Escolar Documentos

Profissional Documentos

Cultura Documentos

Paper Id-34201517

Enviado por

suraj dhulannavarTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Paper Id-34201517

Enviado por

suraj dhulannavarDireitos autorais:

Formatos disponíveis

International Journal of Research in Advent Technology, Vol.3, No.

4, April 2015

E-ISSN: 2321-9637

Review of Solar Powered Pesticide Sprayer

Sarvesh Kulkarni1, Karan Hasurkar2, Ramdas Kumbhar3, Amol Gonde4, Raut A.S. 5

Student (1234)Department of Mechanical Engineering ,Rajendra Mane College of Engineering and Technology,

Ambav ,Devrukh, Ratnagiri, University of Mumbai, India

Faculty (5) Department of Mechanical Engineering ,Rajendra Mane College of Engineering and Technology,

Ambav ,Devrukh, Ratnagiri, University of Mumbai, India

Email:.sarvesh.94.kulkarni@gmail.com1, hasurkarkaran13@gmail.com2, ramankumbhar94@gmail.com 3,

amolgonde50@gmail.com4

Abstract- There is various non conventional energy sources from which the power can be generated. Solar

energy, Wind energy, Tidal energy, Biogas energy these are various non conventional energy sources. Solar

energy is widely available in nature throughout the year. So it can be utilized in miscellaneous application like

spraying, drying and cooking etc. In agricultural areas spraying is one of the essential tasks. This paper gives the

information about solar powered pesticide sprayer as in cost effective manner. Solar pesticide sprayer has

various advantages over conventional sprayers. It also gives information about various components used in

sprayer. As it has various advantages it will become popular in agricultural field.

Index Terms- Solar energy1, Pesticide sprayer 2, Non conventional energy source3.

1. INTRODUCTION

In Agricultural field spraying is one of the essential

task as it affects the growth of the crops .In India

there are three types of pesticide sprayer are used in

agricultural field,

1. Manually operated spray pumps,

2. Fuel operated spray pumps,

3. Electrical spray pumps

1. Manually operated spray pumps

These are manually operated by the person. No any

type of energy source is required in this type.

available from the sun is in nature at free of cost. In

India solar Energy is available around 8 months in

year .so it can be used in spraying operation.

Solar pesticide sprayer can give less tariff or price

in effective spraying. Solar energy is absorbed by the

solar panel which contains photovoltaic cells. The

conversion of the solar energy into electrical energy is

done by these cells. This converted energy utilizes to

store the voltage in the DC battery and that battery

further used for driving the spray pump.

2. METHODOLOGY

2. Fuel operated spray pumps

This pump uses fossil fuels for operation.

Design and fabrication of solar powered pesticide

sprayer has following steps,

3. Electrical spray pumps

Electrical pump uses the electricity for charging the

battery which drives the pump.

2.1. Selection of components

Above convention pumps has following

disadvantages,

1. Manually operated pumps causes fatigue in

operating person and cant be used for longer time.

2. In fuel operated pumps cost of operation is high

due to fuels used in it and pumps emitted pollutant

gases in environment.

3. Electrical pumps cant be used in some of rural

areas due to insufficient supply of electricity.

Now days there are non conventional energy

sources are widely used. The energy which is

The selection of component has done according to the

requirement .following are the list of components,

1. Tank

2. Solar panel

ab

3. DC Motor

4. DC Battery

5. Nozzle type

6. Connecting pipe

7. Mounting elements

3.1.1. Tank

Pesticide tank has capacity of 16 liters. In order to

have less weight of the tank, plastic is purposely used

for it.

30

International Journal of Research in Advent Technology, Vol.3, No.4, April 2015

E-ISSN: 2321-9637

3.1.2. Solar panel

Solar panel is the main component of the system.

It has the following specifications,

Capacity of panel - 40 watts

3.1.3. DC motor

DC motor is used to lift the pesticide from tank and

delivers to the spray gun. DC motor has following

specifications,

Current 2.2 A

Voltage 12V

Flow rate -3.1LPM

Therefore K=1.905

According to BETE manufacturer catalogue

Selected standard K=2.23

2. Calculation of nozzle dimension

So the selected nozzle is NFS 098.

The pipe dimensions are 1/4 inch = 6.35mm

So selected pipe diameter = 7mm

Figure: flat fan nozzle drawing

Dimensions of nozzle has been selected according to

BETE manufacturer catalogue as

A = 11.9 mm

B = 7.11 mm

C = 17.5 mm

Figure: DC Motor

3.1.4. DC battery

DC battery is power source for this spray pump. This

battery is charged by solar panel and removable. It has

following specification,

Current 8Ah

Voltage 12V

3.1.5. Nozzle

Nozzle is the basic component of the spray pump

which generate spray pattern. The nozzle is selected

as per the study. It decides how much area of the plant

should cover. So according to detailed study of

research paper it can be found that the flat fan nozzle

gives the fine spray at 3 bar pressure. It covers the

maximum area according to the spray angle [1]

The selection of nozzle can be done by following

steps:1. Calculation of K factor

Flow rate (lpm) =K*Pressure (bar)

Flow rate=3.3 lpm

Pressure=3 bar

Figure: Metal flat fan nozzle

4. Selection of nozzle material

Generally brass, stainless steel, tungsten carbide,

ceramic are used to manufacturing the nozzles. In this

the brass is cheapest one but the main problem is that

its corrosion resistance is less than that of the steel.

Also it has got more corroded to the liquid fertilizers.

As it is having such kind of drawbacks the material

which is good enough is Stainless steel. It gives

longer performance and produces the uniform pattern

of spray .so that we had selected stainless steel

material for nozzle.

31

International Journal of Research in Advent Technology, Vol.3, No.4, April 2015

E-ISSN: 2321-9637

3.1.6. Connecting pipe

It supplies pesticide from tank to the nozzle.

As discussed above the pesticide will always floe

through the pipe. So it should not wear fast. So

material used for the pipe is stainless steel.

3.1.7. Mounting elements

Mounting element used for making assembly

2.2 General Calculation [4]

Following are the general calculation,

Power generated by solar panel= 40 watts

Power = energy/sec

Battery 12V, 8Ah current

Power =V*I

= 12*8

= 96WH

Time required charging the battery

= (96/40)*2.5

=6 hrs*

*Note-Time varies because of intensity of sun

radiations at different days.

Backup time of sprayer

= (power stored in battery/power

consumed by motor)

= 96/(2.2*12)

=3.63 hrs

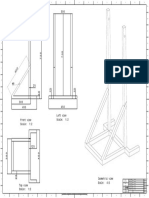

Assembly is done as shown in figure.

4. PRINCIPLE OF OPERATION

Sun radiations are incident on the solar

panel. Solar panel consist of photovoltaic cells

convert this solar energy in to the electric energy.

Further this current generated by the solar cells is

supplied to the battery via electric wires. One

controller is placed between the solar panel and the

battery which control the current which is supplied to

battery. This battery is removable so after fully

charged it can be removed and placed in the sprayer.

In this way charging is done.

When battery is connected in the sprayer, it

supplies the current to the DC motor and it runs at

required speed. Motor has two opening one inlet and

one outlet. Motor develops the suction and lift the

pesticide from the tank and via connecting pipe

supplies to the nozzle. Nozzle generates the spray

pattern .After the in this way the pesticide is spray on

the crops.

5. RESULT, MERITS AND ADVANTAGES:

5.1Result

According to the test conducted it is found that 12V,

8Ah battery can be charged fully in hours during the

day.

3. ASSEMBLY

Figure: spray pattern obtained at 45 angle

Figure: CAD model of the assembly

32

International Journal of Research in Advent Technology, Vol.3, No.4, April 2015

E-ISSN: 2321-9637

Figure: spray pattern obtained at 90 angle

manufacturing and testing of the nozzle

spray pattern in their firm.

We acknowledge Sanmeed Solar Shoppe,

Kolhapur for their help.

REFERENCES

Figure: flat fan nozzles with spray pattern

5.2 Merits

Less power consumption.

Less operation cost

Effective spraying

5.3 Advantages

No any type of pollution.

Less maintenance cost as compare to other.

Easy in operating.

Eco friendly

[1] D.Nuyttens,

K.

Baetens,

M

.De

schampheleire, B.sonck.(2007): Effects of

nozzle type, size and pressure on spray

droplet

characteristic.

Biosystem

Engineering 97,pp 333-345.

[2] Pedro Teixeira Lacava, Demtrio BastosNetto, Amlcar Porto Pimenta (2004):

Design

procedure

and

experimental

evaluation of pressure-swirl atomizers.24th

International Congress of Aeronautical

Science.

[3] MD .Atiar Ali: Solar system calculation and

design.

[4] Brent A. Pringnitz.: Sprayer nozzle selection

for pesticide performance and drift reduction.

Extension program specialist, Department of

Agronomy Iowa State University.

[5] John W. Slocombe: Agricultural spray

nozzle : selection and sizing, extension

agricultural engineer ,Kansas State university

[6] BETE

Flat

fan

nozzle

catalogue,WWW.BETE.COM.

6. CONCLUSION

It is observed that, this model of solar

powered pesticide sprayer is more cost effective and

gives the effective results in spraying operation. As it

runs on the non conventional energy source i.e. solar

energy, it is widely available at free of cost. In now

days where world is moving towards the finding the

new ways for the energy requirement, it can be a

better option for the convention sprayer. As India is a

developing country, this product can be become more

popular in rural areas.

Future scope:

1. The overall weight of the tank can be minimized by

molding techniques.

2. The battery backup can be increased by adopting

some new technology in electronic fields.

Acknowledgments

This entire project was successfully

completed with the valuable support and

guidance of Prof. A.S. Raut .We truly

grateful to have their support and guidance

for completion of this work.

We are thankful to Gunvant Udyog,

Kolhapur for their support during the

33

Você também pode gostar

- Wind Driven Mobile Charging of Automobile BatteryDocumento7 páginasWind Driven Mobile Charging of Automobile Batterysuraj dhulannavarAinda não há avaliações

- Visvesvaraya Technological University BelgaumDocumento2 páginasVisvesvaraya Technological University Belgaumsuraj dhulannavarAinda não há avaliações

- Left View Scale: 1:2: 1:1 XXX A0Documento1 páginaLeft View Scale: 1:2: 1:1 XXX A0suraj dhulannavarAinda não há avaliações

- 1:1 XXX A1: Toshavi PCDocumento1 página1:1 XXX A1: Toshavi PCsuraj dhulannavarAinda não há avaliações

- FrameDocumento1 páginaFramesuraj dhulannavarAinda não há avaliações

- M.H.Saboo Siddik PolytechnicDocumento5 páginasM.H.Saboo Siddik Polytechnicsuraj dhulannavarAinda não há avaliações

- D e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N eDocumento13 páginasD e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N esuraj dhulannavarAinda não há avaliações

- 1:1 XXX A1: Toshavi 5/3/2016Documento1 página1:1 XXX A1: Toshavi 5/3/2016suraj dhulannavarAinda não há avaliações

- 1:1 XXX A4: Designed By: DateDocumento1 página1:1 XXX A4: Designed By: Datesuraj dhulannavarAinda não há avaliações

- FrameDocumento1 páginaFramesuraj dhulannavarAinda não há avaliações

- WWW Mechengg Net 2015 09 Design and Fabrication of InjectionDocumento17 páginasWWW Mechengg Net 2015 09 Design and Fabrication of Injectionsuraj dhulannavarAinda não há avaliações

- 1:1 XXX A4: Toshavi 4/8/2016Documento1 página1:1 XXX A4: Toshavi 4/8/2016suraj dhulannavarAinda não há avaliações

- 1:1 XXX A1: Designed By: DateDocumento1 página1:1 XXX A1: Designed By: Datesuraj dhulannavarAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Vemu Institute of Technology: Department of Computer Science & EngineeringDocumento79 páginasVemu Institute of Technology: Department of Computer Science & EngineeringSiva SankarAinda não há avaliações

- Back Propagation Neural NetworkDocumento10 páginasBack Propagation Neural NetworkAhmad Bisyrul HafiAinda não há avaliações

- Module6 Quiz1Documento4 páginasModule6 Quiz1karthik1555Ainda não há avaliações

- RMC 102-2017 HighlightsDocumento3 páginasRMC 102-2017 HighlightsmmeeeowwAinda não há avaliações

- 1916 South American Championship Squads - WikipediaDocumento6 páginas1916 South American Championship Squads - WikipediaCristian VillamayorAinda não há avaliações

- CORP2165D Lecture 04Documento26 páginasCORP2165D Lecture 04kinzi chesterAinda não há avaliações

- Gomez-Acevedo 2010 Neotropical Mutualism Between Acacia and Pseudomyrmex Phylogeny and Divergence TimesDocumento16 páginasGomez-Acevedo 2010 Neotropical Mutualism Between Acacia and Pseudomyrmex Phylogeny and Divergence TimesTheChaoticFlameAinda não há avaliações

- Smart Gas Leakage Detection With Monitoring and Automatic Safety SystemDocumento4 páginasSmart Gas Leakage Detection With Monitoring and Automatic Safety SystemYeasin Arafat FahadAinda não há avaliações

- 1B20 40Documento4 páginas1B20 40Electrival TcatallerAinda não há avaliações

- Introduction To Retail LoansDocumento2 páginasIntroduction To Retail LoansSameer ShahAinda não há avaliações

- Playing With Pop-Ups - The Art of Dimensional, Moving Paper DesignsDocumento147 páginasPlaying With Pop-Ups - The Art of Dimensional, Moving Paper DesignsSara100% (4)

- Instant Download Ebook PDF Ecology Concepts and Applications 8th Edition PDF ScribdDocumento41 páginasInstant Download Ebook PDF Ecology Concepts and Applications 8th Edition PDF Scribdsteven.cross256100% (45)

- 19c Upgrade Oracle Database Manually From 12C To 19CDocumento26 páginas19c Upgrade Oracle Database Manually From 12C To 19Cjanmarkowski23Ainda não há avaliações

- Electronic Spin Inversion: A Danger To Your HealthDocumento4 páginasElectronic Spin Inversion: A Danger To Your Healthambertje12Ainda não há avaliações

- Exotic DVM 11 3 CompleteDocumento12 páginasExotic DVM 11 3 CompleteLuc CardAinda não há avaliações

- Computer Class 3 ThirdDocumento1 páginaComputer Class 3 ThirdbeakraamAinda não há avaliações

- Midi Pro Adapter ManualDocumento34 páginasMidi Pro Adapter ManualUli ZukowskiAinda não há avaliações

- Standard Test Methods For Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield Type) ViscometerDocumento8 páginasStandard Test Methods For Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield Type) ViscometerRodrigo LopezAinda não há avaliações

- This Study Resource Was: For The Next 6 ItemsDocumento9 páginasThis Study Resource Was: For The Next 6 ItemsJames CastañedaAinda não há avaliações

- 1 Bacterial DeseaseDocumento108 páginas1 Bacterial DeseasechachaAinda não há avaliações

- Bad Memories Walkthrough 0.52Documento10 páginasBad Memories Walkthrough 0.52Micael AkumaAinda não há avaliações

- Introduction To BiogasDocumento5 páginasIntroduction To BiogasLouis EldertardAinda não há avaliações

- MME 52106 - Optimization in Matlab - NN ToolboxDocumento14 páginasMME 52106 - Optimization in Matlab - NN ToolboxAdarshAinda não há avaliações

- SreenuDocumento2 páginasSreenuSubbareddy NvAinda não há avaliações

- Participants ListDocumento13 páginasParticipants Listmailway002Ainda não há avaliações

- BJAS - Volume 5 - Issue Issue 1 Part (2) - Pages 275-281Documento7 páginasBJAS - Volume 5 - Issue Issue 1 Part (2) - Pages 275-281Vengky UtamiAinda não há avaliações

- TFGDocumento46 páginasTFGAlex Gigena50% (2)

- Iphone and Ipad Development TU GrazDocumento2 páginasIphone and Ipad Development TU GrazMartinAinda não há avaliações

- Elpodereso Case AnalysisDocumento3 páginasElpodereso Case AnalysisUsama17100% (2)

- ETAP Power Station ErrorDocumento5 páginasETAP Power Station ErroryogacruiseAinda não há avaliações