered so the edges do not

extend past the outside of the module case otherwise the rear cover will not screw on.

It is easiest to solder the diode to the board if the diode pins and driver board pads are coated with a little

solder (tinned) before the board is put in position for soldering.

Use some Blu-Tac or similar to hold the board in position while you solder the tinned diode leads to the driver

board pads.

Standard Laser Module Kit

Issue Date: 4-2014

Wire

Connections

The driver board has optional TTL control. For continuous use the TTL + (ENABLE) is connected to the Power + so

the laser is on all the time the board is powered up. The MicroSlice uses Pin 12 on the Arduino controller to switch the

TTL signal to the driver.

A black wire (power ve) should be soldered to the Power - pad on the driver board.

A red wire (power ve) should be soldered to the Power + pad on the driver board.

A white wire (TTL) should be soldered to the TTL + (Enable) pad on the driver board.

Setting The Laser Driver Current (Laser Power)

Laser diodes need to be driven at a constant current that is controlled by the driver board. The driver board is supplied

with the current adjuster potentiometer set to give an output of approximately 170-180mA giving a laser output of

around 120mW. The maximum driver output is approximately 350mA.

The driver output current is increased by turning the adjuster (with a fine screwdriver or trimmer tool) clockwise.

The laser diode current can be monitored using a multimeter to check the input current from the power supply to the

driver board. The driver uses ~30mA so the output to the laser diode is ~ 30 mA less than the measured input

current.

The 3.8mm Mitsubishi laser diode is rated at 200mW continuous output (expected lifetime > 2000hrs) which requires

~250mA driver output (280mA driver board input measured with a multimeter).

In our tests the laser diode will not burn out over short periods at the maximum driver output but its lifetime will be

considerably reduced. We have reproduced our test data for this diode below.

Laser Safety

All laser devices produce beams of intense

monochromatic light that can present potential

biological hazards. Laser safety eyewear is

required if there is a possibility of direct exposure

or specular reflectance from a Class 3B Laser.

Lens

Adjustment

The focusing lens is held in position by a tension spring. It is sometimes useful to wrap a couple of turns of plumbers

PTFE thread-seal tape around the lens before screwing it in. This ensures the lens is held tightly in position.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Logo Font & Lettering BibleDocumento244 páginasLogo Font & Lettering BibleAlexandre Macedo França100% (18)

- Hebi Teardown PresentationDocumento22 páginasHebi Teardown PresentationPrashant Kumar100% (1)

- Zilano Update May 11 UpdateDocumento124 páginasZilano Update May 11 UpdateFiditti100% (5)

- Logo and Brand Identity Guidelines Template PDFDocumento8 páginasLogo and Brand Identity Guidelines Template PDFÁngel HerdoraAinda não há avaliações

- Personal Branding V - 1Documento9 páginasPersonal Branding V - 1Marius Bunea100% (5)

- Eleven Lessons - Managing Design in Eleven Global BrandsDocumento144 páginasEleven Lessons - Managing Design in Eleven Global BrandsDesign Council100% (17)

- Tutorials On MachinesDocumento2 páginasTutorials On Machinesjenniferi_7Ainda não há avaliações

- TSP BCH 1 MethodDocumento10 páginasTSP BCH 1 MethodMarius BuneaAinda não há avaliações

- Material Guide Feb 17 USDocumento3 páginasMaterial Guide Feb 17 USMarius BuneaAinda não há avaliações

- Pulse - Sense - Evolve: Introductory HandbookDocumento18 páginasPulse - Sense - Evolve: Introductory HandbookMarius BuneaAinda não há avaliações

- Responsivetypography Jpamental KeyDocumento119 páginasResponsivetypography Jpamental KeyMarius BuneaAinda não há avaliações

- Grafik - Issue 187Documento100 páginasGrafik - Issue 187Marius Bunea100% (2)

- Grafik - Issue 181Documento110 páginasGrafik - Issue 181Marius Bunea100% (2)

- TSP BCH 10 AnnexDocumento6 páginasTSP BCH 10 AnnexMarius BuneaAinda não há avaliações

- Drawing Resource IndexDocumento1 páginaDrawing Resource IndexMarius BuneaAinda não há avaliações

- BAColorWheel PDFDocumento2 páginasBAColorWheel PDFMarius BuneaAinda não há avaliações

- Megatech BrandBookDocumento12 páginasMegatech BrandBookMarius BuneaAinda não há avaliações

- Day4 Surrealistic Drawing ReferenceDocumento1 páginaDay4 Surrealistic Drawing ReferenceMarius BuneaAinda não há avaliações

- EZCAD 2.7.6 Software Manual PDFDocumento154 páginasEZCAD 2.7.6 Software Manual PDFMarius Bunea100% (1)

- Day1 My SolutionDocumento1 páginaDay1 My SolutionMarius BuneaAinda não há avaliações

- Day3 My SolutionDocumento1 páginaDay3 My SolutionMarius BuneaAinda não há avaliações

- Placuta Plastic PT MihaiDocumento1 páginaPlacuta Plastic PT MihaiMarius BuneaAinda não há avaliações

- Construction-Manual Small Summary v4Documento8 páginasConstruction-Manual Small Summary v4Marius BuneaAinda não há avaliações

- 3V GeodesicDome ManualDocumento46 páginas3V GeodesicDome ManualMarius BuneaAinda não há avaliações

- Shape SmithDocumento1 páginaShape SmithMarius BuneaAinda não há avaliações

- Styleguide Coca Cola PDFDocumento146 páginasStyleguide Coca Cola PDFMarius BuneaAinda não há avaliações

- BagDocumento1 páginaBagMarius BuneaAinda não há avaliações

- X-Carve LicenseDocumento5 páginasX-Carve LicenseMarius BuneaAinda não há avaliações

- CNC - A Manufacturing ProcessDocumento43 páginasCNC - A Manufacturing Processnaveenkumar_madasett100% (2)

- Golden SectionDocumento4 páginasGolden SectionstemandersAinda não há avaliações

- RockNRoll - Sculptchair by Gregg FleishmanDocumento1 páginaRockNRoll - Sculptchair by Gregg FleishmanMarius BuneaAinda não há avaliações

- New Wave - SculptChair by Gregg FleishmannDocumento1 páginaNew Wave - SculptChair by Gregg FleishmannMarius BuneaAinda não há avaliações

- Sean Wolcott Graphic Design 2008 2014Documento87 páginasSean Wolcott Graphic Design 2008 2014Audrey WrightAinda não há avaliações

- Report On Power SupplyDocumento14 páginasReport On Power SupplyBhavesh MaheshwariAinda não há avaliações

- The Easter Solar EngineDocumento13 páginasThe Easter Solar EngineEduardo Milani MoraAinda não há avaliações

- Infineon An Ice3ar2280jg An v01 00 enDocumento29 páginasInfineon An Ice3ar2280jg An v01 00 enbambang sujanarkoAinda não há avaliações

- Introduction To Dilute Magnetic Semiconductors: PACS NumbersDocumento7 páginasIntroduction To Dilute Magnetic Semiconductors: PACS NumbersSubhash ChandraAinda não há avaliações

- Microcontroller Projects Digital Voting Using Pic MicrocontrollerDocumento3 páginasMicrocontroller Projects Digital Voting Using Pic MicrocontrollerAbdullah Omar NasifAinda não há avaliações

- Ccsmodel PPTDocumento25 páginasCcsmodel PPTRam Prasad100% (1)

- Bd9153muv T-Con Samsung Pl43d450a2Documento21 páginasBd9153muv T-Con Samsung Pl43d450a2WILLIAM MARINAinda não há avaliações

- Littelfuse Selecting An Appropriate Esd Device Application NoteDocumento4 páginasLittelfuse Selecting An Appropriate Esd Device Application NoteluroguitaAinda não há avaliações

- Ch10 BondDocumento10 páginasCh10 BondUday Prakash SahuAinda não há avaliações

- Power Electronics 2-MDocumento9 páginasPower Electronics 2-M20EUEE053- MADHUBALAN.SAinda não há avaliações

- Soft Robotics PDFDocumento11 páginasSoft Robotics PDFAbhishek UpadhyayAinda não há avaliações

- Paper 5 PDFDocumento6 páginasPaper 5 PDFrhusheinAinda não há avaliações

- A Wide-PCE-Dynamic-Range CMOS Cross-Coupled Differential-Drive Rectifier For Ambient RF Energy HarvestingDocumento5 páginasA Wide-PCE-Dynamic-Range CMOS Cross-Coupled Differential-Drive Rectifier For Ambient RF Energy Harvestinghusam hamidAinda não há avaliações

- Drying Ovens / Heating Ovens: Heating Oven With Mechanical ConvectionDocumento7 páginasDrying Ovens / Heating Ovens: Heating Oven With Mechanical Convectionmshabanero2359Ainda não há avaliações

- GKDocumento48 páginasGKOmkar SheteAinda não há avaliações

- UHF Digital/Analog Mobile Transceiver Service Manual: Vertex Standard LMR, IncDocumento31 páginasUHF Digital/Analog Mobile Transceiver Service Manual: Vertex Standard LMR, IncIng Marco Antonio Hernandez LimaAinda não há avaliações

- AU7843 DatasheetDocumento15 páginasAU7843 DatasheetDavid AlfaAinda não há avaliações

- Whiston BridgeDocumento4 páginasWhiston BridgeAbhijit RoyAinda não há avaliações

- Sylvania Fluorescent Starters COP 40-400 Bulletin 1964Documento2 páginasSylvania Fluorescent Starters COP 40-400 Bulletin 1964Alan MastersAinda não há avaliações

- DEP StructureDocumento23 páginasDEP StructureishaharomAinda não há avaliações

- All About EPOXYDocumento13 páginasAll About EPOXYEllen Kay CacatianAinda não há avaliações

- A12x Bionic ChipDocumento4 páginasA12x Bionic ChipAbhishek AggarwalAinda não há avaliações

- General Purpose Input/Output: All Rights ReservedDocumento20 páginasGeneral Purpose Input/Output: All Rights ReservedAlexgriAinda não há avaliações

- Hardware Design Guidelines: Espressif SystemsDocumento34 páginasHardware Design Guidelines: Espressif SystemsJose Angel Duarte MartinezAinda não há avaliações

- A21f075517071304Documento126 páginasA21f075517071304josue jetavionicsAinda não há avaliações

- CV of NABILA NAWAZDocumento2 páginasCV of NABILA NAWAZbilalhanifAinda não há avaliações