Escolar Documentos

Profissional Documentos

Cultura Documentos

Coke Deposition From Acetylene, Butadiene and Benzene Decomposition at 500 - 900 C On Solid Surfaces

Enviado por

Karen RomeroDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Coke Deposition From Acetylene, Butadiene and Benzene Decomposition at 500 - 900 C On Solid Surfaces

Enviado por

Karen RomeroDireitos autorais:

Formatos disponíveis

Carbon Vol 20, No. 4. pp 319-330.

19R2

Printed in Great Britain.

00086223:8?/04031~12~3.~/0

Pergamon Rest Lid.

COKEDEPOSITIONFROMACETYLENE,BUTADlENEAND

BENZENE DECOMPOSITIONSAT 500-900C

ONSOLIDSURFACES

MICHAELJ. GRAFF? and LYLE F, AL~RIGH~

School of Chemical Engineering, Purdue University, West Lafayette, IN 47907,U.S.A.

(Receiwd IO Ckiuber 1981)

Abstract-Coke formation from decomposition of acetylene, butadiene, and benzene and decoking were investigated on Incoloy 800, aluminized Incoloy 800, and Vycor glass surfaces at SOO-900C.On Incoloy 800, the

coke was greater in quantity and contained iron and nickel particles. On aluminized Incoloy 800, the coke contained

a trace of aluminum, but on Vycor glass, no metal was in the coke. Coking-decoking sequences were highly corrosive

on Incoloy800 surfaces, but they had much less effect on the aluminized Incolny8OOorVycor glass. Filamenteous coke

which is formed catalytically and contains nickel and iron was formed only on Incoloy 800 surfaces. A general

mechanism for formation and deposition of coke is proposed. Filamenteous coke helps collect tar droplets formed by

gas-phase reactions. Such droplets decompose on the surface to produce coke that contains no metal.

Although coke is produced in only relatively small

amounts when hydrocarbons are pyrolyzed to produce

ethylene and valuable by-products or when 1, 2-dichloroethane is dehydrochlorinated to produce vinyl

chloride, coke production results in a significant increase

in operating expenses. Because of coking, the pyrolysis

furnaces have to be shut down periodically to decoke,

the heat transfer coefficients in the furnaces are often

drastically reduced, and coking generally results in corrosion of the stainless steel surfaces on which the coke is

deposited. Significant advantages would occur if coking

could be reduced, and there is a need to better understand the mechanism of coking and of decoking.

Albright, McConnell and Welther[l] demonstrated that

valuable new information can be obtained by comparing

the character of coke formed from acetylene, butadiene,

ethylene and propylene. The former two compounds are

generally considered to be important coke precursors.

They had employed a scanning-electron microscope

equipped with EDAX to analyze the metal content of the

coke. The coke formed on Incoloy 800 surfaces often

contained highly dispersed metal particles making the

coke magnetic in nature. These metal particles contained

nickel, chromium and especially iron that had obviously

been removed in some manner from the surfaces. Baker

ef al. [5,6]

and associates [2-4] and Bernard0

have postutated a mechanism that explains the simultaneous corrosion of the surface and the catalytic

production of a filament-type coke. Of interest, Incoloy

800 surfaces that had first been aluminized were never

found to contain these three transition metals.

The results of Albright, McConnell and Welther[l] are

most interesting but they raise more questions than they

answer. In the present investigation, more information

has been obtained relative to the coke produced from

acetylene, butadiene and benzene. Information has been

obtained on the effect of temperature, partial pressure of

*Presentaddress: Amoco Oil Co., Chicago, Illinois, U.S.A.

coke precursor and time of operation for cokes deposited

on Incoloy 800, aluminized Incoloy 800 and Vycor glass

surfaces.

2.EXPERIMENTAL

The equipment and operating procedures were essentially identical to those employed by Albright, McConnell

and Welther[l]. Coupons that were about 0.5 x 2 x

0.15 cm were positioned inside a Vycor glass tube that

was 2.2cm I.D. and 107cm long. This tube was positioned horizontally in an electrical furnace controlled at

any desired temperature in the 500-900C range. Acetylene, butadiene, helium and oxygen flows were metered as

desired to the inlet of the Vycor glass tube. For benzene

experiments, helium was bubbled through liquid benzene

at room temperature to produce gas mixtures containing

about 12% benzene. Steam was provided by boiling a

flask filled with water. Residence times of the gas stream

in the constant-temperature portion of the Vycor glass

tube were about 20 sec. In most cases, the coupons were

positioned at the beginning of this portion of the reactor

which is designated as the lead position. The rear position, or end of this portion of the reactor, was about

25cm beyond. The aluminized (or aionized) Incoloy

800 coupons were furnished by Alon Processing, Inc. of

Tarentum, Pa. Incoloy 800 coupons had been subjected

at high temperatures to gaseous aluminum; as a result,

some aluminum diffused into the metal resulting in a high

concentration of aluminum of the surface.

Coupons after being removed from the Vycor glass

tube were cooled in an inert atmosphere, and pictures

were then taken using a JSM-U3 scanning-electron

microscope at magnifications varying from 1000 to

20,000. The metal content of the solid surfaces of the

coupon or of the coke produced was measured using an

EDAX, model 707.

3.CO~GANDDECO~NG~~~TS

Significant changes were noted in the surface composition and appearance of the Incoloy 800 as a result of

319

320

MICHAELJ. GRAFFand LYLE F, ALBRIGHT

coking and subsequent decoking, especially for runs at

900C. To clarify the effect of heating, an Incoloy 800

coupon was heated to 900C in a helium atmosphere. The

chromium content of the surface increased from 22 to

60% after 8 hr heating as indicated by EDAX. Similar

chromium enrichment of the surface also occurred at

900C when acetylene, butadiene or benzene was

employed. The titanium content of the surface of the

coupon also increased to perhaps 2-370 because of heating at 900C.

The appearance of the Incoloy 800 surface changed

significantly during helium treatment at 900C as indicated in Fig. 1; coupons are shown before and after the

heat treatment. The Incoloy 800 coupons as received has

a rather heterogeneous surface. The white areas shown

in the upper left picture were iron-rich particles covering

Fig. 1. Untreatedand helium treated metal coupons.

Cokedepositionfrom chemicalsat 500-900Con solid surfaces

about .5-10% of the surface. EDAX analysis of the

remainder of the surface indicated 45% iron, 33% nickel

and 22% chromium. Heat treatment in the presence of

helium resulted in tiny whiskers, columns or spikes which

are mainly iron or chromium rich particles.

Heat treatment of aluminized Incoloy 800 coupons at

900C in the presence of helium resulted in little change

of either the composition or the appearance of the surface. The surface exhibited chicken wire markings and

contained some almost pure aluminum deposits which

are the white areas of pictures shown in Fig. 1. Part of

the surface aluminum, however, undoubtedly existed as

alumina. The areas between the markings analyzed approximately 46% aluminum, 27% iron, 1% nickel and 9%

chromium. The few pitted areas shown were somewhat

less aluminum rich. With heat treatment, there were

probably fewer pitted areas.

3.1 Coke formation from acetylene

Filmenteous coke was the predominant type of coke

formed in Incoloy 800 surfaces at 500C when either pure

acetylene or helium-acetylene mixtures containing 5%

acetylene were used. Both constant-diameter and braided

(or rope-like) filaments were produced as shown in Fig.

2, and most filaments had diameters of about 0.1-0.2 pm.

A few very long and almost straight filaments with

constant diameters of 0.5-1.0 pm were also noted; three

such filaments are shown in the lower left picture of Fig.

2. The length-to-diameter ratios of the filaments were

often at least 200: 1. The upper right picture of Fig. 2

shows a double helix of filaments; such a double helix

was also noted in another case. The coupon treated with

pure acetylene at 500C was re-examined after several

months, and one filament was then found that appeared

to be hollow or basically a tube. All filaments contained

metal particles as indicated by EDAX analysis. Nickel

and especially iron were predominant in these particles.

For runs at longer times, such as 8 hr, more coke was

noted on the surface and a higher fraction of the coke

appeared to be chunky or amorphous coke such as

shown on the center left section of the lower left picture.

Some globular coke, such as will be described later, was

also noted.

No filamentous coke was ever observed on aluminized

(or alonized) Incoloy 800 or on Vycor surfaces regardless

of the conditions used or the hydrocarbon feed stream

employed. Only amorphous coke was formed from

acetylene in such cases at SOoOC[l].Lesser amounts of

coke were apparently formed on both aluminized and

Vycor glass surfaces based on visual observations. The

coke formed on both aluminized steel and Vycor glass

surfaces never contained detectable amounts of iron or

nickel. Cokes deposited on aluminized steel surfaces

contained however traces of aluminum or alumina.

Figure 3 shows the coke formed at 500C with a feed

stream having an acetylene partial pressure of 0.05 atm.

Only a very few filaments were noted on the coupon

located in the lead position of the Vycor glass tube; these

filaments were, however, very long. One constantdiameter filament and one braided filament appear to be

joined. The other end of the constant-diameter filament

321

seems to be connected to surface. The coupon located in

the rear position of the constant-temperature zone was

apparently almost coke free.

Coke formed from acetylene at 900C appeared to be a

mass of rather spherical droplets that had partially fused

together as shown in Fig. 3. This type of coke is called

globular in this investigation whereas it was called

knobby by Albright, McConnell and Welther[l]. The

globular coke varied in shape from rather perfect

spheres, partly fused together, to droplets that were

fused to a much greater extent. The general characteristics of cokes deposited at 900C on Incoloy 800,

aluminized Incoloy 800 and Vycor glass surfaces were

similar in all cases but with perhaps some differences in

the diameter of the droplets. In some portions of an

aluminized coupon, it was possible to see the metal

surface below or through the coke; apparently less coke

was deposited on these surfaces as compared to Incoloy

800 coupons. When the globular cokes deposited in Incoloy 800 coupons were scrapped with a knife blade,

there were essentially two layers of coke. The layer

closest to the metal surface was highly adherent to the

metal, but the top layer was rather easily removed. The

top layer of coke formed on all coupons contained no

detectable iron, nickel or other metals. The amount of

coke increased with time of operation and with higher

partial pressures of acetylene. At 900C and with acetylene at atmospheric pressures, the Vycor glass tube

plugged after about 1 hr. With a partial pressure of

0.05 atm, only a relatively small thickness of coke was

noted after 16hr of operation. It is estimated, based on

this finding, that the rate of globular coke deposition at

900C is second order or higher based on the acetylene

partial pressure. Such a finding seems consistent with the

fact that condensation reactions of acetylene to produce

heavier hydrocarbons are probably mainly second-order

reactions.

3.2 Coke formation from butadiene

Coke was produced from butadiene at temperatures of

500, 700 and 900C and at partial pressures of 0.05 and

1.0 atm.

Temperature had a major effect on the morphology of

the deposited coke. Figure 4 shows the results for Incoloy 800 coupons subjected for 8 and 16 hr to a heliumbutadiene mixture containing 5% butadiene. At 5OOC,a

thin brown but smooth film of coke was formed. At

700C more coke was present on the coupon and appeared to be a cloudy film. At 9OOC,profuse needle coke

was present; in some cases the coke gave the appearance of finely cut ribbons which seemed to

originate at iron- or chromium-enriched particles on the

surfaces of the coupons. The lower right picture of Fig. 4

shows a column-like filament growing out of a

chromium-enriched particle on the surface. This column

was formed on the coupon positioned at the rear position

of the constant-temperature zone, and it was similar in

appearance to formations noted on the Incoloy 800 coupon heated to 900C in the presence of helium. Both

coupons also had concentrations of about 3% titanium on

their surfaces.

322

MICHAEL

I. GRAFFand LYLEF. ALBRIGHT

Fig. 2. Pure CzHz over Incoloy 800 at 500C.

At 900C and for 1 hr runs, globular and/or spaghettilike cokes were formed on al1 three surfaces. The

spaghetti-like characteristics were particularly noted on

the Incoloy 800 coupons as compared to aluminized

Incoloy coupons as indicated by Fig. 5. The globular and

spaghetti cokes were fused together in many cases. The

precursor for these cokes is thought to be tar droplets

that flowed rather readily before being converted to coke

as will be discussed later. On aluminized Incoloy 800, the

diameter of the coke spheres increased with time, as

shown for exampie in the lower right hand picture of Fig.

5.

For 900C runs using fncoloy 800 coupons, the outer

layers of coke after 8 and 16hr were primarily needle or

cut ribbon-type cokes. Some chunks of amo~hous coke

were also observed after 16 hr. Less coke formed on the

Coke deposition from chemicals at 500-900Con solid surfaces

(1 micron = f--w)

323

(1 micron = e---4

Fig. 3. 5% C2H2over Incoloy 800for 8 hr.

aluminized Incoloy 800 or Vycor glass surfaces as compared to the Incoloy 800 surface; portions of the aluminized metal could sometimes be seen for coupons

investigated at 900C. More coke was formed in all cases

when pure butadiene was employed as compared to a

mixture containing 5% butadiene.

For runs at SOOC,the exit gases from the Vycor tube

were mainly butadiene, but some liquid product was

collected in an ice trap. Based on gas chromatography,

this liquid was mainly Cs hydrocarbons with lesser

amounts of C6 and C4 hydrocarbons. The Gs and Gs

are probably mainly aromatics based on the more

detailed analyses by Albright and Yu[7] for comparable

experiments. At 9OOC,most of the butadiene reacted in

MICHAELJ. GRAFFand LYLE F. ALBRIGHT

Fig. 4. 5% C& over Incoloy 800 (1 pm = ---I.

the Vycor glass reactor, and considerable hydrogen and

methane were noted in the exit gas stream. Essentially

no liquid product was obtained, however, for 16 hr of

operation when a feed mixture containing 5% butadiene

was employed.

For all runs considerable tars were deposited in especially in the cool exit end of the Vycor glass tube. For a

run at SOT using pure butadiene, liquid deposits formed

in the tube where the temperatures are 170C or lower.

For a 7OOT run, brown liquid droplets formed in the exit

end of the tube where temperatures varied from about

600 to 3OOT. For a 900C run, brown tar collected in the

exit end where the temperatures dropped from 800 to

170C.

3.3 Coke ~o~~~~oR from benzene

For a benzene run at 5OOC,an Incoloy 800 coupon

was tarnished with a spotted, light-brown residue after

Coke deposition from chemicals at NC-900C on solid surfaces

16hr. With the scanning-electron microscope, the base

metal was still cleariy visible through the coke which

appeared amorphous in character. At 7OOC,more coke

formed in the lncoloy 800 coupon which appeared to

have a filmy clouded surface. Figure 6 shows pictures

taken of both the Incoloy 800 and aluminized Incoloy

800 surfaces. An amorphous coke with the beginnings of

globular coke were noted on both surfaces. In one area

325

of the aluminized surface, there were large columns or

chunks of coke (see lower right picture of Fig. 6); such

deposits were not observed on any other coupons.

At 900C, globular coke was observed on both Incoloy

800 and aluminized Incoloy 800 surfaces as shown in Fig.

7; the top two pictures are for runs of 1 hr whereas the

bottom two pictures are for runs of 8 hr. Three features

are of interest. First, considerable more coke occurred in

326

MICHAEL

J. GRAFFand LYLEF. ALBRIGHT

Fig. 6. 12% C6H6at 700Cfor 16hr (IO Fm = -).

all ca!res on the Incoloy 800 coupons as compared to the

alumiisized Incoloy coupons; the aluminized surface can

be seten even after 8 hr operation. Second, the diameter

of the: coke spheres increased in the 1-8 hr time period.

Third , the spheres of coke on the aluminized surfaces

were sometimes transparent to the SEM beam as shown

in the lower right picture of Fig. 7.

3.4 Decoking of metal coupons

Two decoking experiments were made using Inr:oloy

800 coupons on which coke had been deposited . To

deposit the coke, the coupons were exposed to a mi:vture

of 5% acetylene in helium for 8 hr at 900X Decc&king

was accomplished for one coupon by contacting it with

pure steam at 700C for 24 hr; the other coupon was

Coke depositionfrom chemicals at 5WWC

contacted with pure oxygen at 800C for 24 hr. Photographs of the resulting surfaces are shown in Fig. 8.

After steam, the surface indicated numerous iron-rich

particles, but several protruding chromium-rich spikes

were also noted. These spikes appeared white in the

pictures, and were estimated to be as great as 1.5-2.0 pm

in length. One prominent spike is shown in the two

pictures for steam butnoff shown in Fig. 8; in each case

CAR Vol. 20, No. 4-E

on solid surfaces

327

this spike is slightly to the left of the center of the

picture. EDAX analyses of one spike indicate the following approximate compositions: 62% chromium, 22%

iron and 16% nickel. The composition of the remaining

surface except for iron-rich regions was about 42%

chromium, 36% iron and 22% nickel. There was

obviously both a significant change in surface composition and also in roughness of the decoked Incoloy

328

MICHAEL

J. GRAFFand LYLE F. ALBRIGHT

Fig. 8. Carbon burn-off for 24 hr at 7WC of an Incoloy 800 surface, originally treated with 5% C2H2at 900Cfor

8 hr.

800 surface as compared to the surface before coking

and decoking.

With oxygen decoking, the surface was also roughened

significantly. The background metal indicated approximately 50% chromium, 30% iron and 20% nickel;

the spikes indicated about 62% chromium, 26% iron and

12% nickel.

One steam burnoff was made at 800C of coke on an

aluminized Incoloy 800 coupon. The coke had been

deposited at 900C in 16 hr using a gas mixture containing

5% butadiene in helium. After 24 hr of steam decoking,

the surface still showed some chicken wire markings,

but dark but smooth blemishes were now visible. EDAX

analysis indicated a much higher nickel content on the

surface than in the original aluminized coupons. White

deposits of aluminum (or alumina) were still present over

Coke depositionfrom chemicals at 500-900Con solid surfaces

a portion of the surface. The pitted areas had however

almost disappeared. Of interest, a burnoff at 700C by

Albright, McConnell and Welther [ l] indicated essentially

no changes of the aluminized Incoloy 800 surface. Probably the advantages of an aluminized surface will be

retained much longer if temperatures for decoking are

700C or lower.

329

react to form first various condensation products leading

to production of fairly heavy materials such as tars.

Albright and Yu[7] have published some information on

the initial condensation products. Some tars condense

forming droplets that are suspended in tthe gas phase.

Three routes are available for the production of coke

from these heavy hydrocarbons or tars. In two methods,

the liquid droplets grow in size because of coalescnce

and further condensation of tars. Eventually these droplets impinge and collect on solid surfaces such as

pyrolysis coils or transfer line exchangers. On the hot

surfaces, dehydrogenation occurs with the production of

coke that is essentially pure carbon. When the tar droplets collect on the surface, the droplets can wet the

surface and coalesce with other droplets or the droplets

can fail to coalesce. The degrees to which these two

phenomena occur depends on several factors including

the following:

(a) The viscosity of the droplets which depends on the

temperature and the chemical composition of the liquid.

Higher molecular weight compounds tend to be more

viscous. As dehydrogenation occurs and the tar approaches coke, the viscosity also increases.

(b) The wetting ability between liquid droplets and the

solid surface; this ability depends on the composition

and roughness of the solid surface. Droplets also collect

more readily on lower temperature surfaces.

(c) The velocity of the gas stream near the droplet. In

the present investigation, slow velocities occurred

whereas in commercial units extremely high velocities

are prevalent. In the latter case, there is a greater tendency for spreading of the droplets and for shearing of

filament coke.

(d) The rate of cracking or of dehydrogenation in the

liquid or tar on the surface. At high temperatures, the

liquid tar droplets on the surface would be dehydrogenated more rapidly; hence the original shape of the

4. DISCUS!SIONOFRESULTS

Coking mechanisms have been clarified to a significant

extent for pyrolysis processes and for dehydrochlorination of 1,Zdichloroethane since acetylene, butadiene and benzene are always formed to some extent

in both processes. Figure 9 is a summary of major

mechanisms by which coke are formed. Some of the

coke is formed by catalytic reactions in which stainless

steels such as Incoloy 800 participate and are as a result

corroded. Adsorption of the precursor on the surface is

undoubtedly a first step in the coking mechanism. Details

on the production of filamentous cokes have been reported earlier by Baker et al.[2-4] and by Bernard0 et

al.[5,6]. Excellent examples of filamentous cokes are

shown in Figs. 2 and 3. Coke formed from butadiene to

yield cut-ribbon coke is another example of coke formed

by surface catalytic reactions; the lower left hand picture

of Fig. 4 shows an example of this coke. Cokes formed

by catalytic reactions are apparently the predominant

types of coke formed at lower temperatures and perhaps

especially during the early stage of a pyrolysis run when

the metal surfaces are fairly clean. Yet evidence has

been obtained that during pyrolysis of ethane some

filamentous coke containing metal particles was

produced at 800C[8] and that coke containing metal

particles promotes additional coke formation[9].

Coke can also be produced by a sequence of reactions

of which the initial reactions are in the gas phase.

Hydrocarbons such as acetylene, butadiene and benzene

C2HZ

and other

&He

and

other

acetylenes

dloleflns

Chemvx

condensatton

Wetting

of

Non-w;tt,nq

Fig. 9. Mechanism for production of coke.

Formatton

of coke I

qos phase.

then collection

on surface

330

MICHAELJ. GRAFF and LYLE F. ALBRIGHT

droplets would be retained to a greater extent. Figures 3

and 9 show examples in which globular coke retains, to a

considerable extent, the spherical shape of the droplets.

At lower temperatures, there would generally be more

time (or a greater tendency) for the droplets to wet and

spread out on the surface. This postulate explains the

results obtained with butadiene at 500-9OOC.Black mirror finishes such as noted at fairly low temperatures for

coke formed from butadiene by Yu and Albright [7] can

also be explained.

Some coke is also formed by a sequence of reactions

that occur entirely in the gas phase. Dehydrogenation

and coking reactions occur in the gas phase before liquid

droplets of any appreciable size are formed. Such coke

in sub-microscopic sizes, however, collects on solid surfaces to form initially so-called gas-phase or cotton-like

coke[l]. Filamentous coke on the surface aids in collecting both gas-phase cokes and tar droplets because of a

filtering action. Roughened surfaces also serve as collection points. Both filamentous coke and roughened SWfaces explain why more coke was noted on Incoioy 800

surfaces as ~ompated to aluminized Incoloy 800 surfaces. It also explains why the top layer of globular or

amorphous coke is rather easily removed by scraping

whereas the bottom layer is more adherent.

Gas-phase coke or tar droplets would of course contain

no metal particles. Further confirmation that the top

layer was gas-phase coke is the evidence based on

EDAX analysis that it contained no metal. The bottom

layer on Incoloy 800 coupons was, however, a mixture of

filamentous and globular cokes; this mixture of course

contains some metal particles because of the filamentous

coke. The increased diameter of globular coke formed

during longer length runs and for coupons positioned at

greater distances in the Vycor tube can be accounted for

by increased agglomeration of the tar droplets either on

the surface or in the gas phase.

Coking and decoking results of this investigation have

further demonstrated that rather severe corrosion occurs

on stainless steels such as Incoloy 800 during pyrolysis.

Relatively little quantitative or mechanistic information

can be found in the literature on decoking; clearly a need

for such information exists. Additional information is

also needed on how surface reactions depend on the

specific stainless steel used. This investigation has, for

example, further confirmed that aluminized Incoloy 800

surfaces (and also Vycor glass surfaces) result in complete or essentially complete elimination of all catalytically formed coke and in a significant reduction in surface

corrosion because of coking and decoking. It was

encouraging to learn recently that aluminum was retained

on alonized surfaces for a coil operated for over a year

in a pyrolysis furnace. No specific evidence is

yet available, however, whether the beneficial improvements obtained with aluminized surfaces are maintained

over extended periods of operation. Hopefully such tests

can be obtained in the near future since the benefits to be

obtained with improved materials of construction for

both pyrolysis coils and transfer line exchangers may be

substanti~. Of interest, metal surfaces coated with

microscopic thick layers of silica have also been found

effective in significantly reducing coke formation or

collection[lO].

Quantitative information on weight changes of coupons because of coking, decoking, and various gas

treatments will shortly be reported by the Purdue group.

These measurements will provide further information

relative to coke formation and deposition and to decoking on various metal surfaces.

Ac~ow~edgemen~~-A~~owledgement is made to the donors of

the Petrole~ Research Fund, administered by the Americas

Chemical Society, for partial support of the research. Alon

Processing, Inc. of Tarentum, PA also provided support. Dr. Carl

King of E. I. duPont DeNemours and Co., Inc. suggested the

arrangement for Fig. 9.

REFERENCES

1. L. F. Albrigbt, C. F. McConnell and K. Welther, Thermal

Hydrocarbon Chemistry (Edited by A. G. Oblad, H. G. Davis

and T. R. Eddinger), Advances in Chemistry Series, No. 183,

DO. 175-191.American Chemical Societv.

_ Washington. D.C.

ii979).

2. R. T. K. Baker, P. S. Harris, R. B. Thomas and R. J. Waite, J.

Cata~ysjsSO,36 (1973).

3. R. T. K. Baker and R. J. Waite, I. Cu~~~y~~s

37, 101(1975).

4. R. T. K. Baker and P. S. Harris, Chem. Pfiys. Carbon 14,83

(1978).

5. C. A. Bernard0 and L. S. Lobo, i. Cufa~ysi~37,267 (1975).

6. L. S. Lobo and D. L. Trimm, .J. Catalysis 29, 15 (1973).

7. L. F, Albright and C. Yu, Thermal Hydrocarbon Chemistry

(Edited by A. G. Oblad, H. G. Davis and T. R. Eddinger),

Advances in Chemistry Series, No. 183,pp. 193-203.American Chemical Society, Washington, D.C. (1979).

8. L. F. Albright and 6. F. McCbnnell, Thermal Hydrocarbon

Chemisfrv (Edited bv A. G. Oblad. H. G. Davis and T. R.

Eddingerj, kdvanceiin Chemistry Series, No. 183,pp. 20%

224. American Chemical Society, Washington, D.C. (1979).

9. J. J. Dunkleman and L. F. Albright, Industrial and Laboratory Pyrolyses, (Edited by L. F. Albright and B. L. Crynes),

ACS Symposium Series, No. 32, pp. 241-260, American

Chemical Society, Washi~ton, D.C. (1976).

10. D. E. Brown, 1. T. K. Clark, A. I. Foster, J. J. McCarroll and

M. L. Sims, The ~nhibifio~of Coke Fo~atioa in Ethylene

Steam Cracking. National Meeting of American Chemical

Society, New York (1981).

Você também pode gostar

- Pretreatments of Coils To Minimize Coke Formation in Ethylene Furnaces PDFDocumento4 páginasPretreatments of Coils To Minimize Coke Formation in Ethylene Furnaces PDFAli DarvishiAinda não há avaliações

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectNo EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectAinda não há avaliações

- 62f PDFDocumento20 páginas62f PDFMohsenAinda não há avaliações

- Pce-II Unit-I & II 1Documento84 páginasPce-II Unit-I & II 1Pavan SatishAinda não há avaliações

- Refrigeration System NptelDocumento14 páginasRefrigeration System NptelKapil Goyal100% (1)

- Alpha OlefinsDocumento3 páginasAlpha OlefinsAnkit ModiAinda não há avaliações

- Basic of Refrigeration ProcessDocumento29 páginasBasic of Refrigeration Process한준희Ainda não há avaliações

- Troubleshooting Distillation ColumnsDocumento6 páginasTroubleshooting Distillation ColumnsRahul ChandrawarAinda não há avaliações

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsNo EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilAinda não há avaliações

- Hydrogen PropertiesDocumento47 páginasHydrogen Propertiesfogler833Ainda não há avaliações

- Introduction To DistillationDocumento39 páginasIntroduction To DistillationNada HrenAinda não há avaliações

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979No EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonAinda não há avaliações

- Refrigeration Liquid Recirculation SystemsDocumento7 páginasRefrigeration Liquid Recirculation Systemsgoodspeed_phAinda não há avaliações

- Aspe. Plus User ManualDocumento936 páginasAspe. Plus User ManualKen LandyAinda não há avaliações

- RefrigerationDocumento64 páginasRefrigerationHeat.MotionAinda não há avaliações

- Oxidation of Organic Compounds: Medium Effects in Radical ReactionsNo EverandOxidation of Organic Compounds: Medium Effects in Radical ReactionsNota: 4 de 5 estrelas4/5 (1)

- Ailures in Ammonia Plant Vertical Waste Heat BoilersDocumento14 páginasAilures in Ammonia Plant Vertical Waste Heat BoilersMir AsifAinda não há avaliações

- Cascade Refrigeration SystemDocumento2 páginasCascade Refrigeration SystemHsein WangAinda não há avaliações

- Principles and Case Studies of Simultaneous DesignNo EverandPrinciples and Case Studies of Simultaneous DesignAinda não há avaliações

- ChE 505 Chapter 2NDocumento27 páginasChE 505 Chapter 2NAkshay GopanAinda não há avaliações

- Statistics for Process Control Engineers: A Practical ApproachNo EverandStatistics for Process Control Engineers: A Practical ApproachAinda não há avaliações

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Ainda não há avaliações

- Chemical Engineering ProcessingDocumento317 páginasChemical Engineering ProcessingFagner GomesAinda não há avaliações

- Component Trapping in Distillation Towers Causes, Symptoms and CuresDocumento12 páginasComponent Trapping in Distillation Towers Causes, Symptoms and CuresZangAinda não há avaliações

- Performance Prediction of Polymer Insulators For DistributionDocumento38 páginasPerformance Prediction of Polymer Insulators For DistributionDedit Gunarso PutroAinda não há avaliações

- Reboiler: Types of ReboilersDocumento5 páginasReboiler: Types of ReboilersMigueAngelPFAinda não há avaliações

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationAinda não há avaliações

- Successful Design of Catalysts: Future Requirements and DevelopmentNo EverandSuccessful Design of Catalysts: Future Requirements and DevelopmentAinda não há avaliações

- Reactions of Non-Metallic Inorganic CompoundsNo EverandReactions of Non-Metallic Inorganic CompoundsAinda não há avaliações

- Dehydration Plant Twenty Years PaperDocumento5 páginasDehydration Plant Twenty Years Papersejerson07Ainda não há avaliações

- Improve Flaring OperationsDocumento4 páginasImprove Flaring Operationsaa dd qqAinda não há avaliações

- Cooling Water TreatDocumento10 páginasCooling Water TreatNavaganesh KannappenAinda não há avaliações

- Counter-Current Extraction: An Introduction to the Design and Operation of Counter-Current ExtractorsNo EverandCounter-Current Extraction: An Introduction to the Design and Operation of Counter-Current ExtractorsAinda não há avaliações

- New Aspects of Spillover Effect in Catalysis: For Development of Highly Active CatalystsNo EverandNew Aspects of Spillover Effect in Catalysis: For Development of Highly Active CatalystsAinda não há avaliações

- Risk Assessment of Nox Gum in COLD Box of Olefin Plant Step Forward PDFDocumento10 páginasRisk Assessment of Nox Gum in COLD Box of Olefin Plant Step Forward PDFIbrahimAinda não há avaliações

- Surge ControlDocumento16 páginasSurge ControlSANTOSH KUMARAinda não há avaliações

- Centrifugal Compressor Surge and Speed Control PDFDocumento13 páginasCentrifugal Compressor Surge and Speed Control PDFDaniel Puello RodeloAinda não há avaliações

- Future Coils For Ethylene FurnacesDocumento2 páginasFuture Coils For Ethylene FurnacesAli DarvishiAinda não há avaliações

- Topsoe Sec Ref Cat RKS 2Documento5 páginasTopsoe Sec Ref Cat RKS 2Vo Duc Minh MinhAinda não há avaliações

- Optimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073Documento6 páginasOptimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073fujiman35Ainda não há avaliações

- R 482Documento9 páginasR 482Andre Osmond Nugraha SimorangkirAinda não há avaliações

- Chlorine: International Thermodynamic Tables of the Fluid StateNo EverandChlorine: International Thermodynamic Tables of the Fluid StateAinda não há avaliações

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNo EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsAinda não há avaliações

- Eliminating The Claus FurnaceDocumento9 páginasEliminating The Claus Furnaceoujda1977Ainda não há avaliações

- Chemical Reactor Analysis and Applications for the Practicing EngineerNo EverandChemical Reactor Analysis and Applications for the Practicing EngineerAinda não há avaliações

- Aiche 36 012problematic Low Temperature ShiftDocumento10 páginasAiche 36 012problematic Low Temperature ShiftHsein WangAinda não há avaliações

- Application of Shell Reactor Internals in Huizhou RefineryDocumento6 páginasApplication of Shell Reactor Internals in Huizhou RefineryapitbhuAinda não há avaliações

- Steam9 BlowdownDocumento2 páginasSteam9 BlowdownmantascitaAinda não há avaliações

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4No EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Nota: 5 de 5 estrelas5/5 (1)

- Chapter 11 - Preboiler and Boiler CorrosionDocumento19 páginasChapter 11 - Preboiler and Boiler CorrosionEngr Irfan AkhtarAinda não há avaliações

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDocumento8 páginasA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- Extractive DistillationDocumento22 páginasExtractive DistillationErlandFirmansyahAinda não há avaliações

- 226 Eddystone Station UnitDocumento24 páginas226 Eddystone Station UnitsbktceAinda não há avaliações

- Demister Pads/ Mist EliminatorsDocumento14 páginasDemister Pads/ Mist Eliminatorsaagarwal30Ainda não há avaliações

- Aspen Plus Tutorial SeparationsDocumento15 páginasAspen Plus Tutorial SeparationsLi ChAinda não há avaliações

- Understanding Preventing Corrosion (Thesis) PDFDocumento32 páginasUnderstanding Preventing Corrosion (Thesis) PDFeid elsayedAinda não há avaliações

- Experience As A Process EngineerDocumento1 páginaExperience As A Process EngineerKaren RomeroAinda não há avaliações

- Spanish Lesson: Profesor: Karen RomeroDocumento23 páginasSpanish Lesson: Profesor: Karen RomeroKaren RomeroAinda não há avaliações

- Coverletter (Process Engineer)Documento1 páginaCoverletter (Process Engineer)Karen RomeroAinda não há avaliações

- Portafolio Sensus 2017Documento21 páginasPortafolio Sensus 2017Karen RomeroAinda não há avaliações

- Cracking Furnace Tube Metallurgy Part 1 A PDFDocumento21 páginasCracking Furnace Tube Metallurgy Part 1 A PDFKaren RomeroAinda não há avaliações

- Cracking Furnace Tube Metallurgy Part 1 ADocumento21 páginasCracking Furnace Tube Metallurgy Part 1 AKaren Romero100% (1)

- UntitledDocumento1 páginaUntitledKaren RomeroAinda não há avaliações

- UntitledDocumento1 páginaUntitledKaren RomeroAinda não há avaliações

- 3-Oracle Application Framework (OAF) Training Guide - EO, VO, Page, Query Region, LOV, PPRDocumento73 páginas3-Oracle Application Framework (OAF) Training Guide - EO, VO, Page, Query Region, LOV, PPRPreethi KishoreAinda não há avaliações

- Transmission - Approved List 26-09-2017Documento554 páginasTransmission - Approved List 26-09-2017bkhAinda não há avaliações

- Structural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsDocumento3 páginasStructural Welding Inspection: 2019 CBC: DSA Forms DSA PublicationsfracevAinda não há avaliações

- Activity3 3 1utilitesDocumento2 páginasActivity3 3 1utilitesapi-302096056Ainda não há avaliações

- 20e - cTI-60t - TI Pin Converter: Blackhawk™ Jtag Pin ConvertersDocumento2 páginas20e - cTI-60t - TI Pin Converter: Blackhawk™ Jtag Pin ConvertersvspuriAinda não há avaliações

- Pro.753687 en EU R4Documento14 páginasPro.753687 en EU R4Rakshit SharmaAinda não há avaliações

- MHI NZ Room Sizing Chart 2021Documento1 páginaMHI NZ Room Sizing Chart 2021fsdfsdfsdAinda não há avaliações

- C Aj 1609Documento2 páginasC Aj 1609vhin84Ainda não há avaliações

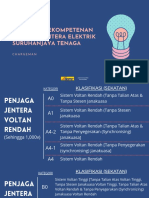

- Kategori Kompeten Penjaga Jentera Elektrik STDocumento9 páginasKategori Kompeten Penjaga Jentera Elektrik STAbun ParadoxsAinda não há avaliações

- LinuxDocumento206 páginasLinuxDinesh BhawnaniAinda não há avaliações

- General Description: Dual Retriggerable Precision Monostable MultivibratorDocumento17 páginasGeneral Description: Dual Retriggerable Precision Monostable Multivibratorsajad hejaziAinda não há avaliações

- PALRUF 100 Technical Guide (En)Documento6 páginasPALRUF 100 Technical Guide (En)mohammed nafethAinda não há avaliações

- Seicos 21l IntrustionDocumento61 páginasSeicos 21l IntrustionkhoaAinda não há avaliações

- M795 Spare PartsDocumento139 páginasM795 Spare Partsวิรัตน์ อัครอภิโภคีAinda não há avaliações

- A Biometric Model For Examination Screening and Attendance Monitoring in Yaba College of TechnologyDocumento6 páginasA Biometric Model For Examination Screening and Attendance Monitoring in Yaba College of TechnologyWorld of Computer Science and Information Technology JournalAinda não há avaliações

- Microsoft SQL Server 2005 Express Edition &Documento95 páginasMicrosoft SQL Server 2005 Express Edition &lgmep350Ainda não há avaliações

- Cat Fines Presentation SlidesDocumento48 páginasCat Fines Presentation SlidescaptkcAinda não há avaliações

- 002 Danfoss PICV Energy Valve Ver 090821 r0Documento2 páginas002 Danfoss PICV Energy Valve Ver 090821 r0Pattana MekkhumAinda não há avaliações

- York Ducted Split Ac Yefe 18-48Documento6 páginasYork Ducted Split Ac Yefe 18-48DANISH0% (1)

- Design and Analysis For Crane HookDocumento6 páginasDesign and Analysis For Crane Hookmukeshsonava076314Ainda não há avaliações

- Flush Column Design FC1Documento1 páginaFlush Column Design FC1ravinchandAinda não há avaliações

- Enel2ea Tut 5 Rev1Documento7 páginasEnel2ea Tut 5 Rev1NOMPUMELELO MTHETHWAAinda não há avaliações

- Lane Departure Warning SystemDocumento7 páginasLane Departure Warning SystemRavisingh RajputAinda não há avaliações

- Cd300m Parts BreakdownDocumento10 páginasCd300m Parts BreakdownAmanda FitzgeraldAinda não há avaliações

- Sir VisvesvarayyaDocumento1 páginaSir VisvesvarayyaJohn SparrowAinda não há avaliações

- Quake Cheat CodesDocumento21 páginasQuake Cheat CodeshugtheslugAinda não há avaliações

- MK Conveyor Technology 5.0Documento484 páginasMK Conveyor Technology 5.0Samuel Getaneh TAinda não há avaliações

- Non Vital BleachingDocumento19 páginasNon Vital BleachingPriyabrat Pattanaik100% (1)

- Schlumberger - Bit Running GuidelinesDocumento38 páginasSchlumberger - Bit Running Guidelinesmanuelperdomot100% (1)