Escolar Documentos

Profissional Documentos

Cultura Documentos

Electrical - East Coast Knit Wear PVT Ltd. - QC - Yusuf - FQC - Rezaul

Enviado por

MohammedNewazTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Electrical - East Coast Knit Wear PVT Ltd. - QC - Yusuf - FQC - Rezaul

Enviado por

MohammedNewazDireitos autorais:

Formatos disponíveis

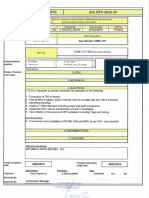

Preliminary Electrical Safety

Assessment Report (EAR)

Factory ID

: B. Code 1466

Factory Name

: East Coast Knit Wear Pvt Ltd.

Address

: Takkar Math, Sheharchor, Stadium Road, Fatullah,

Narayangonj-1420

GPS Coordinate

: 23.65442, 90.48193

Name of Auditor

: Md. Arfan Rahaman, Md. Salah Uddin

Name of Reviewer

: Md. Abu Yusuf

Date of Inspection

: 2015-07-11

Date of Report

: 2015-07-13

Report Status

: V1

VERITAS Engineering & Consultant

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Table of Content

Page No.

Introduction

02

Executive Summary

03

Chapter 1 Geographical Location of the Factory

04

Chapter 2 Factory General Information

05

Chapter 3 Criteria For Electrical Safety Assessment

06

Time Frame for Corrective Action

Chapter 4 Details Observations of non-compliance issues

06

07

4.1

General Documentation on Design and Maintenance

07

4.2

Generator Room

08

4.3

Distribution & Sub-distribution Boards

10

4.4

Wiring System

14

4.5

Continuation of Discrimination & Protection

15

4.6

Earthing System

15

4.7

Lightning Protection System

17

4.8

Thermography

18

4.9

Additional Area of Non-Compliance

19

Chapter 5 Recommendations Summary

21

Chapter 6 DIFE Summary

24

Chapter 7 Disclaimer

26

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 1

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Introduction

Over the past decades the RMG sector has experienced a number of industrial disasters like the fire

at TAZREEN FASHIONS and collapse of RANA PLAZA which claimed the lives of over 1,200 of

workers. In response, the Government of Bangladesh and its development partners have mobilized

unprecedented support and made commitments to improve working conditions and workers safety in

the RMG industry. The ILO (International Labour Organization) has taken a Program (RMGP) on

Improving Working Conditions for the workers in the Ready-Made Garments Sector which has been

developed to support the interventions identified in the National Tripartite Plan of Action (NTPA) on

Electrical Safety, Fire Safety & Building Integrity.

VERITAS Engineering & Consultant, one of the leading engineering firms in Bangladesh, is

carrying out Structural, Fire and Electrical safety inspections of factories as a part of the national

initiative under the National Tripartite Plan of Action (NTPA) for ensuring Fire, Electrical and

Structural Safety for the workers of the RMG sector in Bangladesh.

Executive Summary

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 2

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

East Coast Knit Wear Pvt. Ltd. is a six storied building, located at Stadium Road, Fatullah,

Narayangonj. The factory is powered by one pole mounted transformer (fed from Dhaka Electric

Supply Company Ltd.) and one diesel generator. During the inspection the electrical drawings were

available for review. All the noncompliance issues are described in chapter 4 in details based on

NTPA guidelines, visual inspection, thermographic scanning, engineering judgment and interview of

factory technical personnel. Factory needs to put more concentration on the following noncompliance

issues highlighted below considering fire and electrical hazard.

Panel boards (including panel door) are not properly earthed.

Dedicated earthing is not provided for each circuit.

Electrical cables are not sized according to capacity of circuit breaker.

Bunch of cables are found inside distribution boards.

Lightning protection system is not installed on the building.

Generator room is not fire rated.

Information Related to the Inspection

Client Name

International Labour Organization (ILO)

Factory ID

B. Code 1466

Factory Name

East Coast Knit Wear Pvt. Ltd.

Factory Address

Takkar Math, Sheharchor, Stadium Road, Fatullah,

Narayangonj-1420

Coordinate of the Factory

23.65442

90.48193

Lead Assessor

Md. Arfan Rahaman

Assessor

Md. Salah Uddin

Contact Person of The Factory

Md Mahfuzur Rahman

Phone No. of Contact Person

+88-01675-947547

Email Address of Contact Person

mahfuz.eastcoast@gmail.com

Date of Inspection

2015-07-11

Chapter 1

Geographical location of the Factory

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 3

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

GPS Coordinate of Factory: 23.65442, 90.48193

Inspected Building of East Coast Knitwear (Pvt) Ltd.

Chapter- 2

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 4

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Factory General Information

Number of stories

Buildings in Complex:

Is the building(s) owned or rented by

the Factory?

Number of Building Levels (stories):

Approximate Building Area :

Description of Existing Electrical

System:

One number of 06-storied reinforced concrete building

01 (One)

Owned

06 occupied floors out of 06 floors

Total occupied floor area is 1233 m2

[Main building 202.50x6 =1215 m2 (Ground floor to 5th

floor)]

An 11KV supply from DESCO (Dhaka Electric Supply

company Ltd.) feeds one pole mounted transformer

located outside the factory. 110KVA standby diesel

generator is installed on the ground floor of the production

building. The supply power is delivered to the main

distribution board (MDB/Ground floor) from transformer

through main MCCB and Generator via Changeover

switch (COS/Ground floor). Five nos. sub distribution

boards (i.e. SDB/1st floor, SDB/office, SDB/2nd floor,

SDB/3rd floor and SDB/4th floor) are fed from main

distribution board (MDB/Ground floor).

Chapter - 3

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 5

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Criteria for Electrical Safety Assessment

The following report contains a site profile and summary of non-conformities identified during an

onsite inspection conducted by Veritas Engineering & Consultant. The inspection was conducted

based on the following standard.

i)

ii)

iii)

National Tripartite Plan of Action (NTPA)

Guideline of Building Assessment (Structural & Fire) for RMG Factory Building in

Bangladesh - Electrical Part, Chapter-4

Bangladesh National Building Code (BNBC) 2006 Electrical Part

Time Frame for Corrective Action:

The observations are categorized as A.RED , B.RED/AMBER, C.AMBER, D.YELLOW, E .GREY,

Timeline for corrections are set as Immediate,1 Week, 6 Weeks, 6 months and 1Week+ Ongoing,

respectively.

Severity Level

Color Code

RED

High

Medium

Low

Time Line

Immediate

RED/AMBER

1 Week

AMBER

6 Weeks

YELLOW

6 Months

GREY

1 Week + Ongoing

Chapter - 4

Details Observations of non-compliance issues

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 6

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

4.1 General Documentation on Design and Maintenance

Issue No: 01

Is testing and inspection of insulation and earth resistance program established and recorded?

Observation:

Testing and inspection of insulation and earth resistance program are not

established.

Location:

Not Applicable

Severity

Level:

Medium

Source of

Technical

Findings:

interview

Time frame

6 Months

Color Code

Recommendation:

Standard/Reference:

Establish a periodical Insulation and earth Resistance Measurement Program and

record the related testing data. Also ensure that insulation resistance of power cable

and earth pit resistance are >=5 Mand <=1 respectively.

NTPA- 4.16.2, 4.16.4; & BNBC-2006, 2.11.1.2, 2.11.2

Issue No: 02

Are the electrical switchgear and panel boards inspected periodically to ensure that the equipment is

installed in accordance with the listed ratings?

Observation:

The electrical panel boards are not inspected.

Location:

COS/Ground floor, MDB/Ground floor, SDB/1st floor, SDB/office, SDB/2nd floor,

SDB/3rd floor, SDB/4th floor.

Severity

Level:

Medium

Source of

Technical

Findings:

interview

Time frame

6 Months

Color Code

Recommendation:

Standard/Reference:

Inspect electrical panel boards on an annual basis to ensure that the equipment is in

good working condition.

NTPA- 4.16.2 and BNBC-2006, 2.11.1.2

4.2 Generator Room

Issue No: 03

Are instruction boards for first aid and artificial respiration located in the generator and substation room?

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 7

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Observation:

Location:

Instruction boards for first aid and artificial respiration are not located in the generator

room.

Generator Room.

Severity

Level:

Low

Source of

Photography

Findings:

Time frame

6 Weeks

Color Code

Recommendation:

Standard/Reference:

Provide Instruction board for first aid and artificial respiration in the generator room.

NTPA 3.7.11

Issue No: 04

Is required safety signage, fire-fighting equipment, rubber mats, etc. kept at required location?

Observation:

Safety signage is not posted in the generator room and rubber mats are not kept at

required location.

Location:

For safety signage -- Generator Room.

For rubber mats --- COS/Ground floor, MDB/Ground floor, SDB/1st floor, SDB/office,

SDB/2nd floor.

Severity

Level:

Medium

Source of

Photography

Findings:

Time frame

6 Weeks

Color Code

Recommendation:

Standard/Reference:

Post appropriate type of safety signage in generator room. Also ensure graded

rubber mats are provided in front of all panel boards.

NTPA- 4.16.7.1; BNBC-2006, 2.11.5.1; 2.11.5.3.

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 8

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Issue No: 05

Does the generator room have fire rated wall and door in case of it is located inside or adjacent the

production building?

Observation:

The generator room is located at ground floor of the factory building but it does not

have fire separation.

Location:

Generator room.

Severity

Level:

High

Source of

Photography

Findings:

Time frame

6 Months

Color Code

Recommendation:

Standard/Reference:

Ensure the generator room has adequate fire separation from the production area.

NTPA-4.9.3; 3.7.10; BNBC-2006, 2.6.4.2

Issue No: 06

Are generators earthed at two separate points?

Observation:

The generator is earthed at one point only.

Location:

Generator room.

Severity

Level:

Source of

Findings:

Time frame

Medium

Photography

6 Weeks

Color Code

Recommendation:

Standard/Reference:

Provide two separate and distinct connections of earthing for the generator.

NTPA- 4.9.1

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 9

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

4.3 Distribution & Sub-distribution Boards

Issue No: 07

Are all internal components of switchboards and/or distribution boards properly concealed?

Observation:

Cable entry and exit points of the panel boards are not properly sealed.

Location:

COS/Ground floor, MDB/Ground floor, SDB/1st floor, SDB/office.

Severity

Level:

Source of

Findings:

Time frame

Medium

Photography

6 Months

Color Code

Recommendation:

Standard/Reference:

Ensure panel boards have no opening and all live internal components are

concealed properly.

NTPA- 4.16.7.1, 4.8.2; BNBC-2006, 2.11.5.1

Issue No: 08

Are all switchboards and/or distribution boards properly grounded (earthed)?

Observation:

Panel boards (including panel door) are not properly earthed.

Location:

COS/Ground floor, MDB/Ground floor, SDB/1st floor, SDB/office, SDB/2nd floor,

SDB/3rd floor, SDB/4th floor.

Severity

Level:

High

Source of

Photography

Findings:

Time frame

1 Week

Color Code

Recommendation:

Standard/Reference:

Ensure all panel boards (including panel door) are earthed properly using

appropriate type and size of cables and the earthing cables have continuity up to

main earth.

NTPA- 4.11.2.1; BNBC-2006, 2.8

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 10

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Issue No: 09

Are switchboards and/or distribution boards free of dirt and debris?

Observation:

Distribution boards are not clean.

Location:

COS/Ground floor, MDB/Ground floor.

Severity

Level:

Source of

Findings:

Time frame

Medium

Photography

1 Week

Color Code

Recommendation:

Standard/Reference:

Isolate the panel from the electrical service and clean interior components from dust.

Seal all openings within the enclosure to prevent dust from entering.

NTPA- 4.4.11.1; BNBC-2006, 2.5.5.1; BNBC-2006, 2.11.5.1

Issue No: 10

Is each circuit provided with a dedicated neutral?

Observation:

Dedicated neutral is not provided for each applicable circuit and there is no marking

to identify neutral cable for specified circuit.

Location:

MDB/Ground floor, SDB/1st floor, SDB/office, SDB/2nd floor, SDB/3rd floor, SDB/4th

floor.

Severity

Level:

Medium

Source of

Photography

Findings:

Time frame

6 Months

Color Code

Recommendation:

Standard/Reference:

Provide dedicated & adequate size of neutral with proper identification for each

applicable circuit.

NTPA- 4.4.1; BNBC-2006, 2.5.2.10

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 11

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Issue No: 11

Is each circuit provided with a dedicated earthing?

Observation:

Each circuit is not provided with a dedicated earthing. There is no marking to identify

earthing cable for specified circuit.

Location:

MDB/Ground floor, SDB/1st floor, SDB/office, SDB/2nd floor, SDB/3rd floor, SDB/4th

floor.

Severity

Level:

High

Source of

Findings:

Photography

Time frame

6 Weeks

Color Code

Recommendation:

Standard/Reference:

Provide dedicated & adequate size of earthing with proper identification for each

circuit and ensure continuous earth path is back to main building intake.

NTPA- 4.11, 4.11.2.1, Table 4.5; BNBC-2006, 2.8.3.3, Table 8.2.11

Issue No: 12

Are multi looping of wiring/cables observed at circuit breakers within switchboards and/or distribution

boards?

Observation:

Bunch of cables are found at circuit breaker terminal and bus bars.

Location:

MDB/ground floor, COS/Ground floor, SDB/3rd floor.

Severity

Level:

Medium

Source of

Photography

Findings:

Time frame

6 Weeks

Color Code

Recommendation:

Standard/Reference:

Rewire to avoid the use of multiple cables on outgoing side of MCBs and busbar.

NTPA- 4.4.1; BNBC-2006, 2.5.2.1

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 12

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Issue No: 13

Is electrical wiring/cables sized according to capacity of circuit breakers?

Observation:

Electrical cables are not sized according to capacity of circuit breaker.

Location:

Main MCCB

Severity

Level:

High

Breaker rating -300A,

Source of

Photography

Cable current rating -96

Findings:

Time frame

6 Weeks

Color Code

Recommendation:

Standard/Reference:

Consult with a qualified electrical engineer and ensure all electrical cables are sized

according to capacity of circuit breaker.

NTPA- 4.10; BNBC-2006, 2.7.6

Issue No: 14

Are list and diagram of the circuits available for all distribution boards? Do cables have identification as

per list and diagram?

Observation:

List and diagram of the circuits are not available for all distribution boards and no

means of identification is provided of cables.

Location:

MDB/Ground floor, SDB/1st floor, SDB/office, SDB/2nd floor, SDB/3rd floor, SDB/4th

floor.

Severity

Level:

Low

Source of

Photography

Findings:

Time frame

6 Months

Color Code

Recommendation:

Standard/Reference:

Ensure each distribution board is provided with a circuit list indicating current rating

of circuit and size of fuse element/ breaker. Also ensure the means of identification

(separate color coding, marking tape, tagging, or other approved means) of cable is

provided as per circuit list..

NTPA 4.8.3, 4.16.7.1

4.4 Wiring System

Issue No: 15

Are stranded conductors having a nominal cross-sectional area 6mm2 or greater provided with cable

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 13

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

sockets? Are Conductors below 6mm2 without cable sockets, all strands at the exposed ends soldered

together or are crimped using suitable sleeve or ferrules?

Observation:

Stranded conductors below 6mm2 are not provided with sleeve or ferrules.

Location:

COS/ground floor, MDB/Ground floor, SDB/1st floor, SDB/office, SDB/2nd floor,

SDB/3rd floor. SDB/4th floor.

Severity

Level:

Low

Source of

Photography

Findings:

Deadline:

6 Months

Color Code

Recommendation:

Standard/Reference:

For stranded conductors having a nominal cross-sectional area less than 6mm use

suitable sleeve or ferrules to make sure all strands at the exposed ends are solder

together or crimped.

NTPA- 4.4.10.3; BNBC-2006, 2.5.4.3

Issue No: 16

Are wiring system passes through elements of building construction sealed according to the degree of

fire resistance?

Observation:

Wiring system passes through elements of building construction are not sealed

according to the degree of fire resistance.

Location:

All floors.

Severity

Level:

Medium

Source of

Photography

Findings:

Time frame

6 Weeks

Color Code

Recommendation:

Standard/Reference:

Wiring system passes through elements of building construction such as floors,

walls, the openings remaining after passage of the wiring system have to seal

according to the degree of fire resistance prescribed for the respective element of

building construction before penetration.

NTPA- 4.5.3

4.5 Continuation of Discrimination & Protection

Issue No: 17

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 14

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Are distribution boards marked separately for lighting and power circuit?

Observation:

Distribution boards are not marked separately for lighting and power circuit.

Location:

MDB/Ground floor, SDB/1st floor, SDB/office, SDB/2nd floor, SDB/3rd floor, SDB/4th floor.

Severity

Level:

Low

Source of

Technical interview

Findings:

& Visual inspection

Time frame

6 Months

Color Code

Recommendation:

Standard/Reference:

Install separate distribution boards for lighting and power circuits.

NTPA- 4.8.3

4.6 Earthing System

Issue No: 18

Does all earthing system have provision for periodical inspection and are inspected & documented

periodically?

Observation:

There is no provision for inspection of earthing system.

Location:

Not applicable.

Severity

Level:

Source of

Findings:

Time frame

Medium

Technical

interview

Visual

inspection

1 Week

&

Color Code

Recommendation:

Standard/Reference:

Provide provision for inspection of all earthing system and ensure inspection is being

completed and documented.

NTPA- 4.16.7.2

Issue No: 19

All metal in the building is connected to the building earthing/grounding system?

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 15

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Observation:

Location:

Metal rebar in concrete, metal pipes and the cable channels are not connected to the

building earthing system.

Throughout the building.

Severity

Level:

High

Source of

Technical

Findings:

interview

&

Visual

inspection

Time frame 6 Weeks

Color Code

Recommendation:

Standard/Reference:

Connect all metal in the building to the building earthing system such as metal rebar

in concrete, metal pipes and the cable channels.

NTPA 4.8.1

4.7 Lightning Protection System

Issue No: 20

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 16

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Is lightning protection system installed on the building? If installed, are appropriate numbers of down

conductor and air termination network vertical/horizontal conductors installed to cover the whole

building?

Observation:

Lightning protection system is not installed on the building.

Location:

Roof top of the Building.

Severity

Level:

Source of

Findings:

Time frame

Medium

Photography

6 Months

Color Code

Recommendation:

Consult with an expert electrical engineer to review requirements, calculate risk

index, prepare drawing etc. to make sure the building is secured against lightning.

Also ensure following as per NTPA based on the building size.

Air termination network vertical/horizontal conductors are appropriately spaced

ii) Appropriate numbers of down conductors are installed

iii) Resistance of earth conductor within limit (<=10).

Standard/Reference:

NTPA- 4.12; BNBC-2006, 2.9

4.8 Thermography

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 17

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Issue No: 21

Were temperature differences of 21C to 40C noted based on comparisons between component and

ambient air temperatures?

Observation:

Temperature differences of 21C to 40C were observed based on comparisons

between component and ambient air temperatures

Probable causes are loose connection, over loading, multi cable at single point,

rusted connection, use of improper lug, improper cable joint, improper cable bending,

damage insulation, internal problem etc.

Location:

COS/Ground floor, MDB/Ground floor.

Severity

Level:

Medium

Source of

Thermography

Findings:

Time frame

6 Weeks

Color Code

Recommendation:

Standard/Reference:

Make sure cables are not overloaded ,properly terminated using proper lug, joints

are made proper way, no rusted throughout the connection, proper cable bending, no

insulation damage, single cable at single point etc. to avoid temperature rise. If

necessary consult with a qualified engineer and replace cable or equipment.

NTPA- 4.16.7.1, 4.4.11.2; 4.4.10.5; 4.4.10.1, 4.4.6

4.9 Additional Area of Non-compliance

Issue No: 22

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 18

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Do all switchboards and/or distribution boards have dead front construction?

Observation:

All distribution boards do not have dead front construction.

Location:

SDB/1st floor, SDB/office, SDB/2nd floor, SDB/3rd floor, SDB/4th floor.

Severity

Level:

Source of

Photography

Findings:

Time frame

Color Code

Issue No: 23

Are phase separators/Interphase barriers provided between terminals on Circuit Breaker?

Observation:

Phase separators are not provided between terminals on Circuit Breaker

Location:

Main MCCB, MDB/Ground floor, SDB/1st floor, SDB/office, SDB/2nd floor, SDB/3rd

floor ,SDB/4th floor.

Severity

Level:

Source of

Photography

Findings:

Time frame

Color Code

Issue No: 24

Have workers that operate and maintain the electrical system received electrical safety training and

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 19

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

have practice of using proper personal protective equipment (PPE)?

Observation:

The workers that operate and maintain the electrical system have not received

electrical safety training and do not have practice of using proper personal protective

equipment (PPE).

Location:

Not Applicable.

Severity

Level:

Source of

Technical

Findings:

interview

&

Visual

inspection

Time frame

Color Code

Chapter 5

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 20

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Recommendations Summary

Time Line

Observation

Recommended Action Plan

Immediate

None

None

Short Term

(1 Week)

Panel boards (including

panel door) are not properly

earthed.

Ensure all panel boards (including panel door)

are earthed properly using appropriate type and

size of cables and the earthing cables have

continuity up to main earth.

Isolate the panel from the electrical service and

clean interior components from dust. Seal all

openings within the enclosure to prevent dust

from entering.

Provide provision for inspection of all earthing

system and ensure inspection is being completed

and documented.

Short Term

(1 Week +

Ongoing)

Mid Term

(6 Weeks )

Distribution boards are not

clean.

There is no provision for

inspection

of

earthing

system.

Instruction boards for first

aid and artificial respiration

are not located in the

generator room.

Safety signage is not

posted in the generator

room and rubber mats are

not

kept

at

required

location.

The generator is earthed at

one point only.

Each circuit is not provided

with a dedicated earthing.

There is no marking to

identify earthing cable for

specified circuit.

Bunch of cables are found

at circuit breaker terminal

and bus bars.

Electrical cables are not

sized according to capacity

of circuit breaker.

Wiring

system

passes

through

elements

of

building construction are

not sealed according to the

degree of fire resistance.

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 21

Report No : VEC/ILO/RMGP/EAR/2015/451

Provide Instruction board for first aid and artificial

respiration in the generator room.

Post appropriate type of safety signage in

generator room. Also ensure graded rubber mats

are provided in front of all panel boards.

Provide two separate and distinct connections of

earthing for the generator.

Provide dedicated & adequate size of earthing

with proper identification for each circuit and

ensure continuous earth path is back to main

building intake.

Rewire to avoid the use of multiple cables on

outgoing side of MCBs and busbar.

Consult with a qualified electrical engineer and

ensure all electrical cables are sized according to

capacity of circuit breaker.

Wiring system passes through elements of

building construction such as floors, walls, the

openings remaining after passage of the wiring

system have to seal according to the degree of

fire resistance prescribed for the respective

Color

code

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Time Line

Observation

element of

penetration.

Metal rebar in concrete,

metal pipes and the cable

channels are not connected

to the building earthing

system.

Temperature differences of

21C

to

40C

were

observed

based

on

comparisons

between

component and ambient air

temperatures

Probable causes are loose

connection, over loading,

multi cable at single point,

rusted connection, use of

improper lug, improper

cable joint, improper cable

bending,

damage

insulation, internal problem

etc.

Long Term

(6 Months)

Testing and inspection of

insulation

and

earth

resistance program are not

established.

The electrical panel boards

are not inspected.

The generator room is

located at ground floor of

the factory building but it

does

not

have

fire

separation.

Cable entry and exit points

of the panel boards are not

properly sealed.

Dedicated neutral is not

provided

for

each

applicable circuit and there

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 22

Report No : VEC/ILO/RMGP/EAR/2015/451

Color

code

Recommended Action Plan

building

construction

before

Connect all metal in the building to the building

earthing system such as metal rebar in concrete,

metal pipes and the cable channels.

Make sure cables are not overloaded ,properly

terminated using proper lug, joints are made

proper way, no rusted throughout the connection,

proper cable bending, no insulation damage,

single cable at single point etc. to avoid

temperature rise. If necessary consult with a

qualified engineer and replace cable or

equipment.

Establish a periodical Insulation and earth

Resistance Measurement Program and record

the related testing data. Also ensure that

insulation resistance of power cable and earth pit

resistance are >=5 Mand <=1 respectively.

Inspect electrical panel boards on an annual

basis to ensure that the equipment is in good

working condition.

Ensure the generator room has adequate fire

separation from the production area.

Ensure panel boards have no opening and all

live internal components are concealed properly.

Provide dedicated & adequate size of neutral

with proper identification for each applicable

circuit.

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Time Line

Observation

Recommended Action Plan

is no marking to identify

neutral cable for specified

circuit.

List and diagram of the

circuits are not available for

all distribution boards and

no means of identification is

provided of cables.

Stranded conductors below

6mm2 are not provided with

sleeve or ferrules.

Ensure each distribution board is provided with a

circuit list indicating current rating of circuit and

size of fuse element/ breaker. Also ensure the

means of identification (separate color coding,

marking tape, tagging, or other approved means)

of cable is provided as per circuit list.

For stranded conductors having a nominal crosssectional area less than 6mm use suitable

sleeve or ferrules to make sure all strands at the

exposed ends are solder together or crimped.

Distribution boards are not

marked

separately

for

lighting and power circuit.

Install separate distribution boards for lighting

and power circuits.

Lightning protection system

is not installed on the

building.

Consult with an expert electrical engineer to

review requirements, calculate risk index,

prepare drawing etc. to make sure the building is

secured against lightning.

Also ensure following as per NTPA based on the

building size.

i) Air termination network vertical/horizontal

conductors are appropriately spaced

ii) Appropriate numbers of down conductors are

installed

iii) Resistance of earth conductor within limit

(<=10).

Chapter 6

DIFE Summary

Name of the Factory

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 23

Report No : VEC/ILO/RMGP/EAR/2015/451

: East Coast Knit Wear Pvt. Ltd.

Color

code

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Address of the Factory

Present Status of the Factory

: Takkar Math, Sheharchor, Stadium Road, Fatullah,

Narayangonj-1420.

: Under Operation

Electrical Assessment conducted by

: VERITAS Engineering & Consultant

Date of Electrical Inspection

: 2015-07-11

Time Line

Recommended Action Plan

Immediate

None

Short Term

Ensure all panel boards (including panel door) are earthed properly.

Clean interior components from dust and seal all openings within the enclosure to prevent

dust from entering.

Provide provision for inspection of all earthing system.

Provide Instruction board for first aid and artificial respiration in the generator room.

Post appropriate type of safety signage in generator room. Also ensure graded rubber

mats are provided in front of all panel boards.

Provide two separate and distinct connections of earthing for the generator.

Provide dedicated & adequate size of earthing with proper identification for each circuit

Mid Term

and ensure continuous earth path is back to main building intake.

Rewire to avoid the use of multiple cables on outgoing side of MCBs and busbar.

Ensure all electrical cables are sized according to capacity of circuit breakers.

Seal the openings remaining after wiring system passes through the elements of building

construction according to the degree of fire resistance.

Connect all metal in the building to the building earthing system.

Find out the cause (improper cable/over current selection, over loading, improper lug,

improper cable joints, rusted connection, insulation damage, multiple cables at single

point, ) of overheating { ambient+( 200C-400C)} and take proper action.

Establish a periodical Insulation and earth Resistance Measurement Program and record

Long Term

the related testing data.

Inspect electrical panel boards on an annual basis.

Ensure the generator room has adequate fire separation from the production area.

Ensure panel boards have no opening and all live internal components are concealed

properly.

Provide dedicated & adequate size of neutral with proper identification for each applicable

circuit.

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 24

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

Time Line

Recommended Action Plan

Ensure each distribution board is provided with a circuit list and means of identification is

provided as per list.

Provide proper cable terminator/connector for stranded conductors at its point of

termination.

Install separate distribution boards for lighting and power circuits.

Install lightning protection system on the building.

Chapter- 7

Disclaimer

The report is generated by VERITAS Engineering & Consultant under instructions from ILO on the

basis of visual inspection, technical interviews, documentation/information provided by the factory,

thermographic scanning and engineering judgment. It is not an extensive detailed assessment. Also

this report does not constitute a guarantee of continued or absolute safety against electrical disasters.

The sole purpose of this report is to help the factory for improving the level of electrical safety in terms

of electrical infrastructure and management. The recommendations made represent our assessment

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 25

Report No : VEC/ILO/RMGP/EAR/2015/451

Electrical Safety Assessment Report : East Coast Knit Wear Pvt. Ltd.

of the electrical safety standards considered necessary for the common areas to ensure the safety of

the owners, workers and visitors to the premises as well as the assets of the factory.

VERITAS Engineering & Consultant and its visiting members will not be responsible and will not

accept any further liability if further unsafe work practices, procedures, actions or in-actions create any

non-compliance issue by the factory personnel while performing their assigned duties.

East Coast Knit Wear Pvt. Ltd.

VERITAS Engineering & Consultant

Page | 26

Report No : VEC/ILO/RMGP/EAR/2015/451

Você também pode gostar

- EMD Overhaul and Maintenance of MotorsDocumento24 páginasEMD Overhaul and Maintenance of MotorssingenaadamAinda não há avaliações

- How To Make Network CablesDocumento18 páginasHow To Make Network CablesNoel CastilloAinda não há avaliações

- RFP RefDocumento31 páginasRFP RefHicham MedgazAinda não há avaliações

- Training Facility Norms and Standard Equipment Lists: Volume 2---Mechatronics TechnologyNo EverandTraining Facility Norms and Standard Equipment Lists: Volume 2---Mechatronics TechnologyAinda não há avaliações

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNo EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNota: 3.5 de 5 estrelas3.5/5 (3)

- Technical Specification For Ash Handling SystemDocumento97 páginasTechnical Specification For Ash Handling SystemVijay Rangan Sekar100% (2)

- Method Statement GIS HV TestDocumento28 páginasMethod Statement GIS HV Testnayagammailbox75% (4)

- FAT Procedure of PLC PanelDocumento25 páginasFAT Procedure of PLC PanelDipti Bhanja83% (6)

- Electrical Safety Audit PlanDocumento22 páginasElectrical Safety Audit PlanSakshi DhingraAinda não há avaliações

- Electrical Test ProcedureDocumento13 páginasElectrical Test ProceduretrebsantiaAinda não há avaliações

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionNo EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionNota: 4.5 de 5 estrelas4.5/5 (3)

- Supertex Merchandising Co.,Ltd 9566 Alliance Audit Report Ear 4508 April...Documento29 páginasSupertex Merchandising Co.,Ltd 9566 Alliance Audit Report Ear 4508 April...Ekhlas SayeedAinda não há avaliações

- EPS Startup Test Procedure - SECDocumento45 páginasEPS Startup Test Procedure - SECEng Zaid NawaysehAinda não há avaliações

- Aries Iris Tube ProcedureDocumento26 páginasAries Iris Tube ProcedureVipin ShettyAinda não há avaliações

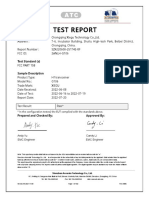

- Test Report For Unit-1 Generator Transformer-B Phase Page NoDocumento4 páginasTest Report For Unit-1 Generator Transformer-B Phase Page NoAnonymous dH3DIEtzAinda não há avaliações

- Electrical Energy Efficiency: Technologies and ApplicationsNo EverandElectrical Energy Efficiency: Technologies and ApplicationsAinda não há avaliações

- Electrical Motor Products: International Energy-Efficiency Standards and Testing MethodsNo EverandElectrical Motor Products: International Energy-Efficiency Standards and Testing MethodsAinda não há avaliações

- Maintenance Schedule For Induction Motor Microproject ReportDocumento18 páginasMaintenance Schedule For Induction Motor Microproject Report44 Tejas JadhavAinda não há avaliações

- PDFDocumento286 páginasPDFAnonymous l2sT4aEAinda não há avaliações

- Sop For Motor Changing JobDocumento10 páginasSop For Motor Changing JobT S Virdi50% (2)

- MNT-INTG-2007OP - Maintenance Welding InspectionDocumento43 páginasMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanAinda não há avaliações

- Herramientas de Mano y Suministros de TallerDocumento472 páginasHerramientas de Mano y Suministros de TallerDavid SantosAinda não há avaliações

- STD 137 PDFDocumento43 páginasSTD 137 PDFSwarup NayakAinda não há avaliações

- SOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSDocumento159 páginasSOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSVikas SinghAinda não há avaliações

- 200 TOP ELECTRICAL ENGINEERING Interview Questions and Answers PDF - EEE Electrical Engineering Interview QuestionsDocumento82 páginas200 TOP ELECTRICAL ENGINEERING Interview Questions and Answers PDF - EEE Electrical Engineering Interview QuestionsMohammedNewaz50% (2)

- Format-6C Checklist-Inspection Report by AEEDocumento1 páginaFormat-6C Checklist-Inspection Report by AEEkltowerAinda não há avaliações

- Preventive Maintenance Electric Service EquipmentDocumento25 páginasPreventive Maintenance Electric Service EquipmentDanielAlejandroRamosQueroAinda não há avaliações

- Report On Relay Co-Ordination & Arc-Flash Study: Ford India PVT LTD Sanand-Vehicle OperationDocumento25 páginasReport On Relay Co-Ordination & Arc-Flash Study: Ford India PVT LTD Sanand-Vehicle Operationramesh cuppuAinda não há avaliações

- High Voltage Test of All Electrical EquipmentsDocumento132 páginasHigh Voltage Test of All Electrical Equipmentsvurumuu100% (1)

- N0579-TJN-ET-MS0005 - R03 Method Statement For AIS InstallationDocumento22 páginasN0579-TJN-ET-MS0005 - R03 Method Statement For AIS InstallationAbat SayekeyevAinda não há avaliações

- SS638 (Rvs CP5) - 22-240419 - SeminarDocumento10 páginasSS638 (Rvs CP5) - 22-240419 - SeminarOoi Wei ShengAinda não há avaliações

- Hse Plan L & TDocumento69 páginasHse Plan L & TNarayanasami Kannan50% (2)

- Electrical Safety Report EXAMPLEDocumento8 páginasElectrical Safety Report EXAMPLEMudde TimothyAinda não há avaliações

- Technical SeminarDocumento10 páginasTechnical Seminarprapto_tmAinda não há avaliações

- Electrical Safety Audit PlanDocumento22 páginasElectrical Safety Audit Planshijohn100% (1)

- Details of The Person Ordering The Report: Domestic Electrical Installation Condition ReportDocumento8 páginasDetails of The Person Ordering The Report: Domestic Electrical Installation Condition ReportOjog Ciprian AlinAinda não há avaliações

- Analisa Harga SatuanDocumento30 páginasAnalisa Harga Satuannorminawati dewiAinda não há avaliações

- Epp 5 ToolsDocumento10 páginasEpp 5 Toolsjonathan mosqueraAinda não há avaliações

- FMM - 4-20ma I56-2991-002Documento2 páginasFMM - 4-20ma I56-2991-002Elias RangelAinda não há avaliações

- Title Plan, Install, Test, and Commission Small Electrical Installations Level 4 Credits 5Documento4 páginasTitle Plan, Install, Test, and Commission Small Electrical Installations Level 4 Credits 5Jason VillaAinda não há avaliações

- Inspection of Electrical Equipment: OISD - STD - 137 For Restricted CirculationDocumento45 páginasInspection of Electrical Equipment: OISD - STD - 137 For Restricted CirculationanandpurushothamanAinda não há avaliações

- Ssem 564 C27 SKM 01Documento6 páginasSsem 564 C27 SKM 01Ahmed Mostafa Fadly MadyAinda não há avaliações

- Training Attendance Sheet - 3-12-2022 SignedDocumento5 páginasTraining Attendance Sheet - 3-12-2022 SignedClaris muthoniAinda não há avaliações

- Precheck Reply of C&RDocumento3 páginasPrecheck Reply of C&Rq.khalid.mAinda não há avaliações

- Inspection of Electrical Equipment: OISD - 137Documento45 páginasInspection of Electrical Equipment: OISD - 137Suraj SarojAinda não há avaliações

- HEP-180011-3-MS-COMMISSIONING-HEPE-017 Test Procedure of Energizing SST4Documento8 páginasHEP-180011-3-MS-COMMISSIONING-HEPE-017 Test Procedure of Energizing SST4SalmanEjazAinda não há avaliações

- ACCC Drake File 3Documento86 páginasACCC Drake File 3Hikmat B. Ayer - हिक्मत ब. ऐरAinda não há avaliações

- Resume: Voltech Engineers PVT LTDDocumento7 páginasResume: Voltech Engineers PVT LTDsarunkvpAinda não há avaliações

- Specific Gravity PDFDocumento457 páginasSpecific Gravity PDFvasantnajanAinda não há avaliações

- Syed Shahid Zafar: Email: Cell #: Address Respected SirDocumento5 páginasSyed Shahid Zafar: Email: Cell #: Address Respected SirMuhammad ZeeshanAinda não há avaliações

- Vinothkannan Quality Control InspectorDocumento5 páginasVinothkannan Quality Control Inspectorabi4evrAinda não há avaliações

- 000007Documento34 páginas000007Rama Krishna Reddy DonthireddyAinda não há avaliações

- Electrical Power Inspection & Check Grup 6Documento10 páginasElectrical Power Inspection & Check Grup 6RahmatAinda não há avaliações

- Handout - Cathodic Protection - AC DC Interference and MitigationDocumento313 páginasHandout - Cathodic Protection - AC DC Interference and Mitigationamritesh pandeyAinda não há avaliações

- 00 Saip 51Documento5 páginas00 Saip 51Rodolius LibaoAinda não há avaliações

- Esa BFB R1Documento36 páginasEsa BFB R1Anwesh Kumar Maddikunta100% (1)

- Iyappan Balu - PeiDocumento3 páginasIyappan Balu - PeiIyappan BaluAinda não há avaliações

- Test Report 6050079Documento102 páginasTest Report 6050079Mircea MoldovanAinda não há avaliações

- Manufacturing, Testing and Calibration Various Electrical EquipmentDocumento30 páginasManufacturing, Testing and Calibration Various Electrical EquipmentHarsh ThakurAinda não há avaliações

- SE-HIO-4AEL-MST-0014 Testing and Commissioning of Wires and Single Core CableDocumento11 páginasSE-HIO-4AEL-MST-0014 Testing and Commissioning of Wires and Single Core Cablevishwas salunkheAinda não há avaliações

- Ravi DoumntsDocumento7 páginasRavi DoumntsRaviAinda não há avaliações

- Project Profile On Repair & Servicing of Electrical AppDocumento11 páginasProject Profile On Repair & Servicing of Electrical AppKavi RehabianAinda não há avaliações

- 66 Ofn QuotationDocumento4 páginas66 Ofn QuotationMohan KumarAinda não há avaliações

- 047-Testing of Electrical Protection PDFDocumento13 páginas047-Testing of Electrical Protection PDFVikrant Deshmukh0% (1)

- P&I BOOK NKLP March 2014Documento46 páginasP&I BOOK NKLP March 2014mansoor0% (1)

- ASPLDocumento3 páginasASPLMohammedNewazAinda não há avaliações

- Joining Letter Joining LetterDocumento1 páginaJoining Letter Joining LetterMohammedNewaz100% (5)

- Performance of Photovoltaic Solar Assisted Heat Pump System in Typical Climate ZoneDocumento9 páginasPerformance of Photovoltaic Solar Assisted Heat Pump System in Typical Climate ZoneMohammedNewazAinda não há avaliações

- Techson Brochure SEP NEWDocumento15 páginasTechson Brochure SEP NEWKamal SharmaAinda não há avaliações

- Piston Pump - High Pressure Stall - Steering 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocumento5 páginasPiston Pump - High Pressure Stall - Steering 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaAinda não há avaliações

- GL2000 SchematicsDocumento24 páginasGL2000 SchematicsPairote IntornAinda não há avaliações

- E&IDocumento4 páginasE&IVenkata Rama KrishnaAinda não há avaliações

- Service Manual: Power SupplyDocumento33 páginasService Manual: Power SupplyMuhammet CanAinda não há avaliações

- Mosebach's Pad-Mounted Load Bank, The X100P FamilyDocumento2 páginasMosebach's Pad-Mounted Load Bank, The X100P FamilyEduardo Puma AriasAinda não há avaliações

- Brochure VPFlowScope In-Line - ENDocumento12 páginasBrochure VPFlowScope In-Line - ENMartin CastroAinda não há avaliações

- Memory and Its TypesDocumento29 páginasMemory and Its Typesneelneel89Ainda não há avaliações

- File Soal Polri NewDocumento5 páginasFile Soal Polri NewZidna IlmaAinda não há avaliações

- User'S Manual: Security Auto TimerDocumento4 páginasUser'S Manual: Security Auto TimerBriliant ImronAinda não há avaliações

- Electric Works InstructionDocumento13 páginasElectric Works Instructionmiraç burak navruzAinda não há avaliações

- Lyman Filament Extruder v4.1 ManualDocumento41 páginasLyman Filament Extruder v4.1 ManualHoang LeAinda não há avaliações

- KPM Round Series Miniature Gas Pumps: DC Power, Pressure To 300 MMHG (5.8 Psi)Documento1 páginaKPM Round Series Miniature Gas Pumps: DC Power, Pressure To 300 MMHG (5.8 Psi)Louis ChenAinda não há avaliações

- Chin Her-12. SLD MSB 2Documento1 páginaChin Her-12. SLD MSB 2uzair rosdiAinda não há avaliações

- Topcon RL-200 1S, RL-200 2S Laser BrochureDocumento2 páginasTopcon RL-200 1S, RL-200 2S Laser Brochurebbutros_317684077Ainda não há avaliações

- DWTT PDFDocumento3 páginasDWTT PDFhavegamAinda não há avaliações

- 524-1724 Electric Governor System (SENR6430-02) PDFDocumento5 páginas524-1724 Electric Governor System (SENR6430-02) PDFMARIO KHOURYAinda não há avaliações

- Mosqueton Olight 3 Matic - BealDocumento2 páginasMosqueton Olight 3 Matic - BealJhon NcAinda não há avaliações

- Sepam 100 LD PresentationDocumento11 páginasSepam 100 LD Presentationalisann87Ainda não há avaliações

- Temp SensorDocumento1 páginaTemp SensorTahir Waseem KhanAinda não há avaliações

- Mechatronic ProjectDocumento9 páginasMechatronic ProjectHafizAfizalAinda não há avaliações

- Datasheet Model C-EL Electrically Operated Control ValveDocumento2 páginasDatasheet Model C-EL Electrically Operated Control ValveRomulo Rodriguez VivasAinda não há avaliações

- Check Valves With Hydrolic DampersDocumento9 páginasCheck Valves With Hydrolic DampersJoy BhattacharyaAinda não há avaliações

- Metode Peralatan Dan Konstruksi LanjutDocumento33 páginasMetode Peralatan Dan Konstruksi LanjutAlin SuarliakAinda não há avaliações

- Toggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintDocumento2 páginasToggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintFelix VelasquezAinda não há avaliações