Escolar Documentos

Profissional Documentos

Cultura Documentos

Solution: EXAMPLE 11-1

Enviado por

Ankit SrivastavaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Solution: EXAMPLE 11-1

Enviado por

Ankit SrivastavaDireitos autorais:

Formatos disponíveis

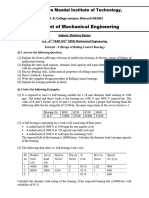

EXAMPLE 111 Consider SKF, which rates its bearings for 1 million revolutions, so that L10

life is

60LRnR = 106 revolutions. The LRnR60 product produces a familiar number. Timken,

for example, uses 90(106) revolutions. If you desire a life of 5000 h at 1725 rev/min

with a load of 400 lbf with a reliability of 90 percent, for which catalog rating would

you search in an SKF catalog?

Solution From Eq. (113),

C10 = FD

_

LDnD60

LRnR60

_1/a

= 400

_

5000(1725)60

106

_1/3

= 3211 lbf = 14.3 kN

If a bearing manufacturer rates bearings at 500 h at 331

3 rev/min with a reliability

of 0.90, then LRnR60 = 500(331

3 )60 = 106 revolutions. The tendency is to substitute

106 for LRnR60 in Eq. (113). Although it is true that the 60 terms in Eq. (113) as

displayed cancel algebraically, they are worth keeping, because at some point in your

keystroke sequence on your hand-held calculator the manufacturers magic number

(106 or some other number) will appear to remind you of what the rating basis is and

those manufacturers catalogs to which you are limited. Of course, if you evaluate the

bracketed quantity in Eq. (113) by alternating between numerator and denominator

entries, the magic number will not appear and you will have lost an opportunity to check.

EXAMPLE 113 The design load on a ball bearing is 413 lbf and an application factor of 1.2

is appropriate.

The speed of the shaft is to be 300 rev/min, the life to be 30 kh with a reliability

of 0.99. What is the C10 catalog entry to be sought (or exceeded) when searching for a

deep-groove bearing in a manufacturers catalog on the basis of 10 6 revolutions for rating

life? The Weibull parameters are x0 = 0.02, ( x0) = 4.439, and b = 1.483.

Solution xD =

L

L10 =

60LDnD

60LRnR =

60(30 000)300

106 = 540

Thus, the design life is 540 times the L10 life. For a ball bearing, a = 3. Then, from

Eq. (117),

Answer C10 = (1.2)(413)

_

540

0.02 + 4.439(1 0.99)1/1.483

_1/3

= 6696 lbf

The purposes of an antifriction-bearing lubricant may be summarized as follows:

1 To provide a film of lubricant between the sliding and rolling surfaces

2 To help distribute and dissipate heat

3 To prevent corrosion of the bearing surfaces

4 To protect the parts from the entrance of foreign matter

Elastohydrodynamic lubrication (EHD) is the phenomenon

that occurs when a lubricant is introduced between surfaces that are in pure

rolling contact. The contact of gear teeth and that found in rolling bearings and in

cam-and-follower surfaces are typical examples. When a lubricant is trapped between

two surfaces in rolling contact, a tremendous increase in the pressure within the lubricant

film occurs. But viscosity is exponentially related to pressure, and so a very large

increase in viscosity occurs in the lubricant that is trapped between the surfaces.

Leibensperger2 observes that the change in viscosity in and out of contact pressure is

equivalent to the difference between cold asphalt and light sewing machine oil.

Você também pode gostar

- Me 301 Chapter 11Documento19 páginasMe 301 Chapter 11Melissa RokaAinda não há avaliações

- Rolling (Antifriction) BearingsDocumento54 páginasRolling (Antifriction) BearingsmohammedelyoussefAinda não há avaliações

- Informative Annex 3 - L10 BRG Selec Aftr Spring 04 SOMEDocumento4 páginasInformative Annex 3 - L10 BRG Selec Aftr Spring 04 SOMEKRUNALAinda não há avaliações

- 7a-Design of Rolling BearingsDocumento33 páginas7a-Design of Rolling BearingsSOUBHIK ROYAinda não há avaliações

- Te 2019 DTSDocumento6 páginasTe 2019 DTSVishalAinda não há avaliações

- BeringDocumento14 páginasBeringRams0% (1)

- 11 Rolling: ContactbearingsDocumento29 páginas11 Rolling: ContactbearingsAndres Alberto Osorio YupanquiAinda não há avaliações

- 6 0Documento26 páginas6 0klawsisAinda não há avaliações

- Mechanical Engineering Design Chapter 11 SolutionsDocumento28 páginasMechanical Engineering Design Chapter 11 SolutionsJeffDavis91205100% (2)

- 235notes Chapter11Documento4 páginas235notes Chapter11Ajmal ArshadAinda não há avaliações

- 76 6 Rolling BearingDocumento8 páginas76 6 Rolling Bearingrip111176Ainda não há avaliações

- Soal#2Documento1 páginaSoal#2saifudin-itsAinda não há avaliações

- Bearing SelectionDocumento6 páginasBearing SelectionKenneth ChawAinda não há avaliações

- FBJ Calculation of Service LifeDocumento10 páginasFBJ Calculation of Service Lifemiscstd2014Ainda não há avaliações

- Calculating Idler L10 LifeDocumento9 páginasCalculating Idler L10 LifeJSweda100% (1)

- Chapter 11 Rolling Contact BearingsDocumento9 páginasChapter 11 Rolling Contact BearingsDhinesh3693Ainda não há avaliações

- MD-III - TUT - 5 and 6Documento5 páginasMD-III - TUT - 5 and 6Sushil ThakkarAinda não há avaliações

- Nguyễn Văn HânDocumento9 páginasNguyễn Văn HânHân NguyễnAinda não há avaliações

- Calculation For The Sucker Rod Design: Assumed DataDocumento5 páginasCalculation For The Sucker Rod Design: Assumed DataMando U WKAinda não há avaliações

- Marin FactorsDocumento14 páginasMarin FactorsAkash DeepAinda não há avaliações

- Re91401 A2foDocumento20 páginasRe91401 A2foTaz Juan GAinda não há avaliações

- DMM-2 Question BankDocumento3 páginasDMM-2 Question BankrajuAinda não há avaliações

- Linear Bushings and Shafts-MiniatureDocumento64 páginasLinear Bushings and Shafts-Miniaturegiu_gloAinda não há avaliações

- Tugas Elemen Mesin Problem SolvingDocumento11 páginasTugas Elemen Mesin Problem SolvingDeandra DenidauliaAinda não há avaliações

- Trib Ology RollerDocumento24 páginasTrib Ology Rollerbalamurugan_meAinda não há avaliações

- Tutorial 10 (Solutions)Documento8 páginasTutorial 10 (Solutions)Mudit SinhaAinda não há avaliações

- Material TeKNIKDocumento6 páginasMaterial TeKNIKDewangga Trisna PradiptaAinda não há avaliações

- 8 Shell Courses 8 FT Wide PDFDocumento2 páginas8 Shell Courses 8 FT Wide PDFImran Ahmed ShaikhAinda não há avaliações

- Design of Hydraulic Ladle Tilting Device at Pig Casting MachineDocumento6 páginasDesign of Hydraulic Ladle Tilting Device at Pig Casting MachinepermesinanAinda não há avaliações

- Section 10Documento16 páginasSection 10ILAYAPERUMAL K100% (1)

- Comparison of Rolling and Sliding BearingsDocumento29 páginasComparison of Rolling and Sliding Bearingsaravindangokul687Ainda não há avaliações

- The Design of Rolling Bearing Mountings: PDF 8/8: GlossaryDocumento21 páginasThe Design of Rolling Bearing Mountings: PDF 8/8: GlossarybearinghuAinda não há avaliações

- BEARINGSDocumento18 páginasBEARINGSNico NiconiconicoAinda não há avaliações

- C - Specifications: 1995 Volvo 850Documento4 páginasC - Specifications: 1995 Volvo 850bulkSoftAinda não há avaliações

- Example 5.4 PDFDocumento7 páginasExample 5.4 PDFJaved NasirAinda não há avaliações

- Solucionario (Ingles) Diseño en Ingenieria Mecanica - Shigley (8ed) (Capitulo 11 en Adelante)Documento167 páginasSolucionario (Ingles) Diseño en Ingenieria Mecanica - Shigley (8ed) (Capitulo 11 en Adelante)Fernando Quenta PeñarandaAinda não há avaliações

- DME Unit Test 4 - 2018Documento3 páginasDME Unit Test 4 - 2018hodmech tjsec.inAinda não há avaliações

- MailordDocumento2 páginasMailordPeter MuriithiAinda não há avaliações

- Problem Set 9-Chapter 14 - Rolling Element BearingDocumento25 páginasProblem Set 9-Chapter 14 - Rolling Element BearingPaulAinda não há avaliações

- (203933964) ME359HW04 Machine Elements IDocumento2 páginas(203933964) ME359HW04 Machine Elements Ielowell7Ainda não há avaliações

- Operator'S Manual 613100-1: 613100 - 1 Wash Pump 613104 Detergent Pump Assembly 4-1/4" AIR MOTOR 10:1 RATIO 4" StrokeDocumento6 páginasOperator'S Manual 613100-1: 613100 - 1 Wash Pump 613104 Detergent Pump Assembly 4-1/4" AIR MOTOR 10:1 RATIO 4" StrokeFernando FloresAinda não há avaliações

- Assignment 7221 MD-IIIDocumento2 páginasAssignment 7221 MD-IIIkalikaAinda não há avaliações

- 15A03602 Design of Machine Members - IIDocumento2 páginas15A03602 Design of Machine Members - IIJagannath CherkuAinda não há avaliações

- Unit 4 Bearings Important ProblemsDocumento3 páginasUnit 4 Bearings Important ProblemsBrijpal PatleAinda não há avaliações

- 11 Shell Courses 6 FT WideDocumento3 páginas11 Shell Courses 6 FT WideImran Ahmed ShaikhAinda não há avaliações

- MDDocumento2 páginasMDAbhijeet PramanikAinda não há avaliações

- Machine Design - LDocumento2 páginasMachine Design - LNilesh Mistry (Nilesh Sharma)Ainda não há avaliações

- Gear Box DesignDocumento24 páginasGear Box DesignBada KimAinda não há avaliações

- 3.10.1 - LRFD Pile Design - 2Documento15 páginas3.10.1 - LRFD Pile Design - 2Minahil SherazAinda não há avaliações

- 1PF1R4 Ra 11263Documento8 páginas1PF1R4 Ra 11263Dias EliAinda não há avaliações

- Gujarat Technological UniversityDocumento3 páginasGujarat Technological Universityrajushamla9927Ainda não há avaliações

- CHAPTER 6 Bearings UpdatedDocumento26 páginasCHAPTER 6 Bearings UpdatedMuhammad Azrul100% (1)

- Seventh Semester B.Tech. Degree Examination, June 2009 03-703: Design of Machine Elements - Ii (M)Documento3 páginasSeventh Semester B.Tech. Degree Examination, June 2009 03-703: Design of Machine Elements - Ii (M)Harish ChandranAinda não há avaliações

- DesignDocumento84 páginasDesignbijendraAinda não há avaliações

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- Semi-Active Suspension Control Design for VehiclesNo EverandSemi-Active Suspension Control Design for VehiclesNota: 5 de 5 estrelas5/5 (1)

- Barc ResultDocumento28 páginasBarc ResultAnkit SrivastavaAinda não há avaliações

- Mathematical Elements For Computer Graphics - David F. RogersDocumento5 páginasMathematical Elements For Computer Graphics - David F. RogersSuraj Dahotre6% (18)

- Structural Analysis in Nastran: Structure's Response Are Assumed To Vary Slowly With Respect To TimeDocumento8 páginasStructural Analysis in Nastran: Structure's Response Are Assumed To Vary Slowly With Respect To TimeAnkit SrivastavaAinda não há avaliações

- Energy Security and Conservation: A Major Part of The Solution To Energy Generation and Environmental DegradationDocumento85 páginasEnergy Security and Conservation: A Major Part of The Solution To Energy Generation and Environmental DegradationAnkit SrivastavaAinda não há avaliações

- Heat Input - Heat Output) - Heat Input - Heat Output) - (D)Documento3 páginasHeat Input - Heat Output) - Heat Input - Heat Output) - (D)Ankit SrivastavaAinda não há avaliações

- RoboticsDocumento33 páginasRoboticsAnkit SrivastavaAinda não há avaliações

- Accommodation at IitbDocumento2 páginasAccommodation at IitbAnkit SrivastavaAinda não há avaliações

- Winning Story at Kirtu ContestDocumento8 páginasWinning Story at Kirtu ContestAnkit SrivastavaAinda não há avaliações

- Skip To NavigationSkip To ContentHelp Using This WebsiteDocumento19 páginasSkip To NavigationSkip To ContentHelp Using This WebsiteAnkit SrivastavaAinda não há avaliações

- Answer Keys of The Written Test For Recruitment To The Post of Scientist/Engineer 'SC' (Mechanical) (Be002) Held On 03.07.2016Documento5 páginasAnswer Keys of The Written Test For Recruitment To The Post of Scientist/Engineer 'SC' (Mechanical) (Be002) Held On 03.07.2016Ankit SrivastavaAinda não há avaliações

- Latest Job & Admission NotificationsDocumento3 páginasLatest Job & Admission NotificationsAnkit SrivastavaAinda não há avaliações

- Product Design Is The Process of Creating A New Product To Be Sold by A Business To Its CustomersDocumento5 páginasProduct Design Is The Process of Creating A New Product To Be Sold by A Business To Its CustomersAnkit SrivastavaAinda não há avaliações

- Estimation of Construction Projects: Prof. K. C. Iyer Civil Engineering Dept. IIT DelhiDocumento32 páginasEstimation of Construction Projects: Prof. K. C. Iyer Civil Engineering Dept. IIT DelhiAnkit Srivastava100% (2)

- SPOTTING ERROR: Mark D If There Is No Error: F-9, Main Road, Katwaria Sarai, New Delhi-16 Mob: 9711713852Documento1 páginaSPOTTING ERROR: Mark D If There Is No Error: F-9, Main Road, Katwaria Sarai, New Delhi-16 Mob: 9711713852Ankit SrivastavaAinda não há avaliações

- For Other Uses, See .: Cadillac Motor Car DivisionDocumento12 páginasFor Other Uses, See .: Cadillac Motor Car DivisionAnkit SrivastavaAinda não há avaliações

- Pressurized Water Reactors (PWRS) Constitute The Large Majority of All WesternDocumento3 páginasPressurized Water Reactors (PWRS) Constitute The Large Majority of All WesternAnkit SrivastavaAinda não há avaliações

- Hydraulic Drive SystemDocumento21 páginasHydraulic Drive SystemAnkit SrivastavaAinda não há avaliações

- Total Available Choices 376: S.No. Institute Name Program NameDocumento9 páginasTotal Available Choices 376: S.No. Institute Name Program NameAnkit SrivastavaAinda não há avaliações

- Batten PlatesDocumento27 páginasBatten PlatesAnkit SrivastavaAinda não há avaliações

- Dictionary of Car TermsDocumento9 páginasDictionary of Car TermsrajmehaAinda não há avaliações

- Public Area CleaningDocumento16 páginasPublic Area Cleaningnitty loveAinda não há avaliações

- State-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateDocumento18 páginasState-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateShaker QaidiAinda não há avaliações

- HSL650 7Documento6 páginasHSL650 7sweetsabinaAinda não há avaliações

- 910 Paint RemoverDocumento5 páginas910 Paint Removersepri manerson sinagaAinda não há avaliações

- Chem Lab Report 9:26:18Documento3 páginasChem Lab Report 9:26:18Andrew SmithAinda não há avaliações

- Force Analysis - PPSXDocumento107 páginasForce Analysis - PPSXÖmer Faruk EkizAinda não há avaliações

- Technical Standards Training Nov01Documento83 páginasTechnical Standards Training Nov01Monish KrishnaAinda não há avaliações

- Surge Suppression BrochureDocumento16 páginasSurge Suppression BrochureselvamejiaAinda não há avaliações

- Manual Taller Outlook Dierre 125 Efi Idioma Ingles PDFDocumento173 páginasManual Taller Outlook Dierre 125 Efi Idioma Ingles PDFWalter Mikel Carrillo Castillo100% (1)

- Transmision FunkDocumento98 páginasTransmision FunkManuel Jesús Zhicay Quillay100% (1)

- ASDFDocumento8 páginasASDFrajesh2ndAinda não há avaliações

- Kaizen WorkshopDocumento24 páginasKaizen WorkshopShiraz S. Syed100% (1)

- Steam Line Mechanical DistributionDocumento25 páginasSteam Line Mechanical DistributionNAYEEMAinda não há avaliações

- Silicon Wafer Wetability On Metal Thin Film MorphologyDocumento8 páginasSilicon Wafer Wetability On Metal Thin Film MorphologyLee chong looAinda não há avaliações

- ZF Fluegelpumpen CP FP E 08Documento9 páginasZF Fluegelpumpen CP FP E 08Matei AlexandruAinda não há avaliações

- Astm B267 07Documento5 páginasAstm B267 07Srinivasan Krishnamoorthy100% (1)

- FM5178R6 TBM Series EnglishDocumento2 páginasFM5178R6 TBM Series EnglishalejgonzAinda não há avaliações

- 22MT FlexitanksDocumento25 páginas22MT FlexitanksYudha NugrahaAinda não há avaliações

- Functional Specification For Three Phase Peak Substation Distribution Transformers 300 12000 Kva Ps202010enDocumento13 páginasFunctional Specification For Three Phase Peak Substation Distribution Transformers 300 12000 Kva Ps202010enFrancisco José Murias DominguezAinda não há avaliações

- Dep Trai Loi Tai AiDocumento192 páginasDep Trai Loi Tai AiHoàng Hồng DươngAinda não há avaliações

- Optitome 15: Automatic Oxyacetylene and Plasma-Arc Cutting EquipmentDocumento8 páginasOptitome 15: Automatic Oxyacetylene and Plasma-Arc Cutting EquipmentFlamur HasaniAinda não há avaliações

- Sulfate Resistance of Filler Cement MortarDocumento4 páginasSulfate Resistance of Filler Cement MortarAbd El Nour KahlochAinda não há avaliações

- Barry Bcdi All Elastomer IsolatorsDocumento10 páginasBarry Bcdi All Elastomer IsolatorsdouglascoombsAinda não há avaliações

- Ecodial Advance Calculation 4.1Documento33 páginasEcodial Advance Calculation 4.1Youwan LeeAinda não há avaliações

- Armstrong - Humidification Handbook PDFDocumento40 páginasArmstrong - Humidification Handbook PDFJawwadTariqAinda não há avaliações

- Reebol Emulsion ConcentrateDocumento2 páginasReebol Emulsion ConcentrateJA WPKAinda não há avaliações

- Poisson's RatioDocumento20 páginasPoisson's RatioFaiz HaikalAinda não há avaliações

- Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesDocumento4 páginasWelded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesmithileshAinda não há avaliações

- $R5AM2WWDocumento2 páginas$R5AM2WWSurood SuruAinda não há avaliações