Escolar Documentos

Profissional Documentos

Cultura Documentos

Danley PD3 Dowel Cradle Brochure

Enviado por

Robbie van LeeuwenDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Danley PD3 Dowel Cradle Brochure

Enviado por

Robbie van LeeuwenDireitos autorais:

Formatos disponíveis

PD3

Dowel Cradle

Load Transfer System

Industrial Slab on Ground

Provides the flattest joints

Assists in reducing long

term maintenance costs

Extends the life-cycle of

the floor and the asset

Engineered to meet Super

Flat Floor (SFF) requirements,

ACI 360-R10

PD3 Dowel Cradle

Load Transfer System

Product Description

Features

The patented PD design features a tapered and sleeveless

plate dowel that provides the worlds best performance in

limiting joint deflection to provide superior joint stability.

The PD Dowel Cradle provides the highest deflection control

tolerance in line with ACI Standards recommendations to limit

joint spalling, facilitate load transfer and provide the lowest risk

of restraint to ensure the best serviceability outcome for the

slab design. The use of the PD system extends the life-cycle

of the floor to provide the highest level of floor efficiency for

tenants and the highest return on investment for the asset owner.

1. The PD Dowel Cradle features a plate dowel with bond breaker

allowing concrete to steel contact.

2. The PD Dowel Cradle utilises a tapered plate dowel that allows

lateral movement without the use of a plastic sleeve.

3. The wire cradle construction ensures the accurate placement and

alignment of the plate dowels at the correct centres and height

within the slab.

PD Dowel Cradles are designed to provide a total

contraction joint system solution by incorporating two

systems in the one solution. The tapered PD dowels that

allow for lateral movement eliminating the need for a plastic

dowel sleeve and the wire cage that acts as a chair and spacer

to ensure the dowels are aligned and maintained at the

correct height and spacing during the pouring of the slab.

Advantages

No plastic sleeves required.

Direct steel contact allows superior load deflection control.

Engineered to meet Super Flat Floor (SFF) requirements, ACI 360-R10.

The use of the PD Dowel Cradle creates a lateral and longitudinal

movement void.

Reduces the risk of restraint.

Dowel Plate to Concrete Direct Contact

Provides fast and accurate horizontal and vertical placement.

The PD Dowel Cradle tapered shape allows for the lateral

movement of the dowel without the need for plastic sleeves

to create cavities.

PD Dowel Cradles superior

engineered performance controls

floor flatness limiting joint spalling.

The elimination of the plastic sleeve from the dowel ensures

direct concrete to steel contact which provides the best

possible control of load deflection by eliminating the crush

factor of the plastic and providing a tighter control tolerance

than other sleeved plate dowel systems.

Slab Deflection

The absence of a plastic sleeve allows direct contact between

the steel plate and the concrete therefore providing minimal

chance of deflection, greatly reducing the risk of damage to

the joint edges.

Benefits

Sectional View of PD Dowel Cradle

Deflection <=0.25 to meet ACI 36O-R10

Concreter Benefits

Engineering Benefits

Speed and accuracy of

dowel placement.

Provides highest performance

in controlling joint deflection.

Lowest placement cost.

Compliance with ACI 360-R10,

design recommendations.

Ensures the flattest

floors at the joint.

Pour through capability.

Greater stakeholder

satisfaction.

Sectional View of Standard Plate Dowel Cradle

Possibility of 3.4 mm deflection

Delivers flatter joints, FF and FL,

ACI 117.

Accuracy of dowel placement

ensures the most effective

load transfer performance.

Asset Protection Benefits

Reduces the risk of spalling

damage to the concrete at

the joints.

Provides a smoother floor

surface at the joints which

ensures tenant efficiency.

Reduces floor maintenance

and downtime costs over

the life-cycle of the facility.

Increases tenant satisfaction

and return on investment.

Reduces wear and tear on

tenants materials handling

equipment.

Plastic sleeve

crushes under load

Please Note: These drawings are not to scale but illustrational to highlight potential load deflection.

(1)

PD3 Dowel Cradle

Load Transfer System

Lateral Movement Of Dowels (Plan View) - How PD Dowels provide lateral and longitudinal shrinkage

Panels shrink diagonally from corners.

If the left side panel shrinks more than

the right side panel differential shrinkage

needs to be accommodated

ACI 360-R10 States

(Chapter 6.2 - Load

Transfer Mechanisms)

Joint and crack stability

measurements below 0.25 mm

for joints or cracks subjected to

lift truck traffic with small hard

wheels will have good service life

As the panels shrink, a small void

is formed in the concrete by

the tapered dowel, allowing for

differential parallel shrinkage

Tapered PD Dowel

(dowel orientation alternates)

Joint opens up due

to slab shrinkage

Early entry sawcut

( slab depth) with

non-compressible

epoxy joint filler

Reinforcing mesh

supported by bar chairs

( the slab cover)

Slab height

(5%)

Slab height

Mesh Reinforced Slab Design - Typical Install

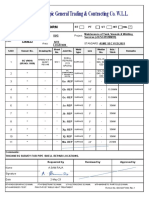

Material Technical Data

COMPONENT

DIMENSION

(mm)

MATERIAL TYPE

MATERIAL

STANDARDS

STEEL GRADE

EQUIVALENT

YIELD

STRESS (MPa)

TENSILE

STRENGTH

(MPa)

STANDARDS

COMPLIANCE

6 mm Dowel

6 x 300

Cold Drawn Steel

Q345

Grade 300

345

550

AS/NZS 3679.1

10 mm Dowel

10 x 300

Cold Drawn Steel

Q345

Grade 300

345

550

AS/NZS 3679.1

Hard Drawn Wire

AS/NZS 4671

Grade 500L

500

650

AS/NZS 4671

Ribbed Wire

AS/NZS 4671

Grade 500L

500

625

AS/NZS 4671

Wire Cage

Travel Bars

Manufacturing Tolerances (Standard Sizes)

OVERALL LENGTH

10 mm

OVERALL HEIGHT

5 mm

(2)

DOWEL CENTRES

5 mm

PD3 Dowel Cradle

Load Transfer System

Installation Guide

Correct Cradle installation:

1. Saw-cut approximately of slab depth.

5. Bar chairs should be as close to the cradle as practical.

2. Dowel height at slab height.

6. Mesh should not overhang past the edge line of the cradle.

3. The mesh should be supported by bar chairs to rest

approximately of the slab height.

7. Mesh should not touch the edge of the cradle, allowing concrete

flow between the mesh and the cradle.

4. Bar chairs should keep the mesh parallel at consistent depth.

Incorrect Cradle Installation:

1. Mesh is too close to top

surface of the slab.

2. Mesh is too close to the

line of the saw cut.

Saw-cut too shallow to be

effective, the crack has not

generated from the top of

the slab therefore the crack

has found its own path to

the surface.

Saw-cut too deep, the load

transfer system has been cut

and therefore has rendered

it ineffective in controlling

deflection.

(3)

PD3 Dowel Cradle

Load Transfer System

Tools Required: Mark Out Paint | Hammer | Wire Cutter

Step 1.

Step 3.

iNSTALLATION

iNSTALLATION

Installation

Installation Process

Mark out joint lines on sub-grade with mark out paint to allow straight and

The mesh should be supported by bar chairs to rest approximately of the

accurate placement of PD Dowel Cradles.

slab height. Make sure mesh is placed back from the joint line (in line with

Place cradles along mark out lines with the PD dowel centred over joint line.

the edge rail of the cradle), do not place directly on the cradles.

Place cradles end to end ensuring dowel spacing is maintained at correct specified

Pour through concrete, ensuring that both the cradles and the reinforcement

spacing. Cradles can be cut to provide infill lengths. Optional Danley Hold Down

are not displaced.

Stakes can be used to secure the cradles in position for the pour.

Important: Do not run cradles through intersections. See intersection positioning

diagrams below for correct layout.

Step 4.

Step 2.

iNSTALLATION

iNSTALLATION

Prior to the pour, cut the 4 mm travel bars (3 cross wires that hold the wire

frames together). Failure to do so may lock the joint.

Form the joint with a soffcut ( slab depth) as soon as the concrete will support the saw

and operator. This is usually within 2-4 hours of the last pass of the power trowel.

Dowel Application Key Points

Dowels are needed to reduce the differential

deflection between adjacent panels so

that lift truck wheels do not create joint

spalling resulting in high maintenance and

rectification costs.

Joint spalling is the critical failure mode of

the joint. Joint systems should be designed

for serviceability (rather than ultimate load).

Dowel selection should be based on the

floor flatness tolerance required.

Control of deflection and cracking

without reducing slab strength should

be the key design factor.

Concrete strength is generally the

controlling factor after the deflection

control considerations.

The dowel systems should never introduce

risk of restraint and uncontrolled cracking

at any time.

Oversized and over strength dowel

systems raise the risk of concrete bursting.

Dowel systems should maximize the

load at the slab edge and minimize the

bursting risk past the joint.

Danley Systems consider the correct type

and amount of doweling required to

control deflection for the type and rated

capacity of the lift truck to be used.

PD Dowel Cradle Positioning

3-Way Intersection Detail

4-Way Intersection Detail

(4)

Standard Length Detail

PD3 Dowel Cradle

Load Transfer System

Specification

How to write a Specification

Product specification for PD Dowel Cradle consists of:

PRODUCT CODE, Dowel Thickness, Dowel Centres,

Slab Height and Finish (Black or Galvanised)

e.g: PD306450150B

REQUIRED INFORMATION

For quoting or manufacturing the following formation is required:

Danley Product Code

Dowel Thickness

Dowel Centres

Dowel

Finish

B/Galv.

Slab Height

Plan View

Standard cradle length 3000 mm

Centres as specified

Dowel positions alternate

Travel bars to

be cut before

pouring concrete

Standard dowel length 300 mm

Slab height

Slab height

Section At Contraction Joint

Standard dowel

options 6 mm

or 10 mm

(5)

Early entry sawcut

( slab height)

PD3 Dowel Cradle

Load Transfer System

PD Dowel Cradles

can be easily cut to required

lengths or butted together to

form large runs and Intersections

PD3 Dowel Cradle Panel Layout

Construction Joints

ArmourMate or loose dowels

(Diamond Dowels) positioned around

the perimeter of each concrete pour.

Contraction Joints

PD Dowel Cradles positioned

at the soffcut joint lines.

Typical 30 x 30 meter slab panel.

(6)

1.

Companion Products

1. ArmourMate

For edge protection of construction joints, Danley ArmourMate provides a range of solutions to best prevent damage

and joint spalling associated with impact from materials handling equipment and other traffic. Joint edge protection

systems can be incorporated into Danley full joint solutions with sacrificial formwork and load transfer systems.

2.

2. Diamond Dowel

Diamond Dowels are plate dowels suited for construction joints in concrete slabs and pavements. They transfer

vertical loads across the joint and minimise differential deflection between adjacent slab panels under load. Easy

to install they attach directly to wooden formboard or metal separation plates. They come pre-packaged with all

components ready for installation.

3. Crack-A-Joint

As an option to saw cutting, place Crack-A-Joint into the wet concrete along the joint line (above the centre of the

PD Dowel Cradle), to induce a crack for the full depth of the concrete. The Crack-A-Joint is available in standard

3 m lengths formed from galvanised sheet steel to a height of 25 mm. It can be supplied as a plain joint or with a

permanent Rip-A-Strip capping in three different colour options (Black, Grey or Sandstone).

3.

4. Ground Crack Inducer

An inverted V-shaped PVC extrusion, 3 m long and available in 25 mm and 50 mm heights. It is positioned on the subgrade before the PD Dowel Cradles are placed. It produces a weakening in the slab that initiates a crack from the

bottom up. Ground Crack Inducer is optional and should only be used when Crack-A-Joint is used, or when saw cuts

are to made in the slab on the same day as the slab is poured.

4.

5. Cradle Hold Down Hook

A small optional wire hook that allows you to anchor the base of your Cradles into the site sub-base. It prevents the

PD Dowel Cradles from moving during the pour process. They hook over the bottom wire of the Cradles securing

them to the ground.

1300 DANLEY (1300 326 539)

5.

www.danley.com.au | sales@danley.com.au

Other related ITW Construction Systems brands

Rev 1 - April 2015

Innovative engineered solutions for the concrete construction

industry with specialty in the design of precast and tilt-up.

Market leading brands that include SwiftliftTM Concrete Lifting

solutions, ReidbarTM Threaded Reinforcing, NirvanaTM Insulated

Panel System and a range of Architectural Concrete products.

Expansion Joint systems for civil and architectural specification

that includes Floor, Wall, Roof, Facade, and Seismic engineered

solutions for Retail Centres, Multi-level Carparks, Hospitals, Bridges

and most other suspended slab environments.

Manufacturing one of the largest ranges of plastic concrete

accessories, bar chairs and spacers, as well as components for

formwork and precast. Working closely with end users, Modfix

has continued to assist in the development of new, cost effective

solutions for the building and construction industries.

www.reid.com.au

www.reids.co.nz

www.miska.com.au

www.modfix.com.au

www.itwcsanz.com | info@itwcsanz.com

Disclaimer: The information contained in this publication is intended to give a fair description of the products and their capabilities.

No responsibility or liability by the manufacturers will be accepted for misuse, misreading or deviation from the recommended guidelines of these products.

As new technology is introduced, or industry standards are altered, ITWCS reserves the right to alter the information without notice.

Você também pode gostar

- Civl432 Bridge Design SummaryDocumento5 páginasCivl432 Bridge Design SummarySheikh Mizanur RahmanAinda não há avaliações

- Fabrication-RNG 24.08Documento230 páginasFabrication-RNG 24.08Habib Ur Rahman100% (1)

- Good Practices For Requirements EngineeringDocumento4 páginasGood Practices For Requirements EngineeringJessicaAinda não há avaliações

- PSC GirderDocumento73 páginasPSC GirderHegdeVenugopal100% (1)

- 26.techtips Sheavesgrooves enDocumento5 páginas26.techtips Sheavesgrooves enVinit AhluwaliaAinda não há avaliações

- Layout and MeasuringDocumento10 páginasLayout and MeasuringRobbie van Leeuwen100% (3)

- Term Paper: Topic:-Dowel BarsDocumento15 páginasTerm Paper: Topic:-Dowel BarsAtish Kumar100% (2)

- Plate Dowels: An Innovation Driven by Industrial Concrete PavingDocumento6 páginasPlate Dowels: An Innovation Driven by Industrial Concrete PavingRizaam Nafiz100% (1)

- 16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionDocumento89 páginas16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionHimanshu SainiAinda não há avaliações

- How to Build a Global Model Earthship Operation II: Concrete WorkNo EverandHow to Build a Global Model Earthship Operation II: Concrete WorkAinda não há avaliações

- Conveyor ComponentsDocumento26 páginasConveyor Componentswmacadd100% (6)

- Effective Methods For Mounting Rail Systems On Concrete FoundationsDocumento7 páginasEffective Methods For Mounting Rail Systems On Concrete FoundationsRana Mubbashir IqbalAinda não há avaliações

- Effective Methods For Mounting Rail Systems On Concrete FoundationsDocumento7 páginasEffective Methods For Mounting Rail Systems On Concrete FoundationsCalva BarreraAinda não há avaliações

- Reinforced Concrete Slab Design Using The Empirical MethodDocumento9 páginasReinforced Concrete Slab Design Using The Empirical MethodRezky MuliaAinda não há avaliações

- Belt Conveyor DesignDocumento21 páginasBelt Conveyor DesignRajesh RanjanAinda não há avaliações

- What Do You Mean by Formwork?: Formwork Is The Term Given To Either Temporary or PermanentDocumento7 páginasWhat Do You Mean by Formwork?: Formwork Is The Term Given To Either Temporary or PermanentJoel MathewAinda não há avaliações

- Reinforced Concrete Buildings: Behavior and DesignNo EverandReinforced Concrete Buildings: Behavior and DesignNota: 5 de 5 estrelas5/5 (1)

- Internals For Down Flow ReactorsDocumento12 páginasInternals For Down Flow Reactorsrodriguez.gaytanAinda não há avaliações

- PB Chapter-3Documento44 páginasPB Chapter-3SHOBHIT KUMARAinda não há avaliações

- Practical Aspects of PSCDocumento73 páginasPractical Aspects of PSCNagpur-Civil MRIDCAinda não há avaliações

- Phraseology From AIP v2 PDFDocumento38 páginasPhraseology From AIP v2 PDFRobbie van LeeuwenAinda não há avaliações

- Casting Box Girder Segments - tcm45-342871Documento3 páginasCasting Box Girder Segments - tcm45-342871AuYongTheanSengAinda não há avaliações

- Rigid Pavement ManualDocumento30 páginasRigid Pavement ManualSarfaraj KhanAinda não há avaliações

- Plate GirderDocumento74 páginasPlate Girderarif_rubin100% (1)

- Hanson Structural Precast ProductsDocumento24 páginasHanson Structural Precast ProductsTanja DjordjevicAinda não há avaliações

- Presented by C.Kevin Joseph B.Tech (CIVIL) Iii YearDocumento68 páginasPresented by C.Kevin Joseph B.Tech (CIVIL) Iii YearVetri VelanAinda não há avaliações

- 5 Liner HangersDocumento26 páginas5 Liner HangersAjar Waspodo50% (2)

- Practical Aspects of PSCDocumento73 páginasPractical Aspects of PSCAnde BhanuAinda não há avaliações

- Sisbang Lotte PDFDocumento17 páginasSisbang Lotte PDFadityaCS3Ainda não há avaliações

- SAFETY in Form Work ProgramDocumento73 páginasSAFETY in Form Work ProgramBharath CjAinda não há avaliações

- Culvert Structural DesignDocumento54 páginasCulvert Structural DesigntipsypigAinda não há avaliações

- Hollow Core HandlingDocumento4 páginasHollow Core HandlingSulaiman Mohsin AbdulAzizAinda não há avaliações

- List of Philippine Aviation Schools, Colleges and UniversitiesDocumento12 páginasList of Philippine Aviation Schools, Colleges and UniversitiesJojo Banzon100% (2)

- Belt Conveyor DesignDocumento21 páginasBelt Conveyor DesignAjith100% (1)

- Lindquist - Secant Pile Shoring - Developments in Design and Construction (DFI2011)Documento8 páginasLindquist - Secant Pile Shoring - Developments in Design and Construction (DFI2011)frog15Ainda não há avaliações

- Stud RailsDocumento3 páginasStud RailsBruno PilieciAinda não há avaliações

- Substructure Taking OffDocumento4 páginasSubstructure Taking Offlutos2100% (5)

- Speed PlateDocumento4 páginasSpeed PlateBibhawesh PandeyAinda não há avaliações

- 16 - Bruce Ireland - Joint DetailsDocumento32 páginas16 - Bruce Ireland - Joint DetailsTian NgAinda não há avaliações

- Precast-Pretensioned Concrete Girder BridgesDocumento27 páginasPrecast-Pretensioned Concrete Girder BridgesglaydelleAinda não há avaliações

- Road Construction DetailsDocumento29 páginasRoad Construction DetailsARUNKUMAR KAinda não há avaliações

- 61a561ec302e2916e11eb4d9 - 2021 Speed Plate Dowel PDFDocumento5 páginas61a561ec302e2916e11eb4d9 - 2021 Speed Plate Dowel PDFAmin AriaeAinda não há avaliações

- Lecture 7-Plate GirdersDocumento44 páginasLecture 7-Plate GirdersBaraka GotoraAinda não há avaliações

- Test 3 FinalDocumento8 páginasTest 3 FinaladithyaAinda não há avaliações

- Sub Con Unit 2 NotesDocumento15 páginasSub Con Unit 2 NotesDarshan KrishnaAinda não há avaliações

- High Performance Composite: SolutionsDocumento24 páginasHigh Performance Composite: SolutionsRay GongAinda não há avaliações

- Pranay Kumar Tode Pktode@yahoo - Co.inDocumento44 páginasPranay Kumar Tode Pktode@yahoo - Co.inKhabib IbragimovAinda não há avaliações

- CG enDocumento24 páginasCG enFederico.IoriAinda não há avaliações

- Bridge Design Considerations - NBDocumento32 páginasBridge Design Considerations - NBkaliabala420Ainda não há avaliações

- Practical Aspects of PSCDocumento73 páginasPractical Aspects of PSCPrem DheepAinda não há avaliações

- Shell StructuresDocumento27 páginasShell StructuresAshish A.Ainda não há avaliações

- Cable Tray SOPDocumento21 páginasCable Tray SOPHasnain NiazAinda não há avaliações

- Pranay Kumar Tode Pktode@yahoo - Co.i NDocumento44 páginasPranay Kumar Tode Pktode@yahoo - Co.i NToyeeb ArowonaAinda não há avaliações

- Introducing Pulleys Into Cable SystemsDocumento4 páginasIntroducing Pulleys Into Cable SystemsYudi SusantoAinda não há avaliações

- Precast Options For Bridge Superstructure DesignDocumento18 páginasPrecast Options For Bridge Superstructure DesignrammirisAinda não há avaliações

- Bridge Design NotesDocumento39 páginasBridge Design NotesGabriel BroascaAinda não há avaliações

- RoofDocumento31 páginasRoofsamAinda não há avaliações

- Ancon Shear Load ConnectorDocumento30 páginasAncon Shear Load ConnectorJonathan WardropAinda não há avaliações

- 1129011951BMCS4Documento24 páginas1129011951BMCS4DHEESHNA DILEEP 200545Ainda não há avaliações

- The Advantages Includes The Following:: SimplicityDocumento26 páginasThe Advantages Includes The Following:: SimplicityEbrahim ElnadyAinda não há avaliações

- Earthbound Canada 2011Documento12 páginasEarthbound Canada 2011Christopher GarciaAinda não há avaliações

- TL 5 X 10Documento10 páginasTL 5 X 10number_25Ainda não há avaliações

- DFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDocumento10 páginasDFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDaniel MarínAinda não há avaliações

- Technical CharacteristicsDocumento36 páginasTechnical Characteristics76027074Ainda não há avaliações

- RCC Floorings PDFDocumento32 páginasRCC Floorings PDFOmei KhaireAinda não há avaliações

- Sewage Disposal Works: Their Design and ConstructionNo EverandSewage Disposal Works: Their Design and ConstructionAinda não há avaliações

- Workedproblems PDFDocumento14 páginasWorkedproblems PDFRobbie van LeeuwenAinda não há avaliações

- AnconDocumento40 páginasAnconRobbie van LeeuwenAinda não há avaliações

- Matlab For Advanced Users, WI4141TU: K.dekker@tudelft - NL P.wilders@tudelft - NLDocumento7 páginasMatlab For Advanced Users, WI4141TU: K.dekker@tudelft - NL P.wilders@tudelft - NLRobbie van LeeuwenAinda não há avaliações

- Ramset Specifiers Anchoring Resource Book ANZ - SpaTec Plus Mechanical AnchoringDocumento8 páginasRamset Specifiers Anchoring Resource Book ANZ - SpaTec Plus Mechanical AnchoringRobbie van LeeuwenAinda não há avaliações

- Engineering Competency StandardsDocumento11 páginasEngineering Competency StandardsRobbie van LeeuwenAinda não há avaliações

- Final Student Handbook - 2Documento35 páginasFinal Student Handbook - 2Girmaye Haile GebremikaelAinda não há avaliações

- Internship Experience Speech Sabtiwu MDocumento3 páginasInternship Experience Speech Sabtiwu Msabmoro88373Ainda não há avaliações

- P InstrumentationDocumento13 páginasP Instrumentationابزار دقیقAinda não há avaliações

- Connection Types: Simple (Shear) ConnectionsDocumento5 páginasConnection Types: Simple (Shear) Connectionsmahhor82_635643838Ainda não há avaliações

- Ryan Rahmat SetiajiDocumento1 páginaRyan Rahmat Setiajiian111980Ainda não há avaliações

- Final Convocation BrochureDocumento28 páginasFinal Convocation Brochurestorm.iitkAinda não há avaliações

- VEDA IIT Course Details - 2012Documento4 páginasVEDA IIT Course Details - 2012jaiminrf100% (1)

- Engineering Dept ScopeDocumento3 páginasEngineering Dept ScopeSehrishAinda não há avaliações

- 5a Engine Ecu Pin OutDocumento2 páginas5a Engine Ecu Pin OutARTURO JESUS Kcomt33% (3)

- 5 Required Courses For Certificate - As of June 2022Documento1 página5 Required Courses For Certificate - As of June 2022singhjobanjit99Ainda não há avaliações

- ANSYS 2d PlaneDocumento13 páginasANSYS 2d Planeadnan100% (1)

- Manual Digi CommDocumento120 páginasManual Digi CommsakshamAinda não há avaliações

- An Introduction To ElectronicsDocumento252 páginasAn Introduction To ElectronicsSvetlanaSvetle100% (1)

- 153 - EPTISA-GM P-2020 - Proposal of Mr. Suhail Khandal For Position of Material EngineerDocumento3 páginas153 - EPTISA-GM P-2020 - Proposal of Mr. Suhail Khandal For Position of Material EngineerMohd UmarAinda não há avaliações

- Construction of Prefabricated CulvertsDocumento2 páginasConstruction of Prefabricated CulvertsJonah ScottAinda não há avaliações

- Observations:: Submitted by Divya Sree Chamarthi, MBA - ADocumento1 páginaObservations:: Submitted by Divya Sree Chamarthi, MBA - AManoj NagAinda não há avaliações

- Trends in Electrical TransmissionDocumento47 páginasTrends in Electrical TransmissionSumit Kumar DattaAinda não há avaliações

- Kohinoor SquareDocumento12 páginasKohinoor SquareAnurag sivaramanAinda não há avaliações

- 2Documento31 páginas2koko srihandokoAinda não há avaliações

- Agile Model in Software EngineeringDocumento40 páginasAgile Model in Software EngineeringThanh PhamAinda não há avaliações

- Nde Request - Thickness SurveyDocumento1 páginaNde Request - Thickness SurveySam RajaAinda não há avaliações

- Shahkar Azam Civil Engineer ResumeDocumento2 páginasShahkar Azam Civil Engineer ResumeazamshahkarAinda não há avaliações

- Code of Professional Ethics For Civil EngineersDocumento6 páginasCode of Professional Ethics For Civil EngineersVictor LimAinda não há avaliações

- Chapter 14 Security Engineering 1Documento48 páginasChapter 14 Security Engineering 1Fattah MuhyiddeenAinda não há avaliações

- Lab Manual - EEE18R171Documento86 páginasLab Manual - EEE18R171K.V. PrabhasAinda não há avaliações