Escolar Documentos

Profissional Documentos

Cultura Documentos

Barrier Bi Ax Film Lines Overview

Enviado por

Akhilesh KumarDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Barrier Bi Ax Film Lines Overview

Enviado por

Akhilesh KumarDireitos autorais:

Formatos disponíveis

Barrier Biax Film

Barrier Biax Film Lines

Multi-Bubble Biax Film Production Solutions

Key Features:

Versatile extrusion technology

can produce films with a variety

of barrier resins (EVOH, PA,

PVdC)

Controllable film shrink

properties

2-bubble and 3-bubble models

are available to achieve the

specific properties needed

Stable process that allows for

long production runs without

bubble breaks

Macro's Series of Coextrusion

Barrier Biax Film Lines is the

ideal solution for processors

seeking to produce high

performance multilayer barrier

films for food packaging

applications, such as meat,

cheese, and poultry packaging

films, shrink bags, and casings.

Using Macros TaperPack die,

along with carefully design

extrusion screws, each extrusion

module allows the processor to

extrude a wide variety of

polymers from PVdC to EVOH,

and Nylon; allowing flexibility to

adapt the product to market

needs.

These lines are configured in

two-bubble, or three-bubble

arrangements, each of which

facilitates the three basic

processes of producing biax

(biaxially-oriented) films:

extrusion, orientation, and

annealing.

The lines water-quenching

system ensures that the primary

tube is precisely calibrated.

Operation of the waterquenching systems calibration

unit is simple and allows for

adjustments to be made without

stopping the line, generating

cost savings from scrap during

production changes.

Each of these multi-bubble lines

is designed for efficiency and

quality, using the latest

proprietary technologies and

state-of-the-art components.

For systems using the waterbased orientation method,

Macros proprietary technology

initiates the MD/TD orientation

process to accurately blow the

second bubble. The orientation

unit is stable, allowing fast

start-ups and long runs without

bubble breaks, and allows the

processor the versatility to

control the shrink properties of

the final film.

Each model is equipped with a

gauge randomizing unit prior to

winding to ensure high-quality

roll production. Final roll

creation is performed by Macros

Automax-S surface winder,

which features programmable

tension tapering and fully

automatic cutovers.

Barrier Biax Film Lines

Multi-Bubble Biax Film Production Solutions

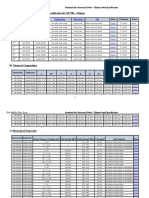

Film Application

Barrier Resin

Oxygen

Barrier

Moisture

Barrier

Shrinkage

Shelf

Life

Line Type

E-beam

treatment

Meat and cheese

packaging

EVOH

High

Medium

High

Medium

Biax-2, Biax-3w

Highly

Recommended

Meat and cheese

packaging

PA terpolymer

EVOH

High

Medium

High

Medium

Biax-3i

Recommended

Meat casings

PA, EVOH

High

Medium

Medium

Medium

Biax-3i

Recommended

Meat packaging

PVdC

High

High

High

High

Biax-2, Biax-3w

Highly

Recommended

Cheese packaging

PVdC

Medium

High

High

Medium

Biax-2, Biax-3w

Highly

Recommended

Cheese packaging

PA terpolymer

Medium

Medium

High

Medium

Biax-3i

Highly

Recommended

CO2 emitting cheese

packaging

PVdC

Medium

High

High

Medium

Biax-2

Highly

Recommended

Poultry, seafood

packaging

n/a

Low

Low

High

Low

Biax-2, Biax-3w,

Biax-3i

Highly

Recommended

Food packaging (flow

pack, lid films, etc.)

PA, EVOH

High

High

Low

Medium

Biax-3w, Biax-3i

Recommended

Model

Barrier Biax-2: two-bubble

Barrier Biax-3w: three-bubble

Barrier Biax-3i: three-bubble

No. of

Layers

5, 7, 9 or 11

5, 7, 9 or 11

5, 7, 9 or 11

Materials

PE, EVOH, EVA, PVdC, Surlyn

PE, EVOH, EVA, PVdC, PA, Surlyn

PE, PP, PS, PET, EVOH, EVA, PA,

Surlyn

Film

Thickness

30-90 m

30-90 m

30-90 m

Layflat

Width

200 600 mm

200 900 mm

200 900 mm

Output

Capacity

40 120 kg/h

40 200 kg/h

40 200 kg/h

Production

Speed

Up to 75 m/min

Up to 105 m/min

Up to 150 m/min

Orientation

Method

Water Heated

Water Heated

Infrared Heaters

Annealing

Method

Heated Rollers

Infrared Heaters

Infrared Heaters

www.macroeng.com

Head Office

Canada - Tel: +1(905)507-9000 | Fax: +1(905)507-3000

Europe

Italy - Tel: +39 0321 182 7286 | Fax: +39 0321 182 7287

Asia

China - Tel: +86-411-86698162 | Fax: +86-411-86641431

Você também pode gostar

- Experiments in M of SDocumento3 páginasExperiments in M of SAkhilesh KumarAinda não há avaliações

- Essentials of Civil EnggDocumento6 páginasEssentials of Civil EnggAkhilesh KumarAinda não há avaliações

- Mechanics of Structure IDocumento4 páginasMechanics of Structure IAkhilesh Kumar0% (1)

- Standard Structural Designs For Low Rise Residential Buildings in RC ConstructionDocumento130 páginasStandard Structural Designs For Low Rise Residential Buildings in RC Constructionsreejit77100% (1)

- Civil Engineering DrawingDocumento6 páginasCivil Engineering DrawingAkhilesh Kumar0% (2)

- Form 28 Noc Rto FormDocumento3 páginasForm 28 Noc Rto FormVikrant DeshmukhAinda não há avaliações

- Diode ApplicationDocumento4 páginasDiode ApplicationASHUTOSH GUPTAAinda não há avaliações

- Civil Engineering DrawingDocumento6 páginasCivil Engineering DrawingAkhilesh Kumar0% (2)

- Concrete Technology: by Dr. R. P. RethaliyaDocumento4 páginasConcrete Technology: by Dr. R. P. RethaliyaAkhilesh Kumar67% (3)

- Bridge EngineeringDocumento4 páginasBridge EngineeringAkhilesh KumarAinda não há avaliações

- Reinforced C Vol IDocumento4 páginasReinforced C Vol IParth GajjarAinda não há avaliações

- Mechanics of Structure IIDocumento3 páginasMechanics of Structure IIAkhilesh KumarAinda não há avaliações

- Medical CertificateDocumento1 páginaMedical CertificateAkhilesh KumarAinda não há avaliações

- Ianimate Rigging WorkshopsDocumento7 páginasIanimate Rigging WorkshopsAkhilesh KumarAinda não há avaliações

- Form 35Documento2 páginasForm 35Rohit Jain0% (1)

- RTO Form29Documento2 páginasRTO Form29Pranav SrivastavaAinda não há avaliações

- Electrical Wiring Distribution System in A Multi Story BuildingDocumento1 páginaElectrical Wiring Distribution System in A Multi Story BuildingAkhilesh KumarAinda não há avaliações

- MA MSC Environmental Science Part-I Part-IIDocumento16 páginasMA MSC Environmental Science Part-I Part-IIAkhilesh KumarAinda não há avaliações

- Single-Screw Extruders and Barrier ScrewsDocumento17 páginasSingle-Screw Extruders and Barrier ScrewsAkhilesh KumarAinda não há avaliações

- Intro To PP. Introduction To Polypropylene by LyondellbasellDocumento3 páginasIntro To PP. Introduction To Polypropylene by Lyondellbasellyamakun100% (1)

- Pop Metals: Intraday Recommendations On Base MetalsDocumento2 páginasPop Metals: Intraday Recommendations On Base MetalsAkhilesh KumarAinda não há avaliações

- Admission Form Navyug Jyotish Shikshan Sansthan Rohini, DelhiDocumento1 páginaAdmission Form Navyug Jyotish Shikshan Sansthan Rohini, DelhiAkhilesh KumarAinda não há avaliações

- Open Commodities Trading AccountDocumento13 páginasOpen Commodities Trading AccountAkhilesh KumarAinda não há avaliações

- SeimensDocumento20 páginasSeimensAkhilesh KumarAinda não há avaliações

- Pop Metals: Intraday Recommendations On Base MetalsDocumento2 páginasPop Metals: Intraday Recommendations On Base MetalsAkhilesh KumarAinda não há avaliações

- Franklin India Prima PlusFundDocumento4 páginasFranklin India Prima PlusFundAkhilesh KumarAinda não há avaliações

- DSIJ DEMOCRATIZING WEALTH CREATIONDocumento2 páginasDSIJ DEMOCRATIZING WEALTH CREATIONAkhilesh KumarAinda não há avaliações

- Introduction To Cover OrdersDocumento8 páginasIntroduction To Cover OrdersAkhilesh KumarAinda não há avaliações

- Nifty Freefloat Method New PDFDocumento16 páginasNifty Freefloat Method New PDFAkhilesh KumarAinda não há avaliações

- Axis LongTerm EquityFundDocumento4 páginasAxis LongTerm EquityFundAkhilesh KumarAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Polyester Partially Oriented Yarn (POY)Documento7 páginasPolyester Partially Oriented Yarn (POY)Dalia MokhmaljeAinda não há avaliações

- Full Scale Test FacilitiesDocumento2 páginasFull Scale Test FacilitiesChangjiang DuAinda não há avaliações

- Module 3: Cutting Tool Materials and FluidsDocumento88 páginasModule 3: Cutting Tool Materials and FluidssushilAinda não há avaliações

- Comparison Between Vacuum and SF6 Circuit BreakerDocumento12 páginasComparison Between Vacuum and SF6 Circuit BreakerecsanyiAinda não há avaliações

- Toyota 8fg Forklift Wiring DiagramDocumento10 páginasToyota 8fg Forklift Wiring Diagrammarilyn100% (45)

- CV TemplateV2Documento9 páginasCV TemplateV2Mark MarianoAinda não há avaliações

- (RDMP) BQ Piping Smp3 170601 Iti Rev0Documento365 páginas(RDMP) BQ Piping Smp3 170601 Iti Rev0Fahmy FlipAinda não há avaliações

- Research Report - Land PollutionDocumento9 páginasResearch Report - Land PollutionMisbah GroupAinda não há avaliações

- ST101 Kiln Over-Temperature TripDocumento2 páginasST101 Kiln Over-Temperature TripDave WalkerAinda não há avaliações

- Disposal of GasesDocumento82 páginasDisposal of GasesChengsi WuAinda não há avaliações

- Relieve Valve Types and OperationDocumento11 páginasRelieve Valve Types and OperationBryan K. Aylas ParedesAinda não há avaliações

- API 653 Tank Inspection StandardsDocumento7 páginasAPI 653 Tank Inspection StandardsEngr Shahid AliAinda não há avaliações

- Standard Specification For GB 700Documento12 páginasStandard Specification For GB 700Ma'arif Nuzul AddibAinda não há avaliações

- PVC Sch40 - Sch80 Industrial Pipe COC 042017Documento1 páginaPVC Sch40 - Sch80 Industrial Pipe COC 042017Hector RojasAinda não há avaliações

- Cost Estimate For 2 - Storey Residential 10.13.22Documento17 páginasCost Estimate For 2 - Storey Residential 10.13.22Regie JoaquinAinda não há avaliações

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesDocumento40 páginasJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemAinda não há avaliações

- 04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesDocumento1 página04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesRonaldAinda não há avaliações

- Wear Parts CatalogDocumento12 páginasWear Parts CatalogLuis Arman100% (2)

- Turbine Maintenance BookDocumento223 páginasTurbine Maintenance Bookbarrunsiswo100% (9)

- Inspection and Test Procedure of SwitchgearDocumento4 páginasInspection and Test Procedure of SwitchgearShahadat HossainAinda não há avaliações

- Manufacturing Engineer or CNC Programmer or CNC Set Up or CNC OpDocumento2 páginasManufacturing Engineer or CNC Programmer or CNC Set Up or CNC Opapi-77548017Ainda não há avaliações

- Cement Properties and Testing MethodsDocumento22 páginasCement Properties and Testing Methodsankit kasanaAinda não há avaliações

- Rehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageDocumento6 páginasRehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageShrikishan Barbrik Joint Venture Pkg-07Ainda não há avaliações

- CVS Controls Series 470 Piston Actuators Sept 2014 PDFDocumento12 páginasCVS Controls Series 470 Piston Actuators Sept 2014 PDFVIVIANA ESQUIVELAinda não há avaliações

- CIC Total Product List 2016Documento1 páginaCIC Total Product List 2016RAMI HAMADAinda não há avaliações

- WWW - Osha.gov Pre Test Answer Key2Documento3 páginasWWW - Osha.gov Pre Test Answer Key2raul_bsu100% (6)

- Pds - Glenium C 317Documento2 páginasPds - Glenium C 317Doby YuniardiAinda não há avaliações

- Simbolos Hidraulicos Din Iso 1219Documento15 páginasSimbolos Hidraulicos Din Iso 1219Angel AlvarezAinda não há avaliações

- Use of Pyroxenite in Place of DolomiteDocumento4 páginasUse of Pyroxenite in Place of DolomiteDhirender KapoorAinda não há avaliações