Escolar Documentos

Profissional Documentos

Cultura Documentos

Perkins 1100 Series HD

Enviado por

SaadTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Perkins 1100 Series HD

Enviado por

SaadDireitos autorais:

Formatos disponíveis

Technical Data

1100D Series

1104D-44TG1

ElectropaK

Basic technical data

Performance

Number of cylinders .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4

Cylinder arrangement ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... in-line

Cycle. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .4 stroke

Induction system ... ... ... ... ... ... ... ... ... ... ... ... ... ... turbocharged

Combustion system .. ... ... ... ... ... ... ... ... ... direct injection diesel

Compression ratio. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 18,2:1

Bore .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 105 mm

Stroke ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 127 mm

Cubic capacity .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4,4 litres

Direction of rotation... ... anticlockwise when viewed from flywheel

Firing order (number 1 cylinder furthest from flywheel) ... .. 1 3 4 2

Estimated total weight of Electropak (dry) ... ... ... ... ... ... ...474 kg

Note: All data based on operation to ISO 3046-1:2002 standard

reference conditions.

Overall dimensions - Electropak

-height ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 967 mm

-length (air cleaner fitted) .. ... ... ... ... ... ... ... ... ... ... ... .. 1238 mm

-width ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 637 mm

Moments of rotational inertia (mk)

Engine rotational components . ... ... ... ... ... ... ... ... ... 0.132 kgm

Flywheel ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 1.2 kgm

Centre of gravity (fan face to flywheel housing)

Forward of rear face of cylinder block... ... ... ... ... ... ... . 227,2 mm

Above crankshaft centre line ... ... ... ... ... ... ... ... ... ... 160,4 mm

Offset to RHS of crankshaft centre line ... ... ... ... ... ... ... . 8,1 mm

All ratings certified to within .. ... ... ... ... ... ... ... ... ... ... ... ... + 5%

Speed variation at constant load ... ... ... ... ... ... ... ... ... .. + 0,25%

Cyclic irregularity for 1,2kgm flyweel inertia @ 1800 rev/min ... ...

0,0118 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

Test conditions

-air temperature . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25 C

-barometric pressure .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 100 kPa

-relative humidity ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 31.5%

-air inlet restriction at maximum power (nominal) .. ... ... ... ... 5 kPa

-exhaust back pressure at maximum power (nominal) .. ... . 15 kPa

-fuel temperature (inlet pump) ... ... ... ... ... ... ... ... ... ... ... ... 40 C

Sound level

Sound power level (exhaust piped away, cooling pack and air

cleaner fitted) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 106,5 dB(A)

Note: Note: Sound power level calculated from the mean of 4

microphones sited, in front, right, left and above the engine (1m

away)

If the engine is to operate in ambient conditions other than those of

the test conditions, suitable adjustments must be made for these

changes. For full details, contact Perkins Technical Service

Department.

Emissions capability: Certified against the requirements of Tier 3

legislation for non-road mobile machinery, powered by constant

speed engines (EPA 40 CFR Part 89 Tier 3).

General installation

Designation

Units

Prime

Standby

Gross engine power

kWb

58,0

64,0

Electropak nett engine power

kWm

57,0

63,0

Brake mean effective pressure

kPa

879

Engine coolant flow (against 35 kPa restriction)

l/min

971

151

Combustion air flow (at rated speed)

m/min

5,2

5,3

Exhaust gas flow (Max.)

m/min

12,8

13,7

Exhaust gas mass flow

kg/min

6,3

6,5

532

571

2,2

2,3

Exhaust gas temperature (turbocharger outlet)

Boost pressure ratio

Overall thermal efficiency (nett)

Typical genset electrical output (0.8pf 25 C)

Assumed alternator efficiency

35

33

kWe

51,3

56,7

kVA

64,1

70,9

90

Energy balance

Energy in fuel

kWt

172,1

190,1

Energy in power output (gross)

kWb

58,0

64,0

Energy to cooling fan

kWm

Energy in power output (net)

kWt

57,0

1,0

63,0

Energy to exhaust

kWt

59,3

66,9

Energy to coolant and lubricating oil

kWt

42,3

46,1

Energy to radiation

kWt

12,5

13,1

ACHN0145

ZM803

ZL002

ZJ006

ZC002

X0001

W0008

VD001

V3201

T0000

SD003

S0114

Q1100

N0101

M2416

L0056

K0001

JD001

J0051

HD004

H1220

G0101

F0022

E0111

D0004

C0001

A8053/A8054

202

221,1

517,5

DEUTSCH CONNECTOR

FOR LUBRICATING OIL

PRESSURE SWITCH

OIL PRESSURE SWITCH

TAPPING M12 X 1,5

M10 X 1

PLUGGED

1000

16 ACROSS

FLATS

94

CUSTOMER CONNECTION

DEUTSCH CONNECTOR

423,3

365,4

140,2

216,7

175,1

BREATHER OUTLET

186,3

55,6

8 BORE

47,6

1500

156,4

264,2

RETURN TO TANK CONNECTION TO SUIT

8 OR

10 BORE RUBBER HOSE

4-M12 X 1,75

BOTH SIDES

136,9

462,5

351,1

INLET CONNECTION TO SUIT

RUBBER HOSE

492,8

226,4

OPTIONS SHOWN

832,4

88,9

76,2

DEUTSCH DT 02P CONNECTOR

509,1

234,3

OVERALL DIMENSION

524,4

558,5

1238,4

1104D-44TG1 - Left side view GAA0760

1104D-44TG1 - Front view GAA0760

Z

637 OVERALL DIMENSION

298,7

291,5

705,9

141,2

131,5

131,5

240,4

243

265,6

262,5

Z

1000

88,9

76,2

221,1

403,5

540,5

627,1

47,6

171

55,6

216,7

519

455,6

1000

16 ACROSS

FLATS

BATTERY TERMINAL

M8 X 1,25

EARTH TERMINAL

M8 X 1,25

ALTERNATOR

416

456,6

545,9

889

887,3

2x

21

TEMPERATURE SWITCH

1500

432,5

232,3

OVERALL DIMENSION

966,6

219

1104D-44TG1 - Right side view GAA0760

260,3

12

1104D-44TG1 - Rear view GAA0760

Z

87,3

224,2

266,8

212,7 MAX

8-3/8-24UNF X 25.4

EQUISPACED ON

333,38 P.C.D.

8-M8 X 1,25 X 14,3

EQUISPACED ON

203,2 P.C.D.

218,1 STARTER MOTOR

8-3/8-24UNF X 25,4

EQUISPACED ON

295,28 P.C.D.

238,1

201,9

238,1

12-M10 X 1,5 X 20

DRILL PATTERN,

FLANGE AND SPIGOT

TO NO.3 S.A.E.

255,5

588,2

64,4

346,5 EXHAUST OUTLET

138,1

DEUTSCH

DT O2P

CONNECTOR

46

223,4

393,6

1104D-44TG1 - Plan view GAA0760

271

Cooling system

Cold start recommendation

Cooling pack

-overall weight (wet) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 71 kg

-overall face area . ... ... ... ... ... ... ... ... ... ... ... ... ... . 275834 mm

-width ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 550 mm

-height .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 762 mm

Radiator

Face area . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 275834 mm

Number of rows and materials . ... ... ... ... ... ... 2 rows, aluminium

Matrix density and material .. ... ... ... 12,7 fins per inch, aluminium

Width of matrix . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 526,2 mm

Height of matrix ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 524,2 mm

Pressure cap setting (min) ... ... ... ... ... ... ... ... ... ... ... ... 100 kPa

Fan

Diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 457,2 mm

Drive ratio.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1.25:1

Number of blades.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 7

Material . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .composite

Type .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . pusher

Cooling fan air flow @ 1800 rev/min . ... ... ... ... ... ... .. 98,2 m/min

Starter

model

At Temp.

C

Oil

viscosity

limit

AZE (1)

-5

AZE (1)

(2)

Minimum Battery CCA

(cold cranking amps)

With glow

plugs

(SAE)

Without

glow plugs

15W40

750

750

-10

15W40

850

950

-15

15W40

1125

(3)

AZF (2)

-20

10W40

1125

(3)

AZF (2)

-25

5W30

1500

(3)

AZF

1. AZE starter - Battery must not exceed 950 CCA.

2. AZF starter - Battery must not exceed 2400 CCA.

3. Glow plugs must be used.

The table above shows the recommended battery sizes against

starter model, temperature and oil viscosity and is based on the

test results from starting a bare engine with batteries at a 75%

state of charge and with a cable resistance of 0,0017 Ohms.

Coolant

Total system capacity ... ... ... ... ... ... ... ... ... ... ... ... ... . 16,5 litres

Engine capacity ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 7,0 litres

Maximum top tank temperature ... ... ... ... ... ... ... ... ... ... .. 112 C

Temperature rise across engine ... ... ... ... ... ... ... ... ... 6,6 - 7,0C

Max. permissible external system resistance ... ... ... ... ... .. 35 kPa

Thermostat operation range.. ... ... ... ... ... ... ... ... ... ... 85 to 95 C

Coolant pump drive type ... ... ... ... ... ... ... ... ... ... ... . Gear driven

Recommended coolant: 50% anti freeze / 50% water. For complete

details of recommended coolant specifications, refer to the

Operation and Maintenance Manual for this engine model

Induction system

Duct allowance

Maximum back pressure

Maximum additional retsriction (duct allowance) to cooling

airflow and resultant minimum airflow

Ambient clearance

50% Glycol

Duct allowance

Pa

m/min

46C

200

60

tba

tba

tba

Electrical system

Maximum air intake restriction

-clean filter.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...5 kPa

-dirty filter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...8 kPa

-air filter type... ... ... ... ... ... ... ... ... ... ... ... ... ... ... paper element

Exhaust system

-1800 rev/min ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..15.0 kPa

Exhaust outlet, internal diameter ... ... ... ... ... ... ... ... ... ... 64 mm

Fuel system

Type of injection . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... direct

Fuel injection pump ... ... ... ... ... ... ... ... ... ... ... ... ..Delphi DP310

Fuel atomiser.. ... ... ... ... ... ... ... ... ... ... . unit injector / multi-hole

Nozzle opening pressure ... ... ... ... ... ... ... ... ... ... ... ... 18,5 MPa

Fuel filter particle size (maximum).. ... ... ... ... ... ... ... ... 2 microns

Fuel lift pump

-type .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 12 Volt negative earth

Alternator type... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Denso A115i

-alternator voltage . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...12V

-alternator output... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..65 - 175A

Starter motor type . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . Iskra

-starter motor voltage ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...12V

-starter motor power AZE.. ... ... ... ... ... ... ... ... ... ... ... ... .. 3,2 kW

-starter motor power AZF .. ... ... ... ... ... ... ... ... ... ... ... ... .. 4,0 kW

Number of teeth on flywheel . ... ... ... ... ... ... ... ... ... ... ... ... ... 126

Number of teeth on starter pinion.. ... ... ... ... ... ... ... ... ... ... ... . 10

Minimum cranking speed .. ... ... ... ... ... ... ... ... ... ... .. 100 rev/min

Starter solenoid maximum

-pull-in current @ 0C ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...62A

-hold-in current @ 0C .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...14A

Cold start recommendations

Minimum required cranking speed over TDC ... ... ... .. 100 rev/min

-max flow through customer filter ... ... ... ... ... ... ... ... 2,2 litres/min

-max fuel supply restriction at lift pump .. ... ... ... ... ... ... ... .40 kPa

-max fuel return restriction @ low idle ... ... ... ... ... ... ... ... .50 kPa

-max fuel return flow ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,8 m/min

Maximum suction head .. ... ... ... ... ... ... ... ... ... ... 17 kPa (1.7 m)

Maximum static pressure head .. ... ... ... ... ... ... ... 10 kPa (1.0 m)

Governor type

LCS electronic - speed control conforms to ... ... ... ..ISO 8528, G3

Mechanical - speed control conforms to. ... ... ... ... ..ISO 8528, G2

1100D Series

1104D-44TG1

Fuel specification

Recommended SAE viscosity

Perkins recommend the use of the following fuel specifications:

z DIN E 590 DERV Grade A, B, C, E, F, Class 0, 1, 2, 3 & 4

Viscostiy grade

BS2869 Class A2 Off-highway Gas Oil Red Diesel

15W-40

ASTM D975, Class 1D and Class 2D

10W-40

JIS K2204 Grades 1, 2 & 3 & Special Grade 3

10W-30

Note: For further information on fuel specifications and restrictions,

refer to P.5 of the OMM Fuels section for this engine model

5W-40

Fuel consumption

0W-40

Load

Standby

rev/min

g/kWhr

rev/min

l/hr

243

18,7

Prime power

240

16,6

75% of Prime power

248

12,8

50% of Prime power

260

9,0

25% of Prime power

300

5,2

Note: Based on gross rated power.

Mountings

Flywheel housing ... ... ... ... ... ... ... ... ... ... ... ... ... SAE3 156,4mm

Maximum static bending moment at rear face of block.. ..1130 Nm

5W-30

0W-30

0W-20

-50

-40

-30

-20

-10

0

10

20

30

Ambient Temperature Deg C

Lubricating oil

-relief valve opens.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 450 kPa

-at maximum no-load speed .. ... ... ... ... ... ... ... ... ..280 - 340 kPa

Oil temperature

-continuous operation ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 125 C

-oil consumption at full load as a % of fuel consumption ... .. 0.15%

Distributed by

Hardy Diesels & Equipment Inc

15749 Lyons Valley Rd.

Jamul,CA 91935

800-341-7027

HardyDiesel.com

60

The below complies with the requirements of classification 3 and 4

of ISO 8528-12 and G2 operating limits stated in ISO 8528-5

Initial load application: When engine reaches rated speed

(15 seconds maximum after engine starts to crank)

Descriptor

Units

60 Hz

80

kWm (kWe)

45,6 (41,0)

Transient frequency

deviation

3,8

Frequency recovery

Seconds

0,6

Load (nett)

Maximum total system oil capacity ... ... ... ... ... ... ... ... ...8,4 litres

Minimum oil capacity in sump ... ... ... ... ... ... ... ... ... ... ...5,6 litres

Maximum oil capacity in sump ... ... ... ... ... ... ... ... ... ... ...6,9 litres

Maximum engine operating angles front up, front down, right side, left side . ... ... ... ... ... ... ... ... . 24

50

Load acceptance

% of prime power

Lubrication system

40

The above figures were obtained under the following test

conditions:

-minimum engine block temperature ... ... ... ... ... ... ... ... ... . 45 C

-ambient temperature .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 15 C

-governing mode . ... ... ... ... ... ... ... ... ... ... ... ... ... ... isochronous

-alternator inertia . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 8kgm

-under frequency roll off (UFRO) point set to .. ... 1 Hz below rated

-UFRO rate set to ... ... ... ... ... ... ... ... 2% voltage / 1% frequency

LAM on/off ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... off

All tests were conducted using an engine which was installed and

serviced to Perkins Engines Company Limited recommendations.

Note: The general arrangement drawings shown in this data sheet

are for guidance only. For installation purposes, latest versions

should be requested from the Applications Dept., Perkins Engines

Stafford, ST16 3UB United Kingdom.

Você também pode gostar

- 1104C-44T IOPU Technical Data Sheet PDFDocumento8 páginas1104C-44T IOPU Technical Data Sheet PDFBob100% (2)

- Caterpiller C32 Marine Engine Parts ManualDocumento533 páginasCaterpiller C32 Marine Engine Parts ManualandreyengAinda não há avaliações

- PRC2000 Operating ManualDocumento121 páginasPRC2000 Operating Manualmjam100Ainda não há avaliações

- Nerc Sra 2022Documento46 páginasNerc Sra 2022The Western Journal100% (1)

- Perkins 2800 Series WorkshopmanualDocumento10 páginasPerkins 2800 Series Workshopmanualmarylee100% (41)

- List of Standards and Guidelines For Drilling, Well Construction & Well OperationsDocumento2 páginasList of Standards and Guidelines For Drilling, Well Construction & Well OperationsInternational Association of Oil and Gas Producers100% (1)

- External Corrosion of PipeDocumento0 páginaExternal Corrosion of Pipejafarimehdi17Ainda não há avaliações

- Show Me YoursDocumento111 páginasShow Me YoursSetang Besar83% (6)

- Caterpillar 30 KVA Parts ManualDocumento486 páginasCaterpillar 30 KVA Parts ManualFarai MpasiAinda não há avaliações

- Fuel Optimized: Specification SheetDocumento3 páginasFuel Optimized: Specification SheetArslan AnnaAinda não há avaliações

- Perkins UkDocumento30 páginasPerkins UkAhmad RiyantoAinda não há avaliações

- 1104C 44taDocumento8 páginas1104C 44taWilmerAinda não há avaliações

- Mitsubishi Modelo S12h-Y1pta-3 - Mny1000 PDFDocumento3 páginasMitsubishi Modelo S12h-Y1pta-3 - Mny1000 PDFSalvador Millán EstradaAinda não há avaliações

- Manual Partes Motosoldadora Trailblazer 302 DieselDocumento12 páginasManual Partes Motosoldadora Trailblazer 302 DieselVictor Timana SilvaAinda não há avaliações

- Technical Data: 400 Series 403D-11GDocumento6 páginasTechnical Data: 400 Series 403D-11GMd ShAinda não há avaliações

- TM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceDocumento221 páginasTM 5-5060 1942 Le Roi Motorized Compressor On GMC DeuceAdvocateAinda não há avaliações

- 150KVA 6M11G4D0-S - StdRad2020 - DatasheetDocumento4 páginas150KVA 6M11G4D0-S - StdRad2020 - DatasheetJohan von Holdt100% (1)

- Perkins M215C and M185C 1006 SeriesDocumento2 páginasPerkins M215C and M185C 1006 SeriesDamian Cid Morales100% (1)

- Caterpillar Montacarga Motor S6S Manual Despiece InglesDocumento75 páginasCaterpillar Montacarga Motor S6S Manual Despiece InglesWuillians GuzmanAinda não há avaliações

- 404D-22T Iopu (Tpd1717e2)Documento10 páginas404D-22T Iopu (Tpd1717e2)hecazorlaAinda não há avaliações

- SS 578 2012 Portable Fire Extinguishers (Formerly CP55)Documento45 páginasSS 578 2012 Portable Fire Extinguishers (Formerly CP55)Andreas Indrakusuma100% (1)

- Dong-I Datos PDFDocumento8 páginasDong-I Datos PDFraulAinda não há avaliações

- 1104c 44t PerkinsDocumento2 páginas1104c 44t PerkinsValeddia Beatriz Gutierrez NinaAinda não há avaliações

- Duplex Drum Compactor LP6505 - HATZ 1D41 1D42 1D50 1D81 1D50 Diesel Operator ManualDocumento104 páginasDuplex Drum Compactor LP6505 - HATZ 1D41 1D42 1D50 1D81 1D50 Diesel Operator ManualBruce LiAinda não há avaliações

- Caterpillar Service Manual CT S Eng3304dDocumento10 páginasCaterpillar Service Manual CT S Eng3304dHugo VillcaAinda não há avaliações

- Pneumatic Maneuvering SystemDocumento65 páginasPneumatic Maneuvering Systemminhankyaw100% (3)

- 06R0862362+6067MK62 Piezas Comunes PDFDocumento2 páginas06R0862362+6067MK62 Piezas Comunes PDFAlexis SanchezAinda não há avaliações

- Perkins 1103A-33T - 50 kVA - 17653 - Generators - Roban TrucksDocumento8 páginasPerkins 1103A-33T - 50 kVA - 17653 - Generators - Roban TrucksAbdulrahman Al Huriby100% (1)

- KTA 19 Parts CatalogueDocumento58 páginasKTA 19 Parts CatalogueMP Vasu Raju100% (1)

- Workshop Manual Lombardini 3ld - 450Documento33 páginasWorkshop Manual Lombardini 3ld - 450Papiga AtosAinda não há avaliações

- VEHICLE 00003721: Spare Parts CatalogDocumento175 páginasVEHICLE 00003721: Spare Parts CatalogRasheed SiddiquiAinda não há avaliações

- TP6053 Catalago KohlerDocumento70 páginasTP6053 Catalago KohlerOperaciones Max Diesel ProAinda não há avaliações

- 9ld561-2 (Standardversion) PDFDocumento33 páginas9ld561-2 (Standardversion) PDFyanimarinAinda não há avaliações

- CEM 7CEA 7CEC 7CEM7 + CEC7Manual start•xx•Manual stop•xx•Automatic start••x•Automatic stop••x•Remote startx•xxRemote stopx•xxCEM 7CEA 7CEC 7CEM7 + CEC7Mains failureDocumento13 páginasCEM 7CEA 7CEC 7CEM7 + CEC7Manual start•xx•Manual stop•xx•Automatic start••x•Automatic stop••x•Remote startx•xxRemote stopx•xxCEM 7CEA 7CEC 7CEM7 + CEC7Mains failureMd MoniruzzamanAinda não há avaliações

- Inst Manual Engine General 47706356Documento164 páginasInst Manual Engine General 47706356giri_placid100% (1)

- 1104 C44 TAG2 TPD1637 Technical Data SheetDocumento8 páginas1104 C44 TAG2 TPD1637 Technical Data SheetFarhan JuttAinda não há avaliações

- 1sbc100122c0202 ch04Documento47 páginas1sbc100122c0202 ch04mathankumar1980Ainda não há avaliações

- Chongqing Cummins Engine Co. LTDDocumento3 páginasChongqing Cummins Engine Co. LTDYadhira Dominguez ZuritaAinda não há avaliações

- 1006tag2 PDFDocumento6 páginas1006tag2 PDFMuhammad Ahmad100% (4)

- Eq Generacion Electrica Iluminacion Olympian GEP150Documento5 páginasEq Generacion Electrica Iluminacion Olympian GEP150Gianni EscalanteAinda não há avaliações

- ENGINE MECHANICAL SECTIONDocumento32 páginasENGINE MECHANICAL SECTIONStelian CrisanAinda não há avaliações

- PERKINS ENGINE Identification Serial Number 35Documento1 páginaPERKINS ENGINE Identification Serial Number 35wilsonAinda não há avaliações

- 3004 kW 16V 4000 P83 Engine SpecsDocumento1 página3004 kW 16V 4000 P83 Engine SpecsAmir Asyraf SuhailiAinda não há avaliações

- Perkins Engines Guide VK - od.UADocumento5 páginasPerkins Engines Guide VK - od.UANoui BouzidAinda não há avaliações

- Deep Sea Electronics: Complex Solutions Made SimpleDocumento57 páginasDeep Sea Electronics: Complex Solutions Made SimpleRobertAinda não há avaliações

- Technical Data: 400 Series 403D-15GDocumento6 páginasTechnical Data: 400 Series 403D-15GOGAinda não há avaliações

- Perkins Companies 2TPD1361E1 PDFDocumento72 páginasPerkins Companies 2TPD1361E1 PDFMH..2023Ainda não há avaliações

- Diesel Generator Set QSL9 Series Engine: Power GenerationDocumento4 páginasDiesel Generator Set QSL9 Series Engine: Power Generationsdasd100% (1)

- Tad730ge 111797s01Documento8 páginasTad730ge 111797s01roozbehxoxAinda não há avaliações

- Valve Mechanism: Shutdown SISDocumento3 páginasValve Mechanism: Shutdown SISMoslem KhanlarpourAinda não há avaliações

- Catalogo Generador Olimpian 150-200 KWDocumento5 páginasCatalogo Generador Olimpian 150-200 KWlujes99Ainda não há avaliações

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocumento18 páginasSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudAinda não há avaliações

- ALLMAND Night-Lite PRO II Parts ManualDocumento93 páginasALLMAND Night-Lite PRO II Parts ManualBodega 3001Ainda não há avaliações

- 574-917 CrossReferenceGuideDocumento9 páginas574-917 CrossReferenceGuideJose Condori SalinasAinda não há avaliações

- FG Wilson F35Documento4 páginasFG Wilson F35Moncef RedAinda não há avaliações

- Ricardo 6105AZLD PDFDocumento2 páginasRicardo 6105AZLD PDFLogistician MALCOMSONAinda não há avaliações

- EBRair PDFDocumento290 páginasEBRair PDFBurik8Ainda não há avaliações

- Case 430Documento4 páginasCase 430Dian SikumbangAinda não há avaliações

- Operator Operator Manual Manual: Standby Power Generator Set, Powercommand® ControllerDocumento78 páginasOperator Operator Manual Manual: Standby Power Generator Set, Powercommand® ControllerDenis ChonAinda não há avaliações

- Engine Cat 3126B 175 HP 330 HP PDFDocumento7 páginasEngine Cat 3126B 175 HP 330 HP PDFdionymackAinda não há avaliações

- Olympian GEP 450 PrimeDocumento4 páginasOlympian GEP 450 PrimeMTU650100% (1)

- Datasheet Deutz 1015 SeriesDocumento2 páginasDatasheet Deutz 1015 SeriesRizki Heru HermawanAinda não há avaliações

- Industrial Open Power Unit: SeriesDocumento9 páginasIndustrial Open Power Unit: Serieseli abdul rohimAinda não há avaliações

- 403d 15g EngineDocumento4 páginas403d 15g EngineIqra khanAinda não há avaliações

- 6M16G275/5 Powerkit Engine Datasheet: RatingsDocumento4 páginas6M16G275/5 Powerkit Engine Datasheet: RatingsDANE80Ainda não há avaliações

- ZetorDocumento2 páginasZetorkokiskoAinda não há avaliações

- 3 1524 (1500)Documento6 páginas3 1524 (1500)mkAinda não há avaliações

- Ficha Tecnica 1006 GTDocumento6 páginasFicha Tecnica 1006 GTJonhatan Duque RamirezAinda não há avaliações

- Cracking The TOEIC PDFDocumento271 páginasCracking The TOEIC PDFSaad0% (2)

- Bank Exam Planner PDFDocumento163 páginasBank Exam Planner PDFSaadAinda não há avaliações

- Complete Car Care Manual PDFDocumento293 páginasComplete Car Care Manual PDFSaadAinda não há avaliações

- 5 TEAS Practice Tests PDFDocumento42 páginas5 TEAS Practice Tests PDFSaad86% (7)

- Straight Line Exam Revision QuestionsDocumento2 páginasStraight Line Exam Revision QuestionsSaadAinda não há avaliações

- 1001 Letters For All Ocassions PDFDocumento463 páginas1001 Letters For All Ocassions PDFSaad0% (1)

- Air Conditioning & Heat Pumps PDFDocumento152 páginasAir Conditioning & Heat Pumps PDFSaadAinda não há avaliações

- Automotive BrakesDocumento374 páginasAutomotive BrakesSaadAinda não há avaliações

- Letter of Complaint Requesting A Remedy For Faulty GoodsDocumento1 páginaLetter of Complaint Requesting A Remedy For Faulty GoodsSaadAinda não há avaliações

- English Secondary1 Part8Documento10 páginasEnglish Secondary1 Part8SaadAinda não há avaliações

- DynamicsDocumento16 páginasDynamicsAnonymous dlSmlsymHAinda não há avaliações

- F00 Final Exam-A.weinsteinDocumento2 páginasF00 Final Exam-A.weinsteinSaadAinda não há avaliações

- AdultDocumento7 páginasAdultSaadAinda não há avaliações

- Ahia Part1 Secondary1Documento7 páginasAhia Part1 Secondary1SaadAinda não há avaliações

- June 2014 Question Paper 11 PDFDocumento12 páginasJune 2014 Question Paper 11 PDFSaadAinda não há avaliações

- IES Mechanical Engineeering 2015Documento48 páginasIES Mechanical Engineeering 2015SaadAinda não há avaliações

- Computerhardwaretroubleshooting 120507230437 Phpapp01Documento26 páginasComputerhardwaretroubleshooting 120507230437 Phpapp01SaadAinda não há avaliações

- Electrical Engineering Objective Questions Part 8 PDFDocumento39 páginasElectrical Engineering Objective Questions Part 8 PDFMuthulakshmi JehanAinda não há avaliações

- Dynamics Solns Ch09Documento109 páginasDynamics Solns Ch09SaadAinda não há avaliações

- WS XI PH Rotational Motion RollingDocumento11 páginasWS XI PH Rotational Motion Rollingkaushik247Ainda não há avaliações

- Fermentor TypesDocumento33 páginasFermentor TypesFahad MukhtarAinda não há avaliações

- MSC.1 Circ.1197 Amendments To The Unified Interpretations To Solas Chapters II-1And XII Approved by MSC Circ.1176Documento5 páginasMSC.1 Circ.1197 Amendments To The Unified Interpretations To Solas Chapters II-1And XII Approved by MSC Circ.1176youngfpAinda não há avaliações

- Induction Material MoPnGDocumento60 páginasInduction Material MoPnGRaghvendra UpadhyaAinda não há avaliações

- Craftsman 320.29004Documento28 páginasCraftsman 320.29004Pablo DAinda não há avaliações

- Chapter 2 Internal Combustion Engine Performance ParametersDocumento10 páginasChapter 2 Internal Combustion Engine Performance ParametersFlancAinda não há avaliações

- "View" "Slide Show.": Resources Chapter MenuDocumento88 páginas"View" "Slide Show.": Resources Chapter Menuelty TanAinda não há avaliações

- Reference List AW Offshore Installation SYS 2007-08-16Documento10 páginasReference List AW Offshore Installation SYS 2007-08-16Sugeng WahyudiAinda não há avaliações

- Control Uniformity in Reactive Magnetron SputteringDocumento4 páginasControl Uniformity in Reactive Magnetron SputteringmikecostantiniAinda não há avaliações

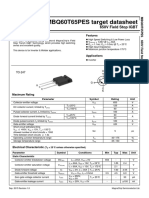

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDocumento1 páginaMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrAinda não há avaliações

- Response of Water Resources Systems To Climate ChangeDocumento355 páginasResponse of Water Resources Systems To Climate ChangePat Prodanovic100% (5)

- Carrier Chiller CatalogDocumento28 páginasCarrier Chiller CatalogYh Leong100% (1)

- Acd (Microproject Report)Documento42 páginasAcd (Microproject Report)Gaurav SapkalAinda não há avaliações

- CFBC Boilers & TG Set Auxillaries SpecificationsDocumento18 páginasCFBC Boilers & TG Set Auxillaries SpecificationsJAY PARIKHAinda não há avaliações

- Ramgarh Gas Power Plant OverviewDocumento31 páginasRamgarh Gas Power Plant Overviewswai singh100% (1)

- Type FL Low Profile NTC Temperature Sensor: AmphenolDocumento3 páginasType FL Low Profile NTC Temperature Sensor: Amphenolmauricio alfonsoAinda não há avaliações

- OCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Documento12 páginasOCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Soham PatwardhanAinda não há avaliações

- Waterwell Catalog WebDocumento96 páginasWaterwell Catalog WebJuan Carlos Sequeira RoblesAinda não há avaliações

- Saacke Steam Pressure Atomizer PDFDocumento2 páginasSaacke Steam Pressure Atomizer PDFKhaled SaadnehAinda não há avaliações

- GreenTech EC Technology enDocumento44 páginasGreenTech EC Technology enspscribd1Ainda não há avaliações

- W SeatDocumento2 páginasW SeatwalleyranAinda não há avaliações

- Electroanalytical Techniques for Studying Redox ReactionsDocumento3 páginasElectroanalytical Techniques for Studying Redox Reactionsjayapandis83Ainda não há avaliações

- TSSR 2g Grahafamily3 PKMDocumento43 páginasTSSR 2g Grahafamily3 PKMHaryo WAinda não há avaliações