Escolar Documentos

Profissional Documentos

Cultura Documentos

Alert Brace Footing Web2

Enviado por

James MizziDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alert Brace Footing Web2

Enviado por

James MizziDireitos autorais:

Formatos disponíveis

Alert

Brace footing installations on concrete

This Alert highlights the precautions that need to be taken when installing brace

footings on concrete slabs at an early age.

September 2010

This Alert provides practical advice for builders, formworkers,

panel erectors and erection design engineers (designers). It will

also be useful for health and safety representatives.

The information and advice relates to the design of brace footings

(including anchors and concrete) where concrete panel braces

are to be fixed to floor slabs or independent pad footings of

150mm or greater thickness.

If the concrete footing thickness is less than 150mm thick, other

safety factors must be considered by an engineer.

There is also a checklist on the reverse which should be used

before each concrete pour. It will assist with your health and safety

management of the site (consider incorporating it into your safe

work method statement or site OHS plan).

Background

For the last 10 years, to improve construction productivity, builders

have started erecting precast concrete wall panels on floor slabs

within 24 hours of pouring the slab.

Concrete strength at any time is greatly influenced by the age

and method of curing. For example, after 24 hours air-cured

concrete, without admixtures, may only achieve about 10 per cent

of its specified characteristic strength.

The anchors used for fixing brace footings consist of a cast-in

ferrule into which the brace is later bolted. When anchors are

installed in concrete slabs that have not achieved the required

strength, they may fail by pulling out under moderate loads. This

may lead to catastrophic failure of the wall panel, resulting in death

or serious crush injuries to workers.

Control measures

To ensure anchors achieve the required pull-out capacity, the

concrete must attain a minimum strength as determined by the

designer (based on manufacturer and supplier specifications).

The required concrete strength to be achieved at erection must

be specified. Unless designated otherwise, the concrete strength

of the brace footing should be at least 20MPa at the time of

fixing of the bracing.

Note: Projects specifically designed and documented by the

designer may use a lower strength of concrete for erection of

braces.

ALE0130/01/09.10

Where a specific design is undertaken for a brace footing to be

fixed into concrete at low strength, the designer in conjunction

with the builder, formwork company and panel erector, need to

consider the following variables that may reduce safety of the

designed brace footing:

how the required minimum concrete strength can be achieved

prior to the erection of the panels

concrete curing method to be used onsite

ferrule placement tolerances

dislodgement/misalignment of ferrules during concrete

placement.

In addition, the designer needs to give consideration to:

ensuring panel braces, fixings and footings are designed to

have a minimum capacity of 10kN

ensuring any modifications to ferrules, including the welding of

base plates, is done in accordance with an engineers design

and relevant Australian Standards

designing the ferrule inserts to have a minimum embedment

depth of 150mm.

Note: Ferrules should also be designed and manufactured to

ensure their designed failure mode is via cone failure of the

concrete, not via direct pullout. This will usually require some form

of enlarged base of the ferrule.

The builder, formwork company and panel erector should:

implement and maintain a documented sign-off system by a

competent person on all slab and anchor details before each

pour (see checklist)

verify the minimum concrete strength required before panel

erection has been achieved under site conditions.

Further information

WorkSafe Industry Standard Precast and tilt-up concrete

for buildings

Australian Standard AS3850-2003: Tilt-up concrete

Contact details

Call on: 1800 136 089 Email: info@worksafe.vic.gov.au

For more information on occupational health and safety,

go to WorkSafes website: worksafe.vic.gov.au

Alert Brace footing installations on concrete

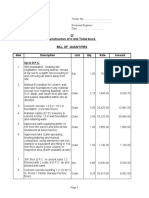

Cast-in ferrule checklist

This checklist applies to concrete designed for less than 20MPa compressive strength at the time of precast installation.

Project: __________________________________________ Principal/head contractor: ___________________________

Subcontractors responsible: ____________________________________________________________________________

Designing engineer: ________________________________ Designated pour area inspected: ______________________

Yes

1.

Is there a project-specific engineered design in place?

2.

Is cast-in ferrule assembly embedment depth in concrete minimum 150mm?

3.

Is all welding to cast-in ferrules to engineers specifications?

4.

Are cast-in ferrules in correct position for propping arrangement?

5(a)

Is cast-in ferrule reinforcement steel configuration to design?

5(b)

Has reinforcement been checked? For example, N12 through-bar, mesh,

baseplate etc or combinations (as per drawings)?

HOLD

POINT

Above details checked and verified by competent person:

6.

Has concrete testing been conducted?

Sign:

Date:

No

N/A

Testing laboratory verified minimum concrete strength (as per design) has been

achieved:

HOLD

POINT

Actual MPa achieved: _______________________________________________

Has this checklist been made available to all relevant parties (eg HSR, panel

erector and formworker)?

HOLD

POINT

Principal/Head contractor verified all above details:

Subcontractor sign:

Sign:

Date: /

Date: /

Note: This checklist recommends hold points when a competent person should verify the actions before proceeding to the

next point on the checklist.

All items on this checklist should be completed and verified as compliant before precast placement to designated pour area.

Subcontractor responsible /authorised representative

Name (print): ________________________________________________________________________________________

Signature: ___________________________________________________________________________________________

Disclaimer: This Alert contains information following WorkSafes inquires into the incident at the date of this report. The information contained in this

report does not necessarily reflect the final outcome of WorkSafes action with respect to this incident. WorkSafe does not warrant the information in

this report is complete or up-to-date and does not accept any liability to any person for the information in this report or as to its use.

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Singapore Electricity MarketDocumento25 páginasSingapore Electricity MarketTonia GlennAinda não há avaliações

- Punching Shear CalculationDocumento18 páginasPunching Shear CalculationNayeemuddin Khaja100% (2)

- Dreamfoil Creations & Nemeth DesignsDocumento22 páginasDreamfoil Creations & Nemeth DesignsManoel ValentimAinda não há avaliações

- SRIA Guide To Seismic Design Online PDFDocumento74 páginasSRIA Guide To Seismic Design Online PDFBabu SundararamanAinda não há avaliações

- Pharmaceutical Microbiology NewsletterDocumento12 páginasPharmaceutical Microbiology NewsletterTim SandleAinda não há avaliações

- ASM INTERNATIONAL Carburizing Microstructures and Properties by Geoffrey ParrishDocumento222 páginasASM INTERNATIONAL Carburizing Microstructures and Properties by Geoffrey ParrishAdheith South NgalamAinda não há avaliações

- Vic Roads Mass LimitsDocumento2 páginasVic Roads Mass LimitsJames Mizzi100% (1)

- Chemical Anchoring ChemSet Reo502Documento2 páginasChemical Anchoring ChemSet Reo502James MizziAinda não há avaliações

- Chemical Anchoring ChemSet Reo502Documento2 páginasChemical Anchoring ChemSet Reo502James MizziAinda não há avaliações

- Aalami CI Mar03 PaperDocumento7 páginasAalami CI Mar03 PaperWalter CastilloAinda não há avaliações

- Optimization of Crude Oil DistillationDocumento8 páginasOptimization of Crude Oil DistillationJar RSAinda não há avaliações

- Post Tensioned Slabs 1 PDFDocumento16 páginasPost Tensioned Slabs 1 PDFAshraf Abu-mahfoudAinda não há avaliações

- Cinnamon Peelers in Sri Lanka: Shifting Labour Process and Reformation of Identity Post-1977Documento8 páginasCinnamon Peelers in Sri Lanka: Shifting Labour Process and Reformation of Identity Post-1977Social Scientists' AssociationAinda não há avaliações

- Price List For Victoria: 1-3 Distribution Drive Truganina VIC 3029 Phone: (03) 9394 5800 Fax: (03) 994 5890Documento22 páginasPrice List For Victoria: 1-3 Distribution Drive Truganina VIC 3029 Phone: (03) 9394 5800 Fax: (03) 994 5890James MizziAinda não há avaliações

- CDM Regulations - How The Regulations Affect You and A QuestDocumento17 páginasCDM Regulations - How The Regulations Affect You and A QuestJames MizziAinda não há avaliações

- Composite Steel Formwork System: Outline of Live-End Anchorage PocketDocumento30 páginasComposite Steel Formwork System: Outline of Live-End Anchorage PocketJames MizziAinda não há avaliações

- Design Capacity Tables For Structural Steel-Volume 1 - Open Sections 3rd EditionDocumento278 páginasDesign Capacity Tables For Structural Steel-Volume 1 - Open Sections 3rd EditionJames Mizzi83% (6)

- Effective Width & Post TensioningDocumento4 páginasEffective Width & Post TensioningJames MizziAinda não há avaliações

- PN 69 2018 Mandatory Notification Stages and Inspection of Building WorkDocumento4 páginasPN 69 2018 Mandatory Notification Stages and Inspection of Building WorkJames MizziAinda não há avaliações

- Bond and AnchorageDocumento20 páginasBond and AnchorageJames MizziAinda não há avaliações

- MC174C BrochureDocumento2 páginasMC174C BrochureJames MizziAinda não há avaliações

- 2016 A4 Post Tensioning 1030 Brochure FINALDocumento12 páginas2016 A4 Post Tensioning 1030 Brochure FINALJames MizziAinda não há avaliações

- Esd Design GuideDocumento74 páginasEsd Design GuideAnonymous mNQq7ojAinda não há avaliações

- Chemical Anchoring ChemSet 101plus Catalogue PageDocumento2 páginasChemical Anchoring ChemSet 101plus Catalogue PageJames MizziAinda não há avaliações

- Structural Modeling Slabs CI Dec2005Documento5 páginasStructural Modeling Slabs CI Dec2005BienSabadoAinda não há avaliações

- CVEN90024 Week 4 Lateral Load Resisting Systems Part 1 NotesDocumento6 páginasCVEN90024 Week 4 Lateral Load Resisting Systems Part 1 NotesJames MizziAinda não há avaliações

- 06 09 KF40 IdmDocumento30 páginas06 09 KF40 IdmJames MizziAinda não há avaliações

- DSD and DSDQ Shear Load Connector Design Sheet 0815Documento1 páginaDSD and DSDQ Shear Load Connector Design Sheet 0815James MizziAinda não há avaliações

- Concure AdditivieDocumento2 páginasConcure AdditivieJames MizziAinda não há avaliações

- Monotop 412 NFG PdsDocumento4 páginasMonotop 412 NFG PdsJames MizziAinda não há avaliações

- 421-502 L - Governance 1Documento27 páginas421-502 L - Governance 1James MizziAinda não há avaliações

- Climate Change in Goulburn BrokenDocumento12 páginasClimate Change in Goulburn BrokenJames MizziAinda não há avaliações

- Concure AdditivieDocumento2 páginasConcure AdditivieJames MizziAinda não há avaliações

- Drawing1 ModelDocumento1 páginaDrawing1 ModelJames MizziAinda não há avaliações

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocumento20 páginasAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenAinda não há avaliações

- Elb v2 ApiDocumento180 páginasElb v2 ApikhalandharAinda não há avaliações

- Teralight ProfileDocumento12 páginasTeralight ProfileMohammed TariqAinda não há avaliações

- ADS Chapter 303 Grants and Cooperative Agreements Non USDocumento81 páginasADS Chapter 303 Grants and Cooperative Agreements Non USMartin JcAinda não há avaliações

- 14 CE Chapter 14 - Developing Pricing StrategiesDocumento34 páginas14 CE Chapter 14 - Developing Pricing StrategiesAsha JaylalAinda não há avaliações

- Andrews C145385 Shareholders DebriefDocumento9 páginasAndrews C145385 Shareholders DebriefmrdlbishtAinda não há avaliações

- Types of Electrical Protection Relays or Protective RelaysDocumento7 páginasTypes of Electrical Protection Relays or Protective RelaysTushar SinghAinda não há avaliações

- Faida WTP - Control PhilosophyDocumento19 páginasFaida WTP - Control PhilosophyDelshad DuhokiAinda não há avaliações

- 16 Easy Steps To Start PCB Circuit DesignDocumento10 páginas16 Easy Steps To Start PCB Circuit DesignjackAinda não há avaliações

- WhatsNew 2019 enDocumento48 páginasWhatsNew 2019 enAdrian Martin BarrionuevoAinda não há avaliações

- Double Inlet Airfoil Fans - AtzafDocumento52 páginasDouble Inlet Airfoil Fans - AtzafDaniel AlonsoAinda não há avaliações

- Mayor Breanna Lungo-Koehn StatementDocumento2 páginasMayor Breanna Lungo-Koehn StatementNell CoakleyAinda não há avaliações

- Coursework For ResumeDocumento7 páginasCoursework For Resumeafjwdxrctmsmwf100% (2)

- Gathering Package 2023Documento2 páginasGathering Package 2023Sudiantara abasAinda não há avaliações

- For Email Daily Thermetrics TSTC Product BrochureDocumento5 páginasFor Email Daily Thermetrics TSTC Product BrochureIlkuAinda não há avaliações

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Documento6 páginasType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheAinda não há avaliações

- Bench VortexDocumento3 páginasBench VortexRio FebriantoAinda não há avaliações

- Change Language DynamicallyDocumento3 páginasChange Language DynamicallySinan YıldızAinda não há avaliações

- Study of Means End Value Chain ModelDocumento19 páginasStudy of Means End Value Chain ModelPiyush Padgil100% (1)

- Grace Strux Beton PDFDocumento33 páginasGrace Strux Beton PDFmpilgirAinda não há avaliações

- INTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Documento7 páginasINTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Shashank DurgeAinda não há avaliações

- IIBA Academic Membership Info-Sheet 2013Documento1 páginaIIBA Academic Membership Info-Sheet 2013civanusAinda não há avaliações

- Brazilian Mineral Bottled WaterDocumento11 páginasBrazilian Mineral Bottled WaterEdison OchiengAinda não há avaliações

- Part A Plan: Simple Calculater Using Switch CaseDocumento7 páginasPart A Plan: Simple Calculater Using Switch CaseRahul B. FereAinda não há avaliações