Escolar Documentos

Profissional Documentos

Cultura Documentos

JK BBP PM BP 0500

Enviado por

Anonymous UsBZYFAGBDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

JK BBP PM BP 0500

Enviado por

Anonymous UsBZYFAGBDireitos autorais:

Formatos disponíveis

Consulting

Transforming

Enterprises

Project Name

JK Cement

Title

Breakdown Maintenance

Version

1.0s

Document ID

JK_BBP_PM_BP_0500_V1.0

Author

Akhilesh Kumar Singh

Reviewed By

XXXXXXX XXXXX

Date

01.11.2012

Business Blue Print- Business Process- Plant

Maintenance

File Name:

Responsibility:

PM

Release:

ECC 6.0

Status:

Closed

IMPLEMENTATION_BLUE PRINT

Business Process Details

Module

Plant Maintenance

Process

Sub Process /

No

Breakdown Maintenance

Breakdown Maintenance & Civil Maintenance

Description

Breakdown Maintenance & Civil Maintenance

Sr No

1.1

1.2

JK_BBP_PM_BP_050

0

Business Process Explanation

As Is Process General Explanation

Explanation of Proposed Process

In case of any Break down, Production User/CCR/Maintenance Engrr.

generates a Maintenance Notification of Notification type M2. He records the

Break down occurrence time, technical object (Equipment/ Function location)

affected, & damage or any kind of observation found. Online information of

Break down & status of technical object will be available to all.

The maintenance team (Electrical/ Mechanical/Instrumentation) attends the

break down and records the malfunction end time, causes & activities

performed while attending the break down. Here he can also add tasks if

required to be performed afterwards, if some temporary arrangements have

been done.

He creates a maintenance order of Order type PM01 to issue materials/spare

parts if required from their local stores. If the material is not available in their

store a purchase requisition can be made directly from the maintenance order.

In operation list of the maintenance order all operation performed, work center

used and man power hour utilization is recorded.

Break down indicator in notification, will be marked if break down occurs.

External services can also be utilized from maintenance order

Spare parts planning can be done using Bill of materials.

Actual/planned/estimated cost incurred on attending break down will be

summarized with labor & spares cost separately.

Failure analysis can be recorded.

Copyright 2011 JKT

Page 2 of 9

Business Blue Print- Business Process- Plant

Maintenance

File Name:

Responsibility:

PM

Release:

ECC 6.0

Status:

Closed

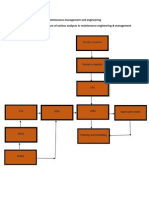

Refer flowcharts below:

1. General Maintenance process (Internal processing)

2. General Maintenance process (External processing both Material &

Service)

o PROCESS FLOW CHARTS

1.1.1 General Maintenance Process (Internal processing)

Create Notification

(Request for maintenance

by plant user/CCR)

-Description of job

-Required Start and

End times of job

-Technical object no.

-Technical findingsObject part, damage

etc. (optional)

-Tasks to perform

Notification

receipt by

Maintenance Dept.

Inspection of

Machine at site by

maint. person

-Enter additional technical

findings and tasks in the

Notification.

-Release the Notification

(Put in process)

Copyright 2011 JKT

Create Maintenance order

for the notification

(by Maintenance planner)

-Description of order

-Technical object details

(transferred from Notification)

-Assign Maintenance work

center (transfers automatically

from the technical object

master record)

Y order

-Plan operations in the

with number of persons

required and work times.

-Plan spare materials with

required quantities

-Assign responsible person

Page 3 of 9

Business Blue Print- Business Process- Plant

Maintenance

File Name:

Responsibility:

PM

Release:

ECC 6.0

Status:

Closed

Schedule the order

(for planned start and end times

depending upon the availability of

manpower at the Maint. Work center)

Release the order

X

Issue spare materials from stores

Execute planned

maintenance work at site

Completion (time) confirmation

(of Maintenance order operations)

Inspection of completed

work at site by authorized

person

-Complete the technical

Findings in Notification.

-Complete the tasks

Notification Completion

(by authorized person)

Technical Completion

Of Maintenance order

(by authorized person)

Settlement

of Maintenance order

(by authorized person)

Business completion

of Maintenance order

(by authorized person )

Order closed

Copyright 2011 JKT

Page 4 of 9

Business Blue Print- Business Process- Plant

Maintenance

File Name:

Responsibility:

PM

Release:

ECC 6.0

Status:

Closed

1.1.2 Maintenance order (External processing)

Create Maintenance order

-Description of order

-Technical object details

-Plan external service operation

in

the order. Enter operation

detailsService description or select

service from the standard service

catalog, service quantity & unit,

price and vendor (optional).

-Plan internal operations, if any

-Plan stock spare materials, if any

Schedule the order

Release the order

1.For Non Stock Material

purchase requisition is made

2.Purchase Order is

created.

3.Receipt of material

Execute internal processing

work at site, if any

Purchase requisition for the

external service is created

automatically.

Purchase requisition

receipt by Purchase Dept.

Create Purchase order

Execution of requested

external service by vendor

Create Service Entry sheet

X

Y

Copyright 2011 JKT

Page 5 of 9

Business Blue Print- Business Process- Plant

Maintenance

File Name:

Responsibility:

PM

Release:

ECC 6.0

Status:

Closed

Y

X

Completion (time) confirmation

(of Maintenance order operations)

Confirm/Accept Services

(By entering exact quantity

of received services in the

Service Entry sheet by an

authorized person)

Technical Completion

Cost

Invoice receipt

Settlement

Business completion

Bill payment

Notification Processing

Transaction code for creating Maintenance Notification is: IW21

Menu path is : Logistics Plant Maintenance Maintenance Processing

Notification Create

Notification type for are: M2: Malfunction Report

1. Identification of Malfunction by Operation or Maintenance department.

2. A Maintenance Notification is created with type M2 in the system depending on

requirement.

3. Specifying the Description of the Notification as per the nature of maintenance

request or malfunction.

4. Mentioning Object Number and time of request with requisitioner identification in

to the notification screen.

5. The initiator of Notification can enter the Technical findings (Object part, Damage

or cause of damage etc) if he knows the details.

6. Saves the notification.

7. After the job is completed the production person will put the timing of malfunction

end and his identification.

8. Maintenance person has to complete any task assigned to notification and enters

the activities.

9. Lastly, the notification has to be completed by the authorized person.

Copyright 2011 JKT

Page 6 of 9

Business Blue Print- Business Process- Plant

Maintenance

File Name:

Responsibility:

PM

Release:

ECC 6.0

Status:

Closed

Order Processing

The transaction code for creating order is IW31.

Menu path : Logistics Plant Maintenance Maintenance Processing

Order Create

Sr

No.

1

Activities

Description

Maintenance

Order Cycle

Permits

Maintenance order is created from the Maintenance

Notification.

Planning operations, Labor resource and materials (if

required) in the maintenance order.

Check Material Availability.

Save Maintenance order and note the Order

Number.

If permits are assigned then those permits has to be

issued by the authorized person.

Physical

Material

Withdrawn

from Main

Stores

If required material is available in main stores

then the material needs to be withdrawn from

the store for executing the maintenance activity.

(The Maintenance Planner will not have

authorization to post Goods issue from main

stores)

Execution of

Maintenance

Work

Completion

Confirmation

Maintenance team will perform the maintenance task

and restore the Object in Ideal condition.

Required material (Spares) will get changed.

Confirms the actual duration and man-hours for the

individual operation.

Records the measurement readings from completion

confirmation screen.

Using the Notification tab button, updates the

catalogs on notification screen.

For other order types the settlement rule is

automatically created, for them rule has to be

checked for its correctness.

After completion of maintenance notification and

entry of tech. Findings, measurement readings the

maintenance order has to be completed technically

to prevent further processing

After completion of all the activities, maintenance

order carries all the maintenance cost; these have to

be settled to the proper cost receiver (Cost Center).

Accounts department will run the settlement of all the

maintenance order periodically to settle the

maintenance orders.

6

7

Completion of

Notification

Creation of

settlement rule

Technical

Completion of

Order

Settlement of

Order

Copyright 2011 JKT

T

Code

IW31

IW32/

IPM2

MIGO

NA

IW41

IW22

IW32

IW32

KO88

/

KO8G

Page 7 of 9

Business Blue Print- Business Process- Plant

Maintenance

File Name:

Responsibility:

10

PM

Business

Completion of

Maintenance

Order

Release:

ECC 6.0

Status:

Closed

After settlement of order, the maintenance planner

can close the maintenance order.

IW32

Civil Maintenance: For jobs related to civil maintenance the Plant User will raise

notification of type M1, Maintenance request, for Civil Function locations & also

mentioning the job description required.

The Concerned Civil Planner & Work center will plan for the job in terms of

material & manpower availability.

He will create Order of type PM03 i.e. General maintenance/Request order & get

the material issued.

Remaining all procedures is of same as Break down Maintenance.

1.3

Sr

No

2.1

2.2

2.3

Sr No

3.1

3.2

Special Organizational Considerations

None

Gap Analysis

Gap Identified in proposed solution against Requirements & Expectations

Not applicable

Impact of Requirement

Not applicable

Solution Proposed

Not applicable

Topics

Changes Management Issues

Not Applicable.

Description of Improvements

1. Online information will be available for breakdown and current status of a

technical object.

2. Effective and clear communication of Break down by end user.

Copyright 2011 JKT

Page 8 of 9

Business Blue Print- Business Process- Plant

Maintenance

File Name:

Responsibility:

Sr

No

4.1

4.2

ECC 6.0

Status:

Closed

3. All record related to technical objects are available at any time for analysis and

decision-making.

4. No separate paper work required to maintain equipment history

Topics

Interface / Enhancements considerations

Not Applicable

Reporting considerations

S

No

1

4.3

PM

Release:

Reports

T Code

Breakdown report

MCI7, IW29,

IW39, IW30,

IW40

IW49

IP19, IP24

MCI8

IW67

IE03

MCI5, IW69

MCJB

MCJC

2

Order operations report

3

Preventive maintenance report

4

Maintenance cost report

5

Maintenance report logbook

6

Equipment history card

7

Defect List

8

MTTR/MTBF Equipment

9

MTTR/MTBF Functional Location

Authorization considerations

As per organizational needs, not finalized yet. Authorization matrix is being prepared

separately.

Business Process Signoff

Module

Plant Maintenance

Process

Sub Process /

No

Breakdown Maintenance

Breakdown Maintenance & Civil Maintenance

Description

Breakdown Maintenance & Civil Maintenance

Copyright 2011 JKT

JK_BBP_PM_BP_050

0

Page 9 of 9

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- BS7430 Earthing CalculationDocumento14 páginasBS7430 Earthing CalculationgyanAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Chapter 2 Axial and Torsional ElementsDocumento57 páginasChapter 2 Axial and Torsional ElementsAhmad FaidhiAinda não há avaliações

- Sap EwmDocumento2 páginasSap EwmsirivirishiAinda não há avaliações

- The Invisible SunDocumento7 páginasThe Invisible SunJay Alfred100% (1)

- Analysis and Design of Well FoundationDocumento40 páginasAnalysis and Design of Well Foundationdhanabal100% (1)

- 10 - QIE in InboundDocumento25 páginas10 - QIE in InboundAnonymous UsBZYFAGB100% (1)

- Catalog NeosetDocumento173 páginasCatalog NeosetCarmen Draghia100% (1)

- Release StrategyDocumento18 páginasRelease StrategyEl Hag Shalata100% (1)

- Selecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationDocumento35 páginasSelecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationJhenn Mhen Yhon100% (1)

- Fleet Maintenance-Tyre ManagementDocumento17 páginasFleet Maintenance-Tyre ManagementNeulers0% (1)

- GoodElearning TOGAF Poster 46 - Adapting The ADMDocumento1 páginaGoodElearning TOGAF Poster 46 - Adapting The ADMFabian HidalgoAinda não há avaliações

- Data Archiving PresentationDocumento25 páginasData Archiving PresentationAnonymous UsBZYFAGBAinda não há avaliações

- JP TS01 PP003 V1 (1) .0 070308Documento6 páginasJP TS01 PP003 V1 (1) .0 070308Anonymous UsBZYFAGBAinda não há avaliações

- JAL-Cement Division: Technical Specification JP - FS01 - PP006 - V1.00100608.doc 1.0 Ajay Agarwal (Abap Consultant) 13.06.2008Documento7 páginasJAL-Cement Division: Technical Specification JP - FS01 - PP006 - V1.00100608.doc 1.0 Ajay Agarwal (Abap Consultant) 13.06.2008Anonymous UsBZYFAGBAinda não há avaliações

- Fs Pp07 Badi MFBF Mf42nDocumento5 páginasFs Pp07 Badi MFBF Mf42nAnonymous UsBZYFAGBAinda não há avaliações

- JP - FS01 - PP0011 - V1.018062008 Mukesh SoniDocumento6 páginasJP - FS01 - PP0011 - V1.018062008 Mukesh SoniAnonymous UsBZYFAGBAinda não há avaliações

- Siemens Information Systems LTD.: Fine Coal Consumption, SP. Heat UHV & NCV Basis and Fly Ash Consumption ReportDocumento7 páginasSiemens Information Systems LTD.: Fine Coal Consumption, SP. Heat UHV & NCV Basis and Fly Ash Consumption ReportAnonymous UsBZYFAGBAinda não há avaliações

- Siemens Information Systems LTD.: Coal Consumption, SP. Heat UHV & NCV Basis and Fly Ash ConsumptionDocumento8 páginasSiemens Information Systems LTD.: Coal Consumption, SP. Heat UHV & NCV Basis and Fly Ash ConsumptionAnonymous UsBZYFAGBAinda não há avaliações

- Plant Maintenance and Customer ServiceDocumento124 páginasPlant Maintenance and Customer ServiceKiran PatnaikAinda não há avaliações

- JKC NBH Iw21 Iw31Documento12 páginasJKC NBH Iw21 Iw31Anonymous UsBZYFAGBAinda não há avaliações

- JKC NBH Iw31 Iw21Documento13 páginasJKC NBH Iw31 Iw21Anonymous UsBZYFAGBAinda não há avaliações

- JK BBP PM BP 0900Documento5 páginasJK BBP PM BP 0900Anonymous UsBZYFAGBAinda não há avaliações

- SAP User Manual JKC-NBH-IE01Documento9 páginasSAP User Manual JKC-NBH-IE01Anonymous UsBZYFAGBAinda não há avaliações

- JK BBP PM BP 0100Documento10 páginasJK BBP PM BP 0100Anonymous UsBZYFAGBAinda não há avaliações

- JK BBP PM BP 0700Documento8 páginasJK BBP PM BP 0700Anonymous UsBZYFAGBAinda não há avaliações

- JK BBP PM BP 0600Documento6 páginasJK BBP PM BP 0600Anonymous UsBZYFAGBAinda não há avaliações

- JK BBP PM BP 0400Documento10 páginasJK BBP PM BP 0400Anonymous UsBZYFAGBAinda não há avaliações

- JK BBP PM BP 0200Documento13 páginasJK BBP PM BP 0200Anonymous UsBZYFAGBAinda não há avaliações

- SAP Configuration JKCLDocumento93 páginasSAP Configuration JKCLAnonymous UsBZYFAGBAinda não há avaliações

- Bohler Dcms T-MCDocumento1 páginaBohler Dcms T-MCFlaviu-Andrei AstalisAinda não há avaliações

- Cultural Practices of India Which Is Adopted by ScienceDocumento2 páginasCultural Practices of India Which Is Adopted by ScienceLevina Mary binuAinda não há avaliações

- Overview of MEMDocumento5 páginasOverview of MEMTudor Costin100% (1)

- RHB Islamic Bank BerhadDocumento2 páginasRHB Islamic Bank BerhadVape Hut KlangAinda não há avaliações

- Gastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterDocumento9 páginasGastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterPier Pasquale TrausiAinda não há avaliações

- Creative LibrarianDocumento13 páginasCreative LibrarianulorAinda não há avaliações

- Advanced Work Packaging: A Fit For Purpose ApproachDocumento17 páginasAdvanced Work Packaging: A Fit For Purpose Approachhafidz bandungAinda não há avaliações

- Tensile Strength of Ferro Cement With Respect To Specific SurfaceDocumento3 páginasTensile Strength of Ferro Cement With Respect To Specific SurfaceheminAinda não há avaliações

- Evolution DBQDocumento4 páginasEvolution DBQCharles JordanAinda não há avaliações

- On The Importance of Learning Statistics For Psychology StudentsDocumento2 páginasOn The Importance of Learning Statistics For Psychology StudentsMadison HartfieldAinda não há avaliações

- SeparexgeneralbrochureDocumento4 páginasSeparexgeneralbrochurewwl1981Ainda não há avaliações

- Using Impact IX49 and 61 With Nektar DAW Integration 1.1Documento21 páginasUsing Impact IX49 and 61 With Nektar DAW Integration 1.1Eko SeynAinda não há avaliações

- Lic Nach MandateDocumento1 páginaLic Nach Mandatefibiro9231Ainda não há avaliações

- Watershed Conservation of Benguet VisDocumento2 páginasWatershed Conservation of Benguet VisInnah Agito-RamosAinda não há avaliações

- Zilog Z80-SIO Technical Manual TextDocumento58 páginasZilog Z80-SIO Technical Manual Textprada.rizzoplcAinda não há avaliações

- Astn/Ason and Gmpls Overview and Comparison: By, Kishore Kasi Udayashankar Kaveriappa Muddiyada KDocumento44 páginasAstn/Ason and Gmpls Overview and Comparison: By, Kishore Kasi Udayashankar Kaveriappa Muddiyada Ksrotenstein3114Ainda não há avaliações

- Xii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Documento13 páginasXii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Stephen SatwikAinda não há avaliações

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDocumento1 páginaSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiAinda não há avaliações

- Motive 27Tmx: Data SheetDocumento2 páginasMotive 27Tmx: Data SheetUlisesGómezAinda não há avaliações

- PLASSON UK July 2022 Price Catalogue v1Documento74 páginasPLASSON UK July 2022 Price Catalogue v1Jonathan Ninapaytan SanchezAinda não há avaliações

- Course Outline Principles of MarketingDocumento3 páginasCourse Outline Principles of MarketingKhate Tria De LeonAinda não há avaliações

- Burn Tests On FibresDocumento2 páginasBurn Tests On Fibresapi-32133818100% (1)