Escolar Documentos

Profissional Documentos

Cultura Documentos

Energy Efficiency of Chillers

Enviado por

Chuma KhanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Energy Efficiency of Chillers

Enviado por

Chuma KhanDireitos autorais:

Formatos disponíveis

International Journal on Architectural Science, Volume 2, Number 1, p.

18-22, 2001

ANALYSIS OF ENERGY EFFICIENCY OF CHILLERS OPERATION AT

NIGHT

Y.A. Li, M.Z. Yu and G.L. Xu

Shandong Institute of Architecture and Engineering, Jinan, 250014, P.R. China

(Received 16 February 2001; Accepted 17 May 2001)

ABSTRACT

This paper is based on actual measurement weather data of recent decade in Jinan, P.R. China, and profile and

characteristics of outdoor air wet bulb temperature are analyzed. It is found that outdoor air wet bulb

temperature has an effect on the performance of chillers. Results show that the cooling capacity is increased by

9.0 percent, consumption power is reduced by 17.2 percent, and coefficient of performance is stepped-up by

31.5 percent when chillers operate at night.

Last summer, the performance of chillers in a hotel building in Jinan was measured. Measurement results

showed good agreement with theory calculation results.

INTRODUCTION

Refrigeration is defined as the process of extracting

heat from a lower-temperature heat source, and

transferring it to a higher-temperature heat sink.

Refrigeration maintains the temperature of the heat

source below that of its surroundings while

transferring the extracted heat, and any required

energy input, to a heat sink.

A refrigeration system is a combination of

components and equipment connected in a

sequential order to produce the refrigeration effect.

The refrigeration systems commonly used for air

conditioning is a chiller of vapor compression. In

chillers, compressors activate the refrigerant by

compressing it to a higher pressure and higher

temperature level after it has produced its

refrigeration effect. The compressed refrigerant

transfers its heat to the sink and is condensed to

liquid form. This liquid refrigerant is then throttled

to a low-pressure, low-temperature vapor to

produce refrigerating effect during evaporation.

The condenser is a water-cooled condenser in

which the cooling water is used to remove

condensing heat from the refrigerant, and cooling

water is the recirculating water from the cooling

tower which is evaporative cooling tower in the

research project.

The chillers run in the day in the traditional air

conditioning systems. The performance of chillers

will change when chillers operate at night.

2.

DAILY WET BULB TEMPERATURE

PROFILE

Inlet temperature of cooling water has a significant

effect on the performance of chillers and it depends

on the wet bulb temperature of outdoor air. In

general, outlet temperature of cooling tower, that is,

inlet temperature of chillers is equal to the ambient

air wet bulb temperature plus 3~5oC. Measured

hourly wet bulb temperature of recent decade in

Jinan in August has been analyzed and studied

based on standard meteorological year [1].

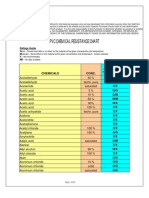

Fig. 1 and Table 1 show that the average wet bulb

temperature of outdoor air is 21.5oC at night, it is

23.2oC in the day and at night is 1.7oC less than

that in the day. In other words, cooling water

outlet temperature of cooling towers, condensation

temperature of refrigerators at night is 1.7oC less

than that in the day.

23.5

23.0

o

Temperature

p

( ( )C)

1.

22.5

22.0

21.5

21.0

20.5

0

10

15

20

25

time (hour)

Fig. 1: Daily wet bulb temperature profile

in Jinan

18

International Journal on Architectural Science

Table 1: Wet bulb temperature in Jinan August (oC)

hour

date

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

11

14

17

24

day

night

26.2

25.4

25.9

20.9

20.5

19.5

19.9

22.5

21.7

22.1

22.1

22.8

21.8

21.4

20.8

24.4

22.8

23.7

23.5

21.9

21.0

22.3

21.6

21.0

21.0

19.3

17.8

9.9

19.0

22.5

21.5

26.0

25.1

25.7

19.5

19.6

19.5

19.3

22.5

21.7

22.2

20.0

22.8

22.4

20.8

21.4

24.1

22.7

23.6

23.7

21.8

21.7

23.6

22.1

20.4

20.8

18.5

18.3

14.3

18.8

22.7

22.0

26.0

25.0

25.6

20.3

19.0

19.6

19.4

22.7

21.8

22.3

22.1

23.7

23.0

20.4

22.0

24.0

22.7

23.7

23.7

21.8

22.3

23.9

22.6

20.0

20.8

18.1

18.8

17.7

18.9

23.0

22.5

26.2

25.1

25.8

21.7

18.8

19.8

20.3

23.3

22.0

22.5

22.3

23.7

23.5

21.4

22.6

24.1

22.9

23.8

23.7

22.0

22.8

24.2

23.1

19.9

20.9

18.1

19.2

20.0

19.8

23.2

22.8

27.1

25.8

26.9

24.1

19.9

20.2

24.9

26.8

22.5

23.0

22.4

23.4

24.3

26.5

22.7

25.2

24.2

24.6

23.4

22.8

23.1

25.1

24.7

20.6

21.8

19.7

19.8

20.3

22.1

24.0

23.3

27.6

26.2

27.5

23.7

20.3

20.6

27.5

28.0

22.8

23.3

24.0

22.1

24.6

20.7

24.5

25.4

24.9

24.9

22.9

23.2

23.6

24.9

24.9

21.0

22.3

20.5

20.2

20.4

23.5

23.9

23.3

27.8

26.4

27.8

21.8

20.1

20.9

28.1

27.0

22.8

23.5

24.1

21.5

24.3

19.6

25.0

24.6

25.1

24.8

22.2

23.1

24.3

23.7

23.9

21.2

22.6

20.4

20.4

20.3

23.7

23.1

23.9

27.0

25.8

26.8

20.2

17.2

21.5

21.9

16.1

21.7

23.5

22.4

20.8

21.5

19.4

25.0

18.9

23.6

22.7

19.8

21.0

26.5

17.0

16.3

20.8

22.0

16.9

20.1

19.1

19.3

18.4

20.6

27.1

25.8

27.0

22.5

19.8

20.4

25.2

26.3

22.5

23.1

23.5

22.7

24.2

22.1

24.0

24.8

24.3

24.5

23.1

23.0

23.5

24.5

24.2

21.0

21.9

19.7

19.9

20.3

22.3

23.6

23.1

26.3

25.3

26.0

20.6

19.1

20.0

20.1

21.0

21.7

22.5

22.2

22.5

22.2

20.5

22.3

22.9

22.9

23.4

22.7

21.6

22.9

22.0

20.7

20.6

21.2

18.2

19.8

15.3

19.0

21.7

21.7

3.

day

night

28

27

ANALYSIS

EFFICIENCY

OF

ENERGY

26

Temperature () o

Temperature ( C)

25

A hotel building in Jinan has a gross space of 9200

m2 (8-story). The total conditioned space is 7700

m2. The buildings peak air-conditioning load is

636 kW. Piston compressors in this building are

used and the refrigerant is R22. Thermal

calculation of one chiller is carried out in the day

and at night respectively.

24

23

22

21

20

19

18

17

16

15

14

0

10

15

20

25

30

Time (day)

35

With the aid of the pressure-enthalpy diagram,

cooling capacity may be expressed as:

Fig. 2: Comparison of wet bulb temperature

19

International Journal on Architectural Science

o = VRqv

= Vhqv

= Vhqo /V1

(1)

Factors that influence the of the compressor

include: clearance volume and compression ratio v.

Both factors affect the volume of reexpansion gas

trapped in the clearance volume.

P

v = 1 c 2

P

1

m

1

(2)

Coefficient of heat effect t. When vapor

refrigerant enters the compressor, heat absorbed by

the vapor results in a heating effect that increases

the specify volume of the refrigerant and, therefore,

the VR value.

t = To / Tk

(3)

Coefficient of leakage l. Refrigerant leaks through

the gap and the clearance across the high- and lowpressure sides of the compressor, such as the

clearance between the piston rising and the cylinder

in a reciprocating compressor.

l = 0.98

(4)

Coefficient of throttle p. There is resistance when

vapor refrigerant runs through suction and exhaust

valves.

p = 1

1 + c P1

v P1

(5)

By using Eqs. (2)~(5)

= v t l p

1

1 + c P1

P2 m To

= 1 c 1

0.98 1

v P1

P

T

1

k

1 + c P1

P2 + P2 m To

1

= 0.98 1

1 c

v P1

P1

T

(6)

By using Eqs. (1) and (6)

1 + c P1

P2 + P2

o = 0.98 1

1 c

v P1

P1

m To q o

1

Vh

T V1

(7)

20

The following equation will be used for account

shaft power.

Pe = M R Wth /( i m )

T

= M R Wth o + bt o m

Tk

(8)

The effectiveness of refrigeration cycles, or

coefficient of performance (COP), is one parameter

that affects the efficiency and energy consumption

of the chiller. The COP of a refrigeration cycle

using a specific refrigerant depends mainly upon

the isentropic work input to the compressor at a

given condensing and evaporating pressure

differential, as well as the refrigeration effect

produced.

The COP of chillers is also defined as:

COP = o Pe

(9)

Experimental fitting formulas of calculation

cooling capacity and shaft power are derived from

references [2-6] in order to simplify the calculation.

0 = a1 exp[b1 (to + b2)2 + b3 (tk + b4)2 + b5 (totk

+b6)2]

(10)

Pe = a2 exp[c1 (to + c2)2 + c3 (tk + c4)2 + c5 (totk +c6)2]

(11)

Since refrigerant in the chillers is R22, these

coefficients are respectively as follows:

a1 = 2362.01,

b2 = -46.12189,

b4 = 6.534695,

b6 = -6557.827.

b1 = -3.066017 10-4,

b3 = -1.616698 10-4,

b5 = -1.762319 10-8,

a2 = 280.1342,

c2 = 7.454992,

c4 = -73.58168,

c6 = -3519.666.

c1 = -3.160405 10-4,

c3 = -2.049994 10-4,

c5 = -5.494057 10-8,

It is over-simplified to assume that the condensing

temperature drops by the same amount as the wet

bulb temperature in Fig. 3. 12341 is the

rating condition in the day, the condensation

temperature is 40 oC and the evaporation

temperature is 5oC. 12341 is the rating

condition at night, the evaporation temperature is

still 5 oC, and the condensation temperature is

38.3 oC which is 1.7 oC less than that in the day.

International Journal on Architectural Science

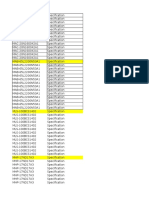

Table 2: Comparison of chillers performance in the day & at night

Rating condition

Calculation

Measurement

Day

Night

Day

Night

0 /

0

(kW)

Pe

(kW)

COP

314.0

342.9

310.0

337.8

89.9

72.6

90.5

74.9

3.49

4.72

3.43

4.51

Pe / Pe

(%)

COP / COP

(%)

9.2

-19.2

35.2

9.0

-17.2

31.5

(%)

increased, and energy consumption is reduced at

night.

Because energy situation is now very serious, so it

is right time that chillers operate at night as far as

possible. The development of operation method is

very important and has a bright future.

Pressure

NOMENCLATURE

Enthalpy

Fig. 3: Condensation temperature vs

performance of chillers

Last summer, the cooling capacity and shaft power

of the chiller were measured. The cooling capacity

is known after the rate of flow, inlet temperature

and outlet temperature of chilled water are

surveyed. Shaft power is known with the help of

dynamometer. Calculation of cooling capacity and

shaft power is carried out by using Eqs. (10) and

(11) after evaporative and condensing pressures are

gauged because evaporating and condensing

temperature result from evaporating and

condensing pressure.

Table 2 indicates that the cooling capacity is

increased by 9.0 percent, shaft power is reduced by

17.2 percent, coefficient of performance is steppedup by 31.5 percent when chillers operate at night.

In addition, the operation efficiency of chillers is

greatly increased since they run with peak load, the

times of chillers stops are reduced at night.

4.

ANALYSIS AND DISCUSSION

Wet bulb temperature in outdoor air changes hourly

and average wet bulb temperature of 10 years at

night is 1.7oC less than that in the day in Jinan,

P.R. China.

The wet bulb temperature is the primary parameter

that affects the performance of the cooling tower,

and so wet bulb temperature has greatly an effect

on the performance of chillers. The cooling

capacity and coefficient of performance are

to

evaporation temperature, oC

condensation temperature, oC

tk

0 cooling capacity, kW

Pe shaft power, kW

COP coefficient of performance

To evaporation temperature, K

Tk condensation temperature, K

qo mass refrigerating capacity, kJkg-1

Vl specific volume, m3kg-1

Wth work of compression, kJkg-1

MR mass rate of flow of refrigerant, kgs-1

b

constant

m expansion index number

c

relative clearance volume

P1 suction pressure, Pa

P1 suction pressure difference, Pa, P1 = P1 - Po

P2 exhaust pressure, Pa

P2 exhaust pressure difference, Pa, P2 = Pk - P2

m friction efficiency, %

Po evaporation pressure, Pa

Pk condensation, Pa

VR actual induced volume of suction vapor at

suction pressure, m3

Vh theoretical displacement of compressor, m3

volumetric efficiency, %

i compression efficiency, %

v cleance volume and compression ratio

t coefficient of heating effect

l coefficient of leakage

p coefficient of throttle

REFERENCES

1.

Y.A. Li, Study and application of standard

meteorological year, Ventilation & Dust Control,

No. 2 (1993).

21

International Journal on Architectural Science

2.

Z.Q. Guan, Several experimental fitting formulas

in refrigerant calculation, Refrigeration, No. 3

(1995).

3.

Y. Hwang, J. Judge and R. Radermacher,

Experience with refrigerant mixture, ASHRAE

Transaction, Part I (1997).

4.

J.D. Millar, G.K. Morris and B.G. Shelton,

Legionnaires

Disease:

Seeking

effective

prevention, ASHRAE Journal, No. 1 (1997).

5.

W. Kirsner, 3gpm/ton condenser water flow rate:

Does it waste energy?, ASHRAE Journal, No. 2

(1996).

6.

ASHRAE,

ASHRAE

Handbook

1998,

Refrigeration, ASHRAE inc., Atlanta, GA (1998).

22

Você também pode gostar

- Modeling & Simulation of Secondary ReformerDocumento8 páginasModeling & Simulation of Secondary ReformerChuma KhanAinda não há avaliações

- Che-481 - Fuel and Combustion - Group 09Documento24 páginasChe-481 - Fuel and Combustion - Group 09Osama HasanAinda não há avaliações

- Na NO2Documento10 páginasNa NO2Trần Thùy LinhAinda não há avaliações

- Learning From AiChEDocumento74 páginasLearning From AiChEChuma Khan100% (1)

- ImprovementofstrippingindexofcatacarbsystemDocumento15 páginasImprovementofstrippingindexofcatacarbsystemChuma KhanAinda não há avaliações

- Catalyst Performance Assessment MethodsDocumento3 páginasCatalyst Performance Assessment MethodsMuthu KumarAinda não há avaliações

- Catalyst Performance Assessment MethodsDocumento3 páginasCatalyst Performance Assessment MethodsMuthu KumarAinda não há avaliações

- Che-481 - Fuel and Combustion - Group 09Documento24 páginasChe-481 - Fuel and Combustion - Group 09Osama HasanAinda não há avaliações

- State Point ArticleDocumento15 páginasState Point Articlealfredmbewe6308Ainda não há avaliações

- Inspection For High Temperature H2 AttackDocumento29 páginasInspection For High Temperature H2 AttackChuma KhanAinda não há avaliações

- PVC Chemical ResistanceDocumento20 páginasPVC Chemical ResistanceYamin MohdAinda não há avaliações

- Economics Sample QuizDocumento5 páginasEconomics Sample QuizChuma KhanAinda não há avaliações

- FIORDA Case Study Corrosion Attack On Primary Reformer TubesDocumento7 páginasFIORDA Case Study Corrosion Attack On Primary Reformer TubesChuma Khan100% (1)

- Activated Sludge Treatment Lecture NotesDocumento22 páginasActivated Sludge Treatment Lecture NotesChuma KhanAinda não há avaliações

- Catalyst Performance Assessment MethodsDocumento3 páginasCatalyst Performance Assessment MethodsMuthu KumarAinda não há avaliações

- OrificeDocumento5 páginasOrificeyuvionfireAinda não há avaliações

- JSSW Vessel Design CriteriaDocumento38 páginasJSSW Vessel Design CriterialafondejsAinda não há avaliações

- Tabel Bunga Untuk Ekonomi TeknikDocumento32 páginasTabel Bunga Untuk Ekonomi TeknikElvina Noviarni Chandra78% (9)

- Shell and Tube Heat Exchanger DesignDocumento41 páginasShell and Tube Heat Exchanger DesignAhmad Budiman100% (2)

- Easy-Line 05 EDocumento2 páginasEasy-Line 05 EChuma KhanAinda não há avaliações

- Appl. Environ. Microbiol. 1983 Bancroft 683 8Documento7 páginasAppl. Environ. Microbiol. 1983 Bancroft 683 8Chuma KhanAinda não há avaliações

- The Control of PHDocumento6 páginasThe Control of PHRoman MangalindanAinda não há avaliações

- CRITICAL EVALUATION OF KOHLBERG's THEORYDocumento3 páginasCRITICAL EVALUATION OF KOHLBERG's THEORYChuma Khan100% (1)

- CMCDocumento9 páginasCMCChuma KhanAinda não há avaliações

- Preparing An Effective Case AnalysisDocumento4 páginasPreparing An Effective Case AnalysisMuhammad MujahidAinda não há avaliações

- Project Management, Tools, Process, Plans and Project Planning TipsDocumento16 páginasProject Management, Tools, Process, Plans and Project Planning TipsChuma Khan100% (1)

- How To Excel at Project ManagementDocumento27 páginasHow To Excel at Project ManagementChuma KhanAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Circulating Heat Pump Water Heater Versati (Air To Water Heat Pump)Documento10 páginasCirculating Heat Pump Water Heater Versati (Air To Water Heat Pump)blmasinaAinda não há avaliações

- Mollier Diagram Can Be Improved 0 PDFDocumento6 páginasMollier Diagram Can Be Improved 0 PDFJason LimAinda não há avaliações

- ICE PRODUCTION PROCESSDocumento7 páginasICE PRODUCTION PROCESSRonaldAinda não há avaliações

- Pulse Tube RefrigeratorDocumento7 páginasPulse Tube RefrigeratorRickson Viahul Rayan CAinda não há avaliações

- Performance (COP) Analysis of A Vapour Compression Refrigeration System Component With Nano CoatingDocumento4 páginasPerformance (COP) Analysis of A Vapour Compression Refrigeration System Component With Nano CoatingantonytechnoAinda não há avaliações

- Copeland Scroll Compressors For Air Conditioning ApplicationsDocumento28 páginasCopeland Scroll Compressors For Air Conditioning ApplicationsSrikanta ChoudhuryAinda não há avaliações

- Professional Refrigeration ProductsDocumento4 páginasProfessional Refrigeration ProductsMeghana YedunuthalaAinda não há avaliações

- ARABACA - XDD - Module 3 Activity No. 4 - REFSYSDocumento4 páginasARABACA - XDD - Module 3 Activity No. 4 - REFSYSXAVIERDOMINIC ARABACAAinda não há avaliações

- Refrigerators 2015-2016 Company Profile Features Designs SpecsDocumento96 páginasRefrigerators 2015-2016 Company Profile Features Designs SpecsMuamera HodzicAinda não há avaliações

- 95 TOP Refrigeration and Air Conditioning MCQsDocumento19 páginas95 TOP Refrigeration and Air Conditioning MCQsNagaraj Muniyandi80% (5)

- RefrigeratorsDocumento11 páginasRefrigeratorsNguyen Thanh SangAinda não há avaliações

- FAA 2020-21 HoldoverTablesDocumento108 páginasFAA 2020-21 HoldoverTablesSanteBrucoliAinda não há avaliações

- Bell 429 Helicopter - High Resolution PanelDocumento1 páginaBell 429 Helicopter - High Resolution Panelguicordova0% (1)

- Parts of A RefrigeratorDocumento3 páginasParts of A RefrigeratorneilmijaresAinda não há avaliações

- Mini Ice PlantDocumento3 páginasMini Ice PlantGemma Gamolo Buntag100% (3)

- Refrigeration and Air Conditioning - Jordan-PriesterDocumento532 páginasRefrigeration and Air Conditioning - Jordan-PriesterJuan Jerez67% (3)

- Absorption Chiller Refrigeration CycleDocumento2 páginasAbsorption Chiller Refrigeration CycleSarah DeanAinda não há avaliações

- Thermosyphon CoolingDocumento4 páginasThermosyphon CoolingMd Naim HossainAinda não há avaliações

- Energen Heat PumpDocumento2 páginasEnergen Heat PumpgkpAinda não há avaliações

- Chiller Efficiency ConversionDocumento3 páginasChiller Efficiency Conversionsujan1980Ainda não há avaliações

- Embraco Aftermarket Product Line Catalog With Wiring Diagrams 85x112021Documento28 páginasEmbraco Aftermarket Product Line Catalog With Wiring Diagrams 85x112021Pradeep JhaAinda não há avaliações

- Exploded View: 22031050000281 RF-S218XAR1 Product Model Customer ModelDocumento9 páginasExploded View: 22031050000281 RF-S218XAR1 Product Model Customer ModelPablo GuerraAinda não há avaliações

- Aceites TraneDocumento12 páginasAceites TraneHomero Polanco100% (1)

- Import Specs ChileDocumento75 páginasImport Specs ChileHector Alejandro Zamorano CardenasAinda não há avaliações

- Neil Chester C. HernaezDocumento9 páginasNeil Chester C. HernaezSka doosh100% (1)

- Sadara Business Complex: Sports CentreDocumento4 páginasSadara Business Complex: Sports CentreraziAinda não há avaliações

- Guide On Energy Efficient Refrigerator-V.2Documento6 páginasGuide On Energy Efficient Refrigerator-V.2Ar Hussain MojahidAinda não há avaliações

- List of Refrigerants: List Type and Flammability See Also References NotesDocumento13 páginasList of Refrigerants: List Type and Flammability See Also References NotesEm GomezAinda não há avaliações

- CAMEL Authorized Service CentersDocumento69 páginasCAMEL Authorized Service CentersJason NadaroAinda não há avaliações

- Maximizing Cooling Efficiency of VCR SystemsDocumento41 páginasMaximizing Cooling Efficiency of VCR SystemsRuturaj UmaranikarAinda não há avaliações