Escolar Documentos

Profissional Documentos

Cultura Documentos

The Packages PDF

Enviado por

RaghDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

The Packages PDF

Enviado por

RaghDireitos autorais:

Formatos disponíveis

Page 149 of 462

4.0

THE PACKAGES

4.1

Foreword

With the technical term package, it is indicated by the Engineering

Companies, but generally speaking in the industrial field, a small

system constituted by two or more equipment, connected each others

with piping, including some instruments and often electric components;

therefore in this little plant, four of the six classic departments of the

Engineering

Company

are

present:

Mechanical,

Piping,

Instrumentation, Electrical.

The Civil work department is indirectly involved, in the sense that this

small plant has, of course, to stand and to rest on a basement, but the

Civil Word division could be directly concerned, for example, in case

that the Package should include a steel structure; the Process

department obviously, does not appear in evident manner, but it is

upstream located, being the guide and the informing principle of all the

equipment and complexes.

We have repeated more times little plant, small system to indicate

the package. But there are also significant units, for size and

complexity, which can be considered as a package unit.

Among these complex packages we will deal with, as examples, the

Pneumatic Transport System and Air Conditioning System.

As far as the small packages are concerned we will consider, as

examples, three of them: Solid Handling System Oil Water Treatment

Unit Dosing Unit.

STP-011/13

Just for curiosity we want remind that the term package comes from

the English word package that in the common acception means

parcel of things packed together.

Page 150 of 462

4.2

Air Conditioning System

4.2.1 Notes on the Psychrometry

The atmosphere, in which we live, is constituted by a mixture of dry air

and water vapour.

Its moisture content is referred to as humidity. The proportion of

moisture in the air, affects personal comfort.

The psychrometry studies the properties of the mixture air-vapour, with

particular regard to the ambient and technological necessities.

4.2.1.1 Psychrometric Diagrams

Since a conditioning system has to provide a proper thermo-hygrometric

treatment of the air, it is convenient to use suitable charts for the

calculation of such treatment. There are various types of these charts:

Molliers diagram, Carriers diagram, Carr-Ashraes diagram.

We will refer to the ASHRAE in the metric version provided by CARR

group.

4.2.1.2 Application of Psychrometric Chart

It is sufficient to have two quantities, to get all the other ones.

Example (see the attached diagram 2.1.2.F):

dry air temperature

30C

wet bulb temperature

21,3C

STP-011/13

We can read from the diagram:

specific humidity

12,2 g/kg

relative humidity

47%

specific volume

0,875 m3/kg

temperature of dew point

17,1C

enthalpy

14,7 kcal/kg

STP-011/13

Page 151 of 462

Page 152 of 462

4.2.2 Ambient Conditions for the Comfort

4.2.2.1 Comfort, Industrial and Production Conditioning

Purpose of the air conditioning is the one to generate, in the ambient,

satisfactory conditions for the presence of people.

The purpose of the industrial conditioning is the one to get artificial

climate in order to permit the carrying out work particular cycles,

dictated by requirement of technological process.

The conditioning of production borns from the necessity to conciliate

demands imposed by established technological process with the ones of

comfort for the continuous presence of operators. We will analyze

various cases, taking however into account that we can pass from a

system to another one, for the calculation, only changing the

parameters.

4.2.2.2 Basic Parameters

The basic parameters for the air conditioning are:

Pureness of the air

Velocity of the air near the people

Temperature

Relative humidity

Pureness of the Air

The impurities developed inside the air conditioned rooms as toxins,

smokes, bad smells can be eliminated by means of air changes with

external air.

STP-011/13

In the following table are indicated the air changes per hour for different

building or room, with the note that air changes up to eight per hour,

provide for removing contamination normally caused by human

occupants.

The higher rates of air changes provide for removing heat and steam in

temperate zones.

Page 153 of 462

The indicated table refers to the pure ventilation; it is clear that air

changes higher than 8 can be reduced with a complete air conditioning.

Other adopted criteria are:

On the basis of the number of occupants (20 80 m3 per

occupant);

On the basis of quantity of fresh air in relation to the volume air

on work ambient ( 1 2 air changes per hour, till to 8 changes);

On the basis of surface of the floor (2 8 m3/h per square meter

of floor).

Velocity of the Air near to the People

The range of the values of the air velocity near the person is limited

between 10 20 cm/sec. Of course, these values have nothing to do

with the velocity at the outlet of the diffuseurs or grilles.

Temperature and Relative Humidity of the Air

Statistics and various experiences suggest the following values for

temperature and relative humidity:

for the R.U. on assume a value between 40% and 70% (normally

50%) both in summer and in winter

for the temperature on assume a value limited between 18C and

20C (max. limit of 20C has been fixed in order to reduce the

energetic consumption) while, in summer the suggested

temperature is connected to the external one, by means of the

relation

te

ti =

+ 10

STP-011/13

2

that means that, with the increasing of the external temperature also

the internal temperature rises, and this is not only for energy saving

reasons, but also in order to limitate the (delta) between inside and

outside, since the human organism well tolerates positive sudden

changes of temperature, while does not tolerate negative sudden

Page 154 of 462

changes. Always for comfort reasons, the difference of the temperature

of the entering air and the air present in the room, has to be controlled.

The advised values are:

te = 8 12C summer

ti = 12 14C winter

As far as the allowance on the thermo-hygrometric conditions is

concerned, usually on assume a value of 5% for the U.R., and 1%

for the temperature, in accordance with the normes UNI 5104.

Ventilation Requirements

TABLE 1 Air Changes per Hour

Situation

Assembly Halls

Bakeries

Banks

Banquet Halls

STP-011/13

Billiards Rooms

Air changes per hour

4-6

20-30

2-4

6-10

6-8

Boiler Houses

20-30

Cafs and Coffee Bars

10-12

Canteens

4-6

Churches

-1

Cinemas

10-15

Club Rooms

8-10

Dance Halls

6-8

Dye Works

20-30

Engine Rooms

20-30

Factories (Workshops)

6-10

Foundries

20-30

Furnace Shops

30-60

Page 155 of 462

Garages

6-8

Hospitals: General Wards

4-6

Hotel Bars

4-6

Kitchens (Commercial or School)

15-20

Kitchens (Domestic)

10-15

Laboratories

Lavatories

10-15

Laundries

20-30

Machine Shops

6-10

Mushroom Houses

10-20

Offices

4-6

Paint Shops

30-60

Photographic Darkrooms

10-15

Pig Houses

6-10

Poultry Houses: Deep Litter

6-10

Residences

1-2

Restaurants

6-10

School Classrooms

STP-011/13

4-6

2-3

Ships Accomodation Lounges

10-20

Ships Apple Storage

20-30

Ships Cargo Holds (general)

6-10

Ships Holds carrying Eggs, Meat, etc.

10-20

Swimming Baths

20-30

Theatres

10-15

Page 156 of 462

4.2.3 Types of Air Conditioning Plants

4.2.3.1 General

All types of plant have, as common unit, equipment called air

treatment unit.

The air treatment units have the task to provide for the air, to be sent

into various rooms, different treatments according to the project

requirements.

The obtaining of these results is reached by means of modular

construction of particular equipment called as already said air

treatment units (ATU or in Italian Language UTA).

The linking of different sections, each of these able to develop a

determinate operation, allows to obtain the necessary performance for

the plant with high precision.

These units do not usually include the components for the production

of hot and cold fluids; such machines, refrigeration units and heat

generators, have to be provided separately.

The air treatment units, are normally constituted of the following

sections:

Mixing sections of fresh air and recirculated air

Filtration section

Pre-heating coil section

Humidification section

Cooling and dehumidification coil section

Post-heating section(*)

Ventilation section

STP-011/13

Now we will examine the main air conditioning plants, with the remarks

that the combination of these, can give place to many other systems,

each of them with its particular characteristics.

(*) According to various cases, the post-heating battery, can be located

into ducting.

Page 157 of 462

4.2.3.2 Conditioning Systems for Single Zone

This is the more simple type of the air treatment unit. From the unit,

the air is supplied, at the required conditions controlled by thermostat

and/or humidistat of zone, to the various rooms.

The air, so distributed can treat a zone (constituted by one or more

rooms) where the thermo-hygrometric conditions are uniforms.

4.2.3.3 Conditioning of Multiple Zones Type

The air conditioning system of multiple zones type, is the natural

extension of the single zone one, when the various rooms, to be

conditioned, have different thermo-hygrometric requests.

Substantially on dials of only one conditioning group, but the ducting of

which, is splitted into various ducts, each of them serves one room (or

one group of room). At the beginning of the ducts post-heating coils are

installed; these coils are controlled by their respective thermostats.

Usually, a pilot room (the more binding one for extension and for

thermal loads) is selected to demand and control the cold requirement,

while, for the other rooms, the regulation is obtained by the postheating the air at the required temperature.

Therefore it can happen that in summer, the maximum cooling power,

on the basis of which the plant has been dimensioned, is neutralized by

means of these post-heating treatments. We understand very well as the

exercise cost, for this type of plant, can considerably raise, in

comparison with the plant of single zone type.

4.2.3.4 Conditioning System of Multi-Zones Type

STP-011/13

The systems of air conditioning of multizone type, as the ones of

multiple zones, permit the simultaneous air conditioning of more rooms

or groups of rooms which present different thermic internal loads.

But, while the air conditioning plants of multiple zone type,

substantially born from the single zone system, with subsequent

splitting of the air supply ducting into additional ducts, the multi zone

systems consist of centralized air treatment units of package type that

contain just inside the unit, the splitting into zones.

Page 158 of 462

In detail, the conditioners are constituted of mixing section of fresh air

and recirculated air, a filtering section, a fan section, one treatment

section including, in parallel, one cooling coil and one heating coil, and

at the end a set of mixing dampers (one for each foreseen zone) for the

variation of mixture ratio between the hot air and the cold air, with a

constant flow rate for each zone.

These dampers are located at the outlet of the unit and each couple of

dampers is at the head of one independent duct.

4.2.3.5 Conditioning System of Air-Water Mixed Type

In this type of plant, the supply of heat and cold into rooms to

compensate the thermic-hygrometric load is given both to the air and to

the water.

The water at the required temperature is sent, by piping to the local

unit that include one coil, one filter and one fan, called fan coil, while

the primary air is sent to the various rooms by ducting.

The fresh air is submitted to the same treatments in an air treatments

centralized unit already described. It is clear that in this case the unit,

treating only external air, is smaller, under similar conditions than ones

which have to treat fresh and recirculated air.

This type of plant permits, in comparison of other types, great flexibility

in the design and in the planimetric arrangement.

For example the fan-coils can be visible (under the windows for

example) or located in the false ceiling.

There is also the possibility to carry out an air conditioning plant

without the use of centralized air treating unit, simply by providing the

local units by means of external air intake.

STP-011/13

The limits of this simplified system are easy to individuate.

Page 159 of 462

4.2.3.6 Conditioning System of Double Duct Type

With this system the cooling and heating coils are properly placed in

order to feed two separated ducts which depart from the unit.

One duct conveys the cooled air, the other one the hot air, both arriving

to the rooms which have to be air conditioned. In each room, a mixing

box is installed provided with conjugated dampers which provide for the

mixing of the two air flows coming from the conditioners, according to

the ambient thermostat.

Generally speaking this air distribution is made at high speed (mainly

for space reasons) and therefore the mixing boxes have also the

function to attenuate the velocity and the noise. The system of double

duct type, is a system of quality, particularly suitable for large

complexes both civil and industrial.

4.2.4 Filtration of The Air

As already said one of the purpose of the air conditioning plants, is the

one to maintain in the served rooms, a proper pureness of the air; the

above is usually got, by means of adequate changes of fresh air, but in

the mean time, by cleaning fresh air and recirculated air by means of

proper filtration system.

The choice of the more suitable filter depends from various factors,

mainly connected to the characteristics of impurities present in the air

and to final destinations of the conditioned places.

The main characteristics of the filter are: the efficiency, the retention

capacity and load losses.

The filter efficiency is measured by the ratio:

up stream concentration down stream concentration

eff. =

x 100

STP-011/13

up stream concentration

Page 160 of 462

4.2.5 Equipment of the HVAC Systems

The main equipment used in the HVAC system, in addition to the air

treatment unit, already described, are mentioned here below,

accompanied with a very short description: for more detailed

specification, man has to refer to specialised literature.

4.2.5.1 Monoblock Self-Contained Conditioning Units

These equipment, foreseen for inside or outside installation, are

constituted by two parts assembled in the same box:

One moto

condensation

condensation

condensation

condensing unit composed by compressor,

coil and fans for the cooling of the coil if

is made by air, or by heat exchanger if the

is of water type.

One evaporating section composed by a cooling coil, of direct

expansion type, a centrifugal fan for the supply and return of the

air, filters and the necessary piping and valves. A control panel is

also provided.

Therefore it is realised a complete and hermetically closed refrigerating

circuit. In this case the unit require only to be connected to the supply

and return air ducts and the electric and hydraulic feeding.

STP-011/13

These monoblock units are available on the market for a powers range

from 10 to 200 Kw.

Page 161 of 462

4.2.5.2 Self-Contained Conditioning Unit, Roof Top Type

These units, belonging to the self-contained type previously seen, are

foreseen for outside installation to be positioned on the roofs of the

building, for the direct climatization of the below rooms. Depending

from the refrigerating requested capacity, these conditioners can be

equipped with one, two or more compressor, with the condensating and

evaporating coils in one or more sections.

4.2.5.3 HVAC System, Split Type

The air conditioning machine of split type are constituted by a motocondensing unit air cooled for outside installation and by a

ventilating/evaporating unit (that can be provided with ducting) to be

positioned inside. Both the units have to be connected each to other

with 2 refrigerating lines (one for the refrigerating liquid, the other one

for the gas). Of course, electrical lines have to be also provided.

These split units originated for the cooling, can be today used for the

heating, on the basis of the heat-pump principle.

We can find on the market, split units of various capacity:

Split units of 1,5 15 Kw refrigerating power.

They are employed

applications.

STP-011/13

for

residential

and

light

commercial

Split units with a refrigerating power till 80 Kw.With these

capacities it is possible to carry out systems provided with a

certain extensive ducting or it is possible to carry out VFR

systems (Variable Refrigerant Volume) of minor power but that

can be connected to a greater number of internal units. This type

can be used also for minor industrial buildings.

Page 162 of 462

4.2.5.4 Refrigerant Groups of Compression Type

Of course, in addition to the self-contained equipment, previously

noted, refrigerant groups of compression and absorption type are used,

especially for high refrigerating capacity.

Here below we give short notice on the refrigerant groups of compressed

type for capacities till 200 Kw compressors, scroll type are used.

For higher capacities till to 900 Kw the screw compressors are

employed.

Over these capacities the centrifugal compressor are used.

The refrigerating fluids, now given up the Freon, are the HFC 410 A for

the refrigerating groups of scroll type and HFC 134 A for refrigerating

groups, screw and centrifugal type.

4.2.6 Data and Information to be given to the HVACs Supplier

4.2.6.1 General

Purpose of an air conditioning plant consists, as already said, of the

simultaneous control of the temperature, relative humidity, ventilation

and pureness of the air.

Before starting in the design it is necessary to gather and to organize all

the information and the available data, to be transmitted, attached to

the Material Requisition to the suppliers of HVAC System, intended as

Package Unit.

STP-011/13

It remains understood that an engineering company can design, define

and purchase the single items constituting the HVAC plant, without

applying to the specialised supplier of HVAC system; this choice

depends from the internal resources of the engineering company

(availability of specialists in this field) from the complexity of the system

and for the timing. It is a fact that, apart little systems as electrical

substations or offices, it is always more convenient to address to

specialised Vendors, the sole responsible of the HVAC plant.

Page 163 of 462

These data and information will include:

Drawings of the buildings and of the rooms

(plants and sections)

to be conditioned

Design external conditions (temperature, relative humidity, in

winter and summer)

Design internal conditions (temperature, relative humidity, with

the required tolerances, filtration level)

Type and thickness of the walls, floors, ceilings and roofs

Characteristics of doors, windows, rolling shutters or curtains

Internal sources of heat (for each room) gains from:

- lighting : w

- crowding: n of people

- fluid evaporating: kg/h

- stoves, heater, dryer: kcal/h

characteristics of the utilities:

- water, compressed air, steam, electric power

use of the rooms (offices, laboratory, control room, etc.)

type of the required system:

STP-011/13

- all air, air and fancoils, air and split units, etc.

Number of the required air changes

Room foreseen for the installation of air conditioning equipment

Foreseen daily hours of operation.

Page 164 of 462

4.2.6.2 External Thermohigrometric Design Conditions

The external design conditions change for the different geographic

locations. It is not reasonable to dimension the plants for the heaviest

conditions that happen during only few hours in a certain years

number; this should cause additional costs with the limited benefits.

Standard tables indicating external design conditions are generally

adopted, in case of lack or other requests and indications.

4.2.6.3 The Heat Transmission through the External Structures due to the

Temperatures Difference

The transmitted heat, in regime condition, through a wall because of

the different temperatures between external and internal air, is given

by:

q = K S (te ti)

where

S = wall area m2

te = external temperature

ti = internal temperature

K = global coefficient of thermic transmission kcal/m2 Ch

Where K is given by:

1

=

K

+

c

ai

ae

STP-011/13

or more generally for composite structures

=

K

S1

S2

Sn

+ .

ai

c1

c2

ai, ae = unit surface conductances in kcal/h m2C

+

cn

ae

Page 165 of 462

s1, s2,sn = thicknesses of the various layers of structure in m

STP-011/13

c1, c2,cn = coefficients of thermal internal conductivity of materials per

kcal/m hC

Page 166 of 462

Thermal Internal Conductivity c (kcal/m hC) for some materials

Materials

Specific weight kg/m3

Asphalt

0,6

2.400

Bitumen

0,15

1.050

- cement, sand, gravel, armor Fe

1,2

2.100

- cement, sand gravel

1,0

1.800

- pumice

0,31

1.150

- cellular

0,2

700

Cement

0,78

820 + 1.950

Cardboard

0,23

1.300

Bitumen cardboard

0,16

1.100

1,8

2.700

Resin laminate

0,10/0,15

600

Plast

0,35/0,80

1.000 + 1.200

Gres

2.650

0,14

1.000

- with lime mortar

0,8

1.900

- with cement mortar

1,2

2.200

- with plast mortar

0,6

1.200

0,7

1.800

- hollow bricks

0,45

800

- cutting stones

1,4/2,2

1.400 + 2.800

- tuff

0,7/1,0

1.100 + 1.900

0,1

550

Construction Materials

Concrete:

Roofing sheet:

- ribbed plates in Al (i.e. coverrar from TML alusio

from

SICIT alucover from ASA)

Natural or synthetic rubber plates

Coating:

Pattern:

STP-011/13

- full bricks

Panels:

- plywood

Page 167 of 462

- plast

0,14

970

- linoleum

0,16

1.200

- rubber

0,26

1.600

- P.V.C.

0,25

2.000

- asphalt and resin (i.e. vinilom AT)

0,47

1.950

0,45

1.600

1,0

2.000

2,0

2.000

- dry

0,45

1.400 + 1.900

Glass

0,50/0,80

2.400 + 2.800

- Armaflex

0,037

112

- foam

0,026

73

- ultrafoom

0,035

100

- Fiberglass

0,030

80

- Ultralite

0,036

160

Rock wool

0,031/0,032

80/112

0,2

750

0,135

630

0,04

200

- plast light panels

0,14

800

- wood fibers with MgSO4

0,06

800

Floors:

Sand:

- dry

- moist

Land:

- clayey

Insulating materials

Expanded elastomers i.e.:

Felt

Fiberglass (mattresses, panels, chapels) i.e.:

Insulating bricks:

- 29% clay, 28% sawdust, 43% coke

- pumice

STP-011/13

- cork

Thermal insulating panels:

Page 168 of 462

Expanded elastic poliuterano

0,03

20

0,033

85

0,05

220

Cork:

- dissolved cork

- cork slabs with bituminous binder

4.2.7 Figures to be used for Quick Estimates

Here below we give some data, to be considered only indicative, but

certainly useful for preliminary estimates of costs and services

consumption.

4.2.7.1 Costs

A system very convenient for quick estimates, could be the one to fix the

cost, of the conditioning plant per m3, empty for full of the building; in

this respect, we must immediately say that the fluctuation of this cost is

rather wide according to the type of installation; in fact, a part the

carrying out modalities of the building, particularly as regards the

thermal insulation, its destination, the availability of cooling water, etc.,

the cost per m3 varies greatly, up to fluctuations in the range of 100%,

depending from the buildings size.

So while for a building of normal dimensions, cubature for example of

5.000 m3, the cost per m3 could be around 90,00 , for small rooms,

on the contrary, with volume around to the 500 + 800 m3 (typical case

of the control room) the cost could raise up to 110,00 + 130,00 per

m3.

With the increase of the size of the building and therefore of the

importance of the plant, the cost per m3 tends to reduce; still today also

for large air-conditioning plant from several hundreds of thousands of

frigories/hour, it is difficult to decrease under 50 60 per m3.

STP-011/13

The above mentioned prices are inclusive of all: design, materials

supply and installation.

Page 169 of 462

4.2.7.2 Services Consumption

Electrical Power

The requirements of frigories can be fixed with sufficient accuracy

around 30 - 50 frigories/hour per m3 of the building; therefore

estimated 1 kw for each 3.000 + 3.500 Fr/hour (values valid for

medium-high potential) the electrical power required, it is easy, on the

basis of the only cubature, to estimate, with sufficient approximation,

the power absorbed by the cooling system.

Cooling Water

The preliminary evaluation of the water rate, necessary for the cooling

of the condenser, can be immediately calculated from the knowledge of

electrical power absorbed by the cooling system. In fact a reliable

parameter is the one that sets in 0.5 + 0.8 m3/h for kW installed, the

required water rate. Note that this water rate is reflected in a real

consumption only in the case in which the water, at the outlet of the

condenser, is recycled and is therefore "lose".

In the case in which the plant is provided with cooling tower or

condenser cooler with air, the consumption of water, may set around

3% + 4% of the water rate above established.

Steam

The requirements of heat, for winter conditions, can change from a

minimum of 15 + 20 Kcal/h per m3 to a maximum of 30 + 35 Kcal/h.

Knowing the buildings cubature is immediate to get a reasonable

estimate of the necessary steam.

STP-011/13

Engine Room

The practice shows that many times it overlooks, in the design of a

building, to provide adequate space for the engine and the equipment

room. In principle we can consider that the engine room should have,

with a height of 3 + 4 meters, a surface of 0, 6 + 1 m2 for each 100 m3

of conditioned space.

Page 170 of 462

4.3

Pneumatic Transport Systems

With the technical term Pneumatic Transport, we define a particular

transport system that uses a flowing gas in order to transport different

kind of products, such as: dry solid material of different shape and size

(chips, granules, powdery, etc.).

4.3.1 Definitions

As follows the definitions of the most frequently quantities and terms

used in Pneumatic Transport field are listed.

4.3.1.1 Equivalent length

It concerns the effective length of the circuits, which is appropriating

increased in order to consider the localized resistances.

4.3.1.2 Concentration

It concerns the relation between the weight of the transported product

and the weight of the gas constituting the vehicle which is involved in

the transport.

4.3.1.3 Velocity of Support or Flotation

It is the velocity for which the thrust induced on the product particles,

balances their weight.

STP-011/13

4.3.1.4 Specific Gravity in Bulk

It concerns the apparent specific gravity that considers the existing

voids among the particles. In order to assure a good evaluation of this

quantity, it is necessary to indicate as well the context in which the

measure has been performed (in condition of aeration, whether

compacted etc.)

Page 171 of 462

4.3.1.5 Angle of Repose

It is the angle for which the material free surface, let free to glide,

assumes the final position in comparison with the horizontal level.

4.3.1.6 Granulometry

It gives the dimensions of the granules or of the particles that constitute

the material. It is determined from the quantity in percentage of the

granules that have defined dimensions.

4.3.1.7 Flowability

It is the characteristic of the material obtainable from laboratory

research. It gives useful guidelines about the transportability of the

material.

It is function of the following parameters:

Humidity

Density in bulk

Compressibility

Angle of repose

Uniformity coefficient

4.3.1.8 Floodability

It is the characteristic of the material obtainable from laboratory

research. It gives useful guidelines about the possibility to be

maintained in suspension.

STP-011/13

It is function of the following parameters:

Transport aptitude

Angle of fall

Aptitude to dispersion

Page 172 of 462

4.3.1.9 Electro-excitability

It is the tendency of the material to acquire an electric charge due to

wiping.

4.3.1.10 Explosiveness

It is the possibility of the material, in determined conditions of

temperature, pressure and humidity, to create explosive mixture.

4.3.2 Classification

The pneumatic transport can be essentially divided into two main

categories:

Transport of powdery and granulate material by means of

horizontal and vertical ducting, using pressure or suction

pressure gas.

Transport of suitable material easily to be fluidized by means a

kind of a little sloping duct with bottom constituted by a porous

septum crossed by gas.

The pneumatic transport that belongs to the first category, can be

classified in function of the following parameters.

STP-011/13

4.3.2.1 Classification according to the Operating Requirements

Transports of suction type

Transports of pressure type

Transports of suction-pressure type (combined)

Page 173 of 462

4.3.2.2 Classification on Concentration Basis

Low concentration transports on pressure

Low concentration transports on suction

Medium concentration transports on pressure

Medium concentration transports on suction

Low and medium concentration transports on suction-pressure

High concentration transports on pressure

4.3.2.3 Classification according to Pressure Level

The transports on pressure can be classified as follows:

Low pressure transports ( 10.000 mm w.c.)

Medium pressure transports (10.000 30.000 mm w.c.)

High pressure transports ( 30.000 mm w.c.)

4.3.2.4 Classification according to the Machines and/or Equipment Used

Transports carried out by means of fan

Transports carried out by means of blowers, Root type

Transports carried out by means of compressors

Transports carried out by means of liquid ring pumps

with the use of rotary valves for the loading

with the use of launch pots for the loading

STP-011/13

4.3.2.5 Classification according to the Type of Circuit

Transports by means of open circuit

Transports by means of closed circuit

Page 174 of 462

4.3.3 Selection

4.3.3.1 The use of pneumatic transport for solid or powdered materials, in place

of other type of transport, is mandatory, a part of any other

consideration, when:

There is the demand to make the transport, without the

contamination of the surrounding environment.

There is the requirement to make the transport, avoiding any loss

of product even if occasional.

Man has to send and/or to take the product to/from points not

otherwise accessible.

Man has to transport products perishable on contact with

atmosphere; in this case man resorts the transport in close

circuit, with inert gas, or in close circuit with air properly treated.

4.3.3.2 The use of pneumatic transport, instead of other types of transport, is

suggested when:

Complicated and tortuous courses have to be followed because of

various facilities (railway and for pedestrian crossing, harbour

docks, big equipment and existing structures etc.)

Man has to take the products from points of not easy accessibility

(corners of storehouse, wagons and trucks, unloading, bags

breakers etc.)

Man has to avoid forced stops of product (which could cause

fermentations) that could require expensive action for cleaning

and maintenance.

4.3.3.3 Selection among the various types of pneumatic transport

STP-011/13

The logistic configuration and the number of the loading and unloading

points of the plant establish the basis choice of transport type; therefore

the following transports will be used:

Page 175 of 462

Transports of suction type, when we have to pick up the product

from more points and we have to send it to an only one point

(provided that the transport distance and flow rate allow this type

of transport)

Transport of pressure type, when we have to convey the product

from one loading point to various unloading points.

Transport of suction-pressure type, when we have to take the

product from various points and we have to send it to various

unloading points

4.3.4 Design Criteria

4.3.4.1 Dust exhausting and filtering

Whether for the treated product the maximum quantity of dust, which

is given out from the dust exhausting system, it is not in accordance

with the Standard or it is not plainly indicated, it shall be specified by

the supplier (mass flow for unitary transporting air volume). In any case

it shall not be higher than 25 mg/m3.

The dust exhausting system shall be built up with not combustible

stuff.

The filtering suction hose material shall be dealt with the operative

requirements and also with the transported product type. In particular

provided that the powders can produce explosive mixtures, the suction

hoses shall be made with electro-conductive material in order to avoid

the accumulation of static electricity.

The use of hoses filters with mechanical shaking, it is allowed only for

transports with an operation purely discontinuous.

STP-011/13

If the supplier has forecast only one cyclone system in the vacuum

system, as dust exhausting system, the fan (or the blower) that is used,

shall be formally guaranteed against the wear.

Page 176 of 462

4.3.4.2 Materials

All the ducts will be realized with the use of not combustible stuff. If,

there is the possibility that the product could be damaged by the

ferrous pollution, it will be used stainless steel or aluminium.

Diameters

The diameter of the ducts will be estimated depending on the effective

volume of the gas. In case of transports with high compression ratio,

the variation of the ducts diameter shall be provided.

Thickness

The thickness of the ducts will depend on the diameter, on the operative

conditions and at last, on the type of the material. If it is not specified,

the selection of the suitable thickness will be a supplier duty.

Bend

The minimum radius of the bends, carried out in only one piece, will be

equal to:

10 diameters concerning the transport supply lines

1,5 diameters concerning the dust exhaust lines

The lines that are realized with segments, shall be constituted, at least,

by 10 stub pipes when the angle of the bend measures 90.

STP-011/13

Whether it is possible, it would be better to avoid, between two

consecutive bends, the intermediate lengths (sections), if it is lower than

10m.

Page 177 of 462

Connections

Flanged connections

In conformity with the to ducting, the flanges will be in

accordance with, if it is possible, the Standard ANSI, excepted the

thickness, that would be a supplier duty.

Welded connections

In case of ducts butt-welded, the execution of the welding shall

ensure the absence of distortions especially for thickness of a

modest entity.

Supports

Vertical Ducting

The supports for vertical ducting shall be positioned at distance

not higher than 7m.

Horizontal Ducting

STP-011/13

The supports for horizontal ducting shall be made with the

following distances:

diameter

span

up to 3

4 + 8

4,5

10 + 14

Whether the realisation of the ducting supports should not be a duty of

the supplier of the pneumatic system, anyhow in his design, the

supplier shall provide and therefore permit a correct and safe anchorage

of the supports, for instance considering beams or supports for the

consequents overloads.

Page 178 of 462

4.3.5 Rotary Valves

The maximum difference of pressure that it is allowed for the rotary

valves is 6.000 mm w.c.

Within the systems under pressure, the rotary valves shall be supplied

with a breather pipe to allow the correct loading of the alveoli and to

avoid the formation of air pockets above the valve.

The minimum number of the radial blades shall not be lower than eight.

Moreover the number of blades from the side air that are used in the

seal, has to be higher than the side product.

The rotary open valves are operating only for pressure values that are

lower than 2.500 mm w.c. and never for granulated products or anyhow

brittles.

The rotary valves will be normally activated by means of a chain. In case

of complex or a not well known product, the rotary valves of feeding will

be provided of speed variators.

4.3.6 Switches Valves

The choice of the type of the switch valve, if otherwise not specified, is

left to the supplier. In any case the following prescriptions shall be

observed.

4.3.6.1 Switches Valves of Elastic Strain Type

These types of valves are not usable when:

The system has been used for transports of several products that

can not be in contact

The temperature overcomes 100C.

STP-011/13

4.3.6.2 Two Way Valves, Blade Type

Usable only for the transport of granules.

Page 179 of 462

4.3.6.3 Switches Valves with Flexible Hydraulically Operated Devices

These types of valves are not usable for products that can not be in

contact with the atmosphere.

4.3.6.4 Two Way Valves, Drum Type

To be used only in extreme case.

4.3.7 Operating Equipment

The selection of the suitable equipment provided with all the necessary

devices, such to make the system safe and reliable, shall be at the

manufacturer care if not otherwise indicated. In any case the following

guidelines shall be considered:

Rotary compressors, blade type, shall not be used in case of the product

does not accept oil traces even if minimal.

In case the product can generate explosive mixtures and the plant is

under pressure, the blower blades shall be in anti-sparking execution.

Fans and blowers shall be provided with the belt transmission in order

to vary the characteristics, if any.

4.3.8 General Criteria for Installation

4.3.8.1 Operative Accessibility

STP-011/13

The supplier shall assure the operative accessibility of all the

equipment. In case of mandatory logistic or process reasons, the

ducting should completely contain the equipment positioned at ground

level; the supplier shall provide the space for a proper settlement of

overpasses.

The roofs of the silos and the service levels of the structure supporting

the transport equipment shall be accessible by means of ladders with

interruption point positioned at maximum of 9 meters of high.

Page 180 of 462

When the silos, connected to pneumatic transport, are grouped in such

way to constitute a battery (adjoining or reasonably close) the roofs of

these silos shall be connected each other by means of platforms. In this

case possible differential gradient between the silos shall be duly

considered.

On the top of the silos served by pneumatic transport it shall be

foreseen the space and the support for the arm of the hoist intended for

the lifting of the heaviest piece to be handled during the maintenance

operation.

Such hoist shall be suitable to permit the descent inside the silo of a

crate apt to contain one person.

4.3.9 Safety Rules

Design of silos, filters and of any other possible vessel and/or

equipment to the pneumatic transport assigned for product that can

cause explosive mixtures.

A part of specific rules on the matter, the following provisions have to be

considered as prescriptions of good engineering:

To provide proper discharge holes (vents) which allow to limit the

pressure values in case of explosions

To carry out the vessel adopting a design pressure such as its

components (roof, bottom and shell) can, in case of explosion,

cause warping without constituting danger for the surrounding

environment.

STP-011/13

The vents can be of the following type:

Hinged hatch covers; to be used in case the product is not subject

to deterioration to the though least contact with the atmosphere.

Diaphragms; to be used in case the contact of the product with

the atmosphere is absolutely to be avoided.

In lack of other specific guidelines, the vents surface, shall be

calculated on the bases of what recommended by National Fire Codes

last edition.

In case the roofs of the silos, provided by the pneumatic transport

system, are also partly realized with diaphragms, immediately under the

roof shall be provided an opportune safety net.

Page 181 of 462

The silos provided by the pneumatic transport, shall be supplied with a

taking gate for the fireproof plant (sprinkler).

In case the transported product can cause explosive mixture or in case

the plant, also transporting product that does not cause explosive

mixture, comes to be, also partially, in classified area, the grounding of

the ducting and of the equipment, shall be assured.

4.3.10 Tests

4.3.10.1 Dimensional Check by the Shop

This check will be carried out in shop during the fabrication of the

equipment and ducting to verify the correspondence of the various

components with the working and detailed drawing approved for the

construction.

4.3.10.2 Working Test by the Shop

For all that components, for which it is demanded the seal to the dusts

and the air, as switches, filters, tank of discharge etc. a resistance test

to water and/or air will be carried out according to the modalities that

will be agreed between the engineering company and the manufacturer.

4.3.11 Material Requisition

Since a Pneumatic Transport is a package rather complex for the

number of the involved items, for the ducting routes, sometimes very

meandering

for the installation and safety problems, particular

attention and care have to be given in the preparation of the material

requisition for quotation.

STP-011/13

The following data, information and drawings, to not be considered,

anyhow, exhaustive, have to be supplied to the Vendors of these units:

Physical and chemical

pneumatically conveyed.

properties

Size of maximum lump size.

Maximum rate.

Temperature and moisture content.

of

the

material

to

be

Page 182 of 462

Possible abrasiveness, stiking, gumming, etc, of the product.

Type of the transport to be adopted (to be confirmed by the

Vendor).

Suggested lay-out of the system (to be confirmed by the Vendor).

Data Sheet or technical description of all required equipment and

materials as: storage silos, feeding hoppers, bag breaker (if any),

intermediate and final silos, cooling coils (if any), pneumatic

transport screw conveyors (if any), rotary valves, exhausting

systems.

Battery limits. As far as the battery limits are concerned, they can

be fixed in very short and simple modality; in fact, the battery

limits of the product generally are: the first loading hopper at the

beginning of the transport system and the last silo at the end of

the same.

STP-011/13

For the utilities the battery limits shall be:

for the electrical part, the cables glands on the power and control

panel(s) supplied by the Vendor. All the connections to the other

electrical users, starting from the control panel shall be at Vendor

care and charge.

in case of need of water to cool the transported product, the

battery limits shall be flanged connection to each exchangers or

coil; it is not convenient, even if possible of course, to let Vendors

make the connection among the various exchangers or coils with

piping of their supply. In other words the piping distribution will

be at the Contractor care and charge.

In case of instrument air need, the same considerations, made for

the cooling water, are still valid.

Page 183 of 462

4.4

Material Handling Systems

These systems have the purpose to transport dry material of different

origin, shape and size; they are employed in various industrial fields as

coal-mine, pharmaceutical industries, food industries, plastic materials

production plants, etc..

In this chapter, we will not deal with dusty or granular products of

which we will refer to the pneumatic transport systems.

Therefore we are considering Belt Conveyor, Bucket Belt Elevator,

Chain Conveyor etc..

Manufacturers literature on conveyors usually contains suggestions for

the selection of more convenient and useful handling system.

STP-011/13

In any case the process engineer, the project engineer and the

mechanical specialist, always in close contact, have to supply to the

Manufacturer all the necessary data and information as:

Physical and chemical properties of the material to be handled

Maximum rate

Size with the indication of maximum lump size

Temperature and moisture content

Bulk and real density

Possible abrasiveness, chemical reactivity, sticking, gumming etc.

Length and location of the conveyor including sketch showing the

proposed path, the equipment directly connected in the operation,

as sylos, mixers, etc.; of course type of the building or shelter has

to be specified with the indication of the internal temperature and

humidity.

Page 184 of 462

4.5

Oily Water Treatment Unit

The oily water treatment unit, CPI type (corrugated plates interceptor),

of contained dimensions, can be considered a typical skid mounted

package.

With the term skid mounted we intend an unit package completely

assembled in the manufacturer shop, installed on skid.

The unit, after the transport on site, has to be only connected to the

inlet and outlet piping, while the local control panel has to be

electrically fed.

The system is used to eliminate the oil from the water.

The water to be treated is sent, for gravity, to the CPI unit in order to

avoid the formation of emulsion due to the action of the pumps.

The oil is separated for the differences of specific weights; the

separation is favoured by means of the action of the coalescent plates,

located in the basin of separation.

The oil is removed by means of a skimmer and discharged into a tank

and, from this, transferred by a pump of screw type.

Then the water is sent to a second tank and discharged by a floodway,

adjustable along the height. Finally the water is transferred into a vessel

in order to be discharged by the action of a centrifugal pump.

The slush, formed for the sedimentation of the suspended solids, can be

discharged by a manual valve.

Differently from other equipment and units, for this kind of package

particular knowledge and studies are not required by the process and

project engineers since this type of units is enough standardized.

STP-011/13

The necessary data and information

manufacturers are the following:

to

be

supplied

to

the

Flow rate of the water to be treated

Oil content (in mg/l) at the inlet

Oil specific gravity

Suspended solids (in mg/l) at the inlet

Oil content in the water (in mg/l) at the outlet

Max dimension of the separated oil drop (in mm value, if

indicated, to be confirmed by the Vendor)

STP-011/13

Page 185 of 462

Temperature of the water

Environmental conditions

Page 186 of 462

4.6

Dosing Units

Also a dosing unit, as well as the Oil Treatment Unit, of CPI type,

previously examined, can be considered a typical example of package

unit, completed shop assembled, mounted on skid, complete with

drivers and all the other necessary accessories.

As example we will consider an Antifoam Dosing Unit for the Injection

and Measuring of an antifoam product into an amine liquid flow.

The unit, taken into consideration, is very simple and of limited

dimensions; it is mainly constituted by:

N 1 atmosphere tank, SS made, for the storage of the product

solution

N 2 dosing pumps (one as spare)

N 1 calibration pot

Oscillation dampers

Connecting piping and the necessary instrumentation

STP-011/13

Also in this case, since the package of this type are largely

standardized, the only care and attention that the process engineer and

project engineer have to be given are the completeness of data and

information to be furnished to the manufacturer, they are:

Flow rate of the dosing pump (in lt/h)

Material of the dosing pump (SS)

Codes for the pumps (f.i. API 675)

0 100 % with the pump in operation

Outlet pressure (bar g)

Capacity and material of the tank

Type of antifoam product (f.i. Chimec 8049 or equivalent)

Você também pode gostar

- 2..GT 3 Final Paper Dual HRW 050114Documento9 páginas2..GT 3 Final Paper Dual HRW 050114Narasimha DvlAinda não há avaliações

- Mel 5Documento9 páginasMel 5Yhan SombilonAinda não há avaliações

- 1.1 The Meaning of Air ConditioningDocumento5 páginas1.1 The Meaning of Air Conditioning1986424Ainda não há avaliações

- Air Conditioning Control System Simulation ResultsDocumento10 páginasAir Conditioning Control System Simulation ResultsMuhammad AnwarAinda não há avaliações

- eArt-Air Conditioning Systems With Desiccant Wheel For Italian ClimatesDocumento21 páginaseArt-Air Conditioning Systems With Desiccant Wheel For Italian ClimatesJurizal Julian LuthanAinda não há avaliações

- HVAC Load Calculation and Design for Medical HospitalDocumento7 páginasHVAC Load Calculation and Design for Medical HospitalMohammed MujahedAinda não há avaliações

- Final Report For HVAC2Documento8 páginasFinal Report For HVAC2Benny BennyAinda não há avaliações

- Hvac Load CalculationDocumento20 páginasHvac Load CalculationLalit Sisodia75% (4)

- Central Air Conditioning Systems ReviewDocumento23 páginasCentral Air Conditioning Systems ReviewlalaAinda não há avaliações

- Hvac PDFDocumento35 páginasHvac PDFAbhishek OjhaAinda não há avaliações

- Paint Booth HVAC Control SystemDocumento6 páginasPaint Booth HVAC Control SystemPraveenkumar KashyabAinda não há avaliações

- ME 115 Experiment 1 Analysis of A Hilton Air Conditioning Laboratory UnitDocumento5 páginasME 115 Experiment 1 Analysis of A Hilton Air Conditioning Laboratory UnitCoby IlasAinda não há avaliações

- Hvac NotesDocumento98 páginasHvac NotesHellena VivianAinda não há avaliações

- The Effect of Refrigerant Charge and Outdoor TempeDocumento7 páginasThe Effect of Refrigerant Charge and Outdoor Tempeحسن عرقسوسيAinda não há avaliações

- 5 6319041475430580612Documento66 páginas5 6319041475430580612Shobhit SahuAinda não há avaliações

- Air Handling UnitDocumento11 páginasAir Handling UnitSaranya Kannan100% (1)

- 5.1. Air Preparation: Chapter 5: Pneumatic SystemsDocumento36 páginas5.1. Air Preparation: Chapter 5: Pneumatic SystemsSiraj BusseAinda não há avaliações

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Documento11 páginas(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifAinda não há avaliações

- Air Handlers FinalDocumento8 páginasAir Handlers FinalHeber MarinAinda não há avaliações

- Project Report of HvacDocumento56 páginasProject Report of HvacPrince Syed83% (59)

- Nuaire Commercial Useful InfoDocumento10 páginasNuaire Commercial Useful InfoYaser AkarAinda não há avaliações

- System of Compressed Air For Electrofilter in Thermal Power PlantDocumento4 páginasSystem of Compressed Air For Electrofilter in Thermal Power PlantAmit JainAinda não há avaliações

- Air HandlerDocumento15 páginasAir HandlerShashank BijweAinda não há avaliações

- Paper DeshumidifiersDocumento31 páginasPaper DeshumidifiersWalter J Naspirán CastañedaAinda não há avaliações

- Lab Sheet Air CondDocumento8 páginasLab Sheet Air CondAhmad AbaAinda não há avaliações

- Air Conditioner: 01 - Classification of Air Conditioning SystemsDocumento3 páginasAir Conditioner: 01 - Classification of Air Conditioning Systemsshubhadipete123Ainda não há avaliações

- ASSIGNMENT OF PLFD AIR CONDITIONINGDocumento18 páginasASSIGNMENT OF PLFD AIR CONDITIONINGSarita Bali Srivastava100% (1)

- Air Conditioning 1Documento17 páginasAir Conditioning 1Esmail AnasAinda não há avaliações

- Air Condition With PicturesDocumento37 páginasAir Condition With Picturesmy09Ainda não há avaliações

- Assignment 2Documento36 páginasAssignment 2Monika SadhaAinda não há avaliações

- Example Fahu VFDDocumento6 páginasExample Fahu VFDpradeepdonAinda não há avaliações

- Rac Lab ManualDocumento30 páginasRac Lab ManualPrakharGupta100% (1)

- Hvac Thesis TopicsDocumento5 páginasHvac Thesis Topicsgj3vfex5100% (2)

- Heat Pump vs Mechanical Steam Compression DryersDocumento8 páginasHeat Pump vs Mechanical Steam Compression DryersMuhammad AhmadAinda não há avaliações

- BE DehumidificationDocumento31 páginasBE DehumidificationAbdul RaheemAinda não há avaliações

- HvacDocumento15 páginasHvacKiran KumarAinda não há avaliações

- 02 Chapter 2Documento0 página02 Chapter 2Imtinan MohsinAinda não há avaliações

- Chapter One 1.0 Introdiction History of Air Conditioning SystemDocumento79 páginasChapter One 1.0 Introdiction History of Air Conditioning Systemikperha jomafuvweAinda não há avaliações

- Dehumidification For OR Healthcare - SmithGroupJJR - Engineered SystemsDocumento7 páginasDehumidification For OR Healthcare - SmithGroupJJR - Engineered SystemsVince DavidAinda não há avaliações

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Documento11 páginas(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifAinda não há avaliações

- HVAC Handbook 11 All Water SystemDocumento35 páginasHVAC Handbook 11 All Water SystemTanveer100% (2)

- Air Change RateDocumento18 páginasAir Change Ratemumbaimale20009776Ainda não há avaliações

- HVAC ApplicationsDocumento20 páginasHVAC ApplicationsSrashmiAinda não há avaliações

- Lecture # 11: Dr. Muzaffar AliDocumento40 páginasLecture # 11: Dr. Muzaffar AliNadeem AbbasAinda não há avaliações

- Air Conditioning Laboratory Unit: SolteqDocumento4 páginasAir Conditioning Laboratory Unit: SolteqRafael CanquizAinda não há avaliações

- Experiment About Air-Conditioning UnitDocumento32 páginasExperiment About Air-Conditioning UnitVerlon Vincent100% (1)

- Fundamentals of HVAC ControlsDocumento68 páginasFundamentals of HVAC Controlsbenson100% (2)

- HVAC Design Considerations for AuditoriumDocumento18 páginasHVAC Design Considerations for Auditoriumchitta sandeep dattuAinda não há avaliações

- ME 512A Aircon Systems Guide (39Documento73 páginasME 512A Aircon Systems Guide (39Arsenio OvillaAinda não há avaliações

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemAinda não há avaliações

- Advanced Temperature Measurement and Control, Second EditionNo EverandAdvanced Temperature Measurement and Control, Second EditionAinda não há avaliações

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsNo EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsAinda não há avaliações

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialAinda não há avaliações

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideNo EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideNota: 4 de 5 estrelas4/5 (8)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsAinda não há avaliações

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesAinda não há avaliações

- Rectangular TankDocumento6 páginasRectangular TankEsapermana RiyanAinda não há avaliações

- Smaw and Tig WeldingDocumento46 páginasSmaw and Tig WeldingRajesh Kumar Ravi100% (1)

- New - Reinforcement of NozzleDocumento31 páginasNew - Reinforcement of NozzleChagar HarshpalAinda não há avaliações

- API 650 Tank Design CalculationDocumento8 páginasAPI 650 Tank Design Calculationmail_younes659283% (29)

- Heinkel Flyer Classifying Centrifuge v630 BK TiocentDocumento2 páginasHeinkel Flyer Classifying Centrifuge v630 BK TiocentRaghAinda não há avaliações

- BS-2654 1989 Design Standard For Vert Steel Welded Storage TanksDocumento103 páginasBS-2654 1989 Design Standard For Vert Steel Welded Storage TanksAndrew Ko100% (2)

- API 685 BrochureDocumento8 páginasAPI 685 BrochureDenar PurnamaAinda não há avaliações

- Tutorial Motor Basics Lecture PDFDocumento23 páginasTutorial Motor Basics Lecture PDFBenjaminas OrlovasAinda não há avaliações

- Weld WeightDocumento10 páginasWeld WeightDivyesh PatelAinda não há avaliações

- Ro-Flo Packaging Guidelines ENG PDFDocumento42 páginasRo-Flo Packaging Guidelines ENG PDFRaghAinda não há avaliações

- Centrifuges For The Chemical IndustryDocumento4 páginasCentrifuges For The Chemical IndustrypintaratAinda não há avaliações

- AISC Design Guide 33 Curved Member Design 2018Documento166 páginasAISC Design Guide 33 Curved Member Design 2018saital92% (12)

- Specs For Aluminum Geodesic Batten Domes 2012Documento5 páginasSpecs For Aluminum Geodesic Batten Domes 2012RaghAinda não há avaliações

- Ro-Flo Iom Manual EngDocumento52 páginasRo-Flo Iom Manual EngSlamet Purwadi S.T100% (1)

- Pressure Vessel HandBook Megyesy11th EdDocumento247 páginasPressure Vessel HandBook Megyesy11th EdRaghAinda não há avaliações

- TycoDocumento69 páginasTycog4goharAinda não há avaliações

- Ro-Flo BrochureDocumento4 páginasRo-Flo BrochureRaghAinda não há avaliações

- Methodology For RepairsDocumento1 páginaMethodology For RepairsRaghAinda não há avaliações

- Strength Calculation For PlatformDocumento2 páginasStrength Calculation For PlatformRaghAinda não há avaliações

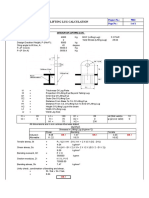

- Lifting Lug - Skid - 2018.07.16Documento4 páginasLifting Lug - Skid - 2018.07.16RaghAinda não há avaliações

- Methodology For RepairsDocumento2 páginasMethodology For RepairsTaufik WhaeAinda não há avaliações

- Tank ErectionDocumento13 páginasTank Erectionsajay2010Ainda não há avaliações

- Engineering Standard Specification For Steam TracingDocumento53 páginasEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- Hi-T Pigalert LiteratureDocumento2 páginasHi-T Pigalert LiteratureRaghAinda não há avaliações

- Hi-T Pigalert IOM ManualDocumento14 páginasHi-T Pigalert IOM ManualRaghAinda não há avaliações

- Apt 60928 Evs TM 08 1Documento108 páginasApt 60928 Evs TM 08 1Mohan JhaAinda não há avaliações

- Apt 60928 Evs TM 08 1Documento108 páginasApt 60928 Evs TM 08 1Mohan JhaAinda não há avaliações

- STEAM TRACING Engineering - Guide PDFDocumento0 páginaSTEAM TRACING Engineering - Guide PDFkresimir.mikoc9765Ainda não há avaliações

- Sweco CatDocumento21 páginasSweco CatArmandoZacariasAcostaAinda não há avaliações