Escolar Documentos

Profissional Documentos

Cultura Documentos

Gearless Power Transmission For Skew Shafts (A SRRS Mechanism)

Enviado por

चन्दनप्रसादTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Gearless Power Transmission For Skew Shafts (A SRRS Mechanism)

Enviado por

चन्दनप्रसादDireitos autorais:

Formatos disponíveis

International Journal of Advanced Science and Technology

Vol.79 (2015), pp.61-72

http://dx.doi.org/10.14257/ijast.2015.79.06

Gearless Power Transmission for Skew Shafts (A SRRS

Mechanism)

Amit Kumar1 and Mukesh Kumar2

1

Department of Mechanical Engineering,Baba Saheb Dr. Bheem Rao Ambedkar

College of Ag. Engineering & Technology,etawah U.P. Pin-206001. India ,E2

Assistant professor, Department of Mechanical Engineering. G. L. Bajaj Institute

of Technology and Management, Greater Noida. (U.P.) Pin-201306 India E-mail

1

Amit.jnv188@gmail.com, 2mukesh.1185@gmail.com

Abstract

Introduced gearless power transmission arrangement used for skew shafts. In this

transmission system no. of pins or links used must be odd..3,5,7,9..& centers of any two

pins or links hole must not be on that line which represent the diameter of the shaft. If

more pins or links used motion will be smoother, but increase in no. of pins or links not at

the cost of strength of the shaft. Pins or links are fixed (may be permanent of temporary)

in the drilled holes at the both shaft ends due to which motion is transferred. The

dimensions of the pins or links and angle for the pins are all given very precisely, holes

drilled very accurately.

Proposed arrangement used for skew shafts at any angle & if there is a need we can

change the angle between shafts during motion or during intermittent motion with any

profile of shafts having rotational motion along its own axis. The Working of this

arrangement is very smooth & use very effectively with a very minimum amount of power

losses.

Keywords: skew shaft, revolute pair, sliding pair, hyperboloids, front/side/top view,

intermittent motion

1. Introduction

Power transmission for skew shafts is with the help of either crossed helical gear or

worm gear or hypoid gears in a machine, but the manufacturing of these gear is very

complex, power loss in gears due to sliding motion and the shaft orientations is very

limited means not for every shaft orientation because of standardization of gears, so need

arises for a better system.

So here I introduced a gearless power transmission system for skew shafts which

reduce the losses, cost & save the time and space. This system allows the changing in the

orientation of shafts during motion which is very interesting and fascinating about this

mechanism.

Also during analysis of mechanism and working it is seen that this gearless

transmission can be used for both intersecting shafts and skew shafts but here we

introduced a solution for skew shafts so main attention is towards the skew shafts.

ISSN: 2005-4238 IJAST

Copyright 2015 SERSC

International Journal of Advanced Science and Technology

Vol.79 (2015)

Figure 1.1. SRRS Link in Space

As the name is introduced is SRRS mechanism that is

S -sliding pair made between link 1 and shaft 1.

R -revolute pair made between link 1 and link 3.

R -revolute pair made between link 3 and link 2.

S -sliding pair made between link 2 and shaft 2.

This link further classified as two types [ Type 1 and type 2 ] with different constrained

for each.

2. Literature Review

1- Skew Shaft :- The term shaft , used in this standards has a wide meaning and

serves for specifications of all outer elements of the part , including those

elements , which do not have cylindrical shapes And skew means non-parallel

and non-intersecting so the shafts which are non-parallel and non-intersecting are

known as skew shafts.

2- Crossed helical gears - Helical or "dry fixed" gears offer a refinement over spur

gears. The leading edges of the teeth are not parallel to the axis of rotation, but are

set at an angle. Since the gear is curved, this angling causes the tooth shape to be

a segment of a helix. Helical gears can be meshed in parallel or crossed

orientations. The former refers to when the shafts are parallel to each other; this is

the most common orientation. In the latter, the shafts are non-parallel, and in this

configuration the gears are sometimes known as "skew gears". For a 'crossed' or

'skew' configuration, the gears must have the same pressure angle and normal

pitch; however, the helix angle and handedness can be different. The relationship

between the two shafts is actually defined by the helix angle(s) of the two shafts

and the handedness, as defined:

for gears of the same handedness.

for gears of opposite handedness.

Where is the helix angle for the gear & E is the angle between two shaft. The

crossed configuration is less mechanically sound because there is only a point

contact between the gears, whereas in the parallel configuration there is a line

contact.

3- Worm Gears - A worm drive is a gear arrangement in which a worm (which is a

gear in the form of a screw) meshes with a worm gear (which is similar in

appearance to a spur gear, and is also called a worm wheel). The terminology is

often confused by imprecise use of the term worm gear to refer to the worm, the

worm gear, or the worm drive as a unit. [Fig 2.2]

62

Copyright 2015 SERSC

International Journal of Advanced Science and Technology

Vol.79 (2015)

Like other gear arrangements, a worm drive can reduce rotational speed or allow

higher torque to be transmitted.

Worm gears having three types, the first are non-throated worm gears. These

don't have a throat, or groove, machined around the circumference of either the

worm or worm wheel. The second are single-throated worm gears, in which the

worm wheel is throated. The final type are double-throated worm gears, which

have both gears throated. This type of gearing can support the highest loading. An

enveloping (hourglass) worm has one or more teeth and increases in diameter

from its middle portion toward both ends [Figure 2.3].

Double-enveloping worm gearing comprises enveloping worms mated with fully

enveloping worm gears. It is also known as globoid worm gearing.

4- Hypoid gears - Hypoid gears resemble spiral bevel gears except the shaft axes do not

intersect. The pitch surfaces appear conical but, to compensate for the offset shaft, are

in fact hyperboloids of revolution. Hypoid gears are almost always designed to

operate with shafts at 90 degrees. [Figure 2.4 ] Depending on which side the shaft is

offset to, relative to the angling of the teeth, contact between hypoid gear teeth may

be even smoother and more gradual than with spiral bevel gear teeth, but also have a

sliding action along the meshing teeth as it rotates and therefore usually require some

of the most viscous types of gear oil to avoid it being extruded from the mating tooth

faces, the oil is normally designated HP (for hypoid) followed by a number denoting

the viscosity. Also, the pinion can be designed with fewer teeth than a spiral bevel

pinion, with the result that gear ratios of 60:1 and higher are feasible using a single set

of hypoid gears. This style of gear is most common in driving mechanical

differentials, which are normally straight cut bevel gears, in motor vehicle axles.

Figure 2.1. Crossed Helical Gears

Figure 2.2. Worm Gears

Copyright 2015 SERSC

63

International Journal of Advanced Science and Technology

Vol.79 (2015)

Figure 2.3. Forms of Worm Gears

Figure 2.4. Hypoid Gears

3. Components of the Model and Operation

In this section different views of the arrangement and the components used for

arrangement are shown, which is necessary for understanding the proper working and

setup of the arrangement.

A. View of the Planes

Here in the below diagram, planes are shown in the 3D, which helps us in the

understanding of the mechanism and movement of shafts and link used.

Figure 3.1. View of the Planes

64

Copyright 2015 SERSC

International Journal of Advanced Science and Technology

Vol.79 (2015)

B. View of the Shafts

Below diagram shows a different view of the shaft arrangement which are skew and

angle between them is 90 degrees, which helps us in the understanding of the arrangement

of shafts. In below figure (a) front view (b) side view (c) top view.

(a)

(b)

(c)

Figure 3.2. View of the Shafts Arrangement

C. Views of Setup

Different views of the setups are shown in Figure (a) Front view. (b) Side view (c) Top

view. These views show the arrangement of links and shafts.

Copyright 2015 SERSC

65

International Journal of Advanced Science and Technology

Vol.79 (2015)

(a)

(b)

(c)

Figure 3.3. Views of the Setup

D. Views of the Pins

Here different views of the pins according to the setup are shown (a) Front view (b)

Side view (c) Top view. These pins are used for transmitting the power when there is no

change in orientation of shafts during motion.

66

Copyright 2015 SERSC

International Journal of Advanced Science and Technology

Vol.79 (2015)

(a)

(b)

(c)

Figure 3.4. View of the Pin

E. Type of SRRS Links Used

The Links type used for providing the flexibility in motion of skew shafts is shown in

Figure 3.5. (a ) SRRS link type 1. (b) SRRS link type 2. Here we introduced the two

types of the link, for the ease of understanding of working with different type links. In

further discussions we use these types as by the substitution of SRRS from the name of

links , so keep in mind link type 1 at the place of SRRS link type 1 & link type 2 at the

place of SRRS link type 2.

Link type 1- In this link having two revolute pairs present and this link permit the

constrained movement of both linked shafts in same plane during the motion as need.

Link constrained as Let if the link 1 is in XZ plane along X axis link 3 in YZ plane

along Y axis then link 2 in XZ plane along Z axis and permit the rotation of link 2 in XZ

plane About Y axis in clockwise direction about 180 degree rotation if viewed from top,

such that the initial position of link 2 in XZ plane along ve axis and after full rotation

(180 degree in clockwise direction) final position of link is also in XZ plane along +ve Z

axis.

Copyright 2015 SERSC

67

International Journal of Advanced Science and Technology

Vol.79 (2015)

Link type 2- In this link also two revolute pairs present only the difference is that this

link permit the constrained movement of shafts in the planes perpendicular to each other.

Link constrained as Let if the link 1 is in XZ plane along X axis link 3 in YZ plane along

Y axis then link 2 in XZ plane along Z axis and permit the rotation of link 2 in YZ plane

in clockwise direction about X axis with 270 degree rotation if viewed from second

quadrant in YZ plane , such that the initial position of link 2 is between ve Z axis and

ve Y axis (45 degree from both axis) in YZ plane and after full rotation (270 degree in

clockwise direction) final position of link is between +ve Z axis and ve Y axis in same

plane (45 degree from both axis) .{ this link permit the more angular movement of link but

for efficient power we use upper criteria}

(a)

Link type 1

(b)

Link type 2

Figure 3.5. Links

F. Arrangement of Pins in Shaft

In the below diagram for basic arrangement of pins in the shaft holes are shown. The

diagram clearly shows that pins used are in odd no.3,5,7,9 and centers of any two pin

holes must not be on that line which represent the diameter of the shaft and angle between

all consecutive holes should be equal for smoother power transmission. Value of angle

such that the its multiple with any integral not equal to 180 degrees.

Let the Value of angle = x degree

Then n*x 180 degree. Where n is an integral value.

As mentioned, Angle between the centers of any two pin holes must not be on that

line which represent the diameter of the shaft because if this happen angle between

them is 180 degrees and during motion pins or links use are trying to overlap each

other because of this motion interrupted.

Also, as we mentioned that pins no. should be odd and angle between consecutive

holes are equal so it can be easily understood by below table that why it is necessary.

68

Copyright 2015 SERSC

International Journal of Advanced Science and Technology

Vol.79 (2015)

No. of

pins

2(even)

3(odd)

4(even)

5(odd)

6(even)

7(odd)

8(even)

9(odd)

Angle between

consecutive

hole(degree)

180

120

90

72

60

51.43

45

40

Is value of angle

with any integral

equal to 180 degree

Yes

No

Yes

No

Yes

No

Yes

No

Value

integral

of

1

No integral

2

No integral

3

No integral

4

No integral

In upper table it is seen that with any no. of pins other than odd there must be an

integral whose multiplication with angle gives the value 180 degrees so only odd no. of

pins used.

Figure 3.6. View of Shaft with Holes

G. Analysis of Mechanism

From the above diagrams and views the setup is clearly established in the mind, but as

for convenience here we use the front view of the setup for analysing the mechanism of

setup.

Figure 3.7. Setup

Let at the starting instant shaft 1 starts rotation with 3 pins in anticlockwise direction

and a reaction force developed at the pin surface which in contact with the shaft and this

force transferred to the other end of the pin which is in the shaft and applying on the shaft

2 due to which shaft 2 starts rotating in the same direction as shaft 1, after 120 degree

rotation pin 1 comes at the place of pin 2 & pin 2 comes at the place of pin 3 & pin 3

comes at the place of pin 1 by sliding in shaft and self adjusting. This motion repeated for

next 120 degrees and further for next 120 degrees and pins are exchanging the position in

successive order as discussed before.

Copyright 2015 SERSC

69

International Journal of Advanced Science and Technology

Vol.79 (2015)

Figure 3.8. Movement of Link 2 of Link Type 1 in XZ Plane

Working with pins pins are used with the arrangement when there is no need of change

in positions of pins during motion and very high speed required.

Working with links- links are used in the arrangement at the place of pins if we required

flexible motion or orientation on pins are changes during motion or during intermittent

motion.

I.

Working with link type 1 permits that during motion shaft 2 can move in the plane

XZ from initial position to final position (initial and final position is indicated in

section E and also in upper Figure 3.8 )

II. Working with link type 2 permits that during motion shaft 2 can move in the plane

YZ from the initial position to final position as indicated in section E and also in

below Figure 3.9.

Figure 3.9. Movement of Link 2 of Link Type 2 in YZ Plane

More arrangement can be possible for the shafts with such type of links which can be

easily understandable during working.

Some intermittent positions during working which are well known and shows that

70

Copyright 2015 SERSC

International Journal of Advanced Science and Technology

Vol.79 (2015)

introduced setup is working well Working with link type 1 During motion initial position is skew shafts at 90 degrees and this

arrangement is similar to working with pins as discussed previous so first

position is working.

After 90 degrees rotation of link 2 of link type 1 system is transformed as

gearless transmission for offset shaft and it is well established arrangement

for pins , which can be seen with the help of reference [2], so this position is

also working.

After 180 degrees rotation shafts again in position as first so this position is

also working.

From above intermittent positions it is easy to understand that system with link 1 is

working well.

Working with link type 2 First position is easy to understand with setup and also by imagination as

similar to working with pins.

Second position, After 45 degrees rotation of link 2 position is similar to the

initial position of for working with link type 1, so this position is working

well.

After 135 degrees rotation setup is changed as gearless power transmission

for intersecting shafts at 90 degree which is used in elbow engine with pins

and can be easily understand with the help of reference [3] , so this position is

also working well.

After 225 degrees and 270 degrees rotation positions of setup is similar to

first and second position so these positions also working well.

Hence working with both type of link is well and correct.

4. Comparision with Existing Solutions

1- This arrangement gives the coverage of a wide range of shaft diameter, which

may be standard or non standard which is not possible in the existing gear

arrangement because the manufacturing of gears for skew shafts very complex

and because of standardization its only use of shafts of standard diameter.

2- Proposed gear less transmission with pins can be used for very high speeds and

for high loads which is comparable to the worm gear and not possible for crossed

helical gears.

3- This system not having any possibility of like sliding and point contact as in

crossed helical gears so power loss is very low in introduced arrangement and

used for high loads with proper rigidity of shafts and pins.

4- The main and very interesting advantage of this proposed system is that we can

changes the position of shafts during motion or during intermittent position

according to need by using given type of links at the place of pins which is not

possible in any existing system till now.

5- Since any dimension of any component used is not out the shafts dimensions

limit, a large reduction in the size of the machines is possible .in short a large

space saving should be done.

6- Repairing cost on failure of any component is very low.

7- Very low setup cost.

8- Easy and time saving installation of setup.

9- Easy manufacturing of links and pins in comparison of crossed helical and worm

gear.

10- Very less skill is required for setup.

Copyright 2015 SERSC

71

International Journal of Advanced Science and Technology

Vol.79 (2015)

11- Proposed arrangement can be used for shaft of any profile but shafts must be

having rotational motion about its axis.

5. Applications

Applications areas of skew shafts is very less because of the complexities entailed in

their manufacture and in installation of setup so the propose gearless transmission is very

efficient and good for the use of skew shafts. As in the introduced arrangement we can

change the orientations of shafts during motion or by intermittent motion, new

possibilities in transmission design opened up. Also where the space availability is less

and crossed helical gears or any other appliance cannot be used, this arrangement can

employed very easily and effectively with very less amount of power loss.

6. Conclusions

During working on experimental setup and after a long discussion it is observed that

proposed arrangement used for any set of diameters with any profile of shafts for skew

shafts of any angle but the shafts must be having the rotational motion about his own

axis, transmission of motion is very smooth and desirable and used only for the equal

R.P.M. of driving shaft and driven shaft by employing pins or given type of links for

appropriate joints for revolute pair.

References

[1]

[2]

[3]

[4]

Book s. s. rattan Mc Graw Hill Education ( India ) private limited, new delhi.

A. Kumar and S. Das, An arrangement for power transmission between co-axial shafts of different

diameter, International journal of engineering research and technology , ISSN:2278-0181, vol. 4, (2015)

January.

,Mahantesh Tanodi1, S. B. Yapalaparvi2, Anand. C. Mattikalli3, D. N. Inamdar2, G. V. Chiniwalar2,1,

PG Scholar, Department of Mechanical Engineering, Maratha Mandal Engineering College Belgaum,

Karnataka, India, 2Asst.Professor, Department of Mechanical Engineering, Hirasugar Institute of

Technology Nidasoshi, Karnataka, India, 3Asst.Professor, PG Coordinator, Department of Mechanical

Engineering, Maratha Mandal Engineering College Belgaum, Karnataka, India, Gear less power

transmission: parallel offset shaft coupling, Journal:- IJERT

https://www.youtube.com/watch?v=Que1Uhsk4wE or Navneet Bardiya1, karthik.T2, L Bhaskara Rao3

School of Mechanical and Building Sciences VIT University Chennai campus, Chennai, India Email:

navneet.bardiya2013@vit.ac.in1,karthik.t2013@vit.ac.in2,bhaskararao@vit.ac.in3 journal :- IJCEM.

Authors

Amit Kumar, 12 th pass out from jawahar navodaya vidyalaya

bareilly (u.p.) and now Pursuing bachelor of technology in

dicipline of mechanical engineering from Baba Saheb Dr. bheem

rao ambedkar College of Ag. Engineering & Technology,

etawah U.P. Affilation:- C.S.A. univ. of Ag. And tech. kanpur,

Pin-206001. India, E-mail- Amit.jnv188@gmail.com.

Mukesh Kumar, B.tech in mechanical engineering from

V.I.E.T. GZB and M.tech from I.I.T BHU currently working as a

assistant professor in G. L. Bajaj Institute of Technology and

Management, Greater Noida. (U.P.) Pin-201306, India.

72

Copyright 2015 SERSC

Você também pode gostar

- The ABCs of Gears - BDocumento49 páginasThe ABCs of Gears - BDavid Mejido0% (1)

- SRP SeriesDocumento19 páginasSRP SeriesPlingu RazvanAinda não há avaliações

- Jigs - and Fixtures PDFDocumento29 páginasJigs - and Fixtures PDFNiel Cool100% (1)

- Chapter 5 - SteeringDocumento15 páginasChapter 5 - SteeringLalith Koushik Ganganapalli100% (1)

- Catia v5 - Biw Welding Fixture DesignDocumento5 páginasCatia v5 - Biw Welding Fixture Designचन्दनप्रसादAinda não há avaliações

- Chapter 2-Gear SystemDocumento26 páginasChapter 2-Gear SystemNui Yuhu KuwAinda não há avaliações

- Rotary TableDocumento12 páginasRotary TableNakul Devaiah50% (2)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsNo EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsNota: 4 de 5 estrelas4/5 (1)

- GearsDocumento14 páginasGearsZulhilmi Chik TakAinda não há avaliações

- Mechanisms Notes 2012Documento12 páginasMechanisms Notes 2012kookwfAinda não há avaliações

- Power Transmission: Rotational PulleyDocumento19 páginasPower Transmission: Rotational PulleyQim SvAinda não há avaliações

- Bda20303 Chapter 1-Gear SystemDocumento27 páginasBda20303 Chapter 1-Gear SystemWan SamiraAinda não há avaliações

- Types of GearsDocumento6 páginasTypes of GearsSantosh GoudarAinda não há avaliações

- Noncircular GearsDocumento6 páginasNoncircular GearsRăzvan NicolaeAinda não há avaliações

- Design of Transmission System Local AuthorDocumento533 páginasDesign of Transmission System Local AuthorSuryaPrasanth100% (1)

- Gearless Power Transmission For Skew Shafts (A SRRS Mechanism)Documento12 páginasGearless Power Transmission For Skew Shafts (A SRRS Mechanism)Prasanna PurohitAinda não há avaliações

- Gearless Power Transmission For Skew Shafts (A SRRS Mechanism)Documento7 páginasGearless Power Transmission For Skew Shafts (A SRRS Mechanism)Aung Khin ZawAinda não há avaliações

- Gears HandoutDocumento28 páginasGears Handoutapi-3827852100% (3)

- Navigation Search Sprocket Gear (Disambiguation)Documento38 páginasNavigation Search Sprocket Gear (Disambiguation)M HarmanAinda não há avaliações

- Mass College ProjectDocumento68 páginasMass College ProjectGLOBAL INFO-TECH KUMBAKONAMAinda não há avaliações

- Type of Gears Trains and The Methods To Find Train ValueDocumento14 páginasType of Gears Trains and The Methods To Find Train Valueabbas bilalAinda não há avaliações

- CHP 3 Power Transmission GEARSDocumento18 páginasCHP 3 Power Transmission GEARSabinmwangiAinda não há avaliações

- GEARDocumento24 páginasGEARbabublsAinda não há avaliações

- For The Gear-Like Device Used To Drive A Roller Chain, See - This Article Is About Mechanical Gears. For Other Uses, SeeDocumento25 páginasFor The Gear-Like Device Used To Drive A Roller Chain, See - This Article Is About Mechanical Gears. For Other Uses, SeeNasir HadranAinda não há avaliações

- TransmissionDocumento13 páginasTransmissionvnpriyamsAinda não há avaliações

- GearsDocumento110 páginasGearsBujjibabu KattaAinda não há avaliações

- Gear T.worksyop 3Documento26 páginasGear T.worksyop 3Cakap AhAinda não há avaliações

- Term Paper As in 2 YearDocumento25 páginasTerm Paper As in 2 YearRoopak GoyalAinda não há avaliações

- Title: Design and Analysis of Gearless Transmission SystemDocumento6 páginasTitle: Design and Analysis of Gearless Transmission SystemLokeshAinda não há avaliações

- GearsDocumento22 páginasGearsAnurag MidhaAinda não há avaliações

- Design and Performance Analysis of Helical Gear For Al and Steel Material by Using AnsysDocumento10 páginasDesign and Performance Analysis of Helical Gear For Al and Steel Material by Using AnsysankAinda não há avaliações

- 3 TYPES OF GEARS & Gear TrainsDocumento17 páginas3 TYPES OF GEARS & Gear TrainsabinmwangiAinda não há avaliações

- 881 Final T2Documento22 páginas881 Final T2Ankit BurnwalAinda não há avaliações

- Bevel Gear PraveenDocumento23 páginasBevel Gear Praveen18WJ1A03F4 Shashank reddyAinda não há avaliações

- Comparison With Drive Mechanisms: Cogs, Which Mesh With Another Toothed Part in Order To Transmit TorqueDocumento23 páginasComparison With Drive Mechanisms: Cogs, Which Mesh With Another Toothed Part in Order To Transmit TorqueAshish DeotaleAinda não há avaliações

- Gear Chikuku 1Documento37 páginasGear Chikuku 1Kelvin Kindice MapurisaAinda não há avaliações

- Gear System: Shri Balwant Institute of TechnologyDocumento12 páginasGear System: Shri Balwant Institute of TechnologySreejith BabuAinda não há avaliações

- Reporte EngranesDocumento10 páginasReporte EngranesOscar SaldivarAinda não há avaliações

- Gearbox 210509074427Documento59 páginasGearbox 210509074427mussietilahungessesseAinda não há avaliações

- Design and Finite Element Analysis of HiDocumento6 páginasDesign and Finite Element Analysis of HiHenok GhidayAinda não há avaliações

- Mech - Ijmperd-Design and Finite Element-Nihad Hasan TalibDocumento12 páginasMech - Ijmperd-Design and Finite Element-Nihad Hasan TalibTJPRC PublicationsAinda não há avaliações

- Gear Backlash: 6.1 Types of BacklashesDocumento13 páginasGear Backlash: 6.1 Types of BacklashesRamazan MERALAinda não há avaliações

- Me III II DMM II LnotesDocumento33 páginasMe III II DMM II LnotesChandu MallamAinda não há avaliações

- Punjab Aircraft Maintenance Engineering College, Patiala Procedure Sheet: Module 6 (6.5 To 6.10)Documento4 páginasPunjab Aircraft Maintenance Engineering College, Patiala Procedure Sheet: Module 6 (6.5 To 6.10)Arjun SharmaAinda não há avaliações

- Types of GearDocumento6 páginasTypes of GearMira EvaAinda não há avaliações

- Sahani 2016-17Documento27 páginasSahani 2016-17upendraAinda não há avaliações

- Lab 1Documento8 páginasLab 1Mansoob BukhariAinda não há avaliações

- GearDocumento30 páginasGearsai babuAinda não há avaliações

- Parkinson Gear Tester ReportDocumento35 páginasParkinson Gear Tester Reportkirubason100% (3)

- Design of Transmission System Unit IIIDocumento57 páginasDesign of Transmission System Unit IIIRaj MohanAinda não há avaliações

- Project ReferDocumento5 páginasProject ReferTYMB 29 Prasad GirdhariAinda não há avaliações

- Maintain and Repair Mechanical Drives and Transmission AssembliesDocumento141 páginasMaintain and Repair Mechanical Drives and Transmission AssembliesMelku Abebe100% (1)

- Gear Mechanisms IntroductionDocumento9 páginasGear Mechanisms Introductionsteve ogagaAinda não há avaliações

- Continuous: External Vs Internal GearsDocumento22 páginasContinuous: External Vs Internal GearservaishaliAinda não há avaliações

- Thesis ReportDocumento72 páginasThesis ReportMayur ShetAinda não há avaliações

- Bme - Part 2Documento44 páginasBme - Part 2Sumanth ChallaAinda não há avaliações

- Experiment No: 06 Name of The Experiment: Study of Gear ChangingDocumento5 páginasExperiment No: 06 Name of The Experiment: Study of Gear ChangingTalat FarhanAinda não há avaliações

- Gear TrainsDocumento16 páginasGear Trainsraju100% (1)

- ME 7 - Activity 6Documento9 páginasME 7 - Activity 6Rygen Faye Del RosarioAinda não há avaliações

- Gear Wikipedia The Free EncyclopediaDocumento27 páginasGear Wikipedia The Free EncyclopediaVikas SinghAinda não há avaliações

- Power Transmitting ElementsDocumento20 páginasPower Transmitting ElementsAsma Khan100% (1)

- Chain Drives and V BeltsDocumento6 páginasChain Drives and V BeltsNiño PerezAinda não há avaliações

- 04 Power TransmissionDocumento16 páginas04 Power TransmissionVasudev Gupta100% (1)

- OBJECT: To Study of A Lathe Gear Box. TheoryDocumento5 páginasOBJECT: To Study of A Lathe Gear Box. TheoryThe AIRS CreationsAinda não há avaliações

- Mod-3. Spur GearDocumento18 páginasMod-3. Spur GearSharthak GhoshAinda não há avaliações

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNo EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisAinda não há avaliações

- Planar Linkage Synthesis: A modern CAD based approachNo EverandPlanar Linkage Synthesis: A modern CAD based approachAinda não há avaliações

- Manohar Kumar Yadav: Career ObjectiveDocumento1 páginaManohar Kumar Yadav: Career Objectiveचन्दनप्रसादAinda não há avaliações

- Automotive Company (Mechanical) 5000+ Location-AllDocumento57 páginasAutomotive Company (Mechanical) 5000+ Location-Allचन्दनप्रसादAinda não há avaliações

- Subodh B.Tech ECE 2015 73.70Documento2 páginasSubodh B.Tech ECE 2015 73.70चन्दनप्रसादAinda não há avaliações

- All Fields Are Mandatory, Without These Details Registration Is Not AcceptedDocumento1 páginaAll Fields Are Mandatory, Without These Details Registration Is Not Acceptedचन्दनप्रसादAinda não há avaliações

- MJR CollegeDocumento77 páginasMJR Collegeचन्दनप्रसादAinda não há avaliações

- Uniphar Biotech Price List (Oct.,2016)Documento6 páginasUniphar Biotech Price List (Oct.,2016)चन्दनप्रसादAinda não há avaliações

- Biw TrGTYDocumento7 páginasBiw TrGTYankurAinda não há avaliações

- Raju New Resume 2016Documento3 páginasRaju New Resume 2016चन्दनप्रसादAinda não há avaliações

- GATE Test ExaminationDocumento1 páginaGATE Test Examinationचन्दनप्रसादAinda não há avaliações

- Invoice TemplateDocumento2 páginasInvoice Templateचन्दनप्रसादAinda não há avaliações

- Project and Requirnment - ZinavoDocumento1 páginaProject and Requirnment - Zinavoचन्दनप्रसादAinda não há avaliações

- Autodesk - Authorised Training Centres - India - KarnatakaDocumento3 páginasAutodesk - Authorised Training Centres - India - Karnatakaचन्दनप्रसादAinda não há avaliações

- Mechanical Design Engineer Resume Sample - LiveCareerDocumento4 páginasMechanical Design Engineer Resume Sample - LiveCareerचन्दनप्रसादAinda não há avaliações

- Faq GDTDocumento3 páginasFaq GDTचन्दनप्रसादAinda não há avaliações

- CGSCE - Regular - Brochure SansodhitDocumento25 páginasCGSCE - Regular - Brochure Sansodhitचन्दनप्रसादAinda não há avaliações

- Tolerance Chart Is 919-1963Documento11 páginasTolerance Chart Is 919-1963Kausik Ray0% (1)

- Company Info 20001 22000 SarkarDocumento235 páginasCompany Info 20001 22000 Sarkarचन्दनप्रसादAinda não há avaliações

- AshishDocumento2 páginasAshishचन्दनप्रसादAinda não há avaliações

- Company Presentataion 1Documento11 páginasCompany Presentataion 1चन्दनप्रसादAinda não há avaliações

- AutoCAD ExerciseDocumento22 páginasAutoCAD Exerciseचन्दनप्रसादAinda não há avaliações

- Foundation CAD 2 Hours - Day (AutoCAD)Documento2 páginasFoundation CAD 2 Hours - Day (AutoCAD)चन्दनप्रसादAinda não há avaliações

- Analog Oem Camera: S.No Model NO Camera Type Chip TVLDocumento2 páginasAnalog Oem Camera: S.No Model NO Camera Type Chip TVLचन्दनप्रसादAinda não há avaliações

- Curriculum Vitae: Sunil Kumar SinghDocumento2 páginasCurriculum Vitae: Sunil Kumar Singhचन्दनप्रसादAinda não há avaliações

- Fixture (Tool) - Wikipedia, The Free EncyclopediaDocumento4 páginasFixture (Tool) - Wikipedia, The Free Encyclopediaचन्दनप्रसादAinda não há avaliações

- Jig (Tool) - Wikipedia, The Free EncyclopediaDocumento2 páginasJig (Tool) - Wikipedia, The Free Encyclopediaचन्दनप्रसादAinda não há avaliações

- Kim IsaacsDocumento5 páginasKim Isaacsचन्दनप्रसादAinda não há avaliações

- Solidworks ProblumDocumento1 páginaSolidworks Problumचन्दनप्रसादAinda não há avaliações

- CH 13-GearsDocumento97 páginasCH 13-GearsGrezy MagnoAinda não há avaliações

- Modelingof Worm GearDocumento12 páginasModelingof Worm Gearkarthik venkatachalamAinda não há avaliações

- Design and Analysis of A Spur Gear With Composite Material IJERTV10IS040129Documento13 páginasDesign and Analysis of A Spur Gear With Composite Material IJERTV10IS040129ahmadAinda não há avaliações

- Model Questiones For Engineering Mechanics 1 Year All BranchesDocumento10 páginasModel Questiones For Engineering Mechanics 1 Year All BranchesFeolo Riel TarayAinda não há avaliações

- Circle BarrelDocumento9 páginasCircle BarrelDarmawan PutrantoAinda não há avaliações

- Bb5000 Rdu Assembly ReductorDocumento3 páginasBb5000 Rdu Assembly Reductormarlon diazAinda não há avaliações

- Turning Rolls AlignmentDocumento10 páginasTurning Rolls AlignmentsauravAinda não há avaliações

- Worm Gear Design ProcedureDocumento7 páginasWorm Gear Design ProcedureSzymon RosikAinda não há avaliações

- ElectricActuatorBasics CEPMagazine JustinLedger PDFDocumento6 páginasElectricActuatorBasics CEPMagazine JustinLedger PDFElvis Alberto Rodriguez BravoAinda não há avaliações

- LUBCON High Performance Gear Lubricants enDocumento4 páginasLUBCON High Performance Gear Lubricants enTiến Dũng TrầnAinda não há avaliações

- Intall Maint Worm GBDocumento40 páginasIntall Maint Worm GBraobabar21100% (1)

- Part Ii: Electrical Drives Chapter TenDocumento37 páginasPart Ii: Electrical Drives Chapter TenDawit Shimeles TesfayeAinda não há avaliações

- Worm Gear Sets enDocumento30 páginasWorm Gear Sets enKarim FawziAinda não há avaliações

- Chap-7Gear 2Documento20 páginasChap-7Gear 2AlysAinda não há avaliações

- Screw JackDocumento29 páginasScrew JackShivam KumarAinda não há avaliações

- Machine Design - U. C. JindalDocumento224 páginasMachine Design - U. C. Jindalsagar15030% (5)

- Cylindrical Cam Design PDFDocumento81 páginasCylindrical Cam Design PDFMustafa ŞENAinda não há avaliações

- Differential IndexingDocumento2 páginasDifferential IndexingTejal Kamble100% (5)

- Nord Clincher CatalogDocumento356 páginasNord Clincher CatalogPaulo HenriqueAinda não há avaliações

- Terms of UseDocumento56 páginasTerms of UsekicsispermaAinda não há avaliações

- Valve Gear Operators and AccessoriesDocumento20 páginasValve Gear Operators and AccessoriesGourav SharmaAinda não há avaliações

- Project Report G4 (V3)Documento57 páginasProject Report G4 (V3)Irfan K MAinda não há avaliações

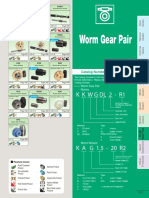

- Worm Gear Pair: K W G DL 2 - R1 KDocumento56 páginasWorm Gear Pair: K W G DL 2 - R1 KShuvam ShuvamAinda não há avaliações

- Gear Boxes and MotorsDocumento170 páginasGear Boxes and MotorsAshish MishraAinda não há avaliações