Escolar Documentos

Profissional Documentos

Cultura Documentos

Lecture 2

Enviado por

hatelDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Lecture 2

Enviado por

hatelDireitos autorais:

Formatos disponíveis

8/24/00

Engine Design and

Operating Parameters

Part 2

Module Objectives

Define and use in a

sentence the different rated

conditions

Calculate engine volume,

piston speed, and cylinder

surface area as a function

of crank angle

Draw a cylinder schematic

and identify the bore,

stroke, crank radius, TDC,

BDC, and crank angle

Calculate engine torque and

hp from dynamometer

tests

Define indicated, brake,

and friction quantities

Define net and gross

quantities

Calculate sfc, AF, vol. eff.

and engine efficiency

Correct performance data

for atmospheric conditions

2

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

Definitions

Maximum Rated Power: the highest power an

engine is allowed to develop for short operational

periods

Normal Rated Power: highest continuous power is

engine is allowed to make

Rated Speed: crankshaft rpm at which rated

power is developed

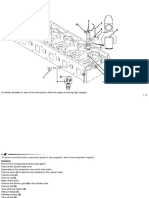

Cylinder Geometry

rc =

TDC

Vt

Vc

B

L

Vd

Maximum Cylinder Volume Vd + Vc

=

Vc

Minimum Cylinder Volume

B 2

Vd =

L

4

0.8 12

. Small

0.5 Large, low rpm

3 4 Small

R = l /a 1

5 9 Large, low rpm

L = 2a

RBS = B / L

BDC

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

Volume at any Crank Angle

bg

bg

V = Vc + V '

l 2 a 2 sin 2

OP

LM

MMb g PP

Q

N

B 2

V' =

l+a s

3

4 1424

bg

puts piston

at TDC

Note:

a cos

s BDC = l a V' BDC =

B 2

l+a la

144244

3

4

b g b g

2 a = L =Vd

5

Volume at any Crank Angle

(Cont.)

LM

OP

MMb g PP

N

Q

B 2

V = Vc + V ' , V ' =

l+a s

3

4 1424

bg

bg

bg

puts piston

at TDC

l 2 a 2 sin 2

bg

B

V b g = V +

bl + ag a cos l a sin

4

B

V b g = V +

l + ab1 cos g l a sin

4

s = a cos + l 2 a 2 sin 2

2

a sin

a cos

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

More Volume at any Crank

Angle

B 2

V = Vc +

l + a 1 cos l 2 a 2 sin 2

4

V

B 2 a l

2

= 1+

+ 1 cos l / a sin 2

Vc

4Vc a

Remember: R l / a

bg

bg

b

LM b

N

bg

g

g b g

OP

Q

V

B 2 a

= 1+

R + 1 cos R 2 sin 2

Vc

4Vc

Still More Volume vs. Crank

Angle

bg

V

B 2 a

= 1+

R + 1 cos R 2 sin 2

Vc

4Vc

b g

2

1

1 Vd

B 2 a B 2 2 a B 2a

=

=

=

4Vc

4

2 Vc

4

2Vc 2 Vc

B a 1 Vd

=

4Vc

2 Vc

2

LM

OP

FV V I 1 1 V +V V P

+G J = M

V

V

H V V K 2 2 M12

4 4

3 0P

MN

PQ

c

= rc

=1

B 2 a 1

= rc 1

4Vc

2

8

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

Finally: Volume vs. Crank Angle

b g = 1 + 1 r 1 R + b1 cos g

V

Vc

R 2 sin 2

Where:

R=l/a

V + Vc

rc = d

Vc

Example: V() vs.

B = 14 in L = 14 in rc = 9 R = 6

b g

b g

14 in

B 2

Vd =

L=

14 in = 2,155 in 3

4

4

Vc rc = Vd + Vc Vc rc 1 = Vd

Vc =

Vd

2,155 in 3

=

= 269.4 in 3

rc 1

9 1

b g RST 21 r 1 R + b1 cos g R sin UVW

U

R 1

V b g = V S1 + 9 1 6 + b1 cos g 36 sin V

T 2

W

V = Vc 1 +

10

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

Graph of V vs.

1500

Intak

e

V (in3)

900

600

300

ust

Exha

ion

press

Com

1200

Expa

nsion

Bottom Dead Center

Top Dead Center

-400

-300

-200

-100

-0

100

200

300

400

11

Cylinder Surface Area (Heat

Transfer)

bg

bg

A = Ach + A p + B l + a s

B 2

A p = Piston crown surface area =

4

Ach = Cylinder head surface area

bg

s = a cos + l 2 a 2 sin 2

Therefore:

bg

LM

N

A = A p + Ach + Ba l / a + 1 cos +

bl / ag

sin 2

OP

Q

12

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

Surface Area (Cont.)

bg

Ab g = A

LM

N

A = A p + Ach + Ba l / a + 1 cos +

+ Ach +

bl / a g

OP

Q

sin 2

BL

R + 1 cos + R 2 sin 2

2 144444244444

3

L

2a

Same variation as the cylinder volume

13

Converting RPM to rad/sec ()

d 2 rad rev

min

=

dt 123

rev

min

sec

1

4

4260

44

3

Conversion

Therefore:

LM rad OP = N ML rev OP 2 rad min

N sec Q N min Q rev 60 sec

14

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

Piston Speed

ds ds d

=

dt d dt

d 2 rad rev

=

dt degree min

Therefore:

ds

Sp =

N 2

d

Sp =

Need to differentiate

15

Piston Speed (Cont.)

ds

ds

d

N 2 ,

=

a cos + l 2 a 2 sin 2

d

d d

d sin 2

Note:

= 2 sin cos

d

Sp =

a 2 sin cos

ds

= a sin +

= a sin

d

l 2 a 2 sin 2

S p = LN sin

MNL

cos

R 2 sin 2

OP

Q

LM

N

cos

R 2 sin 2

OP

Q

16

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

Piston Speed vs

L=14 in, R=6, N=330 RPM

1500

Piston Speed (ft/min)

1200

900

600

300

0

-300

-600

-900

-1200

-1500

-360

-270

-180

-90

90

180

270

360

17

Piston Speed vs. R

L=14 in, N=330 RPM

1500

Piston Speed (ft/min)

R=4

R=6

R=2

1200

900

600

300

0

-300

-600

-900

-1200

-1500

90

180

270

360

18

ME-620, Kirby S. Chapman, Rev. 082300

8/24/00

Mean Piston Speed

Better than using rotational speed (RPM)

Gas flow velocities in the intake manifold and

cylinder all scale with mean piston speed

Should be between 1,500 and 3,000 ft/min

Lower end is typical of large industrial engines

High end is typical of automotive engines

19

Calculating the Mean Piston

Speed

Sp =

360

180

bg

S p d =

360

180

2N

ds

d

d

b g b g

sb360g = a cosb360g + R sin b360g = a b1 + R g

sb180g = a cosb180g + R sin b180g = a b R 1g

Sp = 2N

360

ds

d = 2 N s 360 s 180

180 d

S p = 2 Na 1 + R R + 1

L

= 2 NL

2a

20

ME-620, Kirby S. Chapman, Rev. 082300

10

8/24/00

Example: Mean Piston Speed

An engine has a stroke of 12 in. What should be the maximum

engine speed?

2 12 in

14rev

24

3

S p = 2 NL =

ft

=

12 in

Distance piston travels

in one revolution

3,000 ft

min4

12

4

3

Max design piston speed

3,000 ft rev

min

2 ft

1,500 rev

=

min

N=

21

Torque and Horsepower

Horsepower is the rate of

doing work. Torque is the work.

Dynamometer:

Driven by Engine

Brake quantities

Stator

T = F b

Rotor

P = 2 N T

Force, F

b

Load

Cell

2N

b g 1000

b rev / sgT b N - m g

N b rpm gT b ft - lbf g

P b hp g =

5252

P kW =

22

ME-620, Kirby S. Chapman, Rev. 082300

11

8/24/00

Example Calculation

Vd=2.8 liters, B=89 mm, L=76 mm, rc=8.5

Peak Power@4,800 RPM=86 kW

Calculate the mean piston speed, the torque, and the specific power

4800 rev 76 mm 729.6 m 12.16 m

=

=

min

rev

min

sec

P

4

14,805 kW

Specific Power =

= 86 kW

=

2

Ap

m2

86 mm

S p = 2 NL = 2

T = 86 kW

N - m 60 sec I

gFGH 4800minrev IJK FGH 2revrad IJK FGH 1000

J = 171 N - m

kW - sec

min K

23

Mean Effective Pressure

The constant pressure that would have to exist to do the same

work over Vd as is done by the actual cycle.

A better measure of engine work than torque

Depends more on engine design than engine size

At maximum torque:

Naturally aspirated: 125 to 150 psi (850 to 1050 kPa)

Turbocharged: 180 to 250 psi (1250 to 1700 kPa)

These are about 10% lower at maximum power

24

ME-620, Kirby S. Chapman, Rev. 082300

12

8/24/00

Mean Effective Pressure

The cycle

cycle = 2nR , nR =

W=

P

P

cycle

d =

2N

2N

is different for a 4 - and 2 - stroke cycle.

W = Pt , d = 2Nt W =

RS2

T1

4 - stroke

2 - stroke

PnR

N

Relationship between

W and P(ower)

25

Mean Effective Pressure (Cont.)

p=mep

PnR

= pdV = mep Vd

N

Pn R

mep =

NVd

W=

26

ME-620, Kirby S. Chapman, Rev. 082300

13

8/24/00

Example Calculation -- mep

Vd=2.8 liters, B=89 mm, L=76 mm, rc=8.5

Peak Power@4,800 RPM=86 kW

Calculate the mean effective pressure in psi and kPa

mep =

FG

H

FG

H

IJ

K

PnR

86000 J

1

rev

=

2

NVd

s

2.8 liters cycle

IJ FG min IJ FG 60 sIJ

K H 4,800 rev K H min K

IJ FG kPa - m IJ = 767.9 kPa

K H 1000 N K

F 14.7 psi IJ = 1114. psi

mep = 767.9 kPa G

H 101.3 kPa K

FG

H

767.9 N - m

liter

mep =

liter

103 m3

27

Indicated Work per Cycle

Based on the p-V trace of the in-cylinder gases

Represents the work done on / by the gases

Does not represent the work done by the engine!

Pmax

Combustion

VBDC

Expansion

Pamb

Comp.

IVO Exhaust

EVC

VTDC

ME-620, Kirby S. Chapman, Rev. 082300

EVO

IVC

Intake

28

14

8/24/00

Indicated Work

Pmax

Combustion

VBDC

Wc ,i =

pdV

Wexpan Wcomp = Area A

Wexhaust Wintake = Area B

Wc ,ig = Area A

Expansion

Pamb

Comp. A

Exhaust

Intake

VTDC

Wc ,in = Area A Area B

Pi =

Wc ,i N

nR

29

Net and Gross Indicated Work

Gross indicated work

work delivered to the piston

over the compression and

expansion strokes only

(Area A only)

Net Indicated Work

work delivered to the piston

over the entire four-stroke

cycle (Area A - Area B)

30

ME-620, Kirby S. Chapman, Rev. 082300

15

8/24/00

Pumping Work--Emptying the

Cylinder

Wp =

pexh dV +

exhaust

pint dV

intake

g b

g = RST((+))

Wp = pexh VTDC VBDC + pint VBDC VTDC

Wp = Vd pint pexh

naturally aspirated

turbocharged

Exhaust

Pamb

Intake

VTDC

Naturally aspirated case

B

VBDC

31

Specific Fuel Consumption

sfc =

m& f

P

b g

b g

m& f bg / hg

sfcbg / kW - hr g =

= 608.3 sfcblbm / hp - hg

PbkWg

m& f blbm / hg

sfcblbm / hp - hg =

= 1644 sfcbg / kW - hr g

Pbhpg

b

sfc mg / J =

m& f g / s

P kW

Typical Values:

0.47 lbm/hp-h

0.32 lbm/hp-h

32

ME-620, Kirby S. Chapman, Rev. 082300

16

8/24/00

Indicated, Brake, and Friction

Applies to hp, torque, mep, and sfc

Brake

Delivered by the engine shaft

Measured with a dynamometer

Friction

Difference between Brake and Indicated

Due to engine losses (bearings, auxiliary systems, etc.)

Indicated

Delivered by the gas

Need to know the p-V trace in the cylinder

33

Mechanical Efficiency

Measures the mechanical ability of the engine to transfer

the work transferred from the gas to the output shaft.

Pig = Pb + Pf

m =

Pig Pf

Pf

Pb

=

= 1

Pig

Pig

Pig

Typical Values:

90% at 1,800 to 2,400 rpm

~75% at maximum rated speed

Reduces with engine throttling to zero at idle

34

ME-620, Kirby S. Chapman, Rev. 082300

17

8/24/00

Fuel Conversion Efficiency

Dimensionless

Wc

P

Relates power output to rate f = m Q = m& Q

f HV

f HV

of energy input

1

Fuel Conversion Effic.

f =

sfc QHV

Need to know the fuel

2545

heating value

=

QHV,Nat. Gas1,000 Btu/ft3

QGASOLINE 18,000 Btu/lbm

f =

sfc lbm / hp - h QHV Btu / lbm

3600

sfc g / kW - h QHV MJ / kg

35

Thermodynamic Efficiency

W

Wc

P

Similar to the f

t = c =

=

Qin m f QHV c m& f QHV c

Considers only the

fuel burned

f

t =

c

Can relate brake and

indicated thermal

Pb

t ,b =

efficiencies to

t ,b

m& f QHV c

m =

mechanical efficiency

Pi

t ,i

t ,i =

m& f QHV c

U|

|V

||

W

36

ME-620, Kirby S. Chapman, Rev. 082300

18

8/24/00

Air-to-Fuel Ratios

m& a

Air mass flow rate

=

Fuel mass flow rate

m& f

AF =

FA =

m& f

m& a

Fuel mass flow rate

Air mass flow rate

Typical Values:

12 AF 18 or 0.056 FA 0.083 (SI Engines)

18 AF 70 or 0.014 FA 0.056 (CI Engines)

37

Volumetric Efficiency

Measure of losses in the intake system

Air filter

Throttle plate

Ports

Valves

Ducts

v =

2 m& a

mass inducted

=

mass at inlet T and P a ,iVd N

v =

ma

, ma Air mass in cylinder

a ,iVd

Actually a mass ratio!

Can be greater than 100% for turbocharged engines. Normally

between 80% and 90% for NA engines

Only meaningful for a 4-stroke cycle (not used to describe 2stroke cycles)

38

ME-620, Kirby S. Chapman, Rev. 082300

19

8/24/00

Power and Vol. Eff. Correction

Factors

At a given engine speed, the air temperature,

pressure and relative humidity affect the engine

power and volumetric efficiency

Correction factors correct measured values to

standard atmospheric conditions

Correction factors are based on the compressible

flow equation.

39

Corrections--Compressible Flow

Eqn.

m& =

AE p0

RT0

R| 2 LF p I

S| 1 MMGH p JK

T N

p

p0

T0

AE

2 /

b

F

pI

G J

Hp K

1 + /

OPU|

PQV|W

0 .5

Pressure at restriction throat

Total pressure upstream of restriction

Total temperature upstream of restriction

Ratio of specific heats

Effective throat area

40

ME-620, Kirby S. Chapman, Rev. 082300

20

8/24/00

Correction Factors

m& =

AE p0

RT0

R| 2 LF p I

S| 1 MMGH p JK

T N

0

2 /

b

F

pI

G J

Hp K

1 + /

OPU|

PQV|W

0 .5

For a given engine, the pressure ratio is assumed constant

at wide open throttle:

m& a

RS p / p is constant

TGeometry is the same for a given engine

p0

T0

41

Correction Factors

If the proper amount of fuel is added to the air so that

complete combustion results, then:

Pi m& a

p0

T0

and:

Pi , s = C F Pi ,m

where:

Pi ,s Power at the standard atmosphere

Pi ,m Power at the measured conditions

42

ME-620, Kirby S. Chapman, Rev. 082300

21

8/24/00

Correction Factors

Pi m& a

p0

and Pi , s = C F Pi ,m

T0

p0 ,s

Ts

= CF

p0 , m

Tm

p0,s p s ,d = Standard dry - air absolute pressure

p 0 ,m = p m p v ,m

where:

pm

p v ,m

Tm

Ts

Measured ambient air absolute

Measured ambient water vapor pressure

Measured ambient air temperature

Standard ambient air temperature

43

Correction Factor

p0 ,s

Ts

= CF

p 0 ,m

Tm

CF =

p s ,d

pm pv ,m

Tm

Ts

where:

pm

p v ,m

p s ,d

Ts

Tm

Measured ambient air absolute

Measured ambient water vapor pressure

Standard dry - air ambient air pressure

Standard ambient air temperature

Measured ambient air temperature

44

ME-620, Kirby S. Chapman, Rev. 082300

22

8/24/00

Power Correction

Pb ,s = C F Pi ,m Pf ,m

Friction power is unaffected by ambient conditions

45

Volumetric Efficiency

Correction

V

C' F =

m& a

p T

T

a

T p

v ,s

v ,m

Ts

Tm

46

ME-620, Kirby S. Chapman, Rev. 082300

23

8/24/00

Parameter Relationships

P

P = f m& f QHV

m& f QHV

f =

n R m& a

ma

Nma

=

m& a =

a ,iVd N a ,iVd

nR

V =

FA =

P=

m& f

m& a

b g

Nma FA

nR

m& f = m& a FA

b g

f QHV ma N FA

nR

47

Torque, Power, & Other

Parameters

V =

P=

ma

ma = V a ,iVd

a ,iVd

b gP=

f QHV ma N FA

nR

b g

b g

Vd QHV N FA

a ,i

f V a ,iVd Q HV FA

P

=

2N

4

Pn R

mep =

= f V a ,i QHV FA

Vd N

T=

f V a ,i

P

=

Ap

b g

d A LiQ N b FAg =

p

HV

2 Ap

b g

a ,i

b g

LQHV N FA

2

f V a ,i S p Q HV FA

P

=

4

Ap

48

ME-620, Kirby S. Chapman, Rev. 082300

24

8/24/00

Example: Compression Ignition

Engine

A CI 4-stroke cycle engine is tested using an electric dynamometer.

The ambient conditions during the test are 60F, 14.7 psia. The load

cell on the dynamometer reads 80 lbf for the bhp and 58.2 lbf for

the fhp. Fuel (19,890 Btu/lbm) is consumed at a rate of 20.1 lb/hr

and the AF=20. The engine speed is 1,192 rpm, the bore is 4.75 in

and the stroke is 6.5 in. The conversion equation to convert the load

cell reading to hp is:

hp =

bLoad Cell - lbf g brpmg

3,000

Calculate the bhp, fhp, ihp, bsfc, bmep, torque, volumetric efficiency,

mechanical efficiency, thermal efficiency, and air consumption.

49

Horsepower & bsfc Calculations

80 1192

,

= 318

. hp

3,000

58.2 1192

,

fhp =

= 231

. hp

3,000

ihp = fhp + bhp = 318

. hp + 231

. hp

ihp = 54.9 hp

bhp =

bsfc =

m& f

bhp

FG 201. lbmIJ 1 = 0.632 lbm

H hr K 318. hp hp - hr

50

ME-620, Kirby S. Chapman, Rev. 082300

25

8/24/00

Torque and bmep Calculations

T=

FG

H

318

min

P

. hp

=

2N

1

1,192 rev

IJ FG rev IJ FG 550 ft - lbf IJ FG 60 sIJ

K H 2 rad K H hp - s K H min K

T = 140 ft - lbf

FG ft IJ = 0.0692 ft

H 12 in K

Pn

318

. hp F min I F 2 rev I

=

bmep =

G

JG J

V N 0.0692 ft H 1,192 rev K H cycle K

F 550 ft - lbf IJ FG 60 sIJ FG ft IJ = 177 psi

G

H hp - s K H min K H 12 in K

Vd =

4.75 in

B 2

L=

4

4

6.75 in

51

Air Consumption and

Volumetric Efficiency

AF = 20 =

v =

m& a

20.1 lbm 402 lbm

m& a = 20

=

hr

hr

m& f

2m& a

a ,i Vd N

IJ 1 144 in = 0.0764 lbm

K b460 + 60g R ft

ft

b4.75 ing

B

F ft IJ = 0.0692 ft

=

L=

6.75 inG

H 12 in K

4

4

IJ FG 1 IJ FG min IJ FG hr IJ

ft

2 rev F 402 lbm I F

=

G

J

G

cycle H hr K H 0.0764 lbm K H 0.0692 ft K H 1,192 rev K H 60 min K

a ,i =

FG

H

lbm- R

p

14.7 lbf

=

2

in

53.3 ft - lbf

RT

2

Vd

v

v =

402

= 213%

189

52

ME-620, Kirby S. Chapman, Rev. 082300

26

Você também pode gostar

- Chapter 6 PerformanceDocumento111 páginasChapter 6 PerformanceLenh Nguyen0% (1)

- Pelton Wheel Experiment: Fig-1 Fig-2Documento5 páginasPelton Wheel Experiment: Fig-1 Fig-2Caleb KreegerAinda não há avaliações

- A2 41b CircularmotionDocumento38 páginasA2 41b CircularmotionHany ElGezawyAinda não há avaliações

- Handbook of Formulae and ConstantsDocumento43 páginasHandbook of Formulae and Constantssuhaib hassanAinda não há avaliações

- Ch19 ISMDocumento84 páginasCh19 ISMJessamine KurniaAinda não há avaliações

- Chap2 Lect06 RC ModelDocumento11 páginasChap2 Lect06 RC ModeldkishoreAinda não há avaliações

- PETE 411 Well Drilling: Surge and Swab PressuresDocumento40 páginasPETE 411 Well Drilling: Surge and Swab PressuresJosue FishAinda não há avaliações

- 3 To 8 Decoder in NGSPICEDocumento14 páginas3 To 8 Decoder in NGSPICEJaydip FadaduAinda não há avaliações

- Akai MPC2000XL Main Board Schematics 1 PDFDocumento1 páginaAkai MPC2000XL Main Board Schematics 1 PDFAnonymous QgauLK2jdnAinda não há avaliações

- Makalah Gas PlanDocumento27 páginasMakalah Gas PlanPutriRobiihahAinda não há avaliações

- Thesis Chiller Hongxi Yin Appendix ADocumento20 páginasThesis Chiller Hongxi Yin Appendix Acefa84Ainda não há avaliações

- ME-1013-Basic Engineering ThermodynamicDocumento36 páginasME-1013-Basic Engineering ThermodynamicThwe Thwe MonAinda não há avaliações

- Lecture 5Documento11 páginasLecture 5عبدالله عمرAinda não há avaliações

- Final Slide - RonyDocumento14 páginasFinal Slide - RonyOMar FaruqAinda não há avaliações

- 40 Ei 4p2-Lic Lab ManualDocumento94 páginas40 Ei 4p2-Lic Lab ManualsoundsisterAinda não há avaliações

- HVACS Errata ForWeb Updated01042010xDocumento12 páginasHVACS Errata ForWeb Updated01042010xAldrin AbuegAinda não há avaliações

- Introduction To Switched-Mode Converter Modeling Using MATLAB/SimulinkDocumento37 páginasIntroduction To Switched-Mode Converter Modeling Using MATLAB/SimulinkAhana MalhotraAinda não há avaliações

- Tutorial 4 - SolutionDocumento12 páginasTutorial 4 - SolutionThabo ThaboAinda não há avaliações

- Tda 7499Documento8 páginasTda 7499franklimtecnico100% (1)

- Nidhi EM Numerical - Examples - For - TestsDocumento10 páginasNidhi EM Numerical - Examples - For - Testsapi-26910047Ainda não há avaliações

- 1 1 5 A GearspulleydrivessprocketspracticeproblemsDocumento4 páginas1 1 5 A Gearspulleydrivessprocketspracticeproblemsapi-308395650100% (1)

- Alcance Proyecto CartagenaDocumento3 páginasAlcance Proyecto CartagenamarraezAinda não há avaliações

- Heat Capacity Ratio of Real GasesDocumento2 páginasHeat Capacity Ratio of Real GasesilyesinAinda não há avaliações

- A Seamless Mode Transfer Maximum Power Point Tracking Controller For Thermoelectric Generator ApplicationsDocumento10 páginasA Seamless Mode Transfer Maximum Power Point Tracking Controller For Thermoelectric Generator Applicationssumiths32Ainda não há avaliações

- C8Samsung: KA2263 Linear Integrated CircuitDocumento4 páginasC8Samsung: KA2263 Linear Integrated CircuitHanse69Ainda não há avaliações

- Me 434 SolutionDocumento1 páginaMe 434 SolutionlowgangstaAinda não há avaliações

- KALI PresentationDocumento26 páginasKALI PresentationLuptonga100% (1)

- 2014-5-MIller Atkinson Strategy For Future Downsizing (BMEP 29 Bar)Documento8 páginas2014-5-MIller Atkinson Strategy For Future Downsizing (BMEP 29 Bar)Benedek ZoltánAinda não há avaliações

- 4Documento5 páginas4Alsmany ArdabAinda não há avaliações

- Mosfet Power Dissipation CalculationDocumento8 páginasMosfet Power Dissipation CalculationDinesh DangiAinda não há avaliações

- Bascom and AVR, EncodersDocumento5 páginasBascom and AVR, Encodersulil amriAinda não há avaliações

- AMP Assignment 2Documento1 páginaAMP Assignment 201fe16bme163Ainda não há avaliações

- DiffusionDocumento43 páginasDiffusionKenil JaganiAinda não há avaliações

- Ce8E - Mechanics of Fluids Ay2018-2019Documento5 páginasCe8E - Mechanics of Fluids Ay2018-2019Lyka Jane PesiganAinda não há avaliações

- Sony HCD-CP100 PDFDocumento50 páginasSony HCD-CP100 PDFvideosonAinda não há avaliações

- Trial On CompresorDocumento3 páginasTrial On CompresorA JAinda não há avaliações

- S L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryDocumento4 páginasS L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryAbel AzieAinda não há avaliações

- Buck-Boost and Flyback ConverterDocumento30 páginasBuck-Boost and Flyback Converterlambanaveen123Ainda não há avaliações

- Solución Tarea N°2: Parte A Modelo de Paneles PV Con Convertidor DC/AC MonofásicoDocumento13 páginasSolución Tarea N°2: Parte A Modelo de Paneles PV Con Convertidor DC/AC MonofásicocamiloAinda não há avaliações

- Verilog Lab SolutionsDocumento15 páginasVerilog Lab Solutionsraja_ramalingam07Ainda não há avaliações

- PV and Ts DiagramDocumento14 páginasPV and Ts DiagramParbat Shrestha100% (1)

- Pin Details For Evaluation Board SKIND061101 For SKYPER32ProDocumento1 páginaPin Details For Evaluation Board SKIND061101 For SKYPER32Proshyam_iitbAinda não há avaliações

- 3 Phase Extra PDFDocumento9 páginas3 Phase Extra PDFUnknownAinda não há avaliações

- Answers To Assignment 5 Continuity, Bernouilli and Energy EquationDocumento4 páginasAnswers To Assignment 5 Continuity, Bernouilli and Energy EquationAbhinandan RamkrishnanAinda não há avaliações

- Mechanical Engineering Dynamics of Machines Analysis of Cams NotesDocumento26 páginasMechanical Engineering Dynamics of Machines Analysis of Cams NotesSphumelele SibuthaAinda não há avaliações

- IIT-JEE 2011 Paper1 Solutions HindiDocumento37 páginasIIT-JEE 2011 Paper1 Solutions HindiResonance Kota60% (5)

- Turnerloading - XLS: Step 1: Update Input Data in Blue Step 2: View ResultsDocumento2 páginasTurnerloading - XLS: Step 1: Update Input Data in Blue Step 2: View Resultsmath62210Ainda não há avaliações

- Case - 8 (Amarco Inc.)Documento21 páginasCase - 8 (Amarco Inc.)shreykaran0% (1)

- 17b Transformer Class Exercise Solution r13Documento10 páginas17b Transformer Class Exercise Solution r13طه محمدAinda não há avaliações

- ECE2274 Pre-Lab For MOSFET Logic NAND Gate, NOR Gate, and CMOS Inverter 1. Nmos Nand GateDocumento6 páginasECE2274 Pre-Lab For MOSFET Logic NAND Gate, NOR Gate, and CMOS Inverter 1. Nmos Nand GateRudra MishraAinda não há avaliações

- Aircraft Control Lecture 13Documento32 páginasAircraft Control Lecture 13Arief HadiyantoAinda não há avaliações

- Bit HydraulicsDocumento11 páginasBit HydraulicstibismtxAinda não há avaliações

- CH 13Documento32 páginasCH 13hirenpatel_universalAinda não há avaliações

- Hydraulics and Water Resources (CEE 340) (Topic 2) : TurbineDocumento12 páginasHydraulics and Water Resources (CEE 340) (Topic 2) : TurbineRachel YarasavichAinda não há avaliações

- 14 Jet Bit Nozzle Size SelectionDocumento46 páginas14 Jet Bit Nozzle Size Selectiontotos20100% (2)

- HW 02 Solutions Spring 2012Documento6 páginasHW 02 Solutions Spring 2012shlaeaAinda não há avaliações

- Jet Bit Nozzle Size SelectionDocumento46 páginasJet Bit Nozzle Size SelectionBharat BhattaraiAinda não há avaliações

- Ic EngineDocumento72 páginasIc Enginekedirabduri88Ainda não há avaliações

- Basic Drilling Engineering EquationsDocumento4 páginasBasic Drilling Engineering EquationsaungnmAinda não há avaliações

- Gas Power CyclesDocumento76 páginasGas Power CyclesJuan JoseAinda não há avaliações

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocumento350 páginasCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- 2017 EPA Tier3 Exhaust Emission - C60Documento1 página2017 EPA Tier3 Exhaust Emission - C60Carlos AlbertoAinda não há avaliações

- Valve Timing DiagramDocumento17 páginasValve Timing DiagramAnush R AminAinda não há avaliações

- QT5 Roc 104 PDFDocumento20 páginasQT5 Roc 104 PDFCarlos RamirezAinda não há avaliações

- Unit V Cooling SystemDocumento20 páginasUnit V Cooling SystemRavindra_1202Ainda não há avaliações

- Diesel FuelDocumento29 páginasDiesel FuelSisay SolomonAinda não há avaliações

- 9412Documento3 páginas9412Mihai-Eugen Popa100% (1)

- Fuel System: Systems OperationDocumento7 páginasFuel System: Systems OperationbejoythomasAinda não há avaliações

- Catalago Parts Book PC200 PDFDocumento387 páginasCatalago Parts Book PC200 PDFامین پارسا100% (3)

- NEF45AM1A.S500 Exploded Views (D50IST)Documento17 páginasNEF45AM1A.S500 Exploded Views (D50IST)Daniel MuratallaAinda não há avaliações

- SM - 7 Jeep ElectricoDocumento86 páginasSM - 7 Jeep Electricoedgar danielAinda não há avaliações

- L Jetronic For Porsche 912EDocumento28 páginasL Jetronic For Porsche 912EAtone Romeo100% (1)

- (WM) L200 (Ka#,kb#)Documento1 página(WM) L200 (Ka#,kb#)Gabriel HreczyńskiAinda não há avaliações

- Fuel Injectors: Denny Schroeter Injectors / Removal / Fitting 25/01/23Documento14 páginasFuel Injectors: Denny Schroeter Injectors / Removal / Fitting 25/01/23Евгений МуллаяновAinda não há avaliações

- Mercedes-Benz Mbe 4000 Valve Lash CheckingDocumento7 páginasMercedes-Benz Mbe 4000 Valve Lash CheckingIslam ShoukryAinda não há avaliações

- Ajax Integral Engine-Compressor Dpc-2802: Legends Don't Stop. We Make Sure of ItDocumento2 páginasAjax Integral Engine-Compressor Dpc-2802: Legends Don't Stop. We Make Sure of ItHazem RamdanAinda não há avaliações

- Bf40D - Bf50D Remote Control Type Wiring DiagramDocumento1 páginaBf40D - Bf50D Remote Control Type Wiring DiagramJoe75% (4)

- Continental CD-300 Engine AnnouncementDocumento2 páginasContinental CD-300 Engine AnnouncementSilvije Filipović100% (1)

- Toyota AvensisDocumento55 páginasToyota Avensispankituna5487100% (4)

- Hyundai SparePartsDocumento44 páginasHyundai SparePartsMarcel Baque100% (1)

- Cilindri Cos enDocumento4 páginasCilindri Cos enNguyen Hai VanAinda não há avaliações

- Ddec Vi (CPC) Vehicle Interface Harness: All Information Subject To Change Without Notice. (Rev. 3/06)Documento2 páginasDdec Vi (CPC) Vehicle Interface Harness: All Information Subject To Change Without Notice. (Rev. 3/06)ALEJO100% (1)

- Cummins-System & Component Understanding Report-V1-151117 PDFDocumento194 páginasCummins-System & Component Understanding Report-V1-151117 PDFSyed100% (4)

- F4BM (F5BM) : Parsun Outboard Engine Service ManualDocumento93 páginasF4BM (F5BM) : Parsun Outboard Engine Service ManualСергей ОсипенкоAinda não há avaliações

- Cat 3126 Manuals PDFDocumento2 páginasCat 3126 Manuals PDFJuanJoseMecanicadieselArias100% (2)

- Bravo Service Manual Part 1Documento544 páginasBravo Service Manual Part 1carlsdigaround100% (2)

- Man B&W WarningDocumento284 páginasMan B&W WarningMarcin SrokaAinda não há avaliações

- HD InfoDocumento86 páginasHD InfoViktor SpeicherAinda não há avaliações

- 2009 Yamaha TMAX XP500 Service ManualDocumento386 páginas2009 Yamaha TMAX XP500 Service ManualAntonio Jose Planells100% (3)

- IPD KT Cummins Quick Ref Guide - 112017Documento4 páginasIPD KT Cummins Quick Ref Guide - 112017fjaristizabalAinda não há avaliações