Escolar Documentos

Profissional Documentos

Cultura Documentos

Denso Petrolatum Products Spec

Enviado por

Roland Nicolas0 notas0% acharam este documento útil (0 voto)

84 visualizações4 páginasThis document provides specifications for applying petrolatum products from Denso to protect surfaces like pipes, valves, tanks and structural steel from corrosion. It describes requirements for surface preparation, primers, mastics and tapes. Denso petrolatum tapes are to be applied in overlapping spirals or longitudinally with at least 1" seams. Special application details are provided for underground pipes, cooling tower piping, wind line penetrations and structural steel.

Descrição original:

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document provides specifications for applying petrolatum products from Denso to protect surfaces like pipes, valves, tanks and structural steel from corrosion. It describes requirements for surface preparation, primers, mastics and tapes. Denso petrolatum tapes are to be applied in overlapping spirals or longitudinally with at least 1" seams. Special application details are provided for underground pipes, cooling tower piping, wind line penetrations and structural steel.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

84 visualizações4 páginasDenso Petrolatum Products Spec

Enviado por

Roland NicolasThis document provides specifications for applying petrolatum products from Denso to protect surfaces like pipes, valves, tanks and structural steel from corrosion. It describes requirements for surface preparation, primers, mastics and tapes. Denso petrolatum tapes are to be applied in overlapping spirals or longitudinally with at least 1" seams. Special application details are provided for underground pipes, cooling tower piping, wind line penetrations and structural steel.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

Petrolatum Products

Specification Guide

1.0 Scope

1.1

1.2

This specification may be used for the priming, caulking

and wrapping with Denso petrolatum products of any

of the following surfaces: piping, nuts, bolts, flanges,

dresser couplings, valves, tanks, structural steelwork,

dissimilar metals/materials, mechanical or electrical

penetrations, mechanical equipment and other surfaces

as specified herein for above and below ground service.

The Engineer shall select appropriate sections of

the specification to ensure that the specification is

comprehensive for specified work.

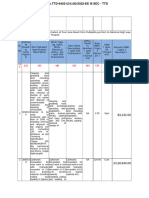

3.2.3 The physical specification values shall meet the values

given on the data sheet for the type of Denso Mastic

required.

3.3

Denso Petrolatum Tapes

3.3.1 Petrolatum tapes shall have a character stable in

composition and plasticity over a wide temperature range.

The tape shall be non-hardening and non-cracking.

The tape shall accommodate vibration and extreme

movement of substrate. Superficial oxidation renders

surface less tacky. The tape is highly resistant to mineral

acids and alkalis.

3.3.2 The physical specification values shall meet the values

given on the data sheet for the type of Denso Petrolatum

tape required.

2.0 General Requirements

2.1

Contractor shall comply with all written recommendations

of the manufacturer regarding applications of the

specified system.

2.2

To obtain the specified materials contact Denso North

America, 9747 Whithorn Drive, Houston, TX 77095, Tel:

(281) 821-3355 or 90 Ironside Crescent Unit 12, Toronto,

Ontario, Canada M1X1M3, Tel: 416-291-3435. E-mail:

info@densona.com.

3.0 Materials

3.1

Denso Primers

3.1.1 The Primer shall be comprised of saturated petroleum

hydrocarbons (petrolatum) inert fillers and passivating

agents.

4.0 General Surface Preparation

Requirements

4.1

Remove dirt, grease and oil including excessive moisture

and frost in accordance with the requirements of SSPCSP-1, Solvent Cleaning.

4.2

Remove weld spatter, sharp points and edges.

4.3

Remove loose rust, paint and foreign matter by hand and/

or power tools cleaning in accordance with SSPC-SP-2,

or SP-3, Hand Tool Cleaning or Power Tool Cleaning

respectively.

4.4

High pressure water blasting may be used to prepare the

surface.

5.0 Application of Denso Primers

3.1.2 The Primer will be an integral component of most Denso

Tape systems for the preparation of metal surfaces

prior to wrapping. Denso Primers will displace moisture,

passivate surface oxides, fill surface imperfections and

ensure intimate contact between Denso Petrolatum

Tapes.

5.1

Apply specified paste/primer: Denso Paste, Denso S105,

Denso Priming Solution, or Denso Hi-Tack Primer by

hand, brush, glove, rag or roller.

5.2

Apply a thin uniform film over the entire surface to be

wrapped.

3.2

5.3

Apply a liberal coating to threads, cavities, shoulders,

pits, etc.

Denso Mastics

3.2.1 The Denso Mastics shall be comprised of saturated

petroleum hydrocarbons (petrolatum) inert fillers,

reinforcing fibers and thermal extenders. Variations

may contain beads of cellular polymer and flow control

additives.

3.2.2 Denso Mastics shall be cold applied self supporting Mastics for molding around irregular shaped fittings to provide

a suitable profile for applying anti-corrosion tapes.

6.0 Application of Denso Mastics

6.1

To protect complex surfaces and configurations

such as valve bodies, flanges, dresser couplings, etc.,

apply Densyl Mastic or Denso Profiling Mastic by filling

and packing to achieve a uniform contour to which tape

can be applied without bridging or voids.

7.0 Application of Denso Petrolatum

Tape on Straight Line Pipe

7.1

The tape shall be spirally wrapped on pipe, cable,

conduit fittings etc., using a minimum 1" overlap on all

applications. Where additional protection is required, the

overlap shall be increased to 55% which will provide a

double thickness of tape.

7.2

The tape may be applied longitudinally, i.e. cigarette

wrapped, (except Denso Hotline Tape) when the space

is too restricted or confined to apply in the preferred spiral

matter. Use a minimum 1" overlap, and keep the overlap

on the topside of the pipe to provide a weatherboard

effect.

7.3

Hold end of tape firmly against the starting point and

firmly press on the surface. Unroll the tape, keeping the

roll close to the surface. Do not get a long lead of tape as

it will tend to fold and gap on the surface being wrapped.

The tape is best applied by rolling it around the pipe and

giving it proper tension (See Figure 1).

7.4

Apply sufficient tension to provide continuous adhesion,

but do not stretch the tape. As application proceeds,

press out all folds and air pockets that may occur.

7.5

Maintain a minimum 6" overlap when overlapping one roll

with the end of a new roll. Overlap must occur on the top

half of the pipe.

Application for

most petrolatum

tape systems.

Figure 2

7.6

At the completion of each roll, smooth the overlaps

by hand in the direction of the spiral (See Figure 2) to

ensure sealing of the overlap.

7.7

On all vertical applications begin at the bottom and

proceed up thereby creating a weatherboard overlap

(See Figure 2).

8.0 Application of Tape on Flanges,

Dresser Couplings, Valves Bodies, etc.

8.1

Application for

Hotline Tape,

WB Tape and

Marine Piling

Tape.

Figure 1 - *When applying the Hotline Tape, WB Tape and

Marine Piling Tape, the tape should be applied sticky side

down with the clear film on the outside.

VER 1506.22

After the bolts and nuts have received a filler of mastic,

flanges can be wrapped either with a width of tape wide

enough, that when wrapped circumferentially, enough

tape will lap over the side to allow the installer to smooth

it into the side of the flanges and several inches onto the

pipe; or take several short pieces of tape and by applying

them longitudinally along the axis of the pipe up over the

flanges and down the other side, and overlapping each

piece by a minimum of 1".

9.0 Underground Applications

9.1

Prepare surface as described in Section 4.0.

9.2

Apply applicable primer as described in Section 5.0.

9.3

Apply applicable Denso Petrolatum Tape as required in

Section 7.0.

9.4

Use Denso Utility Tape, Denso Glass Outerwrap, or

Denso Poly-Wrap for an outerwrap when the following

conditions apply:

a. A barrier to prevent backfilling damage.

10.8

Rivet heads, nuts and bolts, etc. may be dealt with by

making an incision in the tape in the form of a cross over

the crown of the rivet etc. Then, a small patch of tape is

pressed over the partially exposed crown and thoroughly

smoothed over.

10.9

Sharp edges and corners require extra care. Avoid

damage caused by stretching or rubbing tape along such

edges. On corroded edges, a prior positioning of a length

of 2" wide tape should be made to cushion the applied

tape.

b. To aid in the prevention of leaching of the petrolatum

in hot, dry, and sandy soils.

c. To maintain dielectric strength when the system

includes cathodic protection.

10.0 Structural Steelwork

10.1

Prepare surface as described in Section 4.0.

10.2

Use Denso Hi-Tack Primer & Denso Hi-Tack Tape which

permit overlaps of at least 1" to be made in a downward

direction (weatherboard effect) on vertical surfaces.

Minimize the overlaps on the underside of horizontal

surfaces (See Figure 3).

10.3

10.4

10.5

10.10 See Figure 3 for examples.

11.0 Cold Sweating Lines or Wet Surfaces

Apply tape longitudinally by unrolling along the structural

shape so that the outside of roll is in contact with the

steelwork. The Denso Hi-Tack Tape should be applied in

6' to 10' lengths for easier application.

11.1

Remove excess moisture or frost with rags or squeegee.

11.2

Apply Denso Paste S105 as described in Section 5.0.

11.3

Apply applicable Denso Petrolatum Tape as recommended in Section 7.0.

Press and smooth down as application proceeds with

particular attention to the overlaps. Care should be

exercised to ensure that the tape is pressed firmly

home in all angles and corners, and then worked along

the adjacent flat surfaces to prevent gaps, bridging or

stretching.

12.0 Cooling Tower Piping and

Associated Steelwork

12.1

An alternative method for the protection of structural steel

H beams is to insert pre-cut polystyrene blocks in the

webs of the members, slightly proud of the flange width,

liberally primed on all sides with Denso Hi-Tack Primer

before placement. The resulting box configuration can

then be spirally wrapped with Denso Tape, using the

appropriate overlap.

All exposed horizontal pipework within 100 feet of the

tower requires a 55% overlap of Denso Petrolatum

Tape. An optional protective outerwrap may be used for

additional protection (See Section 18.0).

12.2

All exposed horizontal pipework downwind of the cooling

tower, subject to fallout from the tower, requires a 55%

overlap.

12.3

A material-saving method may be used to provide a

double thickness of tape on the top half of the pipe.

Apply applicable Denso Petrolatum Tape longitudinally

along the top axis of the pipe and then apply a minimum

1" overlap spirally around the pipe.

10.6

Apply sufficient tension to give complete adherence, but

do not stretch the tape at any time.

10.7

Avoid folds and air pockets, pressing out any which may

appear.

Figure 3

12.4

All other pipework, valves, fittings, etc., including vertical

risers and less exposed surfaces, may use the 1" overlap,

depending upon site and/or environmental conditions.

System, application is made to both the bracket,

U-bolt, pipe surface, etc., as appropriate. The tape is

applied in accordance with Section 7.0.

13.0 Wind Line Corrosion (Pipe Penetration)

17.0 Repair of Damaged Tape or Coating

13.1

The surface of the pipe shall be cleaned a minimum of

12" below and above grade as described in Section 4.0.

17.1

13.2

Apply applicable Denso Primer and Denso Petrolatum

Tape as described in Sections 5.0 and 7.0.

Denso Petrolatum Tape may be used to repair damaged

coatings or tapes. The following procedure should be

followed:

17.2

Remove damaged tape or non-adhering coating. Remove

corrosion products. Apply thin coat of Denso Paste. On

thick-film coatings or tapes, we recommend the use of a

small amount of mastic as a filler to eliminate the abrupt

edge where the old coating or tape ends. Begin the

application of tape a minimum of two inches back from

the damaged area utilizing the recommended overlap for

the service. Complete wrapping of repair area so that the

tape overlaps at least 2" onto the original coating.

17.3

When repairing damaged Denso Petrolatum Tape, the

damaged area frequently can be repaired by applying

a patch or a full circumferential wrap. The new Denso

Petrolatum Tape can readily be pressed onto the old

tape. Patches should only be installed on the top half of a

pipe surface.

13.3

Outerwrapping: Denso Glass Outerwrap shall be spirally

wrapped over entire coated area onto the existing coating by

4". The minimum Denso Glass Outerwrap coverage shall be

50% overlap in each of two separate layers. This will provide a

four-layer thickness throughout the overall coated area. Additional

layers will provide additional mechanical protection. Temperate

water is used to activate the resin in the Denso Glass

Outerwrap. In cold weather, a methyl alcohol (winter windshield

washer fluid) solution can be used. The Denso Glass Outerwrap

can be soaked in water and/or alcohol solution to activate the

resin for twenty to thirty seconds prior to application. Alternately, a

water and/or methyl alcohol solution can be spray applied to each

layer of the Denso Glass Outerwrap as it is applied. Denso Glass

Outerwrap will be considered ready to backfill when the resin in

the Denso Glass Outerwrap has cured to the degree that

it provides adhesion between the layers of itself and is firm

enough not to be affected by the backfilling operation. In cold

weather, the Denso Glass Outerwrap may not achieve full cure

prior to being backfilled, however it will continue to cure even

after being backfilled once it warms up.

14.0 Protection of Insulated Lines

14.1

Apply applicable Denso Primer and Denso Petrolatum

Tape as described in Sections 5.0 and 7.0.

14.2

Insulation may be applied immediately after application of

the Denso Petrolatum System is complete.

18.0 Protective Outerwraps

18.1

Denso Utility Tape and Denso Poly-Wrap is available as

an overwrap for mechanical protection or as a general

non-tack barrier.

18.2

Denso Glass Outerwrap as described in Section 13.3.

18.3

30 to 100 mil Polyethylene can provide a durable

covering for Denso Petrolatum Tape. Jacketing shall be

banded every 18" to 24".

19.0 Inspection

15.0 Field Joints of Shop-Coated Pipe

15.1

Prepare surfaces as described in Section 4.0.

15.2

Apply applicable Denso Primers and Denso Petrolatum

Tapes as described in Sections 5.0 and 7.0. Start and

finish application of tape several inches onto each end of

the substrate.

15.3

Apply Denso Utility Tape or Denso Glass Outerwrap

beginning on the shop applied coating, over the tape

finishing up several inches onto each side of shop

applied coating. Do not exceed the edge of the Denso

Petrolatum Tape.

16.0 Pipe Hangers, Brackets,

Supports, U-Bolts, etc.

16.1

Prepare surfaces as described in Section 4.0.

16.2

Apply applicable Denso Primer as recommended making

certain that all thread are well covered.

16.3

If the pipe is not already wrapped with a Denso Petrolatum

VER 1506.22

19.1

The underlying surface beneath any of the Denso

Petrolatum Tapes may be inspected at any time, while in

service, merely by cutting an H or X in the tape. Peel

back the flaps and inspect the underlying surface. Upon

completion of the inspection, simply press the flaps back

in place. Smooth the tape and smear the cut edges and

tape is again ready for service.

DENSO NORTH AMERICA

HOUSTON:

TORONTO:

9747 Whithorn Drive,

90 Ironside Crescent,

Houston, Texas,

Unit 12, Toronto,

U.S.A. 77095

Ontario, Canada M1X1M3

Tel: 281-821-3355

Tel: 416-291-3435

Fax: 281-821-0304

Fax: 416-291-0898

www.densona.com

A Member of Winn & Coales International

Você também pode gostar

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsNo EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsNota: 5 de 5 estrelas5/5 (1)

- Weatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundNo EverandWeatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundAinda não há avaliações

- 5 Thread Makeup & Installation Procedure: 5.1 ScopeDocumento6 páginas5 Thread Makeup & Installation Procedure: 5.1 ScopeJorge Castro CucurellaAinda não há avaliações

- Application Instructions Denso Butyl Tape System1Documento4 páginasApplication Instructions Denso Butyl Tape System1Khoh Kai ShengAinda não há avaliações

- Residential Building ConstructionDocumento40 páginasResidential Building ConstructionRaj Verma63% (8)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionAinda não há avaliações

- Pipe Wall Thickness Calculation @MechEngineersDocumento77 páginasPipe Wall Thickness Calculation @MechEngineersHeri KurniawanAinda não há avaliações

- Bop PDFDocumento2 páginasBop PDFRoland NicolasAinda não há avaliações

- Method Statement For Field LaminationDocumento13 páginasMethod Statement For Field Laminationkais rguigui0% (1)

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Documento2 páginasWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Draft WPSDocumento3 páginasDraft WPSWale OyeludeAinda não há avaliações

- Solvent Jointing of CPVC PipesDocumento20 páginasSolvent Jointing of CPVC PipesHamza Hashim100% (1)

- Terminaiton Kit SpecificaitonDocumento5 páginasTerminaiton Kit SpecificaitonVaibhav ShahAinda não há avaliações

- Application Guide Penguard MidcoatDocumento6 páginasApplication Guide Penguard Midcoatadeoye_okunoyeAinda não há avaliações

- Chloride Attack of Reinforced ConcreteDocumento8 páginasChloride Attack of Reinforced ConcreteBraydon GoyetteAinda não há avaliações

- 2012 FWP Steps BrochureDocumento12 páginas2012 FWP Steps BrochureFort Wayne PoolsAinda não há avaliações

- MS For Installation of GRE PipingDocumento9 páginasMS For Installation of GRE PipingN P Srinivasarao100% (2)

- Format For Cover Letter For Request For Payment of Progress-BillingDocumento1 páginaFormat For Cover Letter For Request For Payment of Progress-BillingRoland Nicolas0% (1)

- GRP - GRE - GRV Pipes and FittingDocumento11 páginasGRP - GRE - GRV Pipes and FittingPankajAinda não há avaliações

- Application ProcedureDocumento18 páginasApplication ProcedureTeguh SilaAinda não há avaliações

- Time Sheet For Daily Work at MCS-TB1 2016Documento5 páginasTime Sheet For Daily Work at MCS-TB1 2016Roland NicolasAinda não há avaliações

- Amiantit. Field Installation ProcedureDocumento37 páginasAmiantit. Field Installation ProcedureABAID ULLAHAinda não há avaliações

- Testing & Commissioning Procedure (Electrical)Documento100 páginasTesting & Commissioning Procedure (Electrical)Roland Nicolas100% (1)

- Wavistrong Supplemental Installation InstructionsDocumento13 páginasWavistrong Supplemental Installation Instructionsmg4myAinda não há avaliações

- Timber DesignDocumento17 páginasTimber Designshaina mae omandacAinda não há avaliações

- Denso SeaShield Series 2000HDDocumento4 páginasDenso SeaShield Series 2000HDAnonymous wKvJXBJ2iAinda não há avaliações

- Denso Valve Flange Tape Wrapping SpecDocumento3 páginasDenso Valve Flange Tape Wrapping SpecNaufal Firmansyah100% (1)

- Application Instructions Petrolatum Tape SystemDocumento4 páginasApplication Instructions Petrolatum Tape Systemnikita6969Ainda não há avaliações

- Strain GaugeDocumento4 páginasStrain GaugePURAPATAGONIAAinda não há avaliações

- Denso Tank Base Protection System SpecDocumento2 páginasDenso Tank Base Protection System SpecmniteshpAinda não há avaliações

- Work Methodology R1Documento12 páginasWork Methodology R1Anonymous 1uGSx8bAinda não há avaliações

- Seashield Series 70: Engineering SpecificationsDocumento3 páginasSeashield Series 70: Engineering Specificationsmehdi_hoseineeAinda não há avaliações

- IT - Ghid - Aplicare - Membrana - Izolatie - Bazine-Iazuri ArtificialeDocumento8 páginasIT - Ghid - Aplicare - Membrana - Izolatie - Bazine-Iazuri Artificialeandrew_sfiAinda não há avaliações

- Film Thickness Per Coat: Application Guide Tankguard 412Documento1 páginaFilm Thickness Per Coat: Application Guide Tankguard 412TamerTamerAinda não há avaliações

- Guard Part5 PDFDocumento1 páginaGuard Part5 PDFTamerTamerAinda não há avaliações

- Application Guide-Cold-Applied-Tape-Elastomeric-Rev 2, 8-16 - 1 PDFDocumento4 páginasApplication Guide-Cold-Applied-Tape-Elastomeric-Rev 2, 8-16 - 1 PDFEbondAinda não há avaliações

- Denso Densotherm Application SpecDocumento2 páginasDenso Densotherm Application SpecLasandu WanniarachchiAinda não há avaliações

- Klambon Steel PipingDocumento5 páginasKlambon Steel PipingshaunswanbyAinda não há avaliações

- FSEL Strain Gage For Concrete Rev 00Documento7 páginasFSEL Strain Gage For Concrete Rev 00jbmune6683Ainda não há avaliações

- Denso SeaShield Series 100Documento4 páginasDenso SeaShield Series 100Danny RusnaldyAinda não há avaliações

- Masterflex Tapes, When Used To Protect Joints Above andDocumento1 páginaMasterflex Tapes, When Used To Protect Joints Above andMichael AlbuquerqueAinda não há avaliações

- Wrapping MethodDocumento5 páginasWrapping Methodnnuek67% (3)

- Instructions For Doing First Line Maintenance With ZINGA.Documento4 páginasInstructions For Doing First Line Maintenance With ZINGA.jonte kimondioAinda não há avaliações

- Pre 049Documento2 páginasPre 049Josip MedvedAinda não há avaliações

- Denso Bore WrapDocumento3 páginasDenso Bore WrapAlexander MattosAinda não há avaliações

- Solvent Jointing of CPVC PipesDocumento20 páginasSolvent Jointing of CPVC PipesHamza HashimAinda não há avaliações

- A319 - A321 - LAA - and - LUS - A321NX - (A321 Structural Repair Manual) - (51-77-11-911-022)Documento11 páginasA319 - A321 - LAA - and - LUS - A321NX - (A321 Structural Repair Manual) - (51-77-11-911-022)Juan MartelAinda não há avaliações

- BITUSTICK - XL-Tecnical Data SheetDocumento2 páginasBITUSTICK - XL-Tecnical Data Sheetaldred_chezka100% (1)

- Interzone 101 Application Guidelines UkDocumento4 páginasInterzone 101 Application Guidelines UkomsmkAinda não há avaliações

- Construction Specification 97-Geomembrane Liner: 1. ScopeDocumento6 páginasConstruction Specification 97-Geomembrane Liner: 1. ScopeLuis Rolando AguilarAinda não há avaliações

- Expoband Plus PDFDocumento4 páginasExpoband Plus PDFmilanbrasinaAinda não há avaliações

- Conduit Installation GuideDocumento10 páginasConduit Installation GuidelaxmandohanAinda não há avaliações

- Application Guide Penguard Midcoat PDFDocumento6 páginasApplication Guide Penguard Midcoat PDFsajan shaAinda não há avaliações

- Index Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Documento6 páginasIndex Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Biju_PottayilAinda não há avaliações

- Vexcolt - IG - FlexatecDocumento6 páginasVexcolt - IG - FlexatecPhạm Thanh PhươngAinda não há avaliações

- AG 494 Jotafloor Sealer Euk GBDocumento6 páginasAG 494 Jotafloor Sealer Euk GBAhmed SalahAinda não há avaliações

- English Solvent Welding Guide 12 2017Documento24 páginasEnglish Solvent Welding Guide 12 2017Richard EddingtonAinda não há avaliações

- WCD Densopol Tapes - IfU 2020Documento5 páginasWCD Densopol Tapes - IfU 2020Makamu Max Las MokgaoganyiAinda não há avaliações

- Proofex Engage PDFDocumento2 páginasProofex Engage PDFmilanbrasinaAinda não há avaliações

- MS-Precon + Drainage Board-R3 26.3.2020)Documento4 páginasMS-Precon + Drainage Board-R3 26.3.2020)sammyAinda não há avaliações

- Proofex GPE: Cold Applied Polymer Modified Bitumen Waterproofing Sheet MembraneDocumento3 páginasProofex GPE: Cold Applied Polymer Modified Bitumen Waterproofing Sheet Membranemarzuki0202Ainda não há avaliações

- Penguard Clear Sealer: Technical Data Sheet Application GuideDocumento7 páginasPenguard Clear Sealer: Technical Data Sheet Application GuideAnonymous 4SFfEmcHmDAinda não há avaliações

- C 716 - 00 - QZCXNGDocumento4 páginasC 716 - 00 - QZCXNGmercab15Ainda não há avaliações

- Vulkem Athletic Play Surface Application SpecsDocumento4 páginasVulkem Athletic Play Surface Application SpecsOgbedande Awo OrunmilaAinda não há avaliações

- Product Data Booklet Fibertec Ultimate HDD Coating SystemDocumento8 páginasProduct Data Booklet Fibertec Ultimate HDD Coating Systemmkash028Ainda não há avaliações

- Tape Coating StandardDocumento17 páginasTape Coating StandardKaushik DuariAinda não há avaliações

- Installation Guide For Solvent-Welded PVC Pipe: HandlingDocumento3 páginasInstallation Guide For Solvent-Welded PVC Pipe: HandlingKPHMXAinda não há avaliações

- Coating Procedure Hydac PL2653 Siemens D Ineos 1Documento6 páginasCoating Procedure Hydac PL2653 Siemens D Ineos 1rjgoonerAinda não há avaliações

- The Wet-Seal System Waterproofing Membrane: ProductDocumento4 páginasThe Wet-Seal System Waterproofing Membrane: ProductmagdyamdbAinda não há avaliações

- solidworks ขั้นพื้นฐานDocumento74 páginassolidworks ขั้นพื้นฐานChonTicha'Ainda não há avaliações

- Conbextra EP65 SDSDocumento4 páginasConbextra EP65 SDSEdwin HarrisAinda não há avaliações

- Bitustick XLDocumento2 páginasBitustick XLaldred_chezkaAinda não há avaliações

- IT Security Training - 20151204Documento21 páginasIT Security Training - 20151204Roland NicolasAinda não há avaliações

- EOT Due To Typhoon-2016Documento1 páginaEOT Due To Typhoon-2016Roland NicolasAinda não há avaliações

- Primavera (Exercise 6) .Pdf0Documento7 páginasPrimavera (Exercise 6) .Pdf0RAKESH RANJANAinda não há avaliações

- SUBJECT: STG#2 Thermal Insulation Works ID No. (JEL) ID No. (MPS R3)Documento2 páginasSUBJECT: STG#2 Thermal Insulation Works ID No. (JEL) ID No. (MPS R3)Roland NicolasAinda não há avaliações

- Dental Clinic ServicesDocumento3 páginasDental Clinic ServicesRoland NicolasAinda não há avaliações

- Total Q'tyDocumento32 páginasTotal Q'tyRoland NicolasAinda não há avaliações

- Fever ChartDocumento1 páginaFever ChartRoland NicolasAinda não há avaliações

- Primavera Resource Loading (Labor & Materials)Documento4 páginasPrimavera Resource Loading (Labor & Materials)Roland NicolasAinda não há avaliações

- 277 SpecDocumento86 páginas277 Specmanil_5Ainda não há avaliações

- Bulkhead Connector: 1" PM25 EntireDocumento3 páginasBulkhead Connector: 1" PM25 EntireJ Gabriel GomezAinda não há avaliações

- Murtfeldt-Glideskinner (Perfil de Guia)Documento49 páginasMurtfeldt-Glideskinner (Perfil de Guia)Suelen SantosAinda não há avaliações

- Swagelok T SeriesDocumento6 páginasSwagelok T SeriesAkmalAinda não há avaliações

- Hydraulic Fitting Thread Chart - Hydraulics DirectDocumento23 páginasHydraulic Fitting Thread Chart - Hydraulics Directbass305Ainda não há avaliações

- Precast Cement Concrete Block Construction - Seminar Report, PPT, PDF For Civil EngineeringDocumento12 páginasPrecast Cement Concrete Block Construction - Seminar Report, PPT, PDF For Civil EngineeringSoc Rua NguyenAinda não há avaliações

- SCI C Vitaulic Snap-Let Outlet Snap 11.04Documento2 páginasSCI C Vitaulic Snap-Let Outlet Snap 11.04jplutodAinda não há avaliações

- Masoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesDocumento9 páginasMasoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesisctomaslopezAinda não há avaliações

- Brosur - PT. Jaya Beton IndonesiaDocumento8 páginasBrosur - PT. Jaya Beton IndonesiaDita DitaAinda não há avaliações

- Common Pipe Terminology and AcronymsDocumento7 páginasCommon Pipe Terminology and AcronymsDGWAinda não há avaliações

- Daily Construction Report: Commercial & Luxury ApartmentsDocumento3 páginasDaily Construction Report: Commercial & Luxury ApartmentsFaheem MushtaqAinda não há avaliações

- Cherlopalli Vakulamatha Temple RoadDocumento39 páginasCherlopalli Vakulamatha Temple Roadharsha vickyAinda não há avaliações

- Tds of Eterset 2844Documento2 páginasTds of Eterset 2844Nandkumar PawarAinda não há avaliações

- Crack Injection Repair To Concrete Structures: Method Statement For ApplicationDocumento3 páginasCrack Injection Repair To Concrete Structures: Method Statement For ApplicationbotchAinda não há avaliações

- Requirement: 261 Sets. List of Fittings For Steel Channel Sleeper (One Set) List of FittingsDocumento1 páginaRequirement: 261 Sets. List of Fittings For Steel Channel Sleeper (One Set) List of FittingsBWS JALANDHARAinda não há avaliações

- Cross Line CharolasDocumento11 páginasCross Line CharolasMiguel FonsecaAinda não há avaliações

- 415b - Universal Locking SystemDocumento29 páginas415b - Universal Locking SystemAbish KhanAinda não há avaliações

- Technical Information Technical Information: General Information R2 R15Documento42 páginasTechnical Information Technical Information: General Information R2 R15safat parAinda não há avaliações

- ErupgDocumento44 páginasErupgaes limemAinda não há avaliações

- FerrocementDocumento25 páginasFerrocementNandhini NallasamyAinda não há avaliações