Escolar Documentos

Profissional Documentos

Cultura Documentos

Otis PDF

Enviado por

BTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Otis PDF

Enviado por

BDireitos autorais:

Formatos disponíveis

Lux

MACHINE ABOVE - 2,50 m/s

BUILDERS WORK CATALOGUE

07-04-15

Version: a-e

800 kg 1600 kg

Otis Elevator Company 2007, All rights reserved

FAA29100H_BWC

BUILDER'S WORK CATALOGUE

Lux

2/38

MAIN

FAA29100H_BWC

Version : a-e

Date: 07-04-15

This catalogue summarizes useful information for installation of the Otis Gen2TM Machine above

2,5m/s 800 kg1600 kg range in buildings.

The catalogue is divided into three main parts:

Part 1: General information

The first part contains general information about the building interfaces that must be complied

with in order to obtain a good final product.

Part 2: Builders work drawing (single car)

The second part contains a definition of the builders work drawings for the Gen2 Machine

above 2,5m/s 800 kg1600 kg range with:

- The building interfaces and dimensions for a single lift in the hoistway (doors are

installed in the hoistway)

- The mechanical reactions exerted by the lift on the building for a single lift in the

hoistway.

Part 3: Information concerning banks of lifts

The third part contains information for installing the Gen2 800 kg1600 kg range in banks.

Bank

Duplex

Triplex

Number of

lifts in the

bank

Quadruplex Quintuplex

4

Sextuplex

Octoplex

BUILDER'S WORK CATALOGUE

Lux

FAA29100H_BWC

3/38

INDEX

Version : a-e

Date: 07-04-15

PART 1: GENERAL INFORMATION

1.1.

DEFINITIONS

1.2.

DIMENSIONS

1.3.

REQUIREMENTS FOR THE WELL GENERAL WELL TOLERANCES

1.4.

ELECTRICAL POWER SUPPLY AND TELEPHONE LINE

15

1.5.

HEAT DISSIPATION

17

1.6.

MAIN BUILDING LIMITATIONS

17

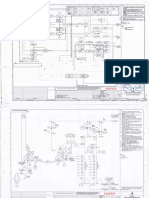

PART 2: EFFORTS ON THE HOISTWAY WALLS

18

2.1.

LIST OF THE COMPONENTS EXERTING EFFORT ON THE WALL AND ON

CEILING

18

2.2.

20

GENERAL VIEW

PART 3: INFORMATION CONCERNING BANKS OF LIFTS

25

3.1.

REQUIREMENTS CONCERNING BANKS OF LIFTS

25

3.2.

RECOMMENDED HOISTWAY DIMENSIONS (ELEVATION)

38

3.3.

HOOKS AND REACTION THE PIT

38

3.4.

LOCATION OF THE HOISTWAY FIXTURES

38

BUILDER'S WORK CATALOGUE

Lux

4/38

PART 1: GENERAL INFORMATION

FAA29100H_BWC

Version : a-e

Date: 07-04-15

1 PART 1: GENERAL INFORMATION

1.1.

DEFINITIONS

CONCEPT

This range of lifts is designed with machine room above the well , one entrance car with center

door opening (CLD) , and rear counterweight .

BUILDING DIMENSIONS

All dimensions used in this catalogue are commercial dimensions.

SYMBOLS

The symbols used in this catalogue are the following:

Identifier

CD

Definition

Car internal depth (mm)

CH

Car internal height (mm)

CLD

Central landing door (Centre Opening)

CW

Car internal width (mm)

HD

Hoistway depth (mm) (including hoistway doors)

HW

Hoistway width (mm)

K

OP

OPH

R

Overhead height (mm)

Door opening width (mm)

Door opening height (mm)

Rise (m)

RW1

Left Return Wall (mm)

RW2

Right Return Wall (mm)

Pit depth (mm)

Rated Speed (m/s)

TLD

TYFAC

WTW

Telescopic Landing Door (Side Opening)

Type of Faade

Wall to wall (mm)

TYPE OF DOORS AND DOOR HAND

Only one car entrance car with center opening doors is proposed

Note: The door-opening axis is located in the car axis.

LANDING DOOR FACADES, DOOR FRAMES AND DOORS INSTALLATION

SF: door panels only are visible. Return walls are compulsory ( SMALL FRAME ),

NF: door panels only are visible. Return walls are compulsory ( NO FRAME )

Landing doors are installed in the hoistway or on the landing.

BUILDER'S WORK CATALOGUE

Lux

5/38

PART 1: GENERAL INFORMATION

FAA29100H_BWC

Version : a-e

Date: 07-04-15

CAR OPERATING PANEL (COP) LOCATION (CAR CONTROL PANEL)

The main COP is located on the car right side panel when entering in the car by the entrance.

The option with a second auxiliary COP at the car opposite side is available.

HALL BUTTONS LOCATION

In case of single lift, the hall buttons are mounted on the return walls adjacent to the landing

doors. The minimum lateral distance between the centre line of the button and any corner of

adjacent walls shall be 500 mm.

1.2.

1.2.1

DIMENSIONS

CAR INTERNAL SIZES

Nb of

passenger

Stamped duty

load (kg)

CW (mm)

CD (mm)

10

800

1350

1400

Door

CLD 800

CLD 900

CLD 900

13

1000

1600

1400

CLD 1000

CLD 1100

17

1275

21

1400

2000

1700

CLD 1100

2100

1600

CLD 1100

CLD 1100

HOISTWAY DIMENSIONS (PLAN)

(MAXIMUM, MINIMUM COMMERCIAL DIMENSIONS IN mm)

CW/2

1

3

CW/2

2

4

Hoistway Axis

Door Opening

and Car Axis

OP

RW1

RW2

HW/2

HW/2

HOISTWAY WIDTH (HW)

FRONT ENTRANCE

HOISTWAY DEPTH HD

CAR WIDTH (CW)

CD

1.2.2

1600

2000

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

1.2.3

6/38

Version : a-e

HOISTWAY-DIMENSIONS-PLAN

1ENTRANCE CAR

(COUNTERWEIGHT

Date: 07-04-15

WITHOUT

OR

WITH

SAFETIES

TYFAC : SF

LIFT

CAPACITY

Load &

Number of

passenger

800 kg

10 Pass.

CAR INTERNAL SIZE

Car Width

Car Depth

Rated

Speed

CW (mm)

CD (mm)

V (m/s)

Door

Opening

Rise

Hoistway

Depth

HOISTWAY DIMENSIONS

Hoistway

Return Walls all landings

Width

OP (mm)

R (m)

HD (mm)

HW (mm)

RW1 (mm)

RW2 (mm)

800

1350

1400

2.50

900

900

1000 kg

13 Pass.

1600

1400

2.50

1000

1100

1275 kg

17 Pass.

1600 kg

21 Pass.

1600 kg

21 Pass.

2000

1400

2.50

1100

2000

1700

2.50

1100

2100

1600

2.50

1100

R80

2010

1950

525

525

R>80

2060

2000

550

550

R80

2010

2050

525

525

R>80

2060

2100

550

550

R80

2010

2200

600

600

R>80

2060

2250

625

625

R80

2010

2200

550

550

R>80

2060

2250

575

575

R80

2010

2400

600

600

R>80

2060

2450

625

625

R80

2010

2550

675

675

R>80

2060

2600

700

700

R80

2310

2550

675

675

R>80

2360

2600

700

700

R80

2210

2650

725

725

R>80

2260

2700

750

750

TYFAC : NF

LIFT

CAPACITY

Load & Number

of passenger

800 kg

10 Pass.

CAR INTERNAL SIZE

Car Width

Car Depth

Rated

Speed

CW (mm)

CD (mm)

V (m/s)

Door

Opening

Rise

Hoistway

Depth

HOISTWAY DIMENSIONS

Hoistway

Return Walls all landings

Width

OP (mm)

R (m)

HD (mm)

HW (mm)

RW1 (mm)

RW2 (mm)

800

1350

1400

2.50

900

900

1000 kg

13 Pass.

1600

1400

2.50

1000

1100

1275 kg

17 Pass.

1600 kg

21 Pass.

1600 kg

21 Pass.

2000

1400

2.50

1100

2000

1700

2.50

1100

2100

1600

2.50

1100

R80

2010

1950

545

545

R>80

2060

2000

570

570

R80

2010

2050

545

545

R>80

2060

2100

570

570

R80

2010

2200

620

620

R>80

2060

2250

645

645

R80

2010

2200

570

570

R>80

2060

2250

595

595

R80

2010

2400

620

620

R>80

2060

2450

645

645

R80

2010

2550

695

695

R>80

2060

2600

720

720

R80

2310

2550

695

695

R>80

2360

2600

720

720

R80

2210

2650

745

745

R>80

2260

2700

770

770

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

1.2.4

7/38

Version : a-e

Date: 07-04-15

HOISTWAY DIMENSIONS (ELEVATION) (MAXI, MINI, COMMERCIAL DIMENSIONS)

1.2.4.1 PIT DEPTH: S (mm)

Speed (m/s)

Door type

2,50

Centre opening

Rise (m)

S mini (mm)

90

2370

>90

2370

S maxi (mm)

2500

1.2.4.2 OVERHEAD HEIGHT : K (mm)

Speed (m/s)

K mini (mm)

K maxi (mm)

2,50

CH + 2050*

10000

* For CH=2200 : K mini = CH+2150

1.2.4.3 AVAILABLE DOOR and CAR HEIGHTS

Door opening Height OPH (mm)

1.2.5

Car height CH (mm)

2000

2200

2300

2400

2100

2300

2400

2500

2200

2400

2500

2300

2500

HOISTWAY DIMENSIONS: RISE - DISTANCE BETWEEN DOORS SILLS

MAXIMUM RISE IN METERS

Speed (m/s)

R Maxi (m)

2,50

150

MAXIMUM DISTANCE BETWEEN DOORS SILLS: FH IN METERS

FH max: 11 m, limitation given by the CEN code if there is no means of evacuating the

passengers. If more than 11 m is required, contact Otis.

MINIMUM DISTANCE BETWEEN DOORS SILLS: FH MIN (IN MILLIMETERS)

Door opening height

FH min (mm)

2000

2470

2100

2570

2200

2670

2300

2770

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

Date: 07-04-15

REQUIREMENTS FOR THE WELL GENERAL WELL TOLERANCES

HOISTWAY DEPTH AND WIDTH TOLERANCES HOISTWAY TOLERANCES FOR SIMPLEX R 80M

MINI HOISTWAY DEPTH

25

25

MAXI HOISTWAY DEPTH

COMMERCIAL HOISTWAY DEPTH

25

25

Maximum out of plumb of each hoistway wall 25 mm

MINI HOISTWAY WIDTH

25

25

COMMERCIAL HOISTWAY WIDTH

25

25

MAXI HOISTWAY WIDTH

FRONT

OPENING

The actual hoistway walls are included between the two perfect vertical parallelepipeds

Maximum out of plumb of each hoistway wall = 50 mm

25mm

Commercial HW

request to the builder

C

om

m

er

ci

al

ci

a

er

Commercial HW - 50

25mm

lH

D

-5

0

50

Commercial HW + 50

om

m

1.3.1

Version : a-e

1.3.

8/38

Actual

location

of the

hoistway

walls

Minimum authorized

location for the wall

Maximum authorized

location for the wall

Effective

constructed wall

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

Version : a-e

Date: 07-04-15

HOISTWAY DEPTH AND WIDTH TOLERANCES HOISTWAY TOLERANCES FOR SIMPLEX R> 80M

MINI HOISTWAY DEPTH

50

50

MAXI HOISTWAY DEPTH

COMMERCIAL HOISTWAY DEPTH

50

50

Maximum out of plumb of each hoistway wall 50 mm

MINI HOISTWAY WIDTH

50

50

COMMERCIAL HOISTWAY WIDTH

50

50

MAXI HOISTWAY WIDTH

FRONT

OPENING

Maximum out of plumb of each hoistway wall = 100 mm

The actual hoistway walls are included between the two perfect vertical parallelepipeds

50mm

Commercial HW

request to the builder

er

ci

al

er

ci

al

m

Commercial HW - 100

om

om

50mm

H

D

-1

00

10

Commercial HW + 100

1.3.2

9/38

Actual

location

of the

hoistway

walls

Minimum authorized

location for the wall

Maximum authorized

location for the wall

Effective

constructed wall

BUILDER'S WORK CATALOGUE

Lux

10/38

PART 1: GENERAL INFORMATION

FAA29100H_BWC

Version : a-e

Date: 07-04-15

The commercial dimensions HW; HD used to order the lift must be included between the

maximum and minimum values (hoistway, commercial dimensions maximum, minimum : see

part 2 ).

The maximum out of plumb of each hoistway wall is 25 mm for rise R

rise R> 80m

80m and 50 mm for

Consequently, the equipment supplied is manufactured for installation in a well, the walls of

which are inscribed in two perfect rectangular parallelepipeds defined in the sketches (dotted

line : chapter 1-3-1 & 1-3-2 ).

ELEVATION - TOLERANCES

1.3.3

Pit depth (s) tolerances

The pit depth (maxi & mini values defined chapter 1.2.4.1) is determined with a building

tolerance of + 20 mm.

The effective pit depth given to Otis and included in these limits must be also with a

tolerance of + 20 mm.

Overhead dimension (K) tolerances

The minimum overhead K defined in chapter 1.2.4.2 is determined with a building tolerance

of 20 mm. The effective overhead dimension (equal or above the minimum) is requested

by Otis for the lift manufacturing (limit = 10000mm).

STRENGTH OF THE WALLS

For the safe operation of the lift, the walls shall have a mechanical strength such that when

a force of 300 N, being evenly distributed over an area of 5 cm in round or square, section,

is applied at right angles to the wall at any point on either face they shall:

- Resist without permanent deformation,

- Resist without elastic deformation greater than 15 mm.

The mechanical reactions exerted by the lift on the building are given in the drawings part 2.

The building walls thickness must be in accordance with the fire regulation.

1.3.4

STRENGTH ON THE PIT FLOOR

The reactions on the pit floor are given in part 2.

If accessible spaces do exist below the car or the counterweight, the base of the pit shall be

designed for an imposed load of at least 5000 N/m and:

a) Either there shall be installed below the counterweight buffer, a solid pier extending down

to solid grown or,

b) The counterweight shall be equipped with safety gear.

The lower part of the hoistway shall consist of a pit, the bottom of which shall be smooth

and approximately level, except for any water drainage devices.

After the building-in of guide rail fixings, buffers, any grids, etc., the pit shall be impervious

to infiltration of water.

For a tanked pit, the builder shall provide a 150 mm thick material (concrete) for fixing

bolts and dowels.

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

1.3.5

11/38

Version : a-e

Date: 07-04-15

VENTILATION OF THE WELL AND THE MACHINE ROOM

The hoistway and the machine room shall be suitable ventilated. It shall not be used to

provide ventilation of rooms other than those belonging to the lift.

Note: in the absence of relevant regulations or standards, it is recommended to provide

ventilation openings at the top of the well, with a minimum area of 1% of the horizontal

section of the well.

The ambient temperature in hoistway and in the machine room shall be maintained

between 0 C and + 45 C, taking into account the heat dissipated by the lift. See Para:

Heat dissipation.

1.3.6

FLOOR USED FOR MATERIAL INTRODUCTION IN THE HOISTWAY

In order to facilitate the handling of the lift material it is requested do not construct before

material installation at the level determined for material introduction.

Both the return walls will be constructed at this floor after the material installation inside the

hoistway.

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

1.3.7

12/38

Version : a-e

Date: 07-04-15

BUILDING STRUCTURE

Gen2 models can be installed in several types of buildings:

- Concrete well,

- Concrete beams and concrete slabs with bricks or block works wall,

- Steel structure

- Block works.

List of the lift components with structural interfaces with the well :

- Guide rail bracket

- Landing door fixations

- Hooks for handling the equipment.

CONCRETE WELL

Minimum compression strength of 30 MPa is required for the concrete.

Two fixation methods are available:

- Steel anchorages: Otis installs the steel dowels after drilling of the concrete.

- The constructor installs suitable rail inserts. The bolts are delivered and installed by Otis.

Contact otis for precise definition.

The maximum vertical distance between guide rails fixation is 3 m.

CONCRETE BEAMS AND CONCRETE SLABS WITH BRICKS OR BLOCK WORKS WALL

The structural Lift components interface on the concrete parts with the same requirements

as for concrete walls.

The maximum distance between slabs is 3 m. One additive concrete beam is required at

the level of the highest guide rails fixations (see part 2).

Consult Otis for detailed information.

STEEL STRUCTURE

The structural lift components are interfaced at the level of the floor beams with a maximum

distance between beams of 3 m. Additive beams are required at the level of the highest

guide rails (side walls). Consult Otis for detailed information.

The natural frequency of the steel structure, which supported the lift, shall be above 5 Hz.

The building beams on which the guide rails brackets are fixed shall have a maximum

deflexion on 2 mm in the local area where the efforts are applied by the lift. Consult Otis for

the value and the location of these efforts.

BLOCK WORKS

(Block works, cellular concrete, full body bricks)

Specific anchorages (chemical dowels...) must be selected by the constructor and Otis,

regarding the max load applied on interfaces components: (guide rails and landing doors).

The maximum vertical distance between guide rails fixation is 3 m.

Consult Otis for detailed information.

See sketches in the following sheets.

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

Version : a-e

Date: 07-04-15

BUILDING STRUCTURE

CONCRETE HOISTWAY

Sketch 1

Hoistway roof

level

Top of hoistway

CONCRETE BEAMS AND CONCRETE SLABS WITH BRICKS OR BLOCK WORKS WALL

400

Hoistway roof

level

3000 Maxi

Sketch 2

Top level

1.3.8

13/38

BUILDER'S WORK CATALOGUE

Lux

14/38

PART 1: GENERAL INFORMATION

FAA29100H_BWC

Version : a-e

Date: 07-04-15

STEEL DRY LINED BUILDING

3000 maxi

Top level

400

Hoistway roof level

BLOCK WORKS

Sketch 4

Hoistway roof

level

Top of hoistway

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

1.4.

15/38

Version : a-e

Date: 07-04-15

ELECTRICAL POWER SUPPLY AND TELEPHONE LINE

1.4.1

ELECTRICAL CABLES INPUT

Suitable electrical conduits shall be routed to the machine room for the following electrical

functions:

- Main power supply: 3 phases (see below 1.4.2)

- Electrical supply for car lighting, hoistway lighting, alarm device and car and pit car and pit

sockets (see below 1.4.3)

- Telephone line (see below 1.4.4)

- Other electrical options : car arrival hall light, car position contact, Intercommunication unit

(car porter lodge) (see below 1.4.5)

1.4.2

MAIN POWER SUPPLY (WITHOUT POWER SUPPLY FOR LIGHTING, SEE 1.4.3)

For each lift, the power supply lines (3 phases + neutral + earth) shall be routed to the

machine room.

Definition in line with (IEC 364-4-63):

IB = Useful current (current for which the circuit is designed)

IZ = Continuous current-carrying capacity of the cable

In = Nominal current of the protective device

Operating characteristic of a device protecting a cable against overload shall satisfy, at

least:

I B In IZ

Table for electrical power supply (DATA NOT CONTRACTUAL)

All the following data are given for a 400 V AC power supply

40A/60A - Regenerative Drives are used .

Number of

Passengers

Speed

(m/s)

Starting

Current

IS (A)

Useful

Current

IB (A)

For information

Rated

Line

Power

S (kVA)

Power

Main

Line

P (kW)

Copper cross

Section

(mm2 )

Calibration of

Protection

Device ( A )

10 (800kg )

2.50

32

26

18

18

10

50

13 (1000kg)

2.50

37

31

21.5

21.5

10

50

17 (1275kg)

2.50

38

31

21.5

21.5

10

50

21 (1600kg)

2.50

47

39

37

37

10

50

Additional information :

It is strongly recommended to separate neutral and protective conductor according to a

TN-S system (5-wire net: 3 phases + neutral + earth).

Rated voltage available: 380 or 400 or 415 V, tolerance: + 10%.

Frequency: 50 or 60 Hz

If an earth leakage circuit breaker is used at the starting point of the power line, the

required rating is 500 mA or more.

Copper cross section of the cable between building and controller in the machine room

has to be calculated following the local code (i.e. IEC 364), considering the rated voltage,

the currents determined with the here-above table and the external influences which can

exist.

BUILDER'S WORK CATALOGUE

Lux

16/38

PART 1: GENERAL INFORMATION

FAA29100H_BWC

Version : a-e

Date: 07-04-15

Electrical supply for lighting and SOcket outlets (en81-1)

For each lift, the power supply line for lighting (1 phase + neutral + earth) shall be routed to

the machine room.

Rated voltage 220 or 230 or 240 V (tolerance + 10%)

Frequency 50 or 60 Hz

Single phase + neutral + earth

This line shall be protected at the starting point according local code (IEC 364).

Useful Current

IB (A

Machinery location

RISE (meter))

Starting Current

IS (A)

< 50

35

25

16 (: 10mA)

6 or 10

50

50

35

16 (: 10mA)

10 or 20

Protection device for car

and socket machinery

FUSE (A) for Lighting In

Hoistway (LIH)

Note: This power supply for lighting could be connected to the main power line, on the

supply side of the main switch.

In this case the value of the current for the lighting must be added to the value of the current

of the main power supply defined in the 1.4.2

In case of interruption of the normal lighting supply, there shall be an automatically

rechargeable emergency supply which is capable of feading a lamp installed in the top of

the hoistway (not supplied by Otis).

1.4.3

TELEPHONE LINE EMERGENCY ALARM DEVICE

For each Simplex or for each bank of lifts (Duplex, Triplex), the telephone line shall be

routed to the machine room of the first lift (Unit A see part 3). Provide 3 m of free cable from

the machine room entrance with a RJ11 plug termination.

Note: to comply with the EN81.1 chapter 14.2.3 (two-way voice communication allowing

permanent contact with a rescue service), the basic device is the Otis REM device

connected to Otis through a public network.

Additional devices are available as options (one between all these 4 options):

a) Car alarm button and wiring to the controller.

Otis provides a normal open switch 2 A ; 50 VAC and the wiring to the controller.

The customer alarm system can be connected to the controller; provide 3 m of free cable

from the machine room entrance to each controller.

b) Car alarm button and wiring to the pit

Similar to a) but wiring to the pit of the lift instead to the controller.

c) Car alarm button, wiring, alarm bell and battery (12 V DC)

All these components are delivered and installed by Otis in the well (no external interfaces).

d) Intercommunication Unit

Communication between the car and a porter lodge. Otis provides the wiring to the

controller Provide 1 cable (2 wires 0,5 or 1 mm) maxi length 200 m from the porter lodge

to the first controller (3 m of free wiring from the machine room entrance).

1.4.4

OTHER ELECTRICAL OPTIONS

- AHL2 (car arrival hall light). When the lift arrives to a floor, the floor corridor lighting shall

come on automatically. For this purpose, Otis provides one contact per floor with the

following characteristics:

. maximum braking switch voltage : 250 V AC

. maximum power rating 2000 VA (AC voltage).

For each lift , the wiring for this function shall be routed to the bottom of the controller (10 m

of free cable from the machine room entrance).

BUILDER'S WORK CATALOGUE

Lux

PART 1: GENERAL INFORMATION

FAA29100H_BWC

1.5.

17/38

Version : a-e

Date: 07-04-15

HEAT DISSIPATION

Lift heat release in the machine room:

Number of Passengers

10

13

17

21

1.6.

1.6.1

Speed (m/s)

Heat Release (kJ/s)

2.50

3,51

2.50

3,67

2.50

4,30

2.50

5,93

MAIN BUILDING LIMITATIONS

GLASS HOISTWAY

Only for totally enclosed well (hoistway) installed inside a building (e.g. atrium).

The glass hoistway structure must comply with EN81.1 requirements (chapters 5.2.1.1 and

5.3.1).

1.6.2

HOISTWAY AND MACHINE ROOM ENVIRONMENT

Environmental conditions:

AE1: presence of foreign solid bodies: negligible

AD1: presence of water: negligible

AG2: mechanical stresses: medium severity

According to IEC 60364 part 5 international standard - Electrical installation of buildings, low

voltage electrical installation.

Degree of protection:

IP21: IP code according to EN 50 102 standard.

IK = 5: IK code according to EN 60 529 standard.

Ambient temperature:

The ambient temperature in the machine room is assumed to be maintained between 0 C

and + 45 C.

1.6.3

SILLS FOR LANDING DOORS

It is recommended to provide a slight counter slope in front of each landing sill to avoid

water from washing, sprinkling, etc., draining into the well.

1.6.4

EARTHQUAKE

Option: earthquake (Consult OTIS for detailed information)

1.6.5

FIREFIGHTERS LIFTS

In case of lift in conformance with the EN81-72 code the building must answer the following

requirements. Refer to EN81-72 chapter 5-1-1; 5-1-4; 5-1-5; 5-1-6; 5-2-2; and 5-3-4.

The maximum distance between floors is limited. Refer to EN81-72 chapter 5-4-7 and consult Otis to

determine this limit for the contract.

BUILDER'S WORK CATALOGUE

18/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

2 PART 2: EFFORTS ON THE HOISTWAY WALLS

Gen2 models can be installed in several types of hoistway structures: see sheet 12. In the

sketches presented in the following sheets of this catalogue, the slabs and walls around

lift wells are shown in blue color, whatever the building structure.

LIST OF THE COMPONENTS EXERTING EFFORT ON THE WALL AND ON

Hoistway width

ow

Wall t

all

ROOF OF THE MACHINERY

Hooks

Location

ROOF OF THE HOISTWAY

Overhead dimensions

2.1.

Holes

1

2

TOP LEVEL

FRONT

CEILING

Guide rail bracket

Landing door fixation

Hooks for handling the equipment

ENTRANCE

BUILDER'S WORK CATALOGUE

19/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

2.1.1

Version : a-e

Date: 07-04-15

HOISTWAY DEPTH - DOORS IN THE HOISTWAY

(For doors installed on the landing: consult Otis)

DIMENSIONS TABLE

HOISTWAY DEPTH (HD) AND FRONT TO REAR WALL DIMENSIONS (WTW)

WTW=HD

LIFT

CAPACITY

Load &

Number of

passenger

800 kg

10 Pass.

CAR INTERNAL SIZE

Car Width

Car Depth

Door

Opening

CW (mm)

CD (mm)

OP (mm)

800

1350

1400

900

900

1000 kg

13 Pass.

1600

1400

1000

1100

1275 kg

17 Pass.

1600 kg

21 Pass.

1600 kg

21 Pass.

2000

1400

1100

2000

1700

1100

2100

1600

1100

Rise

Wall to wall

mini

HOISTWAY DIMENSIONS

Wall to wall

Hoistway

maxi

Depth mini

R (m)

WTW (mm)

WTW (mm)

HD (mm)

HD (mm)

R80

2010

2350

2010

2350

R>80

2060

2300

2060

2300

R80

2010

2350

2010

2350

R>80

2060

2300

2060

2300

R80

2010

2350

2010

2350

R>80

2060

2300

2060

2300

R80

2010

2350

2010

2350

R>80

2060

2300

2060

2300

R80

2010

2350

2010

2350

R>80

2060

2300

2060

2300

R80

2010

2350

2010

2350

R>80

2060

2300

2060

2300

R80

2310

2650

2310

2650

R>80

2360

2600

2360

2600

R80

2210

2550

2210

2550

R>80

2260

2500

2260

2500

Hoistway

Depth maxi

BUILDER'S WORK CATALOGUE

20/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

2.2.

Date: 07-04-15

GENERAL VIEW

MACHINE ROOM INTERFACE

P8

P2

P1

Car axis

4

P3

P4

335

335

HW

ENTRANCE

Number of passenger

10 pass.

13 pass.

17 pass.

21 pass.

CW 2000 x CD 1700

21 pass.

CW 2100 x CD 1600

DIM1 (mm)

863

863

863

1013

963

P1 (N)

21000

22500

29800

37000

37000

P2 (N)

23000

24000

31000

38000

38000

P3 (N)

23000

25500

33600

42000

42000

P4 (N)

23500

25500

33700

42500

42500

P7 (N)

2300

2300

2300

2300

2300

P8 (N)

2300

2300

2300

2300

2300

HD

P7

Car axis

DIM1

2.2.1

Version : a-e

BUILDER'S WORK CATALOGUE

21/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Date: 07-04-15

PIT INTERFACE

Car rail axis

HW

1

Number of passenger

10 pass.

13 pass.

17 pass.

21 pass.

P11 (N)

62000

68300

77000

84000

P12 (N)

100000

115000

138000

165000

P13 (N)

85000

94000

1110000

131000

P17 (N)

41000

46000

52000

58100

Simultaneous loads : P11 or P17 or P12 or P13

HD

2.2.2

Version : a-e

BUILDER'S WORK CATALOGUE

Lux

22/38

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Date: 07-04-15

HOOKS ( MACHINE ROOM ROOF )

CWT DBG/2+30

CWT DBG/2+30

CWT axis

T6 T5

T4

Car DBG/2+90

CTC

150

135

Car DBG/2+90

Car rail axis

T1

T2

T3

220

2.2.3

Version : a-e

HW1

HW2

HW

ENTRANCE

Rails hoisting and Car suspension

Material distribution

Rails hoisting and suspension

Machine introduction and CWT suspension

Simultaneous loads on the hooks T1; T2; T6

SWL: Safe Working Load

Location

SWL (kN)

T1; T2

T3

T4; T5

T6

10

10

5

10

BUILDER'S WORK CATALOGUE

23/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Date: 07-04-15

ALL LANDINGS

TYFAC : SF

For RW1 and RW2 values see part 1 sheet 6

DOORS IN HOISTWAY

OPH + 50 20

RW1

RW2

OP + 100 20

100 for CLD

SILL "0"

FINISHED FLOOR

80 mini

HW

WTW = HD

RW1

OPH + 270 20

OPH + 50 20

DOORS ON LANDING

RW2

OP + 100 20

100 for CLD

SILL "0"

FINISHED FLOOR

60 mini

2.2.4

Version : a-e

WTW

HD

HW

BUILDER'S WORK CATALOGUE

24/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Date: 07-04-15

ALL LANDINGS

For RW1 and RW2 values see part 1 sheet 6

DOORS IN HOISTWAY

TYFAC : NF

OPH + 50 20

RW1

RW2

OP + 60 20

100 for CLD

80 mini

SILL "0"

FINISHED FLOOR

HW

WTW = HD

RW1

OPH + 270 20

OPH + 50 20

DOORS ON LANDING

RW2

OP + 60 20

100 for CLD

SILL "0"

FINISHED FLOOR

60 mini

2.2.5

Version : a-e

WTW

HD

HW

BUILDER'S WORK CATALOGUE

25/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

3 PART 3: INFORMATION CONCERNING BANKS OF LIFTS

3.1.

3.1.1

REQUIREMENTS CONCERNING BANKS OF LIFTS

MAIN INFORMATION

The Gen2 models 10 to 21 passengers are available in a bank of two to height lifts

. Each lift is available with the same limitations as the single car lift.

To be installed in a bank, all the lifts shall have the following parameters:

Same speed.

Same lift capacity (number of passengers and car size).

Same number of floors, and location of entrances.

3.1.2

HOISTWAY LOCATION

Lifts in bank can be installed in the same hoistway or in separated hoistway.

For each lift, all simplex arrangements are available; use the information for single

car (SIMPLEX).

3.1.3

PROTECTION IN THE HOISTWAY

Where the hoistway contains several lifts an 1100 mm height top of car balustrade

is installed.

3.1.4

ELECTRICAL POWER SUPPLY

Use the information for single car (simplex).

BUILDER'S WORK CATALOGUE

26/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

GENERAL WELL TOLERANCES

DUPLEX

SEPARATOR BEAMS

MAXI HOISTWAY DEPTH

25

25

COMMERCIAL HOISTWAY DEPTH

25

25

MINI HOISTWAY DEPTH

Rise <= 80m

UNIT A

25

25

UNIT B

160

MINI TOTAL HOISTWAY WIDTH

COMMERCIAL TOTAL HOISTWAY WIDTH

MAXI TOTAL HOISTWAY WIDTH

FRONT

25

25

OPENING

SEPARATOR BEAMS

MAXI HOISTWAY DEPTH

50

50

COMMERCIAL HOISTWAY DEPTH

50

50

MINI HOISTWAY DEPTH

Rise > 80m

UNIT A

50

50

UNIT B

160

MINI TOTAL HOISTWAY WIDTH

COMMERCIAL TOTAL HOISTWAY WIDTH

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

50

50

BUILDER'S WORK CATALOGUE

27/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

TRIPLEX

160

UNIT B

160

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

MAXI HOISTWAY DEPTH

25

25

COMMERCIAL HOISTWAY DEPTH

25

25

MINI HOISTWAY DEPTH

Rise <= 80m

UNIT C

MINI TOTAL HOISTWAY WIDTH

25

25

COMMERCIAL TOTAL HOISTWAY WIDTH

25

25

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

50

50

160

UNIT B

160

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

MAXI HOISTWAY DEPTH

50

50

COMMERCIAL HOISTWAY DEPTH

50

50

MINI HOISTWAY DEPTH

Rise > 80m

MINI TOTAL HOISTWAY WIDTH

COMMERCIAL TOTAL HOISTWAY WIDTH

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

UNIT C

50

50

BUILDER'S WORK CATALOGUE

28/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

QUADRUPLEX

160

UNIT C

160

SEPARATOR BEAMS

160

UNIT B

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

25

MINI HOISTWAY DEPTH

25

25

COMMERCIAL HOISTWAY DEPTH

25

MAXI HOISTWAY DEPTH

Rise <= 80m

UNIT D

MINI TOTAL HOISTWAY WIDTH

25

25

COMMERCIAL TOTAL HOISTWAY WIDTH

25

25

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

50

50

160

UNIT C

160

MINI TOTAL HOISTWAY WIDTH

COMMERCIAL TOTAL HOISTWAY WIDTH

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

SEPARATOR BEAMS

160

UNIT B

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

50

MINI HOISTWAY DEPTH

50

COMMERCIAL HOISTWAY DEPTH

50

50

MAXI HOISTWAY DEPTH

Rise > 80m

UNIT D

50

50

BUILDER'S WORK CATALOGUE

29/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

QUINTUPLEX

160

160

160

UNIT D

SEPARATOR BEAMS

UNIT C

SEPARATOR BEAMS

UNIT B

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

25

MINI HOISTWAY DEPTH

25

25

MAXI HOISTWAY DEPTH

25

COMMERCIAL HOISTWAY DEPTH

Rise <= 80m

UNIT E

160

MINI TOTAL HOISTWAY WIDTH

25

25

COMMERCIAL TOTAL HOISTWAY WIDTH

25

25

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

160

160

160

UNIT D

SEPARATOR BEAMS

UNIT C

SEPARATOR BEAMS

UNIT B

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

50

MINI HOISTWAY DEPTH

50

COMMERCIAL HOISTWAY DEPTH

50

MAXI HOISTWAY DEPTH

50

Rise > 80m

UNIT E

160

MINI TOTAL HOISTWAY WIDTH

50

50

COMMERCIAL TOTAL HOISTWAY WIDTH

50

50

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

BUILDER'S WORK CATALOGUE

30/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

SEXTUPLEX

160

UNIT B

160

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

MINI HOISTWAY DEPTH

MAXI HOISTWAY DEPTH

25

25

COMMERCIAL HOISTWAY DEPTH

25

25

Rise <= 80m

UNIT C

MINI TOTAL HOISTWAY WIDTH

25

25

COMMERCIAL TOTAL HOISTWAY WIDTH

25

25

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

FRONT

OPENING

MAXI TOTAL HOISTWAY WIDTH

25

25

COMMERCIAL TOTAL HOISTWAY WIDTH

25

25

UNIT E

SEPARATOR BEAMS

UNIT F

UNIT D

SEPARATOR BEAMS

160

SEPARATOR BEAMS

160

MINI HOISTWAY DEPTH

MAXI HOISTWAY DEPTH

25

25

COMMERCIAL HOISTWAY DEPTH

25

25

MINI TOTAL HOISTWAY WIDTH

UNIT C

UNIT A

160

SEPARATOR BEAMS

50

MAXI HOISTWAY DEPTH

50

COMMERCIAL HOISTWAY DEPTH

50

50

MINI HOISTWAY DEPTH

Rise > 80m

UNIT B

160

MINI TOTAL HOISTWAY WIDTH

50

50

COMMERCIAL TOTAL HOISTWAY WIDTH

50

50

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

FRONT

OPENING

MAXI TOTAL HOISTWAY WIDTH

50

50

COMMERCIAL TOTAL HOISTWAY WIDTH

50

50

UNIT F

160

UNIT E

SEPARATOR BEAMS

160

SEPARATOR BEAMS

50

MAXI HOISTWAY DEPTH

50

COMMERCIAL HOISTWAY DEPTH

50

50

MINI HOISTWAY DEPTH

MINI TOTAL HOISTWAY WIDTH

UNIT D

BUILDER'S WORK CATALOGUE

31/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

OCTOPLEX

UNIT B

160

UNIT C

160

SEPARATOR BEAMS

160

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

MINI HOISTWAY DEPTH

25

25

25

MAXI HOISTWAY DEPTH

25

COMMERCIAL HOISTWAY DEPTH

Rise <= 80m

UNIT D

MINI TOTAL HOISTWAY WIDTH

25

25

COMMERCIAL TOTAL HOISTWAY WIDTH

25

25

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

FRONT

OPENING

MAXI TOTAL HOISTWAY WIDTH

25

25

COMMERCIAL TOTAL HOISTWAY WIDTH

25

25

UNIT G

SEPARATOR BEAMS

UNIT H

160

SEPARATOR BEAMS

160

SEPARATOR BEAMS

MINI HOISTWAY DEPTH

25

160

25

25

MAXI HOISTWAY DEPTH

25

COMMERCIAL HOISTWAY DEPTH

MINI TOTAL HOISTWAY WIDTH

UNIT F

UNIT E

160

UNIT C

160

SEPARATOR BEAMS

160

UNIT B

SEPARATOR BEAMS

UNIT A

SEPARATOR BEAMS

50

MINI HOISTWAY DEPTH

50

COMMERCIAL HOISTWAY DEPTH

50

MAXI HOISTWAY DEPTH

50

Rise > 80m

UNIT D

MINI TOTAL HOISTWAY WIDTH

50

50

COMMERCIAL TOTAL HOISTWAY WIDTH

50

50

MAXI TOTAL HOISTWAY WIDTH

FRONT

OPENING

FRONT

OPENING

MAXI TOTAL HOISTWAY WIDTH

50

50

COMMERCIAL TOTAL HOISTWAY WIDTH

50

50

UNIT F

SEPARATOR BEAMS

UNIT G

160

SEPARATOR BEAMS

UNIT H

160

SEPARATOR BEAMS

50

MINI HOISTWAY DEPTH

160

50

COMMERCIAL HOISTWAY DEPTH

50

MAXI HOISTWAY DEPTH

50

MINI TOTAL HOISTWAY WIDTH

UNIT E

BUILDER'S WORK CATALOGUE

32/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

3.1.5

Version : a-e

Date: 07-04-15

HOISTWAY DEPTH DIMENSION (PLAN)

Same dimensions as the dimensions defined for simplex lift (see Part 1 Para 1.3)

3.1.6

HOISTWAY WIDTH DIMENSIONS HW (PLAN) FOR LIFTS IN THE SAME HOISTWAY

DUPLEX

Lifts in line in the same hoistway

R

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

17 pass.

21 pass.

21 pass.

80m

DOOR

OP

THW MINI

THW MAXI

CLD

800

4010

4810

CLD

900

4210

4810

CLD

900

4510

5310

1000

4510

5310

1600

1400

CLD

CLD

1100

4910

5310

2000

1400

CLD

1100

5210

6110

2000

1700

CLD

1100

5210

6110

2100

1600

CLD

1100

5410

6310

DOOR

OP

THW MINI

THW MAXI

CLD

800

4060

4760

CLD

900

4260

4760

CLD

900

4560

5260

CLD

1000

4560

5260

CLD

1100

4960

5260

CLD

1100

5260

6060

R> 80m

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

1600

1400

17 pass.

2000

1400

21 pass.

2000

1700

CLD

1100

5260

6060

21 pass.

2100

1600

CLD

1100

5460

6260

BUILDER'S WORK CATALOGUE

33/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

TRIPLEX

Lifts in line in the same hoistway

R

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

17 pass.

21 pass.

21 pass.

80m

DOOR

OP

THW MINI

THW MAXI

CLD

800

6070

7320

CLD

900

6370

7320

CLD

900

6820

8070

1000

6820

8070

1600

1400

CLD

CLD

1100

7420

8070

2000

1400

CLD

1100

7870

9270

2000

1700

CLD

1100

7870

9270

2100

1600

CLD

1100

8170

9570

DOOR

OP

THW MINI

THW MAXI

CLD

800

6120

7270

CLD

900

6420

7270

CLD

900

6870

8020

CLD

1000

6870

8020

CLD

1100

7470

8020

CLD

1100

7920

9220

R> 80m

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

1600

1400

17 pass.

2000

1400

21 pass.

2000

1700

CLD

1100

7920

9220

21 pass.

2100

1600

CLD

1100

8220

9520

BUILDER'S WORK CATALOGUE

34/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

QUADRUPLEX

Lifts in line in the same hoistway

R

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

17 pass.

21 pass.

21 pass.

1600

1400

80m

DOOR

OP

THW MINI

THW MAXI

CLD

800

8130

9830

CLD

900

8530

9830

CLD

900

9130

10830

CLD

1000

9130

10830

CLD

1100

9930

10830

2000

1400

CLD

1100

10530

12430

2000

1700

CLD

1100

10530

12430

2100

1600

CLD

1100

10930

12830

DOOR

OP

THW MINI

THW MAXI

CLD

800

8180

9780

CLD

900

8580

9780

CLD

900

9180

10780

CLD

1000

9180

10780

CLD

1100

9980

10780

CLD

1100

10580

12380

R> 80m

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

1600

1400

17 pass.

2000

1400

21 pass.

2000

1700

CLD

1100

10580

12380

21 pass.

2100

1600

CLD

1100

10980

12780

BUILDER'S WORK CATALOGUE

35/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

QUINTUPLEX

Lifts in line in the same hoistway

R

Number of

passenger

CW

CD

10 pass.

1350

1400

80m

DOOR

OP

THW MINI

THW MAXI

CLD

800

10190

12340

CLD

900

10690

12340

CLD

900

11440

13590

CLD

1000

11440

13590

CLD

1100

12440

13590

2000

1400

CLD

1100

13190

15590

21 pass.

2000

1700

CLD

1100

13190

15590

21 pass.

2100

1600

CLD

1100

13690

16090

DOOR

OP

THW MINI

THW MAXI

CLD

800

10240

12290

CLD

900

10740

12290

CLD

900

11490

13540

CLD

1000

11490

13540

CLD

1100

12490

13540

13 pass.

17 pass.

1600

1400

R> 80m

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

1600

1400

17 pass.

2000

1400

CLD

1100

13240

15540

21 pass.

2000

1700

CLD

1100

13240

15540

21 pass.

2100

1600

CLD

1100

13740

16040

BUILDER'S WORK CATALOGUE

36/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

SEXTUPLEX

Dimensions for a single hoistway for 3 Lifts

R

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

1600

1400

80m

DOOR

OP

THW MINI

THW MAXI

CLD

800

6070

7320

CLD

900

6370

7320

CLD

900

6820

8070

CLD

1000

6820

8070

CLD

1100

7420

8070

17 pass.

2000

1400

CLD

1100

7870

9270

21 pass.

2000

1700

CLD

1100

7870

9270

2100

1600

CLD

1100

8170

9570

DOOR

OP

THW MINI

THW MAXI

CLD

800

6120

7270

CLD

900

6420

7270

CLD

900

6870

8020

CLD

1000

6870

8020

CLD

1100

7470

8020

2000

1400

CLD

1100

7920

9220

21 pass.

2000

1700

CLD

1100

7920

9220

21 pass.

2100

1600

CLD

1100

8220

9520

21 pass.

R> 80m

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

17 pass.

1600

1400

BUILDER'S WORK CATALOGUE

37/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

Version : a-e

Date: 07-04-15

OCTOPLEX

Dimensions for a single hoistway for 4 Lifts

R

Number of

passenger

CW

CD

10 pass.

1350

1400

80m

DOOR

OP

THW MINI

THW MAXI

CLD

800

8130

9830

CLD

900

8530

9830

CLD

900

9130

10830

CLD

1000

9130

10830

CLD

1100

9930

10830

2000

1400

CLD

1100

10530

12430

21 pass.

2000

1700

CLD

1100

10530

12430

21 pass.

2100

1600

CLD

1100

10930

12830

DOOR

OP

THW MINI

THW MAXI

CLD

800

8180

9780

CLD

900

8580

9780

CLD

900

9180

10780

CLD

1000

9180

10780

CLD

1100

9980

10780

13 pass.

17 pass.

1600

1400

R> 80m

Number of

passenger

CW

CD

10 pass.

1350

1400

13 pass.

1600

1400

17 pass.

2000

1400

CLD

1100

10580

12380

21 pass.

2000

1700

CLD

1100

10580

12380

21 pass.

2100

1600

CLD

1100

10980

12780

BUILDER'S WORK CATALOGUE

38/38

Lux

PART 3: INFORMATION CONCERNING BANKS OF

LIFTS

FAA29100H_BWC

3.2.

Version : a-e

Date: 07-04-15

RECOMMENDED HOISTWAY DIMENSIONS (ELEVATION)

PIT DEPTH AND OVERHEAD DIMENSIONS (S & K)

Same dimensions as the dimensions defined for simplex lift see Part 1: Para 1-2-4

3.3.

HOOKS AND REACTION THE PIT

For each lift use the same values and location as the values and location defined for

simplex lift. See Part 2 Para 2.2 & Part 2 Para 2.3.

3.4.

LOCATION OF THE HOISTWAY FIXTURES

The following hoistway fixtures: direction indicator arrows (hall lantern); hall position if

any; key switches for service operation are affected to each lift and are installed in a

same possible location as for simplex lift.

The hall buttons (HB) are affected to the bank and the number is less or equal to the

number of lifts. Number of hall button rise: 1, 2, 3 , 4 or 5.

NBR1/NBR2/NBR3/NBR4 or NBR5.

Você também pode gostar

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideNo EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideNota: 4 de 5 estrelas4/5 (9)

- Otis Gen2 SpecificationsDocumento13 páginasOtis Gen2 SpecificationsAnonymous 3v1z9l100% (7)

- Elevator Mechanic: Passbooks Study GuideNo EverandElevator Mechanic: Passbooks Study GuideAinda não há avaliações

- Inspector's Guide: Gen2 Machine Room-Less Elevator System - The Next Generation of ElevatorsDocumento16 páginasInspector's Guide: Gen2 Machine Room-Less Elevator System - The Next Generation of Elevatorsbugse100% (2)

- Schindler 3400/5400 EU SAIS Acceptance Inspection ReportDocumento27 páginasSchindler 3400/5400 EU SAIS Acceptance Inspection ReportAli DiabAinda não há avaliações

- IGV DomusLift Service Kit PDFDocumento4 páginasIGV DomusLift Service Kit PDFSawon0% (1)

- Miconic B Et V Doc OtisDocumento45 páginasMiconic B Et V Doc OtisAshraful Shohag100% (5)

- Product - Book - Mk-742 - V15 - ADocumento71 páginasProduct - Book - Mk-742 - V15 - ADani Barallat100% (3)

- The Van Conversion Bible - The Ultimate Guide To Converting A CampervanDocumento170 páginasThe Van Conversion Bible - The Ultimate Guide To Converting A CampervanPil100% (3)

- MCS 220Documento1 páginaMCS 220Taha Alkibsi100% (3)

- Dt-5 User Instructions For Elevator and Escalator Ride Comfort Measurements and AnalyzesDocumento67 páginasDt-5 User Instructions For Elevator and Escalator Ride Comfort Measurements and AnalyzesСакен100% (1)

- 1260000.EN - GS800-NX Maintenance ManualDocumento34 páginas1260000.EN - GS800-NX Maintenance ManualReynold Suarez100% (1)

- Otis 2000 Hyd Rescue PDFDocumento12 páginasOtis 2000 Hyd Rescue PDFSatheesh Rama50% (2)

- GETM1 5、GETM1 9、GETM3 0Documento51 páginasGETM1 5、GETM1 9、GETM3 0Peter75% (4)

- 3300 AP ReportDocumento14 páginas3300 AP ReportWiratama PutraAinda não há avaliações

- 01 Escalator Sec1Documento48 páginas01 Escalator Sec1sanjurkAinda não há avaliações

- Otis Door Drive PDFDocumento43 páginasOtis Door Drive PDFSyed iliyas67% (6)

- TK-50 Installation Manual Rev 1.1 - EVO1 PDFDocumento147 páginasTK-50 Installation Manual Rev 1.1 - EVO1 PDFanh trong100% (7)

- Aaa29000ac Inspg 12512Documento26 páginasAaa29000ac Inspg 12512Ana Rcc100% (9)

- Commissioning Variodyn VF11 22 33 Et PF1 Doc 2010Documento82 páginasCommissioning Variodyn VF11 22 33 Et PF1 Doc 2010Amarnath Yadav100% (2)

- THYSSEN (Maquina Mini Gearless DAF-270)Documento76 páginasTHYSSEN (Maquina Mini Gearless DAF-270)migmarel86% (7)

- Elevator Inspector: Passbooks Study GuideNo EverandElevator Inspector: Passbooks Study GuideAinda não há avaliações

- MF 660Documento7 páginasMF 660Sebastian Vasquez OsorioAinda não há avaliações

- Kone Technical SubmittalDocumento151 páginasKone Technical Submittalzampacaanas73% (11)

- Gen2 MadridDocumento24 páginasGen2 MadridCristal CristalAinda não há avaliações

- Thyssen Installation ManualDocumento18 páginasThyssen Installation ManualFERNSAinda não há avaliações

- Otis Pulse FCTSH 040805 PDFDocumento2 páginasOtis Pulse FCTSH 040805 PDFangela1590Ainda não há avaliações

- GM 2 002796 en 01 PDFDocumento26 páginasGM 2 002796 en 01 PDFEng M ElseaidyAinda não há avaliações

- M C S 2 2 0 M Product DescriptionDocumento1 páginaM C S 2 2 0 M Product DescriptionTaha AlkibsiAinda não há avaliações

- Escalator PDFDocumento44 páginasEscalator PDFDouglasAinda não há avaliações

- Otis Engineering Center Gien Field Component ManualDocumento13 páginasOtis Engineering Center Gien Field Component Manualnr1wolf_co_69529906100% (5)

- Project Managers Program: Technical NoteDocumento20 páginasProject Managers Program: Technical NotealfreliaAinda não há avaliações

- 25 TM Installation ManualDocumento18 páginas25 TM Installation ManualReynold Suarez83% (6)

- Gen2 Otis PDFDocumento6 páginasGen2 Otis PDFEng M ElseaidyAinda não há avaliações

- Gearless LiftEquip enDocumento7 páginasGearless LiftEquip enمحمدحماد100% (1)

- Ba TW45C 08 12 enDocumento64 páginasBa TW45C 08 12 enangela1590100% (1)

- THYSSENKRUPP ElevatorDocumento3 páginasTHYSSENKRUPP Elevatorhamid taher50% (2)

- Inastallastion Manual - Mechanical - +ÍDocumento206 páginasInastallastion Manual - Mechanical - +ÍJoséRodríguez100% (3)

- OTIS SkyriseDocumento16 páginasOTIS SkyriseDebra TurnerAinda não há avaliações

- RCBII RSL Parameters - 4767764251226047386845665916 PDFDocumento67 páginasRCBII RSL Parameters - 4767764251226047386845665916 PDFBartz Santos0% (1)

- Start Up Routine OVF10 PDFDocumento12 páginasStart Up Routine OVF10 PDFEng M ElseaidyAinda não há avaliações

- SVT GreskeDocumento17 páginasSVT GreskePeter100% (6)

- Wittur Gm.2.001049.en.01Documento166 páginasWittur Gm.2.001049.en.01Andre Louis Grangeon0% (1)

- Playboard Iii: User ManualDocumento88 páginasPlayboard Iii: User ManualAliRouyouAinda não há avaliações

- Gaa21310g AdtDocumento68 páginasGaa21310g AdtAlexis MauricioAinda não há avaliações

- TroubleshootingDocumento34 páginasTroubleshootingEagle MayAinda não há avaliações

- Elevator Voice Announcement User Manual V1.0Documento4 páginasElevator Voice Announcement User Manual V1.0Daud Jiong KIMAinda não há avaliações

- LCB Ii PDFDocumento33 páginasLCB Ii PDFTomas Enrique Ramirez GomezAinda não há avaliações

- Gba 26800 H II StartupDocumento15 páginasGba 26800 H II StartupPeter100% (4)

- NV3000 14Documento233 páginasNV3000 14Gustavo Castillo100% (1)

- 1117 32 0013 Assembly Manual EngDocumento31 páginas1117 32 0013 Assembly Manual Engjavier ariasAinda não há avaliações

- Otis Parts ListDocumento48 páginasOtis Parts ListMelina Labor92% (13)

- Mitsubishi Elevator PDFDocumento32 páginasMitsubishi Elevator PDFFERNS100% (1)

- AS380 Series Elevator Integrated Controller Operation Manual V30 201526 Express A5 R15000855Documento104 páginasAS380 Series Elevator Integrated Controller Operation Manual V30 201526 Express A5 R15000855AN Nhiên100% (1)

- Hydraulic Elevator Thyssenkrupp ElevatorsDocumento187 páginasHydraulic Elevator Thyssenkrupp Elevatorshmbx100% (3)

- Tke Synergy Motor PDFDocumento106 páginasTke Synergy Motor PDFWayne100% (1)

- Fermator vf5Documento28 páginasFermator vf5jay100% (2)

- Otis PDFDocumento38 páginasOtis PDFMohammad KazimAinda não há avaliações

- PANORAMA Specifications Feb FINALDocumento13 páginasPANORAMA Specifications Feb FINALagmibrahim5055Ainda não há avaliações

- Amaris Palembang - Spec Dumbwaiter CentroDocumento6 páginasAmaris Palembang - Spec Dumbwaiter CentroAgus BudiyantoAinda não há avaliações

- Ascensor MitsubishiDocumento6 páginasAscensor MitsubishiRicardo ZapataAinda não há avaliações

- PM Gearless Elevator: IRIS Enhancing The Value of The Building..Documento32 páginasPM Gearless Elevator: IRIS Enhancing The Value of The Building..Hoong Jian TanAinda não há avaliações

- Shell Vs Flexible DiaphragmDocumento1 páginaShell Vs Flexible DiaphragmBAinda não há avaliações

- Design MomentDocumento1 páginaDesign MomentBAinda não há avaliações

- Conditional FormattingDocumento3 páginasConditional FormattingBAinda não há avaliações

- Data Validation: IsnumberDocumento3 páginasData Validation: IsnumberBAinda não há avaliações

- Bases ShearDocumento9 páginasBases ShearBAinda não há avaliações

- Deflection Criteria Is CodeDocumento3 páginasDeflection Criteria Is CodeBAinda não há avaliações

- Static Seismic AnalysisDocumento1 páginaStatic Seismic AnalysisBAinda não há avaliações

- Statics Vs Dynamics: But, For A Dynamics ProblemDocumento8 páginasStatics Vs Dynamics: But, For A Dynamics ProblemBAinda não há avaliações

- Precast 2 Floors 2 Pages PDFDocumento40 páginasPrecast 2 Floors 2 Pages PDFBAinda não há avaliações

- Typical Lap DetailsDocumento1 páginaTypical Lap DetailsBAinda não há avaliações

- Column Only Below With Fixed Support at BottomDocumento1 páginaColumn Only Below With Fixed Support at BottomBAinda não há avaliações

- Burj Khalifa CoreDocumento6 páginasBurj Khalifa CoreBAinda não há avaliações

- Frame Results - Wtih ColumnsDocumento1 páginaFrame Results - Wtih ColumnsBAinda não há avaliações

- Forced Air Heating SystemsDocumento32 páginasForced Air Heating SystemsBAinda não há avaliações

- General Concepts of Earthquake Resistant Design: G C E R DDocumento10 páginasGeneral Concepts of Earthquake Resistant Design: G C E R DBAinda não há avaliações

- Flat Slab DeflectionDocumento1 páginaFlat Slab DeflectionBAinda não há avaliações

- Wind Load Calc As Per EurocodeDocumento19 páginasWind Load Calc As Per EurocodeB100% (1)

- Job Description: Extensive ReadingDocumento12 páginasJob Description: Extensive ReadingNatalia VivonaAinda não há avaliações

- Business Works Student User GuideDocumento14 páginasBusiness Works Student User GuideAkram UddinAinda não há avaliações

- Baterías YuasaDocumento122 páginasBaterías YuasaLuisAinda não há avaliações

- FMDQ Codified Rule Book FGN BondsDocumento65 páginasFMDQ Codified Rule Book FGN BondsOladipupo Mayowa PaulAinda não há avaliações

- 9a Grundfos 50Hz Catalogue-1322Documento48 páginas9a Grundfos 50Hz Catalogue-1322ZainalAinda não há avaliações

- Instrumentation and Control Important Questions and AnswersDocumento72 páginasInstrumentation and Control Important Questions and AnswersAjay67% (6)

- Consolidated Digests - Part 2Documento314 páginasConsolidated Digests - Part 2Neil Patrick Pepito ErmacAinda não há avaliações

- List of Newly and Migrated Programs For September 2022 - WebsiteDocumento21 páginasList of Newly and Migrated Programs For September 2022 - WebsiteRMG REPAIRAinda não há avaliações

- Model: The Most Accepted and Respected Engine-Driven Cooler in The Gas Compression IndustryDocumento2 páginasModel: The Most Accepted and Respected Engine-Driven Cooler in The Gas Compression IndustryparathasiAinda não há avaliações

- JKR SPJ 1988 Standard Specification of Road Works - Section 1 - GeneralDocumento270 páginasJKR SPJ 1988 Standard Specification of Road Works - Section 1 - GeneralYamie Rozman100% (1)

- Ara FormDocumento2 páginasAra Formjerish estemAinda não há avaliações

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlDocumento77 páginasAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- LIC Form - Intimation of Death Retirement Leaving ServiceDocumento1 páginaLIC Form - Intimation of Death Retirement Leaving ServicekaustubhAinda não há avaliações

- OPERATING MANUAL Micro Powder MillDocumento51 páginasOPERATING MANUAL Micro Powder MillSher AhmadAinda não há avaliações

- Jicable DAS For Power Industry Applications 2015-A3-4Documento6 páginasJicable DAS For Power Industry Applications 2015-A3-4Richard KluthAinda não há avaliações

- Aermod - DRM - Course NotesDocumento25 páginasAermod - DRM - Course NotesGhulamMustafaAinda não há avaliações

- High-Definition Multimedia Interface SpecificationDocumento51 páginasHigh-Definition Multimedia Interface SpecificationwadrAinda não há avaliações

- Invoice 1281595768Documento3 páginasInvoice 1281595768vikas9849Ainda não há avaliações

- What Is SAP PS (Project Systems) ModuleDocumento3 páginasWhat Is SAP PS (Project Systems) ModuleahmerAinda não há avaliações

- DSP Unit V ObjectiveDocumento4 páginasDSP Unit V Objectiveshashi dharAinda não há avaliações

- Tamil Nadu Industrial Establishments (Conferment of Permanent Status To Workman Act, 1981Documento12 páginasTamil Nadu Industrial Establishments (Conferment of Permanent Status To Workman Act, 1981Latest Laws TeamAinda não há avaliações

- REID CatalogDocumento54 páginasREID Catalogzhaoye maoAinda não há avaliações

- Scrum Gantt Chart With BurndownDocumento4 páginasScrum Gantt Chart With BurndownAsma Afreen ChowdaryAinda não há avaliações

- Beneparts Quotation BYBJ192388 20191024Documento1 páginaBeneparts Quotation BYBJ192388 20191024احمد عبدهAinda não há avaliações

- In Coming MailDocumento4 páginasIn Coming Mailpoetoet100% (1)

- Nishith Desai Associates - Alternative Investment Funds - SEBI Scores Half Century On DebutDocumento2 páginasNishith Desai Associates - Alternative Investment Funds - SEBI Scores Half Century On DebutRajesh AroraAinda não há avaliações

- Pepsico IncDocumento26 páginasPepsico IncYKJ VLOGSAinda não há avaliações

- Media ReportDocumento46 páginasMedia ReportAndrew AB BurgoonAinda não há avaliações