Escolar Documentos

Profissional Documentos

Cultura Documentos

A9110E UBTS Commissioning

Enviado por

Nguyen Nam PhongDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

A9110E UBTS Commissioning

Enviado por

Nguyen Nam PhongDireitos autorais:

Formatos disponíveis

Alcatel BSS

A9110-E BTS Commissioning

Manual

BTS Document

Commissioning Manual

Release B9

3BK 17422 3081 RJZZA Ed.02

BLANK PAGE BREAK

Status

RELEASED

Short title

COM

All rights reserved. Passing on and copying of this document, use

and communication of its contents not permitted without written

authorization from Alcatel/Evolium.

2 / 74

3BK 17422 3081 RJZZA Ed.02

Contents

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2

Weight and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4

Initial State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5

Final State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7

Time Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8

Information Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1

Before Going to the Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2

Before You Start (On Arrival at the Site) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Micro - BTS Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1

Case A: Installation With the Manual Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2

Case B: Installation With the Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1

Specific Safety Instructions for Craning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2

Installation of the Crane on MOFRA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3

Preparation for Craning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4

Installing the Micro-BTS on MOCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making the Connections to the BTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1

OPTION: Installing the Integrated Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2

OPTION: Installing the VSWR Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1

Mechanics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2

Fixing the VSWR Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3

Connecting the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3

Making the Connections to the BTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Power Supply and Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1

Case 1: A9110-E BTS Without SSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2

Case 2: A9110-E BTS With SSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commissioning Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1

BTS Software Downloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2

BTS Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3

Performing BTS Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4

Setting and Checking the External Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1

Set and Check the Alarm Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2

Test the External Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5

Checking the Status of Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6

VSWR Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7

Abis Loop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8

End of Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Transmission Module Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the BSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Finishing Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9

10

10

13

13

13

13

13

15

16

17

17

19

20

20

21

22

26

26

26

28

29

33

34

35

35

36

37

38

41

42

42

45

46

48

49

49

49

50

52

52

55

55

57

Appendix A : Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix B : List of Items Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3BK 17422 3081 RJZZA Ed.02

3 / 74

Contents

Appendix C : Description of ABISCO and ACCO Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Appendix D : Antenna Port and External Alarm Mapping Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4 / 74

3BK 17422 3081 RJZZA Ed.02

Figures

Figures

Figure 1: Example of 6 Modules with Single Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2: Example Low-Loss Configuration With Antenna Diversity (6 sectors) . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3: Evolium A9110-E Pure Configuration (Maximum 6 Evolium A9110-E Modules, 12 TREs) . . . . . . 11

Figure 4: Evolium A9110-E / Evolium A9110 Mixed Configuration (5 Modules: 4 Evolium A9110-E +1 Evolium

A9110, 10 TREs in total) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5: Evolium A9110-E / Evolium A9110 Mixed Configuration (3 Modules: 1 Evolium A9110-E + 2 Evolium

A9110, 6 TREs in total ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6: Example of A9110-E BTS ( Maximum 6 Evolium A9110-E Configuration With Cover ) . . . . . . . . . 14

Figure 7: Example of A9110-E BTS (3 modules with SSC Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8: Installation and Arrangement of the Threaded Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 9: Installation of the Handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10: Installing the Gallows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 11: Installing the BTS Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 12: BTS Handle Fixed on the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 13: Putting the A9110-E BTS in Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 14: Fixing the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 15: Mounting the Lifting Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 16: Installing the Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 17: ACout BTS Power Connector of ACCO Board is Used to Power the Crane . . . . . . . . . . . . . . . . . . 28

Figure 18: Lifting and Plugging in the Micro-BTS Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 19: Fixing the Micro-BTS to MOCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 20: Installation of Integrated Antenna (GSM and DCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 21: The VSWR Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 22: VSWR Detector - RF Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 23: Connecting the ALARM / VCC Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 24: Connection of IEB PG 11 Glands to COBO for All Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 25: ACCO Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 26: SSC Switch Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 27: Sector Mapping Micro BTS Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 28: ABISCO Board for A9110-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 29: ABISCO Board for A9110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 30: Connectors and LEDs on ABISCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 31: Mechanical Drawing of ACCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 32: Electrical Drawing of ACCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 33: Application part Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3BK 17422 3081 RJZZA Ed.02

5 / 74

Figures

6 / 74

3BK 17422 3081 RJZZA Ed.02

Preface

Preface

Purpose

Whats New

This document describes how to commission an Alcatel A9110-E micro BTS.

This document applies to operational BSS, release B9.

In Edition 02

Editorial improvement.

In Edition 01

Creation in B9.

Audience

This document is intended for:

Site administrators

Supervisors

Project managers

Field service technicians

Occasional users.

Assumed Knowledge

The personnel involved must be familiar with:

ALCATEL Operation & Maintenance (O&M) concepts for the Base Station

Subsystem (BSS)

Commissioning tools

Personal Computers (PCs) using the Windows 2000/XP environment.

3BK 17422 3081 RJZZA Ed.02

7 / 74

Preface

8 / 74

3BK 17422 3081 RJZZA Ed.02

1 General Information

1 General Information

This chapter provides general information concerning the operating principle

and requirements of the procedure:

Hardware description

Prerequisites

Restrictions

Initial state

Final state

Tasks sequences

Time schedule

Information required

Conventions.

3BK 17422 3081 RJZZA Ed.02

9 / 74

1 General Information

1.1 Hardware Description

1.1.1 Configurations

With this product, one BTS comprises up to six units of two TRX, in a

hierarchical interconnection.

Only one of these units handles the Abis lines; this unit called the master,

the other units called slaves.

A unit can have one antenna output (3.2 W/TRX max. power) or two

antenna outputs (7 W/TRX max. power).

One lower slave cannot be equipped because of 12 TRX limitation!

In the following exemples the Slave 22 is eliminated, but depending on site

configuration, you can have maximum 3 lower slave units on the 4 possible

positions: Slave11, Slave12, Slave 21, Slave 22.

Figure 1: Example of 6 Modules with Single Antenna

10 / 74

3BK 17422 3081 RJZZA Ed.02

1 General Information

Figure 2: Example Low-Loss Configuration With Antenna Diversity (6 sectors)

The following rules are defined for pure Evolium A9110-E and Evolium

A9110/Evolium A9110-E mixed configurations:

Maximum 6 modules are allowed for Evolium A9110-E.

Maximum 3 hierarchy levels are allowed (Master, Upper Slave, Lower Slave)

M5 M

Master

M5M

M5 M

Upper Slave 1

Upper Slave 2

M5M

M5M

M5M

Lower Slave 11

Lower Slave 12

Lower Slave 21

Figure 3: Evolium A9110-E Pure Configuration (Maximum 6 Evolium A9110-E Modules, 12 TREs)

Evolium A9110 module allowed only as upper slave, no lower slaves can

connect to it.

3BK 17422 3081 RJZZA Ed.02

11 / 74

1 General Information

M5 M

Master

M5M

M4M

Upper Slave 1

Upper Slave 2

M5M

M5M

Lower Slave 11

Lower Slave 12

Figure 4: Evolium A9110-E / Evolium A9110 Mixed Configuration (5 Modules: 4 Evolium A9110-E +1 Evolium

A9110, 10 TREs in total)

M5 M

Master

M4M

M 4M

Upper Slave 1

Upper Slave 2

Figure 5: Evolium A9110-E / Evolium A9110 Mixed Configuration (3 Modules: 1 Evolium A9110-E + 2

Evolium A9110, 6 TREs in total )

12 / 74

3BK 17422 3081 RJZZA Ed.02

1 General Information

1.1.2 Weight and Dimensions

Each unit with cover

Each unit without cover

(2TRX, 2 ANT)

(2TRX, 2 ANT)

Width (mm)

450

385

Height (mm)

815 (w/ o PG)

735 (w/ o PG)

Characteristics

915 with fan (w/ o PG)

Depth (mm)

190

162

Max. weight with 2 ant. (kg)

26

26

Cover weight (kg)

7-9

Support weight (kg)

5.6

5.6

Maximum weight (kg)

38.6 - 40.6

31.6

1.2 Restrictions

None.

1.3 Prerequisites

The following prerequisites apply:

The site must comply with the Safety rules ( See BSS Methods Handbook

)

The BSC must be operational and ready for BTS connection

The following requirement is not mandatory: antenna connected.

1.4 Initial State

Before starting commissioning:

The MOCOs are installed and connected as described in the installation

manual: power supply, PCM (for master unit) even not connected to the

network, external alarms

The micro-BTS units are not plugged into their connection boxes.

1.5 Final State

After finishing commissioning:

The BTS is installed (master and slave units)

3BK 17422 3081 RJZZA Ed.02

13 / 74

1 General Information

The BTS is commissioned, powered up and connected to the BSC via a

PCM interface ready for network integration

Integrated antenna option: integrated antennas are installed on all units

Antennas present: the antennas have been connected

Antennas absent: the tests have been carried out under load.

Figure 6: Example of A9110-E BTS ( Maximum 6 Evolium A9110-E Configuration With Cover )

Alarm points

for Customer

SLAVE 2

MASTER

SLAVE 1

Customer

Alarm

Box

230 VAC

Wire braid

1.5 m

Ground

Plate

Figure 7: Example of A9110-E BTS (3 modules with SSC Option)

14 / 74

3BK 17422 3081 RJZZA Ed.02

1 General Information

1.6 Operating Principle

Preparation before leaving for the site

Preparation after arrival at the site

Manual lift/ Crane

Installation with the crane

Installation with the manual lift

Option: Installation of the integrated antenna

Option: Installation of VSWR detector

Making the connections to BTS

Checking power supply and powering up

BTS software downloading

Setting antenna mapping

BTS initialization

Performing BTS inventory

Setting and checking the external alarms

Checking status of modules

YES

NO

Case: Antenna present

Checking the VSWR under load

Checking the antenna VSWR

Abis loop test

End of commissioning test

Setting transmission module paramenters

Connecting to the BSC

Finishing commissioning

3BK 17422 3081 RJZZA Ed.02

15 / 74

1 General Information

1.7 Time Schedule

Duration (min)

1st person

2nd person

Before leaving for the site

10

10

Before you start

Case A: Installation with the manual lift

10 / unit

10 / unit

Case B: Installation with the crane

15 / unit

15 / unit

Option: Installation of integrated antenna

5 / unit

5 / unit

Option: Installation of the VSWR detector

10 / unit

10 / unit

Making the connections to BTS units

5 / unit

5 / unit

10

10

BTS software downloading

Setting antenna mapping

BTS initialization

Performing BTS inventory

Setting and checking the external alarms

Checking status of modules

VSWR check

5 / unit

5 / unit

Abis loop test(2)

3(2)

3(2)

End of commissioning

5-10

Setting transmission module parameters

Connecting to the BSC

Finishing commissioning

1h 32 - 2h 50

1h 08 - 2h 15

Preliminary checks

Installing the micro-BTS units(1)

Making the connections to the BTS

Checking power supply and powering up

Commissioning tests

(3)

(1)

: Tasks where two persons are mandatory

(2)

: Not performed if MW or TNL equipment installed in SSC

(3)

: 10 min only if the inventory has to be performed again

16 / 74

3BK 17422 3081 RJZZA Ed.02

1 General Information

The times given are based on technical constraints, not taking into account

safety considerations.

1.8 Information Required

Site

Position of breakers on the customers power panel

If DDF cabled: position of PCM cables (Abis1, Abis2) on the DDF side.

Equipment configuration

Configuration of the BTS (number of units, type: Evolium A9110/Evolium

A9110-E)

Configuration of sectors and number of MTREs per sector

Mapping table correlating logical and physical BTS sectors

If DDF installed: external alarm mapping and position of alarm wires on

the DDF side

If SSC option: customer external alarm mapping (other than SSC external

alarms).

Other

Software version

Test frequencies

Transmission configuration

Qmux address

OML TS and signalling rate (optional).

Antennas connected or not.

1.9 Conventions

The following list gives the conventions used in this document:

Press [ Enter ] means press the Enter key

Click [ OK ] means click the button OK with the mouse

Operator input is indicated after a double right-pointing arrow in Courier font

Operator input

To describe a menu path, the menu options are linked as follows:

Tools Options Printer ...

A message is indicated in Courier font:

Message

3BK 17422 3081 RJZZA Ed.02

17 / 74

1 General Information

18 / 74

3BK 17422 3081 RJZZA Ed.02

2 Preliminary Checks

2 Preliminary Checks

This chapter describes the preparation of the operation in two steps:

At base

On arrival at the site.

3BK 17422 3081 RJZZA Ed.02

19 / 74

2 Preliminary Checks

2.1 Before Going to the Site

Check prerequisites fulfillment

See Prerequisites (Section 1.3) .

Check availability of information

required

See Information Required (Section 1.8) .

Check availability of documentation

See List of Documents Required (in section B) .

Check availability of tools

See Tools Required (in section B) , refer to the Tools

catalogue for content checking.

Verify the calibration label when indicated in Tools Required

(in section B) .

Check availability and version of

software

See List of Software Required (in section B) ; refer to the

corresponding documents for checking the SW version.

2.2 Before You Start (On Arrival at the Site)

Check applicable notification list and

Operation Instructions

Refer to Applicable Notifications List (ITL) for checking if

notifications have to applied during the operation.

Refer to Applicable Operation Instructions List (IO) for

checking if operation instructions have to applied.

Check that safety instructions are

applied

Refer to BSS Methods Handbook for checking that safety

precautions have been taken into accordance with safety

instructions.

Read instructions to be applied in case

of anomaly

Refer to BSS methods Handbook for instructions.

Complete premises inspection form

Refer to BSS site premises inspection, post handover and

complete Premises inspection form (CEL).

Fill in completion check list

Complete the header field of the CCL (See Completion

Check List)

In particular, see tools catalogue and note down

measurement accuracy when indicated in tool kit list

(appendix)

The CCL is completed as each installation instruction is

carried out.

Check the antistatic wrist strap

Check that the resistance of the antistatic wrist strap is

greater than 1M .

Connect the antistatic wrist strap to rack earth.

Check availability of Alcatel kits

20 / 74

See List of Items Required (Section B) .

3BK 17422 3081 RJZZA Ed.02

3 Installing the Micro - BTS Units

3 Installing the Micro - BTS Units

This chapter describes the procedure for fixing the micro BTS on MOFRA.

Before the installation of the BTS units, check the lead seal.

If damaged, make a note in the CCL.

The installation procedure is the same for master and slave units.

Do not work under power.

Open the circuit breakers to be sure that the power supply is disconnected.

For an installation with SSC: Check that the " Battery back-up " is OFF (red

LED is lit) !!! (in the case of battery back-up there is 288 V DC on the BTS

connector and the crane will be damaged!!!)

3BK 17422 3081 RJZZA Ed.02

21 / 74

3 Installing the Micro - BTS Units

3.1 Case A: Installation With the Manual Lift

Purpose

Preparation

To install the BTS on the MOCO.

1. Open the front cover to reveal the MOCO (with cover option)

2. Remove the COBO protection cover (3BK 08586 AA).

3. Remove the bottom protection cover of the micro-BTS unit (3BK 08555 AA).

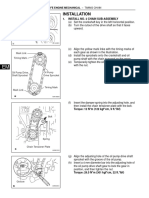

Install the Threaded Bolt

1. The threaded bolt must be screwed into the M8 thread on top of the A9110-E

BTS housing, down to the internal screw-thread stop (See Figure 8 )

2. Do not tighten

3. Arrange the bolt with the flattened sides to the left and right.

Figure 8: Installation and Arrangement of the Threaded Bolt

22 / 74

3BK 17422 3081 RJZZA Ed.02

3 Installing the Micro - BTS Units

Install the Handwheel

1. The handwheel must be screwed down to the threaded bolt stop (See

Figure 9 )

2. Make sure the handwheel and bolt are not damaged

Figure 9: Installation of the Handwheel

Install the Gallows

1. The gallows are plugged into the Mounting Frame (MOFRA) (See Figure 10 )

2. The safety catch (1) keeps the gallows in place.

Figure 10: Installing the Gallows

3BK 17422 3081 RJZZA Ed.02

23 / 74

3 Installing the Micro - BTS Units

Install the BTS-Handle

1. Fix the metal pieces (3) with screws (4 two at each side) to each side of

the BTS Handle (2), see figure 11

2. Fix the assembly to the the hinge flanges, with one screw (4) at each

side (picture 12 )

1

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

123456789012345678

Figure 11: Installing the BTS Handle

3. Remove the A9110-E BTS protective cap.

Figure 12: BTS Handle Fixed on the Module

24 / 74

3BK 17422 3081 RJZZA Ed.02

3 Installing the Micro - BTS Units

Install the A9110-E BTS

in Position

1. Two people place the unit in the gallows (See Figure 13 )

2. The A9110-E BTS housing is let down by rotating the handwheel.

3. Ensure that the housing descends into the right position.

Figure 13: Putting the A9110-E BTS in Position

Fix the BTS in Position

1. Fix the housing on the mounting frame with the two screws on top of

housing (See Figure 14 )

2. Fix the housing on COBO with the two screws left and right of COBO.

Figure 14: Fixing the Unit

Remove the Manual Lift

and the Handle

1. Completely unscrew the handwheel, then remove it

2. Remove the gallows from MOFRA, by lifting it (and pushing the safety catch)

3. Unscrew the threaded bolt and remove it from the housing

4. Detach the BTS-handle from the housing by releasing the screw (5) on

figure 11.

3BK 17422 3081 RJZZA Ed.02

25 / 74

3 Installing the Micro - BTS Units

3.2 Case B: Installation With the Crane

3.2.1 Specific Safety Instructions for Craning

You must carefully read the " A9110 Crane Instruction Manual " and these

instructions before using the crane.

It is strictly prohibited to stand under a floating crane load during the

operation

Hot surface warning : Dont handle the crane by its motor after use, the

temperature can exceed 45 degrees Celsius (see left, " Hot Surface "

label on the crane)

Check availability of the completed " Security control - check list and report

", enclosed with the crane (see " A9110 Crane Instruction Manual " ) the check

must be carried out every six months, note the check date in the CCL.

3.2.2 Installation of the Crane on MOFRA

Procedure

1. Check that the lifting ring and the two screws for fixing to MOFRA are

available

2. Mount the lifting ring onto the top part of the micro-BTS unit. The ring must

be screwed completely (See Figure 15 )

3. Put the crane on top of MOFRA. The small safety blade keeps the crane

in place (See Figure 16 )

4. Open the COBO door

5. Connect the crane power cable to the ACout BTS power connector (See

Figure 17 )

6. Hook the cables as shown in the drawings.

Figure 15: Mounting the Lifting Ring

26 / 74

3BK 17422 3081 RJZZA Ed.02

3 Installing the Micro - BTS Units

Crane

MOFRA

Power cable

Figure 16: Installing the Crane

Ac out BTS connector is

used to power the crane

3BK 17422 3081 RJZZA Ed.02

27 / 74

3 Installing the Micro - BTS Units

Figure 17: ACout BTS Power Connector of ACCO Board is Used to Power the Crane

3.2.3 Preparation for Craning

The following checks and precautions must be considered before craning!

Depending of the country and customer regulations more tests for

overloading and usage time may be required.

To be checked and applied!

Purpose

To check the fixing of the MOCO and crane.

Procedure

1. Check the screws securing the MOCO on the wall

2. Define a safety area 2 m around the MOFRA and make sure that nobody will

enter the area during operations

3. Move the unit under the crane on the floor

4. Remove the COBO protection cover (3BK 08586 AA).

5. Close the circuit breakers that power COBO

6. Using the switching box on the crane power cable, let down the lifting

band to the micro-BTS level

7. Hang the unit on the crane (make sure the belt is not turned on itself)

8. Lift the unit and suspend it 10 cm above the floor

9. Execute a movement up and down with the micro-BTS

10. Lay the micro-BTS an the floor

11. Check the MOFRA - Crane assembly and fixings.

28 / 74

3BK 17422 3081 RJZZA Ed.02

3 Installing the Micro - BTS Units

3.2.4 Installing the Micro-BTS on MOCO

Figure 18: Lifting and Plugging in the Micro-BTS Unit

3BK 17422 3081 RJZZA Ed.02

29 / 74

3 Installing the Micro - BTS Units

Take care not to damage the connectors during the operation.

Do not lift the BTS by hand from the ground, use the crane!

Do not work under power

Open the circuit breakers to be sure that the power supply is

disconnected.

For installation with SSC: Check that the Battery back-up is OFF

(red LED is lit) !!!

Purpose

To install the BTS on the MOCO.

Procedure

1. Lift the micro-BTS unit to an appropriate level for mounting (See Figure 18 )

2. Remove the bottom protection cover of the micro-BTS unit (3BK 08555 AA).

3. Fit the handle on the reel of the crane, on the left side

4. Move the micro-BTS nearer to the MOFRA (by pushing the handle) and fit it

onto the guide bolts (there are two guide bolts on MOFRA that must fit into

the back part of the micro-BTS unit)

5. Plug the micro-BTS unit into the COBO by slowly releasing the unit and

fitting the two guide pins of the COBO into the corresponding holes in the

micro-BTS housing

6. Fix the micro-BTS onto the MOCO using the four screws provided (See

Figure 19 )

7. Unhook the micro-BTS

8. Unplug the crane power cable

9. Remove the crane from MOFRA

10. Unscrew the lifting ring and put it with the crane to avoid losing it.

30 / 74

3BK 17422 3081 RJZZA Ed.02

3 Installing the Micro - BTS Units

Figure 19: Fixing the Micro-BTS to MOCO

3BK 17422 3081 RJZZA Ed.02

31 / 74

3 Installing the Micro - BTS Units

32 / 74

3BK 17422 3081 RJZZA Ed.02

4 Making the Connections to the BTS

4 Making the Connections to the BTS

This chapter describes:

How to install the integrated antenna, with the integrated antenna option

How to instal the VSWR detector, with the VSWR option

How to make the necessary connections to the BTS units

3BK 17422 3081 RJZZA Ed.02

33 / 74

4 Making the Connections to the BTS

4.1 OPTION: Installing the Integrated Antenna

Purpose

To install the integrated antenna on each micro-BTS unit (master and slaves).

This procedure is the same for master and slave units.

Figure 20: Installation of Integrated Antenna (GSM and DCS)

Connect the integrated antenna to the upper housing side of the A9110-E

BTS using the four self tapping screws (M3 x 16) provided in the integrated

antenna kit.

The above figure also shows the special front cover and the final view of a

BTS with integrated antenna.

On fact, the front cover will not be mounted until the end of commissioning.

34 / 74

3BK 17422 3081 RJZZA Ed.02

4 Making the Connections to the BTS

4.2 OPTION: Installing the VSWR Detector

Purpose

To install the VSWR detector on each micro-BTS unit (master and slaves)

This procedure is the same for master and slave units.

4.2.1 Mechanics

Figure 21: The VSWR Detector

3BK 17422 3081 RJZZA Ed.02

35 / 74

4 Making the Connections to the BTS

4.2.2 Fixing the VSWR Detector

The VSWR detector can not be used together with an integrated antenna, if the

isolation between antennas on the same site is < 25 dB.

Procedure

1. Unlock the bottom section of the front protective cover, open it upwards and

fix it at the front cover by the installed magnetic snap-on fastening

2. Connect the VSWR detector to the antenna output connector of the A9110-E

by screwing the N male connector (See Figure 22 )

3. Connect the VSWR RF jumper cable to the RF output N-female connector of

the VSWR detector

4. Connect the standard antenna cable to the RF jumper cable.

Evolium

BTS A9110E

Antenna Jumper

COBO

VSWR

detector

F M

RF Jumper Cable

F M

M : Nmale connector

F : N female connector

Figure 22: VSWR Detector - RF Installation

36 / 74

3BK 17422 3081 RJZZA Ed.02

4 Making the Connections to the BTS

4.2.3 Connecting the Cables

Procedure

1. Open the COBO

2. Unscrew the appropriate PG gland

3. Run the ALARM / VCC cable through that PG gland into COBO

4. Screw the PG gland with the ALARM/ VCC cable

5. Connect the ALARM/ VCC wires inside the COBO to the clamp strips

located on the ABISCO board as shown in Figure 23 .

In a two antenna configuration the isolated wires for VCC-VSWR1 and

VCC-VSWR2 and ground (GND) have to be fixed together with the enclosed

cable and sleeves and inserted in the described terminals of the ABISCO

(See Figure 23 ).

Figure 23: Connecting the ALARM / VCC Cables

3BK 17422 3081 RJZZA Ed.02

37 / 74

4 Making the Connections to the BTS

4.3 Making the Connections to the BTS

One lower slave cannot be equipped because of 12 TRX limitation!

Depending on site configuration, you can have maximum 3 lower slave units

on the 4 possible positions: Slave11, Slave12, Slave 21, Slave 22.

When connecting a slave unit, the position where to plug the IEB cable into

master unit (S1 or S2 connectors) will determine if it is Slave1 or Slave2.

Purpose

To connect the antenna

To connect the IEB cables in a master-slave configuration.

Procedure

1. With the integrated antenna option, connect the integrated antennas RF

cables to the antenna connector(s) of the micro-BTS unit (master and

slaves, as appropriate)

2. With external antennas, connect the antenna jumper(s) to the antenna

connector(s) of the micro-BTS units (master and slaves) according to their

sector number (See Information Required (Section 1.8) )

3. To install the slave units, connect the IEB cables between the master and

slaves:

At the Master unit plug the cable into the Conn. to Slave 1 or

Conn. to Slave 2 connector, depending the slave (1 or 2) that is

going to be connected

At the Slave 1 unit plug the cable from master into the Conn. to

Master connector. Plug the cable to Slave 11 into Conn. to Slave 1

and / or the cable to Slave 12 into Conn. to Slave 2.

At the Slave 2 unit plug the cable from master into the Conn. to

Master connector. Plug the cable to Slave 21 into Conn. to Slave 1

and / or the cable to Slave 22 into Conn. to Slave 2.

At the Slave 11 unit and / or Slave 12 unit plug the cables from Slave1

into the Conn. to Master connector.

At the Slave 21 unit and / or Slave 22 unit plug the cable from Slave2

into the Conn. to Master connector.

38 / 74

3BK 17422 3081 RJZZA Ed.02

4 Making the Connections to the BTS

SLAVE 1

MASTER

To SLAVE 2

From MASTER

To SLAVE 11

To SLAVE 12

To SLAVE 1

SLAVE 11

From SLAVE 1

SLAVE 2

From MASTER

SLAVE 12

To SLAVE 21

SLAVE 21

From SLAVE 2

From SLAVE 1

Figure 24: Connection of IEB PG 11 Glands to COBO for All Modules

3BK 17422 3081 RJZZA Ed.02

39 / 74

4 Making the Connections to the BTS

40 / 74

3BK 17422 3081 RJZZA Ed.02

5 Checking Power Supply and Powering Up

5 Checking Power Supply and Powering Up

This chapter describes how to check the power supply voltage and power up

the micro-BTS units (master and slaves).

Before checking the power supply and powering up the micro-BTS, ensure

that the safety instructions in the SAF procedure are followed ( See BSS

Methods Handbook ). It is essential that:

The protective earth is connected to the equipment earth terminal

The ACout BTS connectors in the COBOs (Figure 25 ) that feed the

micro-BTS units are disconnected.

3BK 17422 3081 RJZZA Ed.02

41 / 74

5 Checking Power Supply and Powering Up

5.1 Case 1: A9110-E BTS Without SSC

Procedure

1. Check the power panel to make sure the breakers are OFF

2. Using a multimeter, check at each COBO that there is no voltage between L

(line) and N (neutral) , N and PE (protective earth), L and PE (See Figure 25 )

3. Close the circuit breakers at the power panel

4. Check the voltage (220 V AC) between line (L) and neutral (N) on the

ACout BTS connector of each COBO

5. Check that there is no voltage between N and PE

6. Power up the unit by plugging in their ACout BTS connectors.

FIRST power up the master unit, THEN power up the slave units!

The slave units MUST be powered up within seconds after powering

up the master unit.

5.2 Case 2: A9110-E BTS With SSC

Procedure

1. Check the power panel to make sure the SSC breakers are OFF

2. Check the SSC to make sure main AC switch S1 is off and no green LEDs

are lit (See Figure 26 )

3. Close the circuit breakers at the site power panel

4. Close main switch S1, the AC mains breaker then the BTS1, BTS2,

BTS3 circuit breakers in the SSC

5. Check the 220 V AC voltage between line (L) and neutral (N) on the ACout

BTS connector (X401) of each COBO (See Figure 25 )

6. Check that there is no voltage between N and PE

7. Check that the Mains Power supply 1 and 2 and Charger LEDs are lit on

the SSC front panel

8. Push (if necessary) the Battery backup button to on (red LED is not lit)

9. Power up the A9110-E units by plugging in their ACout BTS connectors.

FIRST power up the master unit, THEN power up the slave units!

The slave units MUST be powered up within seconds after powering

up the master unit.

10. Check that the BTS remains on battery supply if main switch S1 is

disconnected, then set the switch S1 to ON

11. Push and hold down the Fan Test button and check that the SSC top fans

are working.

42 / 74

3BK 17422 3081 RJZZA Ed.02

5 Checking Power Supply and Powering Up

If the BTS must be powered down, disconnect the batteries first by pushing

the Back-up Off switch to ON (red LED is lit), then set the main power

switch S1 to OFF.

ACout

BTS

IEC Conn.

X402

FAN

BTS fuses

X401

X400

ACin, Mains

(T=2.5 A)

L

PE

N

L PE N

N

FAN fuses

(T=2.5 A)

L PEN

L PEN

SLAVE 2

SLAVE 1

X404

X403

Figure 25: ACCO Board

Fan Test

PS1

PS2

PS3

Power Supply 1

Power Supply 2

Battery

backUp

button

Charger

Mains

BackUp

Off

Battery unit

S1

Power 230V AC

Socket

AC Connection Area 230V AC

AC BTS1 BTS3

mains

BTS2

Figure 26: SSC Switch Configuration

3BK 17422 3081 RJZZA Ed.02

43 / 74

5 Checking Power Supply and Powering Up

44 / 74

3BK 17422 3081 RJZZA Ed.02

6 Commissioning Tests

6 Commissioning Tests

This chapter describes the following operations:

BTS software downloading

Setting antenna mapping

BTS initialization

Performing BTS inventory

Setting and checking the external alarms

Checking status of modules

Checking the antenna VSWR

Abis loop test

End of commissioning.

Use the antistatic wrist strap when working with the ABISCO board.

Check that the BTS is isolated :

At the DDF side by disconnecting terminals, from the PCM link coming

from the network.

For installation with SSC, by disconnecting connectors X2, X3 and X4

on the connection area.

One lower slave cannot be equipped because of 12 TRX limitation!

Depending on site configuration, you can have maximum 3 lower slave units

on the 4 possible positions: Slave11, Slave12, Slave 21, Slave 22.

Configuration is determined by IEB cable connections between units

3BK 17422 3081 RJZZA Ed.02

45 / 74

6 Commissioning Tests

6.1 BTS Software Downloading

Start up BTS Terminal

1. Connect the BTS Terminal cable between the COM1 port of the PC and

the MMI connector (X100) on the ABISCO board of the master unit (See

Figure 28 )

2. Launch the BTS Terminal according to the OS used (Windows 2000/XP)

3. At the BTS Terminal enter:

If software upgrade must be performed during commissioning:

User/Group name :

UPGRAD

Password :

SUMSUP

If only commissioning must be performed:

User/Group name :

COMMTE

Password :

COMMTE

Click [ Logon ].

The Setup Information window usually appears.

Set the Baud Rate

If not already done, set the baud rate of the connection and the path

to the Inventar software

1. If the Setup Information window is displayed:

Click [ Baudrate ] or choose:

Settings Terminal

2. Select 115200 and the port under the Serial Interface tab in the BTS

Terminal part of the window

3. Select the Misc tab and if not already done, click [ Browse ] and select the

path to INVENTAR (usually c:\WINVENT\Program\pwinvent.exe)

4. Click [ Ok ].

Select the terminal

Set up the connection

OPTION:

Select BTS Terminal (Evolium BTS)

File Connect/ Disconnect

Only if the Files are not Already on the PC

1. Create the directory : c:\A9110_fls

2. Copy all the BTS SW files into the above directory.

46 / 74

3BK 17422 3081 RJZZA Ed.02

6 Commissioning Tests

Download the BTS With

the BTS TE

1. Commissioning Download BTS-SW...

If a message asking you to check the Qmux address appears, set the correct

Qmux address and save it !

Select at List files of type: on the left bottom corner: All files (*.*)

Masterfile: bm*sav**.*** (1) (See Information

Required (Section 1.8) )

CPF File: 00o2av**.ddl (1)

(1) Click [ Browse ] to give the path of each file: c:\A9110_fls

2. Click [ Download ].

Check the Downloading

of the BTS

1. A disconnection occurs during the download, wait for the connection to

be re-established

2. The message The connection to the OMU has been established

! appears

3. The following messages or windows appear during downloading:

No operator action during next 80 seconds!!!

BTS SW download in progress...

Start operational software...

No operator action during next 80 seconds!!!

BTS SW download in progress...

Initialization in progress...

Receiving data...

Reading all RIs .

If the file downloading stops during several minutes and the BTS Terminal

is showing no message or action, perform a second download of the BTS

( See Download the BTS With the BTS TE (in section 6.1) .)

BE PATIENT:

WAIT for the Edit frequencies window, about 5 mn:

1. Select the Frequency band (GSM 900/ DCS 1800/ DCS 1900/ EGSM)

2. Select the test frequency by clicking [ Add ] or [ Remove ] in Available

ARFNs list to obtain the correct frequencies in Select ARFNs list. The

test frequencies are given by the customer (See Information Required

(Section 1.8) ).

3. Click [ Submit ].

4. Wait for Sector mapping window (See Figure 27) to open.

5. Set the mapping of BTS units ports to sectors, according to the requested

configuration and the mapping rules (See Information Required & Antenna

Port and External Alarm Mapping Rules (Section D)

6. Click [ Save ]

7. Wait for Updating flash... and Cabling detection in progress... messages

to disappear.

3BK 17422 3081 RJZZA Ed.02

47 / 74

6 Commissioning Tests

Figure 27: Sector Mapping Micro BTS Window

6.2 BTS Initialization

Initialize Commissioning

1. At BTS Terminal select:

Commissioning Initialization All sectors...

2. Wait for the Initialization for commissioning in progress

message to disappear

3. The HW check configuration window appears

4. Check that the configuration shown in the HW check configuration

window corresponds to the requested HW configuration (See Information

Required (Section 1.8) )

5. Wait for the MTRE and ANX module downloading to finish.

Workaround:

48 / 74

If the HW check configuration window information does not correspond

to the antenna mapping information written in RI (this behaviour appears

usually when the final antenna mapping information is different from the initial

information), repeat the initialization of all sectors (steps 1 and 2).

3BK 17422 3081 RJZZA Ed.02

6 Commissioning Tests

Activation is finished when the options in the commissioning menu becomes

active.

6.3 Performing BTS Inventory

1. Use the tasks specified in CI 08 - Site Equipment Inventory for:

Adding additional modules in RI

Executing the Inventar program for the BTS

2. For SSC installation, the SSC is considered as an additional module.

Check that there are no alarms when running the Inventar for BTS. This

means that the modules inside the BTS meet the requirements for a

specific customer.

6.4 Setting and Checking the External Alarms

Purpose

To set the external alarm mapping in the RI according to requirements

To check the reporting of external alarms to the BTS TE.

6.4.1 Set and Check the Alarm Mapping

Set the logical number

of the external alarms

1. AT BTS Terminal select:

Commissioning Edit Remote Inventory (RI)...

2. Module selection: UT_BTS_BCB 17

3. Click [ Upload ]

4. Click [ Application part ]

5. In the Application part window set the external alarm mapping according

to the rules in the Appendix (See Information Required (Section 1.8) &

Antenna Port and External Alarm Mapping Rules (Section D) )

6. Click [ Manufacturing part ]

7. Click [ Write back ] if modifications were made. Wait for Updating

flash... message to disappear.

8. Click [ Close ].

Loop the External Alarm

Loop the External Alarm Inputs that are not Connected to Their Sensors

1. On the DDF loop the external alarms that are not connected to their sensors

to avoid reporting of alarms to the OMC-R

2. On the ABISCO board of each unit (master or slave) loop the declared alarm

inputs that do not reach the DDF and are not yet connected to their sensors.

3BK 17422 3081 RJZZA Ed.02

49 / 74

6 Commissioning Tests

6.4.2 Test the External Alarms

Check the Alarms

1. On the BTS Terminal display the external alarms

2. Monitor Active Alarms

3. On the BTS Terminal check that there are no external alarms.

Check the Alarms in DDF

If the external alarms are transferred to a terminal block, generate an

alarm and check its appearance on BTS Terminal

1. Open the circuits corresponding to the external alarms on the DDF side, by

inserting a red disconnecting pin into the terminal block

2. On the BTS Terminal, check that the appropriate alarm message is

generated

3. Close the circuit that has been opened at the terminal block by removing the

disconnecting pin

4. On the BTS Terminal, check that the external alarm message has

disappeared.

Check the Alarms That

Do Not Reach the DDF

In COBO (master and slaves)

1. For the declared external alarms that do not reach the DDF, generate an

alarm by opening and then closing a loop (See Connectors Description (in

section C) in appendix for connectors description)

2. Check alarm reporting on the BTS Terminal.

Note:

If the Fan option was included, check the fan alarm:

1. Disconnect the fan power supply cable from ACCO board

2. On the BTS Terminal , check that the alarm is present:

BTS1, BTS EXTERN, Air condition (1)

3. Plug in the fan power supply cable and check that the alarm is cleared.

Note:

If the SSC option was included, check the external alarms:

1. Set the mains switch S1 to OFF to check mains power failure

2. On the BTS Terminal, check that alarm 2 is present, then set switch S1

to ON again

3. On the BTS Terminal, check that alarm 3 is present (SSC door open) by

completely closing (with the key) and opening the door.

Note:

If the VSWR option was included, check the external alarms:

1. Make the connections as follows:

For A9110-E BTS units with one antenna output:

use ANT A and the following MTREs for transmission:

UT_TRE 18 or UT_TRE 19 for master

UT_TRE 38 or UT_TRE 39 for slave 1

UT_TRE 54 or UT_TRE 55 for slave 2.

UT_TRE 42 or UT_TRE 43 for slave 11.

UT_TRE 46 or UT_TRE 47 for slave 12.

UT_TRE 58 or UT_TRE 59 for slave 21.

UT_TRE 62 or UT_TRE 63 for slave 22.

50 / 74

3BK 17422 3081 RJZZA Ed.02

6 Commissioning Tests

For A9110-E BTS units with two antenna outputs

use ANT A and the following MTREs for transmission:

UT_TRE 19 for master

UT_TRE 39 for slave 1

UT_TRE 55 for slave 2.

UT_TRE 43 for slave 11.

UT_TRE 47 for slave 12.

UT_TRE 59 for slave 21.

UT_TRE 63 for slave 22.

use ANT B and the following MTREs for transmission:

UT_TRE 18 for master

UT_TRE 38 for slave 1

UT_TRE 54 for slave 2.

UT_TRE 42 for slave 11.

UT_TRE 46 for slave 12.

UT_TRE 58 for slave 21.

UT_TRE 62 for slave 22.

2. Check if an alarm is present at BTS Terminal:

Commissioning Output Power Test

In the Output Power Test window select the MTRE Number:

UT_TRE** (See above)

Select one timeslot and click [ On ] to enable the power

Select an attenuation of -10dB on the used timeslot

Click [ Start ]

Wait for the BTS to start the emission

Disconnect the antenna cable from the RF jumper cable.

As the power level is lower than 50mW you are allowed to disconnect the cable.

.

Wait 15 seconds to see if an alarm is sent to the BTS Terminal.

At the BTS Terminal choose:

Monitor Active alarms

Check that an Alarm related to the tested TRE is present

Connect the antenna cable to the RF jumper cable

Check at the BTS Terminal that no alarms are present

3BK 17422 3081 RJZZA Ed.02

51 / 74

6 Commissioning Tests

Click [ Stop ]

Wait for MTRE to stop transmission.

After pressing the [ Stop ] button wait until MTRE stops transmission.

Follow the messages that appear in the bottom part of the window,

which indicates the state of MTRE.

3. Repeat the actions from step 2 for all the antenna outputs of all BTS

units (master and slaves).

6.5 Checking the Status of Modules

Check the Status of

the BTS

1. At BTS Terminal choose:

Monitor BTS Modules

2. Check that BTS, CLLK, OMU and EACB are IT

3. Check that the MTREs and TR_CLK are OP.

Check the Active Alarms

1. At BTS Terminal choose:

Monitor Active Alarms

2. Check that there are no alarms present.

6.6 VSWR Check

Purpose

To connect the BTS to the antenna

To check the Voltage Standing Wave Ration (VSWR) of the transmit antenna.

Before transmitting on the antenna:

Check that transmission is allowed at the nominal frequency

If there are no antennas, measure the VSWR across the load.

The VSWR measurement must be performed for each antenna output!

Connect the Power

Meter/ Reflectometer

Connect the power meter/ reflectometer between the BTS antenna jumper

and antenna or load as appropiate

1. For A9110-E BTS units with one antenna output:

connect the power meter/ reflectometer to the antenna jumper connected

to ANT A and use the following MTREs for transmission:

UT_TRE 18 or UT_TRE 19 for master

UT_TRE 38 or UT_TRE 39 for slave 1

UT_TRE 54 or UT_TRE 55 for slave 2.

UT_TRE 42 or UT_TRE 43 for slave 11.

52 / 74

3BK 17422 3081 RJZZA Ed.02

6 Commissioning Tests

UT_TRE 46 or UT_TRE 47 for slave 12.

UT_TRE 58 or UT_TRE 59 for slave 21.

UT_TRE 62 or UT_TRE 63 for slave 22.

2. For A9110-E BTS units with two antenna outputs

connect the power meter/ reflectometer to the antenna jumper connected

to ANT A and use the following MTREs for transmission:

UT_TRE 19 for master

UT_TRE 39 for slave 1

UT_TRE 55 for slave 2.

UT_TRE 43 for slave 11.

UT_TRE 47 for slave 12.

UT_TRE 59 for slave 21.

UT_TRE 63 for slave 22.

connect the power meter/ reflectometer to the antenna jumper connected

to ANT B and use the following MTREs for transmission:

UT_TRE 18 for master

UT_TRE 38 for slave 1

UT_TRE 54 for slave 2.

UT_TRE 42 for slave 11.

UT_TRE 46 for slave 12.

UT_TRE 58 for slave 21.

UT_TRE 62 for slave 22.

Measure the VSWR

Measure the VSWR of

the antenna (VSWR1)

Measure the VSWR of the antenna (VSWR1) or across the load (VSWR2) if

there is no antenna

1. At BTS Termial choose:

Commissioning Output Power Test

2. In the Output Power Test window select the MTRE Number: UT_TRE**

(See above)

3. All Timeslots: click [ On ] to enable the power

4. Select an attenuation of -4dB on each timeslot from TS0 to TS7

5. Click [ Start ]

6. Record the VSWR value (VSWRx):

VSWR 1 when measuring with antenna connected

VSWR 2 when measuring across the load.

7. Click [ Stop ]

8. Wait for MTRE to stop transmission.

3BK 17422 3081 RJZZA Ed.02

53 / 74

6 Commissioning Tests

Do not disconnect the power meter, the antenna or the load during MTRE

transmission. After pressing the [ Stop ] button wait until MTRE stops

transmission.

Follow the messages that appear in the bottom part of the window,

which indicates the state of MTRE.

Measure the VSWR

(VSWR 2) Using a Load

If antenna VSWR 1 > 1.3 measure the VSWR (VSWR 2) using a load

1. Instead of antennas use 50 ohm loads

2. Measure the VSWR 2 values with the BTS TE in the same way as in

Measure the VSWR of the antenna (VSWR1)

3. Analyze the results: (See Table 1 )

VSWR 1 is the VSWR value measured in Measure the VSWR of

the antenna (VSWR1)

VSWR 2 is the VSWR value measured in Measure the VSWR (VSWR

2) Using a Load.

Value

Sanction

Action

VSWR 2 >1.2

Fault in equipment supplied by

Alcatel

Check the tightness of the

connectors

VSWR 2 1.2 and

Fault on the feeder or antenna

(when present)

Inform the operator that the

VSWR is within a critical range

Fault on the antenna or feeder

(when present)

Report the high reading to the

Site Manager

VSWR 1 1.5

VSWR 2 1.2 and

VSWR 1 >1.5

Table 1: Interpretation of VSWR Results

Finish the Measurement

1. Disconnect the power meter and reconnect the antenna jumper to

the antenna or load as the case

2. Repeat steps 1 to 4 for all the antenna outputs of all the BTS units

(master and slaves)

54 / 74

3BK 17422 3081 RJZZA Ed.02

6 Commissioning Tests

6.7 Abis Loop Test

Purpose

To test the PCM cabling between the master unit and DDF.

For Microwave or TNL installation in SSC for PCM connection, do not perform

Abis loop test.

Procedure

1. At BTS Terminal choose:

Commissioning Station Unit Test...

The Station Unit Test window appears.

In the Station Unit Test window, select external loop

Click [ Start ].

A message appears prompting you to fit the shortcut connector.

Do not use any shortcut connector, because you are testing the cabling to

the DDF, not the ABISCO board.

2. At the DDF (not on ABISCO) set up loops between TX and RX for Abis1

and Abis2, using wires.

It is important for both Abis links to be looped!

3. At BTS Terminal:

Click [ Ok ]

Remove the loops when the respective message window appears and

then click [ Ok ]

Wait for the test to finish

Check that the list of tests shown in the Station Unit Test window is Ok

Click [ Cancel ].

6.8 End of Commissioning

Purpose

To update the Remote Inventory of all the modules according to the site

To perform an inventar in case any modules were changed during

commissioning

To end the commissioning phase

To save the commissioning report.

Procedure

3BK 17422 3081 RJZZA Ed.02

1. At BTS Terminal :

Commissioning End

commissioning

55 / 74

6 Commissioning Tests

2. Check that the commissioning date is correct:

If not, click [ Close ] and click [ Cancel ]

Modify the internal date of the PC (in Control Panel)

Go back to step 1.

3. Give the name of the BTS site (< 10 characters) and the Network

Identity.

4. Select all the modules from the list on the left (if any) to enter them in

the modules to be updated list

Click [ Add ] for all the modules on the left (if any)

Click [ Submit ].

The following message appears: Do you want to execute INVENTAR

now?

5. Option: If any modules were added or changed during commissioning,

run Inventar:

Click [ Yes ]

The Receiving Remote Inventory Data message appears, and the

INVENTAR application is launched

Use the tasks specified in CI 08 - Site Equipment Inventory for the

following actions:

Adding additional modules in RI (if appropiate)

Running Inventar for the BTS.

6. Option: If no modules were added or changed during commissioning

click [ No ]

When you end commissioning, the BTS is automatically reset after about 2

minutes (the connection is lost for about 5s).

Wait until the connection with the BTS is reestablished.

The BTS is then ready for downloading from the BSC.

7. Save the Commissioning Report window:

Click [ Commissioning Report ] window to make it active

File Save As...

Give a name to the file (Site name and number of BTS - no more then 8

characters) and save the file to a floppy disk.

56 / 74

3BK 17422 3081 RJZZA Ed.02

7 Setting Transmission Module Parameters

7 Setting Transmission Module Parameters

This chapter describes how to configure the transmission module of the SUM

board.

3BK 17422 3081 RJZZA Ed.02

57 / 74

7 Setting Transmission Module Parameters

Purpose

To set the Qmux address

To set the OML TS and signalling rate, if this information is provided.

Make sure the BTS is isolated at the DDF from the network before

proceeding.

Procedure

1. Set the Qmux address:

At BTS Terminal choose:

Settings Transmission Initial Settings...

The Receiving current configuration data... window appears.

Enter the parameter:

Qmux address

Click [ Transmit ]

Click [ Close ].

2. OPTION: Set the position and signalling rate for OML, if required:

Setting the OML TS and signalling rate allows the BTS to load faster from BSC

because MSUMA will not perform OML autodetection when connecting to Abis.

Settings Transmission Board Configuration...

Click [ Get Config ]

Set the signaling TS number and the signalling rate for OMU 1

Click [ Transmit ]

Click [ Close ].

58 / 74

3BK 17422 3081 RJZZA Ed.02

8 Connecting to the BSC

8 Connecting to the BSC

This chapter describes how to connect the BTS to the BSC and verify the

OML status.

3BK 17422 3081 RJZZA Ed.02

59 / 74

8 Connecting to the BSC

Purpose

To connect the BTS to the BSC and check the OML status.

Procedure

1. Connect the BTS to the BSC:

Check that the BIE connectors are connected

With BTS connected via the site distribution frame and an equipment

distribution frame: disconnect the loop between the transmit and

receive terminal blocks on the site distribution frame

With SSC option: connect the PCM cable to connectors X2, X3 and

X4 in the SSC connection area.

2. Check the state of the OML: on the SUM board check that the OML LED

is ON (indicating the OML is IT).

For further information about downloading the BTS from the BSC and

network integration refer to Add BTS procedure.

60 / 74

3BK 17422 3081 RJZZA Ed.02

9 Finishing Commissioning

9 Finishing Commissioning

This chapter describes the final operations before leaving the site.

3BK 17422 3081 RJZZA Ed.02

61 / 74

9 Finishing Commissioning

Purpose

To leave the site

To return the commissioning report and inventory files to base.

Procedure

1. Leave the BTS powered up

2. Leave the log book on site

3. Close the COBO door

4. Reposition the front cover and lock the bottom cover (if appropriate)

5. Close the SSC door (if appropriate)

6. Check the CCL and the appendices

7. Remove all other packaging and surplus equipment.

8. Clean the site

9. Close the site and hand the keys to the key holder

10. Return the completed forms and the inventory file related to the operation

to base.

62 / 74

3BK 17422 3081 RJZZA Ed.02

Appendix A : Abbreviations

Appendix A: Abbreviations

Abis

Abis Interface: Interface between BSC and BTS

ABISCO

ABIS COnnection board

AC

Alternating Current

ACCO

Alternating Current Connection board

AN

Antenna Network

BCB

BTS Control Bus

BCCH

Broadcast Control Channel

BSC

Base Station Controller

BSS

Base Station Subsystem

BTS

Base Transceiver Station

CLK

Clock

COBO

COnnection BOx

CPF

Configuration Parameters File

DC

Direct Current

DDF

Digital Distribution Frame

Dual Rate

Full rate and Half rate

E-GSM

Extended band GSM

ETS

European Telecomunication Standard

FIT

Failure In Time

GSM

Global System for Mobiles (900 MHz)

IEB

Inter Entity Bus (between master and slave units)

MD

Multi Drop

MDT

Manufacturers Delegate Testing

MMI

Man Machine Interface

MOCO

MOFRA+COBO

MOFRA

MOunting FRAme

MSC

Mobile Switching Centre

3BK 17422 3081 RJZZA Ed.02

63 / 74

Appendix A : Abbreviations

MSUMA

Micro-BTS Station Unit Module

MTRE

Micro-BTS Transceiver

MUX

Multiplexer

O&M

Operation and Maintenance

OMC

Operation and Maintenance Centre

OMC-R

Operation and Maintenance Centre - Radio (OMC of BSS)

OML

Operation and Maintenance Link

OMU

Operation and Maintenance Unit

PCM

Pulse Code Modulation (PCM link = 2.048 Mbit/s terrestrial link)

RF

Radio Frequency

RI

Remote Inventory

RIT

Replaceable ITem

RSL

Radio Signalling Link

SDCCH

Slow Dedicated Control Channel

SBL

Security BLock

SSC

Site Support Cabinet

TCH

Traffic Channel

TRE

TRansceiver Equipment

TREA

TRE - Analog part

TRED

TRE - Digital part

VSWR

Voltage Standing Wave Ratio

XBCB

External BTS Control Bus

XIN

External Input

64 / 74

3BK 17422 3081 RJZZA Ed.02

Appendix B : List of Items Required

Appendix B: List of Items Required

Installation Kits

The following table is used to check, on site, the mandatory or optional delivery

item kits.

The used symbols are:

mandatory kit

technical choice kit

customer option kit

Optional kits for BTS configuration

Mnemo

Reference

Qty

Integrated antenna for GSM band

PUIT - ANTG

3BK 08581 AAAA

1/ unit

Integrated antenna for DCS band

PUIT - ANTD

3BK 08582 AAAA

1/ unit

VSWR detector for GSM band

VSWG

3BK 25062 AAAA

1/ ant

VSWR detector for DCS band

VSWD

3BK 25063 AAAA

1/ ant

List of Documents

Required

The following table is used to check, at base, the availability of the necessary

documents.

Catalogue of Techincal and Logistic Information (ITL-PRO)

3DF 00462 0004 AAAGA

Catalogue of Instruction Operation (IO)

3DF 00300 0004 UAZZA

BSS Methods Handbook release B9

3BK 17422 0002 PCZZA

CI 08 Site Equipment Inventory

3BK 17257 0001 RJZZA

Tools Catalogue for Field Activity

3BK 20458 0001 RJZZA

Site Premises Inspection Form (CEL)

8BL 00704 0015 DRBRA

SPP 36 - Specification for Site Preparation A9110 BTS

8BL 00704 0052 DRAGA

BSS Site Premises Inspection, Post Handover

8BL 00704 0016 DRBRA

A9110 Crane HW Instruction Manual

3BK 20489 AAAA PCZZA

3BK 17422 3081 RJZZA Ed.02

65 / 74

Appendix B : List of Items Required

List of Software

Required

The following table is used to check, at base, the availability and version of

the necessary software;refer to corresponding document for checking the

SW version.

Name

Version checking

Operating system

See Tools Catalogue

A9110-E BTS commissioning

BTS-Terminal

B9 Commissioning package/ BTS-TE

A9110 BTS-SW

B9 Commissioning package/ BTS-SW

Tools Required

The following table is used to check, at base, the availability of the necessary

tools (See Tools Catalogue for content checking).

Kit name

Reference

Calibration

Utility PC

DES 002

NO

Power/ reflectometer

DES 003

YES

Basic toolkit

OUT 001

NO

Specific toolkit for A9110/A9110-E BTS

OUT 006

NO

Test cables and plugs for A9110/A9110-E BTS

OUT 013

NO

Radio connection kit

OUT 014

NO

66 / 74

3BK 17422 3081 RJZZA Ed.02

Appendix C : Description of ABISCO and ACCO Boards

Appendix C: Description of ABISCO and ACCO Boards

ABISCO Boards

Figure 28: ABISCO Board for A9110-E

3BK 17422 3081 RJZZA Ed.02

67 / 74

Appendix C : Description of ABISCO and ACCO Boards

LED2: SLAVE2

LED1: SLAVE1

X210

ABISTRACE

LED3: MASTER

X211 HDSL

LED4

BTS_LMT OK

LED8 :

X109

CALCLK

MPS

ON

X108

FCLK

X104,

X115

X105,

X112

X100: MMI

X200

LED5: ABIS1

X106,

X110

X107,

X102

LED6: ABIS2

LED7*

see table

Figure 29: ABISCO Board for A9110

68 / 74

3BK 17422 3081 RJZZA Ed.02

Appendix C : Description of ABISCO and ACCO Boards

Connectors Description

Figure 30: Connectors and LEDs on ABISCO

3BK 17422 3081 RJZZA Ed.02

69 / 74

Appendix C : Description of ABISCO and ACCO Boards

ACCO Board

ACout

BTS

IEC Conn.

FAN

X401

X402

X400

BTS fuses

ACin, Mains

(T=2.5 A)

L

PE

N

L PE N

N

FAN fuses

(T=2.5 A)

L PEN

L PEN

SLAVE 2

SLAVE 1

X404

X403

Figure 31: Mechanical Drawing of ACCO

IEC connector

(cable lenght ~ 10 cm)

X400

LP

X401

AC in

AC BTS

(FFKDSA/V1 7.62)

for 2.5 qmm

T=2 x 2.5 A

X403

T=2 x 1.25 A

X402

ACo1

AC

FFKDSA/V1 7.62

GICV 2.5/ 3GF7.62

X404

ACo2

FFKDSA/V1 7.62

Figure 32: Electrical Drawing of ACCO

70 / 74

3BK 17422 3081 RJZZA Ed.02

Appendix D : Antenna Port and External Alarm Mapping Rules

Appendix D: Antenna Port and External Alarm Mapping

Rules

Rules for antenna port mapping

If there is an antenna port on a micro-BTS unit (master or slave), the

corresponding field will be completed with the sector number (1...6)

If there is no antenna port (units with one antenna output or unconnected

slaves) the corresponding port will be completed with 0 (disabled)

Example 1:

Master unit with no slaves, two antenna outputs 1x2:

Master port A: 1

Master port B: 1

Example 2:

Master-slave configuration 3x4, no diversity

Master port A: 1

Master port B: 0

Slave 1 port A: 1

Slave 1 port B: 0

Slave 11 port A: 2

Slave 11 port B: 0

Slave 12 port A: 2

Slave 12 port B: 0

Slave 2 port A: 3

Slave 2 port B: 0

Slave 21 port A: 3

Slave 21 port B: 0

Example 3:

Master-slave configuration 2x6, with diversity

3BK 17422 3081 RJZZA Ed.02

Master port A: 1

Master port B: 1

Slave 1 port A: 2

Slave 1 port B: 2

Slave 11 port A: 2

Slave 11 port B: 2

Slave 12 port A: 2

Slave 12 port B: 2

Slave 2 port A: 1

Slave 2 port B: 1

Slave 21 port A: 1

Slave 21 port B: 1

71 / 74

Appendix D : Antenna Port and External Alarm Mapping Rules

Rules for alarm mapping

The mapping for alarms 9-56 are take into consideration only if the slave units

are installed. Otherwise they are considered disabled and are not reported.

All the alarms that are not used are set to 255 . This means that they are

disabled.

Select each external alarm 1- 56 (See Figure 28 ) and modify the logical

number as required.

If you select [ Default Setting ] in the Remote Inventory window of

UT_BCB_17, the good values will be directly mapped for the alarms, detailed in

the following tables.

Note:

Note:

72 / 74

If the Fan Option was chosen, typical mapping of the fan alarms is:

Ext. alarm

(physical)

Number (logical) to be

mapped for dedicated

external alarm reporting

Refers to...

08

234

Fan Alarm Master

16

235

Fan Alarm Slave 1

24

236

Fan Alarm Slave 2

32

237

Fan Alarm Slave 11

40

238

Fan Alarm Slave 12

48

239

Fan Alarm Slave 21

56

240

Fan Alarm Slave 22

If the SSC Option was chosen, typical mapping of the SSC alarms is:

Ext. alarm

(physical)

Number (logical) to be

mapped

Refers to...

01

11

SSC - Battery deep discharge

02

02

SSC - Mains power failure

03

03

SSC - Open door alarm

3BK 17422 3081 RJZZA Ed.02

Appendix D : Antenna Port and External Alarm Mapping Rules

Note:

Note:

3BK 17422 3081 RJZZA Ed.02

If the VSWR Option was chosen, typical mapping of the fan alarms is:

Ext. alarm

(physical)

Number (logical) to be

mapped

Refers to...

06

241

VSWR1 Alarm Master (ANT A)

07

242

VSWR2 Alarm Master (ANT B)

09

243

VSWR1 Alarm Slave 1 (ANT A)

10

244

VSWR2 Alarm Slave 1 (ANT B)

17

245

VSWR1 Alarm Slave 2 (ANT A)

18

246

VSWR2 Alarm Slave 2 (ANT B)

25

247

VSWR1 Alarm Slave 11 (ANT A)

26

248

VSWR2 Alarm Slave 11 (ANT B)

33

249

VSWR1 Alarm Slave 12 (ANT A)

34

250

VSWR2 Alarm Slave 12 (ANT B)

41

251

VSWR1 Alarm Slave 21 (ANT A)

42

252

VSWR2 Alarm Slave 21 (ANT B)

49

253

VSWR1 Alarm Slave 22 (ANT A)

50

254

VSWR2 Alarm Slave 22 (ANT B)

Other alarms to be mapped: