Escolar Documentos

Profissional Documentos

Cultura Documentos

Appearance Requirements Batch Galvanized Steel - AGA Dr. Galva

Enviado por

pbp29560 notas0% acharam este documento útil (0 voto)

106 visualizações1 páginaAppearance requirements of batch hot-dip galvanizing specifications focus on safety. None of these requirements discuss variation in appearance or color. Touch-up exist and are not rejectable, they are still materials can alter appearance.

Descrição original:

Título original

Appearance Requirements Batch Galvanized Steel- AGA Dr. Galva

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoAppearance requirements of batch hot-dip galvanizing specifications focus on safety. None of these requirements discuss variation in appearance or color. Touch-up exist and are not rejectable, they are still materials can alter appearance.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

106 visualizações1 páginaAppearance Requirements Batch Galvanized Steel - AGA Dr. Galva

Enviado por

pbp2956Appearance requirements of batch hot-dip galvanizing specifications focus on safety. None of these requirements discuss variation in appearance or color. Touch-up exist and are not rejectable, they are still materials can alter appearance.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

Ask. Dr.

Galv

Q: What are the appearance requirements of

batch hot-dip galvanizing specifications?

A: ASTM specifications ASTM

A123/A123M, A153/A153M, A767, and

A385 all discuss appearance requirements.

Although these requirements are slightly

different for each specification, they

are very similar overall. Here are the

summarized appearance requirements of

A123/A123M, A153/A153M, and A767:

The galvanized coating must be free

of bare areas, blisters, flux deposits,

and gross dross inclusions.

Globules or excess zinc that will

interfere with the intended use of

the product are not permitted.

Edge tears or spikes which are

dangerous to handle are not permitted.

Projections or minor surface

roughness that do not interfere with

the intended use of the product are

not rejectable.

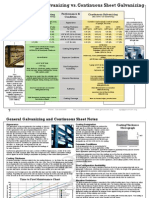

You will notice none of these requirements

discuss variation in appearance or color,

such as mottling (Figures 1 and 2), matte

gray finishes (Figure 3), or dark finishes

(Figure 4). The appearance requirements

of the above hot-dip galvanizing

specifications focus on ensuring a quality

galvanized coating is applied to the steel,

as opposed to visual differences in the

color of the galvanized coating. The reason

for this is the color differences do not

affect the corrosion performance of the

galvanized coating.

Figure 1

Ask

Dr. Galv

Figure 2

ASTM A385 is the only batch hot-dip

galvanizing specification that discusses

variation in appearance or color and states,

in general, hot-dip galvanized coatings are

specified for corrosion protection rather

than appearance. This specification goes

on to state the corrosion protection of

galvanized coatings with varied appearances

is equal for all practical purposes.

Figure 3

In summary, your biggest concerns in

meeting the appearance requirements

of ASTM galvanizing specifications

address safety and ensuring a high quality

galvanized coating that will provide good

corrosion protection is applied to the steel.

Your customer can be sure even though

visual differences in the coating might

It is also important to note touch-up exist and are not rejectable, they are still

materials can alter the appearance of the getting a high quality galvanized coating

galvanizing finish as they are not usually that will last for many years.

an exact color match. These variations are

not cause for rejection. As the galvanized

coating weathers over time, variation in

appearance due to steel chemistry and

touch-up materials will usually assume a

more uniform appearance.

But are your customers allowed to reject

their galvanized steel when it does vary in

color? The answer is no, not according to

the above requirements. The only exception

is when you agree to provide a galvanized

coating with a specific appearance, such as

for architecturally exposed structural steel.

In those cases, steel selection is usually of

utmost importance and a price premium

is usually added to the job to account

for possibly having to galvanize the steel

multiple times to ensure the desired

appearance is achieved. These kinds of

stipulations should be included in the

purchase order.

Figure 4

Você também pode gostar

- Fundamentals of Fluid Flow in Porous MediaDocumento336 páginasFundamentals of Fluid Flow in Porous MediaAnderson Portilla BenavidesAinda não há avaliações

- Astm A123 PDFDocumento2 páginasAstm A123 PDFবিপ্লব পাল67% (6)

- Commercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsNo EverandCommercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsAinda não há avaliações

- Hot Dip GalvanizingDocumento110 páginasHot Dip GalvanizingCandy KendeeAinda não há avaliações

- A 653 - A 653M - 15 PDFDocumento13 páginasA 653 - A 653M - 15 PDFabualamal80% (5)

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyAinda não há avaliações

- Building Code of Pakistan 2021Documento614 páginasBuilding Code of Pakistan 2021Uzair Maqbool KhanAinda não há avaliações

- ASTM Specifications - American Galvanizers AssociationDocumento9 páginasASTM Specifications - American Galvanizers Associationwinarnob100% (1)

- Astm A150Documento5 páginasAstm A150MekhmanAinda não há avaliações

- Inspection of The Hot Dipped Galvanizing ProcessDocumento5 páginasInspection of The Hot Dipped Galvanizing ProcessIrinaAinda não há avaliações

- Astm A123pdf CompressDocumento2 páginasAstm A123pdf CompressYugandharAinda não há avaliações

- Providing High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForDocumento8 páginasProviding High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForIsraelAinda não há avaliações

- Appearance - American Galvanizers AssociationDocumento3 páginasAppearance - American Galvanizers Associationlahidu lakshanAinda não há avaliações

- Hot Dip GalvanizedDocumento6 páginasHot Dip GalvanizedNestor GalianoAinda não há avaliações

- ASTM A123 and G90 Specifications - American Galvanizers AssociationDocumento3 páginasASTM A123 and G90 Specifications - American Galvanizers AssociationwinarnobAinda não há avaliações

- Differences Between Galvalume and Galvanized in Metal RoofingDocumento2 páginasDifferences Between Galvalume and Galvanized in Metal RoofingPPM100% (1)

- V Pro FPGV (Spc7663)Documento1 páginaV Pro FPGV (Spc7663)pandavision76Ainda não há avaliações

- Hot-Dip Galvanizing Vs Continuous Sheet GalvanizingDocumento2 páginasHot-Dip Galvanizing Vs Continuous Sheet GalvanizingMihir JhaAinda não há avaliações

- Bulletin On Zinc Aluminum CoatingsDocumento4 páginasBulletin On Zinc Aluminum CoatingsSithipong PongpraditAinda não há avaliações

- How Does Galvanizing Protect Steel From Corrosion?Documento12 páginasHow Does Galvanizing Protect Steel From Corrosion?jnshreyAinda não há avaliações

- Hot Dip Galvan Neal EdDocumento6 páginasHot Dip Galvan Neal EdEstuardoAAinda não há avaliações

- Architectural Manual: Paintable GalvannealDocumento9 páginasArchitectural Manual: Paintable Galvanneal018601Ainda não há avaliações

- General Galvanizing (Continuous Galvanizing: Performance & ConditionDocumento2 páginasGeneral Galvanizing (Continuous Galvanizing: Performance & ConditionEstuardoA100% (1)

- Hot-Dip Galvanizing Vs Continuous Sheet GalvanizingDocumento2 páginasHot-Dip Galvanizing Vs Continuous Sheet GalvanizingSreedhar Patnaik.M100% (1)

- GalvInfoNote 1 2Documento4 páginasGalvInfoNote 1 2JdjoAinda não há avaliações

- Providing High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForDocumento9 páginasProviding High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForJuanJarvsAinda não há avaliações

- Astm A 1003 A 1003M 2005Documento6 páginasAstm A 1003 A 1003M 2005Jorge ToribioAinda não há avaliações

- Stripping and Regalvanizing - American Galvanizers AssociationDocumento3 páginasStripping and Regalvanizing - American Galvanizers AssociationNsidibe Michael EtimAinda não há avaliações

- Inspectors Course (Presentation) - 04-2012Documento154 páginasInspectors Course (Presentation) - 04-2012Gisselle Morales Torres100% (1)

- Adhesion TestDocumento3 páginasAdhesion TestAhmed AllamAinda não há avaliações

- Inspection of HDG.Documento71 páginasInspection of HDG.Mritunjay100% (1)

- A123 and G90sDocumento3 páginasA123 and G90sAitanaAinda não há avaliações

- Paint Over Galvanized Steel Duplex SystemsDocumento12 páginasPaint Over Galvanized Steel Duplex Systemselectrosysro8560Ainda não há avaliações

- Spot WeldingDocumento8 páginasSpot Weldingtoyota952Ainda não há avaliações

- Peeling Versus Flaking Galvanized Steel 1Documento2 páginasPeeling Versus Flaking Galvanized Steel 1klcy1987Ainda não há avaliações

- A385 01Documento9 páginasA385 01Hendry maysadiputraAinda não há avaliações

- Metal Duct Selection and ApplicationDocumento6 páginasMetal Duct Selection and ApplicationMoiz TinwalaAinda não há avaliações

- ANSI SDI RD-2010 Standard Steel Roof DeckDocumento11 páginasANSI SDI RD-2010 Standard Steel Roof DeckruayoAinda não há avaliações

- Corrosion Protection and Connection DesignDocumento3 páginasCorrosion Protection and Connection Designdimitris22Ainda não há avaliações

- Fastener Compatibility - Final - 1Documento5 páginasFastener Compatibility - Final - 1rahuljoagAinda não há avaliações

- Zinc-Coated Steel Doors and Frames: (Galvanized/Galvannealed)Documento4 páginasZinc-Coated Steel Doors and Frames: (Galvanized/Galvannealed)abualamalAinda não há avaliações

- Hot Dip Galvanizing of Sheet Metal-SpangleDocumento6 páginasHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanAinda não há avaliações

- Design of Products To Be Hot-Dip Galvanized After FabricationDocumento28 páginasDesign of Products To Be Hot-Dip Galvanized After FabricationArlet BibriescaAinda não há avaliações

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocumento13 páginasSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessCarlos Ramirez BaltazarAinda não há avaliações

- HDG Fact Sheet 2017 V4Documento6 páginasHDG Fact Sheet 2017 V4Ra'oufAli-zadehAinda não há avaliações

- Fasteners Zinc CoatedDocumento6 páginasFasteners Zinc CoatedAndres Camilo Benitez100% (1)

- GALVALUME Sheet Carbon Steel SpecsDocumento6 páginasGALVALUME Sheet Carbon Steel SpecsHarshith Rao Vadnala100% (1)

- Astm A-924 PDFDocumento14 páginasAstm A-924 PDFOmar KarinaAinda não há avaliações

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocumento14 páginasGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessOmar KarinaAinda não há avaliações

- Questions To Pose To Customer For - American Galvanizers AssociationDocumento3 páginasQuestions To Pose To Customer For - American Galvanizers AssociationNsidibe Michael EtimAinda não há avaliações

- 2-Durability of Cold-Formed Steel Framing Members AisiDocumento15 páginas2-Durability of Cold-Formed Steel Framing Members AisiSouliman AlkhoderAinda não há avaliações

- Anchoring of Monolithic Refractories - UkDocumento9 páginasAnchoring of Monolithic Refractories - Ukantoniorossini100% (1)

- Galvannealed Coatings How Do They Differ From Galvanized?: GalvinfonoteDocumento5 páginasGalvannealed Coatings How Do They Differ From Galvanized?: GalvinfonoteArifRachmanAinda não há avaliações

- Bolted ConnectionsDocumento9 páginasBolted ConnectionsClaudioDuarte100% (1)

- Soldadura de Hierro ColadoDocumento10 páginasSoldadura de Hierro ColadoclnAinda não há avaliações

- Hot Dip GalvanizingDocumento38 páginasHot Dip Galvanizingtmmsekar100% (1)

- A 385 - 01 - Qtm4ns1sruqDocumento10 páginasA 385 - 01 - Qtm4ns1sruqHans AbantoAinda não há avaliações

- Astm A653-06a - SGCC StandardDocumento13 páginasAstm A653-06a - SGCC Standardcremsky100% (1)

- Hot Dip GalvanizedDocumento4 páginasHot Dip GalvanizedD SRINIVASAinda não há avaliações

- STANDARD - ASTM A792 - Brief DescriptionDocumento3 páginasSTANDARD - ASTM A792 - Brief DescriptionSeyong ParkAinda não há avaliações

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersNo EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersNota: 3.5 de 5 estrelas3.5/5 (2)

- Effect of C & Cr. On Brightness of Galvanizing SurfaceDocumento1 páginaEffect of C & Cr. On Brightness of Galvanizing Surfacepbp2956Ainda não há avaliações

- Tolerance For CHSDocumento1 páginaTolerance For CHSpbp2956Ainda não há avaliações

- Selecting Statistically Valid Sampling Plans: Dr. Wayne A. TaylorDocumento15 páginasSelecting Statistically Valid Sampling Plans: Dr. Wayne A. Taylorpbp2956Ainda não há avaliações

- Hydrogen in Petroleum Fractions: Standard Test Method ForDocumento4 páginasHydrogen in Petroleum Fractions: Standard Test Method Forpbp2956Ainda não há avaliações

- Freezing Points of High-Purity Hydrocarbons: Standard Test Method ForDocumento11 páginasFreezing Points of High-Purity Hydrocarbons: Standard Test Method Forpbp2956Ainda não há avaliações

- Adhesion Tape Specification 51596.Documento1 páginaAdhesion Tape Specification 51596.pbp2956Ainda não há avaliações

- Satrangi Europe 11D 10MDocumento6 páginasSatrangi Europe 11D 10Mpbp2956Ainda não há avaliações

- Flux Skimming PDFDocumento6 páginasFlux Skimming PDFpbp2956Ainda não há avaliações

- Inspection of HDG After FabricationDocumento27 páginasInspection of HDG After Fabricationpbp2956Ainda não há avaliações

- PresentingSixSigma NewDocumento56 páginasPresentingSixSigma Newpbp2956Ainda não há avaliações

- GB 1591 Q420 Steel PropertiesDocumento6 páginasGB 1591 Q420 Steel Propertiespbp2956Ainda não há avaliações

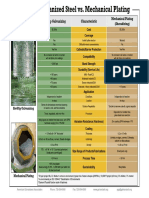

- Hot-Dip Galvanizing Vs Mechanical PlatingDocumento2 páginasHot-Dip Galvanizing Vs Mechanical Platingpbp2956Ainda não há avaliações

- Influence of Alloy Elements On Structure and Corrosion ResistanceDocumento10 páginasInfluence of Alloy Elements On Structure and Corrosion Resistancepbp2956Ainda não há avaliações

- B897 - 03 - Zinc Jumbo BlockDocumento4 páginasB897 - 03 - Zinc Jumbo Blockpbp2956Ainda não há avaliações

- Alloy Additions To The Galvanizing Kettle and Their PurposesDocumento1 páginaAlloy Additions To The Galvanizing Kettle and Their Purposespbp2956Ainda não há avaliações

- ASTM 673 Charpy TestDocumento2 páginasASTM 673 Charpy Testpbp2956Ainda não há avaliações

- Presenting SixSigma NewDocumento56 páginasPresenting SixSigma Newpbp2956Ainda não há avaliações

- Installation Drawing 4508-5a-21Documento62 páginasInstallation Drawing 4508-5a-21Md.Tipu SultanAinda não há avaliações

- Green Synthesis of Silver Nanoparticles Using Seed Extract of CalendulaDocumento5 páginasGreen Synthesis of Silver Nanoparticles Using Seed Extract of CalendulaLaura MarcelaAinda não há avaliações

- Electron Beam Welding of Inconel 617 To AISI 310 - Corrosion Behavior of Weld MetalDocumento4 páginasElectron Beam Welding of Inconel 617 To AISI 310 - Corrosion Behavior of Weld MetalKalyan KumarAinda não há avaliações

- Digital PrintingDocumento24 páginasDigital PrintingPreethi ArunAinda não há avaliações

- Water Softener ResinDocumento3 páginasWater Softener Resinmkgchem100% (1)

- Ok 83.28Documento1 páginaOk 83.28joe_frangiehAinda não há avaliações

- Campus® Datasheet: Zytel® 70G30L Nc010 - Pa66-Gf30 Dupont Engineering PolymersDocumento5 páginasCampus® Datasheet: Zytel® 70G30L Nc010 - Pa66-Gf30 Dupont Engineering PolymersVinayak ImadiAinda não há avaliações

- Chemistry For Engineers: Assignment 1Documento4 páginasChemistry For Engineers: Assignment 1Thanh Tan PhamAinda não há avaliações

- Mason1954 Mason, W., & Wick, R. (1954) - Ferroelectrics and The Dielectric Amplifier. Proceedings of The IRE, 42 (11), 1606Documento15 páginasMason1954 Mason, W., & Wick, R. (1954) - Ferroelectrics and The Dielectric Amplifier. Proceedings of The IRE, 42 (11), 1606Magdy Hussein Mourad MohammadAinda não há avaliações

- Vistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore ADocumento2 páginasVistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore AShalom JohnAinda não há avaliações

- 2010developing Psychrometric Chart For Palestine Main Locations Using Matlab Soft Ware Computer ProgramDocumento69 páginas2010developing Psychrometric Chart For Palestine Main Locations Using Matlab Soft Ware Computer ProgramluqmanAinda não há avaliações

- Design and Fabrication of A Modified Portable BiogDocumento10 páginasDesign and Fabrication of A Modified Portable BiogVN BALAJI GoparajuAinda não há avaliações

- Rubber JointDocumento1 páginaRubber JointAymen AyedAinda não há avaliações

- Lattice Vibrations and Free Electron TheoryDocumento43 páginasLattice Vibrations and Free Electron TheoryᎽᎪsh ᏒᎪj sᎥᏁᎶhAinda não há avaliações

- Pre-Final Bill Supplimentary works-MVGR 02.07.2019Documento112 páginasPre-Final Bill Supplimentary works-MVGR 02.07.2019Anonymous ImoZI0363Ainda não há avaliações

- MSM Medium Updated 2019Documento1 páginaMSM Medium Updated 2019ഗീതു സുരേഷ്Ainda não há avaliações

- Rmi Verif RC Columns 3 2Documento76 páginasRmi Verif RC Columns 3 2Fernando MartinezAinda não há avaliações

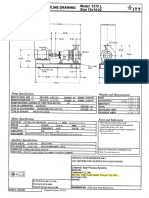

- Model 3175L Goulds Pumps Outline Drawing Size 12x14-22: Weights and SpecificationDocumento6 páginasModel 3175L Goulds Pumps Outline Drawing Size 12x14-22: Weights and SpecificationJavier Fernando Agudelo GómezAinda não há avaliações

- Rates For Rate Analysis Excel FormatDocumento23 páginasRates For Rate Analysis Excel FormatIswers GuptaAinda não há avaliações

- Lecture 3 - Types of RebarsDocumento29 páginasLecture 3 - Types of RebarsJagannathan KAinda não há avaliações

- Science Paper 3 - SolvedDocumento10 páginasScience Paper 3 - SolvedRavi KumarAinda não há avaliações

- 2023 Productcatalogue 2Documento35 páginas2023 Productcatalogue 2Trevor NaidooAinda não há avaliações

- Lec14 PDFDocumento18 páginasLec14 PDFRohan sharmaAinda não há avaliações

- ConstructionDocumento63 páginasConstructionpulilathaAinda não há avaliações

- Moles and Empirical FormulaDocumento11 páginasMoles and Empirical FormulaZenoxu 7zAinda não há avaliações

- Polymer Chemistry For B.SC - Sem-6th PDFDocumento49 páginasPolymer Chemistry For B.SC - Sem-6th PDFSohel Ansari0% (1)