Escolar Documentos

Profissional Documentos

Cultura Documentos

Acoustic Properties of Miter Bends: John W. Coltman

Enviado por

sandbadbahriTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Acoustic Properties of Miter Bends: John W. Coltman

Enviado por

sandbadbahriDireitos autorais:

Formatos disponíveis

Acoustic properties of miter bends

John W. Coltman

3319 Scathelocke Road, Pittsburgh, Pennsylvania 15235

(November 27, 2006)

Miter bends in tubing introduce perturbations in the characteristic impedance of the tube.

Techniques and dimensions are provided to compensate the effect so that at frequencies of

interest the perturbations are eliminated.

Introduction

The air columns of many wind

instruments are often folded to keep them from

being inconveniently long.

This calls for

portions of the column to be bent, usually in the

form of a portion of a toroid. The characteristic

impedance of bends will differ from that of a

straight tube of the same diameter Such a change

amounts to a perturbation in the bore diameter,

which may give rise to undesired perturbations

in intonation. This article provides information

on how this perturbation may be compensated

for, particularly when the bend is in the form of

a mitered joint

Mitered bend

For the amateur instrument maker, a

toroidal bend is very difficult to produce. A

much simpler method is to cut the tubing at 45

degrees and solder or cement the tubes to

produce a 90-degree mitered bend. Two such

bends, not far apart, can be used to fold a tube by

180 degrees. Measured along the centerline, the

volume and therefore the compressibility of the

section bounded by the planes at the beginning

and end of the cuts remains the same. The

inertance however, is decreased as a result of the

vibrations taking a shortcut around the bend,

so that the characteristic impedance is altered

and the effective acoustic length is decreased.

Dequand et al2 calculated and measured the

reflection coefficients due to a variety of 90

degree sharp bends, among them the mitered

bend described above. From their values of the

reflection coefficient it is possible to derive the

shortening of the section due to inertance

change. This turns out to be

Toroidal bends

Nederveen1 has reviewed the literature

on this subject, and presented various treatments

of the effect.. Simply stated, the compliance

(compressibility) of such a section depends only

on its volume, whereas the inertance is altered

because the vibrating motions tend to

concentrate toward the inner wall of the curve, in

effect taking a shortcut in the path around the

section. The effect is a function of the ratio of r,

the radius of the tube, to r0 , the radius of the

centerline of the toroidal bend. The proper

characteristic impedance can be restored by

decreasing slightly the diameter of the tubing in

the curved portion of the bend. For a 180-degree

toroidal bend, a reasonably good approximation

of the factor (slightly less than 1) by which the

tube diameter should be multiplied is:

G = 1 - 0.063 (r/r 0) 2

F = 0.61

(2)

where F is the factor by which the distance

around the bend (which is equal to ID, the

internal diameter of the tubing) is to be

multiplied to get the effective length of the

section. This is the shortening for the case where

the bend is located at a pressure minimum, i.e. a

vibration maximum. The authors do not describe

any means by which the characteristic

impedance of the section may be restored to that

of the main tubing. It is the intention of this

article to describe several ways of accomplishing

this.

(1)

The acoustic length of the bend will be shorter

than the length measured along the toroid

centerline. The new acoustic length can be

calculated by multiplying the physical length by

a factor equal to G2.

1

Compensation of miter bend

Compensation can be achieved either by

introducing additional inertance to restore the

inertance to that of a straight section, or by

reducing the volume of the section so as to

restore the characteristic impedance to that of a

straight tube. In either case, operating on one

usually involves a small change in the other.

Values of dimensions for compensation were

determined experimentally.

Increasing inertance

A tube of ID = 17.86 mm was cut near

one end at 45 degrees. It could be reassembled to

form a straight tube 380 mm in length, or to form

a tube with a 90-degree miter bend having a

short section 40.7 mm long, measured along the

center line. A dynamic driver at the far end

excited the tube while a smal probe microphone

close to the driver measured the response. When

driven at its lowest resonance frequency the

assembly acted as a quarter-wave resonator, with

high particle velocity and low pressure at the cut

where the bend was made. Comparisons of the

resonance frequencies for the straight and bent

configurations gave a measure of the shortening

effect of the bend. Correction was made for the

fact that the bend was located a short distance

from that of the maximum acoustic particle

velocity. The effective shortening due to the

bend was measured as 0.36 ID, close to the value

of 0.39 ID predicted by Equation (1). The same

setup was used to find by experiment the proper

dimensions for the compensation methods

described below.

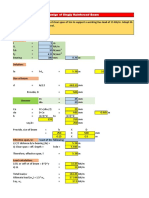

Fig 1. Two ways to compensate miter

perturbations. Inside dimensions are shown.

In the second method a somewhat thicker

plate having a round hole 0.87 times the ID of

the tube is cemented between the two tubes as

they are joined, as shown in Fig. 1b.. The

compensation will depend somewhat on the

thickness of the plate used, but some variation

from that specified can be tolerated, say .05 to

0.15 rather than 0.1 store the inertance in a miter

bend. Inside ID. Again, rounding of the hole

edge is desirable. When calculating distances for

finger hole placement, the effective length of the

tube is that measured along the center lines of the

tubes, plus the thickness of the plate.

Decreasing compliance

A third method for compensation is to

reduce the compliance (volume) at the bend to

In the first method, shown in Figure 1a,

after the tubes are joined, a slot is cut to the

depth shown, and a relatively thin plate or card

with a straight edge is inserted. After sealing

with an appropriate cement (or solder for metal

construction) the outside of the plate can be cut

away to configure to the outside wall of the tube.

The plastic card I used for a 17.86 mm ID PVC

tube had a thickness of 0.73 mm, close to the

thickness of the hacksaw blade used to make the

cut. It is desirable to round the edge of the card

to reduce turbulence. At an insertion length of

0.35 ID the resonance frequency was restored to

that of the straight tube.

Figure 2. Inside dimensions of beveled miter bend

match the inertance, giving a characteristic

impedance for the section equal to that of the

main tube. A simple means of doing this is to

bevel the sharp corner by cutting it off at 45

degrees and cementing a flat plate over the cut.

Figure 2 shows a cross-section of the inside

dimensions of this arrangement.

slight frequency dependence of the velocity of

sound in the tube. A measurement on a straight

length of tubing yielded a value of 2.004 for this

ratio in the case considered here. Thus we wish

to design compensation arrangements that will

make the measured ratio of the frequencies of the

first two modes equal to 2.004.

Measurements were made in the

laboratory to determine the proper amount to cut

off.

A somewhat different technique was

employed for these measurements. The tubes

were arranged with an electromagnetic driver

closing one end, while the other end was closed

with a plastic disc. A small probe microphone

close to the driver measured the acoustic

pressure signal. Resonances were measured by

taking pressure measurements vs. frequency on

either side of the maximum and a measurement

close to the maximum. Solving the resonance

equation for these three points yielded the

frequency of the pressure maximum and the

quality factor Q of the resonance to a high degree

of precision.

The dimension d shown in Figure 2 is the

long axis of the near-elliptical opening created

by beveling the mitered bend. A series of these

was measured, and interpolated to find the value

that gave a mode-frequency ratio of 2.004. The

value found was:

d = 1.26 ID

(3)

The acoustical distance around the bend is

shortened by an amount:

s = 0.32 ID

(4)

Double mitered bend

A pair of ninety degree miter bends

positioned close together may not behave simply

as two bends spaced far apart. There are also

additional options for compensating the

disturbances

in

acoustic

impedance.

Accordingly, experiments were carried out on

the arrangement shown in Figure 3. The tubing

used was PVC pipe inch nominal size, Type

S21. This type has relatively thin walls, allowing

the bend to be quite compact. Dimensions were

23.8 mm ID, wall thickness 1.46 mm and 26.7

mm OD. The two lengths of tubing were in

contact, so that the inside walls were spaced by

2.9 mm .

The first resonance mode of the

assembly is a half-wave resonance with a

pressure max at the two ends and a pressure

minimum at the middle, where the bend is

located. Here the acoustic velocity is at a

maximum.

The second mode is a full

wavelength, with a pressure maximum at the

ends and also at the bend, with a velocity

minimum at the bend. The volume of the bend is

unchanged from that of a straight tube of the

same length measured along the center line.

Therefore, the bend does not affect the resonance

frequency of the second mode, since only

compression is involved and there is no change

in the volume being compressed. However, in

the first mode, the flow lines of the acoustic

velocity take a short cut around the bend,

shortening the total effective length of the

assembly, and raising the frequency of the first

mode. The ratio of these two mode frequencies is

then less than 2; for the case tested it was 1.941.

The assembly will act like a straight tube if and

only if the frequencies of the two modes retain

their normal relationship, close to a factor of

two. This factor is not exactly 2 because

dissipation at the walls of the tube results in a

Figure 3, Cross-section and inside dimensions of

double miter bend and segmented disk

Measurements were made of the resonance

frequencies of a straight tube, a single 90 degree

miter bend and of a double mitered bend as in

Figure 3. The single bend exhibited an effective

first-mode acoustic shortening of 9.2 mm. The

double bend showed a shortening of 18.8 mm.

This is only slightly more than twice that of the

single bend, so the very close spacing of the two

90 degree bends had little effect. We can

conclude that the wall thickness of the tubes,

which determines the minimum spacing of the

bends in a double bend, can be ignored as a

variable in making compensation.

units. The acoustic length of this compensated

bend will be shortened by about 0.4 t where t is

thickness in millimeters.

Beveled miter, double bend

Experiments were made with the double

bend shown in Figure 3, omitting the disk and

beveling the two corners as in Figure 2. The

results specified a distance d for the long axes of

the openings:

d = 1.33 ID

This is somewhat more than the value for a

single 90-degree bend given by equation (3),

implying an decrease in inertance of the bend

section, consistent with the finding of greater

shortening for the close-spaced double bend than

for two 90-degree bends.

An effective way to produce the desired

compensation is to introduce a segment of a thin

disk at the midpoint of the bend. The disk

diameter is the same as the ID of the tube, and it

is cut off on a chord such that its height from the

perpendicular of that line to the circumference

has a value h. The segment is placed at the

narrowest part of the tube bridging the bend.

The width here is twice the tube wall thickness;

in our case 2.9 mm. The disk thickness used was

2.3 mm. In mounting this segment in the short

portion of the bend tube, I found it useful to turn

on the lathe a wooden cylinder that fit into the

tube, facing it off to provide a perpendicular

plane against which the disk can be held while

being cemented into place. The bridging tube can

then be fitted into the mitered ends of the main

tubes. With the disk segment in place, the

acoustic flow path is lengthened, lowering the

frequency of the first mode, but leaving that of

the second mode unchanged except for a small

amount due to the volume taken up by the disk

segment.

The acoustic length of this section is

shortened compared to the distance along the

center line by an amount:

s = 0.69 ID

(7)

Conclusion

Mitered bends are simple to make and

can be readily compensated to act acoustically, at

most frequencies of interest, as if there were no

perturbations in a straight tube. Expressions for

the acoustic length of such modified sections are

easily applied.

References

1. Nederveen, Cornelis. J., Influence of a

toroidal bend on wind instrument tuning, J.

Acoust. Soc. Am. September 1998, Vol. 104,

Issue 3 pp. 1616-1620

Experiments with three disk segments of

different heights gave a value for h of 10.34 mm

to provide complete compensation. The open

area above the segmented disk is thus somewhat

larger than that of the disk segment. An

experiment with a thinner disk gave a rule for

including disk thickness in determining the

segment height.

The rule for providing

compensation then becomes:

Segment height h = 0.49 ID 0.5 t

(6)

2. Dequand, S., Hulshoff, S. J., Ayregan, A.,

Huijnene, J., ter Riet, R., van Lier, L. J.,

Hirschberg, A.,

Acoustics of 90 degree

sharp bends. Part 1: Low-frequency

response, Acta Acustica Vol. 89 (2003), pp.

1025-1037

(5)

where ID is the inside diameter of the tubing and

t is the thickness of the disk, all in the same

4

. Inside dimensions of

beveled miter bendy

Você também pode gostar

- Acoustic Properties of Miter Bends: John W. ColtmanDocumento4 páginasAcoustic Properties of Miter Bends: John W. Coltmandewqdqw2Ainda não há avaliações

- John Johnson P406 Project Report Sp12Documento10 páginasJohn Johnson P406 Project Report Sp12Darius HighAinda não há avaliações

- Wind Tunnel ApparatusDocumento6 páginasWind Tunnel ApparatusPrasetyaJayaputraAinda não há avaliações

- Resonators Reduce Noise from Centrifugal BlowersDocumento11 páginasResonators Reduce Noise from Centrifugal BlowersmaryaoannaAinda não há avaliações

- Flow Characteristics of a Pipe DiffuserDocumento13 páginasFlow Characteristics of a Pipe Diffusermunro_85Ainda não há avaliações

- Deformation Behavior of Thin-Walled Tube Bending With Internal PressureDocumento6 páginasDeformation Behavior of Thin-Walled Tube Bending With Internal PressureHizbar ArsjadAinda não há avaliações

- A Varactor Tuned RF FilterDocumento4 páginasA Varactor Tuned RF FilterA. Villa100% (1)

- Broadband CPW-Fed Square Slot Antennas With A Widened Tuning StubDocumento5 páginasBroadband CPW-Fed Square Slot Antennas With A Widened Tuning StubRam SidhAinda não há avaliações

- Design of A PipeRing Type of Sparger For A Bubble Column Reactor PDFDocumento8 páginasDesign of A PipeRing Type of Sparger For A Bubble Column Reactor PDFAshkanHosseini100% (1)

- GE Bolt Mike III Owner's Manual20160519666133Documento3 páginasGE Bolt Mike III Owner's Manual20160519666133Brenno GonçalvesAinda não há avaliações

- Sonometer AIM Apparatus: To Be Written in The Right Page of The RecordDocumento3 páginasSonometer AIM Apparatus: To Be Written in The Right Page of The RecordHemanth KAinda não há avaliações

- Pipe Bend RadiusDocumento8 páginasPipe Bend RadiusAdagharaAinda não há avaliações

- Achenbach Smooth - Rough CylinderDocumento15 páginasAchenbach Smooth - Rough CylinderVivek KantiAinda não há avaliações

- Gordon1989 PDFDocumento18 páginasGordon1989 PDFKhalil DeghoumAinda não há avaliações

- Broadband CPW-Fed Square Slot Antennas With A Widened Tuning StubDocumento5 páginasBroadband CPW-Fed Square Slot Antennas With A Widened Tuning StubSudesh AgrawalAinda não há avaliações

- Finite Element Method For Optimizing Pipe BendsDocumento3 páginasFinite Element Method For Optimizing Pipe BendsrodrigoAinda não há avaliações

- Geometric and Material Parameters On Tube Hydroforming: Finite Element Analysis of The Effect ofDocumento12 páginasGeometric and Material Parameters On Tube Hydroforming: Finite Element Analysis of The Effect ofdhrumitgajjarAinda não há avaliações

- Pressure Gauge Bourdon Tube Pressure GaugeDocumento7 páginasPressure Gauge Bourdon Tube Pressure GaugeVignesh RajanAinda não há avaliações

- Fabrication of Er3 - Doped Fluoride Fibres With Single-ModeDocumento6 páginasFabrication of Er3 - Doped Fluoride Fibres With Single-Modeqinetiq15Ainda não há avaliações

- Hydrodynamics of small tubular pumpsDocumento19 páginasHydrodynamics of small tubular pumpsmariomatoAinda não há avaliações

- Friction and Its EffectsDocumento39 páginasFriction and Its EffectsOmkar rodeAinda não há avaliações

- Flow MeasurementDocumento26 páginasFlow MeasurementOmkar rodeAinda não há avaliações

- Pressure MeterDocumento17 páginasPressure MeterRakesh7770Ainda não há avaliações

- A Coustic Attenuation Performance of Double Expansion Chamber Silencers With Inter Connecting TubeDocumento4 páginasA Coustic Attenuation Performance of Double Expansion Chamber Silencers With Inter Connecting Tube신동호Ainda não há avaliações

- Confined Photonic Modes in The Fabry-Pérot Based Photonic Crystal Nanobeam Cavity Structures With Mixed Tapered Air-Holes and Curved-Wall CavityDocumento6 páginasConfined Photonic Modes in The Fabry-Pérot Based Photonic Crystal Nanobeam Cavity Structures With Mixed Tapered Air-Holes and Curved-Wall CavityAJER JOURNALAinda não há avaliações

- Instrumentation IIDocumento8 páginasInstrumentation II544 vishwavijay PatilAinda não há avaliações

- End Correction at A Flue Pipe MouthDocumento5 páginasEnd Correction at A Flue Pipe Mouthfzr67Ainda não há avaliações

- Practical Cavity Filters For The Frequency Range 1GHz... 4GHzDocumento21 páginasPractical Cavity Filters For The Frequency Range 1GHz... 4GHzGianfranco100% (1)

- Calculations For Hot Stretch Reducing ProcessDocumento8 páginasCalculations For Hot Stretch Reducing ProcessKAAinda não há avaliações

- 90 Ijmperdoct201990Documento8 páginas90 Ijmperdoct201990TJPRC PublicationsAinda não há avaliações

- Bell e Mehta 1988Documento39 páginasBell e Mehta 1988Nelson LondoñoAinda não há avaliações

- Calculation of An Acoustic Phase InverterDocumento7 páginasCalculation of An Acoustic Phase InverterAnonymous DjWqKpZ1Ainda não há avaliações

- MTE 314 Mechanical Vibrations: Report Experiments 2Documento3 páginasMTE 314 Mechanical Vibrations: Report Experiments 2Yomna EmadAinda não há avaliações

- Pressure and Force MeasurementDocumento8 páginasPressure and Force Measurementpranjal priyeAinda não há avaliações

- Chapter 3 I & M Final PresentationDocumento43 páginasChapter 3 I & M Final PresentationAzizIkramAinda não há avaliações

- LRFD Tension Member Design GuideDocumento72 páginasLRFD Tension Member Design GuideYetty OktavianitaAinda não há avaliações

- Sucw-Single-feed Broadband CP Patch AntennaDocumento3 páginasSucw-Single-feed Broadband CP Patch Antenna蘇哲Ainda não há avaliações

- Strain Gauges NptelDocumento15 páginasStrain Gauges Nptelsushant271992Ainda não há avaliações

- Technical Whitepaper: Sonic V - Acoustic Pulse Reflectometry (APR) Inspection SystemDocumento11 páginasTechnical Whitepaper: Sonic V - Acoustic Pulse Reflectometry (APR) Inspection SystemassurendranAinda não há avaliações

- Electromagnetic pulse crimping axial joints optimizationDocumento14 páginasElectromagnetic pulse crimping axial joints optimizationmohamad zareAinda não há avaliações

- Bending Spring LoadingDocumento2 páginasBending Spring LoadingNisha NtaAinda não há avaliações

- Piezo ResistiveDocumento25 páginasPiezo ResistiveAbcd PqrsAinda não há avaliações

- Core FluxDocumento8 páginasCore Fluxbharat_22nandulaAinda não há avaliações

- NDT Technician: Circumferential Scanning in Ultrasonic InspectionDocumento12 páginasNDT Technician: Circumferential Scanning in Ultrasonic InspectionmaterialsAinda não há avaliações

- A Permeameter For Magnetic Testing at Magnetizing Forces Up To 300 OerstedsDocumento5 páginasA Permeameter For Magnetic Testing at Magnetizing Forces Up To 300 OerstedsEdisson Yesid Rodriguez NAinda não há avaliações

- Pressure and Tempreture MeasurementDocumento61 páginasPressure and Tempreture MeasurementVarad DateAinda não há avaliações

- Stripline-fed circular microstrip antennasDocumento4 páginasStripline-fed circular microstrip antennasJohn WilliamsAinda não há avaliações

- Lab Manual 2016Documento41 páginasLab Manual 2016Dr Ankita UpadhyaAinda não há avaliações

- USD T BeamDocumento10 páginasUSD T BeammanowarAinda não há avaliações

- An All Purpose High Gain Antenna For 2400 MHZDocumento8 páginasAn All Purpose High Gain Antenna For 2400 MHZMahendra SinghAinda não há avaliações

- T9 Loudspeakers: Chapter - 3Documento29 páginasT9 Loudspeakers: Chapter - 3lvsaru100% (1)

- Pressure MeasurementDocumento28 páginasPressure MeasurementbcramcAinda não há avaliações

- Ref 62Documento8 páginasRef 62Jim SkoranskiAinda não há avaliações

- 3.2. Contraction: Design Methodology For A Quick and Low-Cost Wind Tunnel 9Documento2 páginas3.2. Contraction: Design Methodology For A Quick and Low-Cost Wind Tunnel 9Dang Tien PhucAinda não há avaliações

- HDPE Pipe Thickness CalculationsDocumento5 páginasHDPE Pipe Thickness CalculationsBudi SantonyAinda não há avaliações

- Cylindrical Compression Helix Springs For Suspension SystemsNo EverandCylindrical Compression Helix Springs For Suspension SystemsAinda não há avaliações

- Spec Sheet VendingDocumento1 páginaSpec Sheet VendingsandbadbahriAinda não há avaliações

- Resume and Cover Letter Guide: Trends, Tips and TemplatesDocumento48 páginasResume and Cover Letter Guide: Trends, Tips and TemplatessandbadbahriAinda não há avaliações

- Buddhist Stories From The Dhammapada Commentary Part 4Documento33 páginasBuddhist Stories From The Dhammapada Commentary Part 4Buddhist Publication Society100% (1)

- Joint Model of PipesDocumento28 páginasJoint Model of PipessandbadbahriAinda não há avaliações

- HDT Vicat StandardDocumento2 páginasHDT Vicat StandardsandbadbahriAinda não há avaliações

- PIPING MATERIALS FOR GEOTHERMAL HEATING SYSTEMSDocumento6 páginasPIPING MATERIALS FOR GEOTHERMAL HEATING SYSTEMSsandbadbahriAinda não há avaliações

- VendDocumento13 páginasVendWilson LimAinda não há avaliações

- Middle East Product GuideDocumento20 páginasMiddle East Product GuidesandbadbahriAinda não há avaliações

- GRP SystemsDocumento18 páginasGRP SystemsVamasAinda não há avaliações

- Lole Kompos Va MasolateshDocumento8 páginasLole Kompos Va MasolateshsandbadbahriAinda não há avaliações

- Literature Coating - Epoxy Resin & Hardeners For Coating Selector GuideDocumento10 páginasLiterature Coating - Epoxy Resin & Hardeners For Coating Selector GuideSoutrik GuptaAinda não há avaliações

- Naghshe Haye LolexDocumento24 páginasNaghshe Haye LolexsandbadbahriAinda não há avaliações

- GRP SystemsDocumento18 páginasGRP SystemsVamasAinda não há avaliações

- JimboDocumento16 páginasJimbosandbadbahriAinda não há avaliações

- Literature Coating - Epoxy Resin & Hardeners For Coating Selector GuideDocumento10 páginasLiterature Coating - Epoxy Resin & Hardeners For Coating Selector GuideSoutrik GuptaAinda não há avaliações

- Hamechi Rajebe Gloss Va Nabshe CopeglasDocumento44 páginasHamechi Rajebe Gloss Va Nabshe CopeglassandbadbahriAinda não há avaliações

- Fibrelogic Flowtite Engineering Guidelines DES M-004Documento122 páginasFibrelogic Flowtite Engineering Guidelines DES M-004Wilfredo GuerreroAinda não há avaliações

- GRE Pipes Eng Okt2014 WebDocumento2 páginasGRE Pipes Eng Okt2014 WebsandbadbahriAinda não há avaliações

- Katalog Intek Bara PaltrosionDocumento32 páginasKatalog Intek Bara PaltrosionsandbadbahriAinda não há avaliações

- Material Design For GRP Fekr KonamDocumento2 páginasMaterial Design For GRP Fekr KonamsandbadbahriAinda não há avaliações

- F6000Documento90 páginasF6000sandbadbahriAinda não há avaliações

- The Conference of the BirdsDocumento6 páginasThe Conference of the BirdssandbadbahriAinda não há avaliações

- The Conference of the BirdsDocumento6 páginasThe Conference of the BirdssandbadbahriAinda não há avaliações

- Stencil SampleDocumento1 páginaStencil SamplesandbadbahriAinda não há avaliações

- Alaki Mage SherteDocumento3 páginasAlaki Mage ShertesandbadbahriAinda não há avaliações

- Technical SpecificationDocumento117 páginasTechnical Specificationsenioor2004Ainda não há avaliações

- Tia Eia 222 GDocumento7 páginasTia Eia 222 GAnil Kumar GudipudiAinda não há avaliações

- 1q09 Tia-222 Rev-G StandardsDocumento4 páginas1q09 Tia-222 Rev-G StandardssandbadbahriAinda não há avaliações

- DesignManual Specifications PRSC400Series 401WaterMainPressurePipelineConstructionDocumento53 páginasDesignManual Specifications PRSC400Series 401WaterMainPressurePipelineConstructionsandbadbahriAinda não há avaliações

- TN54E DatasheetDocumento2 páginasTN54E DatasheetGreggs ShopukAinda não há avaliações

- Forklift Daily Checklist ElectricDocumento2 páginasForklift Daily Checklist Electricmikel derrickAinda não há avaliações

- Module 5 DC MachinesDocumento94 páginasModule 5 DC MachinesABC XYZAinda não há avaliações

- Measuring Distance of Heavenly BodyDocumento28 páginasMeasuring Distance of Heavenly BodykhanAinda não há avaliações

- Determination of The Tensile Strength of An OCF Canister FoamDocumento3 páginasDetermination of The Tensile Strength of An OCF Canister Foamemre sönmezAinda não há avaliações

- ASME Technical Presentation 2013Documento152 páginasASME Technical Presentation 2013Siraj KhanAinda não há avaliações

- United States Patent (19) (11) Patent Number: 5,236,285: Prough (45) Date of Patent: Aug. 17, 1993Documento9 páginasUnited States Patent (19) (11) Patent Number: 5,236,285: Prough (45) Date of Patent: Aug. 17, 1993Herlan Setiawan SihombingAinda não há avaliações

- RMC ParameterDocumento4 páginasRMC Parameterkishor150688Ainda não há avaliações

- Manual Recambios 3.152.4 (CM51027) PDFDocumento149 páginasManual Recambios 3.152.4 (CM51027) PDFValoys MirandaAinda não há avaliações

- X Motion 125Documento219 páginasX Motion 125Vicente Torres LopezAinda não há avaliações

- DS PM0217 en Co 3755Documento2 páginasDS PM0217 en Co 3755prasad336Ainda não há avaliações

- Co Po MappingDocumento71 páginasCo Po MappingPoun KumarAinda não há avaliações

- PMS Series Hand Pumps PDFDocumento3 páginasPMS Series Hand Pumps PDFTran DucAinda não há avaliações

- Singly Reinforced Beam ExcelDocumento3 páginasSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Doors PDFDocumento34 páginasDoors PDFoz23Ainda não há avaliações

- Accra Technical University: Index NumberDocumento6 páginasAccra Technical University: Index NumberMoro Adams100% (1)

- Oil SeparatorDocumento2 páginasOil SeparatorOnofreAinda não há avaliações

- View thousands of Crane Specifications on FreeCraneSpecs.comDocumento64 páginasView thousands of Crane Specifications on FreeCraneSpecs.comD Rider Casanova100% (1)

- Lecture 4 - Particle Under A Net ForceDocumento15 páginasLecture 4 - Particle Under A Net ForceJ KimAinda não há avaliações

- Lecture VI - PID Controller in Pneumatic System (Use Case)Documento21 páginasLecture VI - PID Controller in Pneumatic System (Use Case)R.W. Saputra100% (1)

- Training System DS4Documento164 páginasTraining System DS4Henrry Roberto Amaya BazánAinda não há avaliações

- Naza Ria Rover KV6 Engine Cam Marking Manual PDFDocumento7 páginasNaza Ria Rover KV6 Engine Cam Marking Manual PDFAdrian PhillipsAinda não há avaliações

- Ies 1997 - II ScanDocumento21 páginasIes 1997 - II ScanK.v.SinghAinda não há avaliações

- Preliminary Heat Exchanger Sizing: These Calculations Are Provided For Educational Use Only - USE AT YOUR OWN RISKDocumento4 páginasPreliminary Heat Exchanger Sizing: These Calculations Are Provided For Educational Use Only - USE AT YOUR OWN RISKRaol VarshabenAinda não há avaliações

- Grundfos Catalogue Industry and Water UtilityDocumento542 páginasGrundfos Catalogue Industry and Water UtilityAdina Mariana Costache100% (7)

- Gmaw Fcaw PrinciplesDocumento136 páginasGmaw Fcaw PrinciplesReza SalimiAinda não há avaliações

- Alfa Laval BioPharm Fittings Catalog PDFDocumento102 páginasAlfa Laval BioPharm Fittings Catalog PDFcneo59Ainda não há avaliações

- Fluids and Buoyancy QuizDocumento2 páginasFluids and Buoyancy QuizWaleed El ShirbeenyAinda não há avaliações

- Protection, Monitoring and ControlDocumento22 páginasProtection, Monitoring and ControlSarah FrazierAinda não há avaliações

- Fire Test Report: ANSI/API Standard 607, 6th Edition, 2010 ISO 10497: 2010Documento16 páginasFire Test Report: ANSI/API Standard 607, 6th Edition, 2010 ISO 10497: 2010jamil voraAinda não há avaliações