Escolar Documentos

Profissional Documentos

Cultura Documentos

Experimental Investigation of Four Stroke Single Cylinder Rope Brake Dynamometer Assisted CI Engine Fueled With Biodiesel From Waste Cooking Oil

Enviado por

Premier PublishersTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Experimental Investigation of Four Stroke Single Cylinder Rope Brake Dynamometer Assisted CI Engine Fueled With Biodiesel From Waste Cooking Oil

Enviado por

Premier PublishersDireitos autorais:

Formatos disponíveis

International Research Journal of Power and Energy Engineering

Vol. 2(1), pp. 012-018, August, 2016. www.premierpublishers.org, ISSN: 2141-5032x

IRJPEE

Review

Experimental investigation of four stroke single

cylinder rope brake dynamometer assisted CI engine

fueled with biodiesel from waste cooking oil

Himansh Kumar*

Chemical Conversion Division, Sardar Swaran Singh National Institute of Renewable Energy, Kapurthala, Punjab144601

Tel.: +91- 9456016503, Email: himansh.rmu@gmail.com

The present work is focused on the effects of waste cooking oil based methyl ester and its

blends with petrodiesel on a single cylinder, 4 stroke, naturally aspirated, direct injection, water

cooled, rope brake dynamometer assisted CI engine at varying loads. The physical and

chemical properties of WCO based methyl ester were determined using standard ASTM

methods. The suitability of WCO based methyl ester and its blends were evaluated through

determining the performance and emission characteristics of CI engine. These results were

compared to petrodiesel for validation. By analyzing these results, it was observed that the

performance and emission characteristics were shown both satisfactory and unsatisfactory

results. This was due to lower calorific value and high viscosity of waste cooking oil methyl

ester resulted delay in combustion. From the critical analysis, it was observed that B20 of WCO

based methyl ester reserved 32.2% brake thermal efficiency slightly greater than petrodiesel i.e.

32% without any engine modifications. It is concluded that B20 of WCO based methyl ester is

suitable with no modification in engine.

Keywords: Transesterification, CI engine, performance analysis, waste cooking oil, rope brake dynamometer

INTRODUCTION

From the last decades it has become clear that the

petroleum products will no longer supply than demand.

So that different techniques for alternative fuels were

being developed which can take petroleum fuels place

(Patil et al 2012). Alternative fuel can be defined as any

liquid substance, other than petroleum, which is used to

provide energy to power in compression ignition engine

and other energy generating equipments (Subramaniam

et al., 2013). So the word biodiesel refers to any

petrodiesel equivalent processed fuel, derived from

biological sources. Therefore, it is a processed fuel,

which is ready to use in common CI engines. Biodiesel

has successful promise to be used as alternative fuels for

CI engines because it derives from renewable sources

and could emit substantially less harmful gases. But due

to its high viscosity and low calorific value it is not

recommended without blending as a fuel for engine

operation (Alamu et al., 2007, Salmani et al., 2015).

Every gallon of biodiesel displaces 0.90 gallons of

petroleum-based diesel over its life cycle. For every

single unit of fossil produced 3.37 units of biodiesel

(Subramaniam et al., 2013, Misra et al., 2010). It creates

less CO and HC than petrodiesel also the crops which

are used to produce biodiesel absorb large amounts of

CO2 while growing. As biodiesel is nontoxic and

recyclable, it is an excellent fuel for use in easily broken

environments such as estuaries, lakes, rivers, and

national parks (Prakash et al., 2013, Buyukkaya et al.

2010).

Experimental investigation of four stroke single cylinder rope brake dynamometer assisted CI engine fueled with biodiesel from waste cooking oil

Kumar H.

012

Table 1. Physicochemical properties of different types of vegetable oil

S No.

Fuel Properties

Palm

oil

Petrodiesel

B10

WCO

B20

WCO

B50

WCO

B100W

CO

Density at 40C

3

(g/cm )

.9101

.8702

.8722

.8822

.8922

.9066

Viscosity

40C / cSt

43

2.7

2.9

3.2

3.9

Flash point C

250

67

70

74

80

112

Cetane number

42

47

48

48

49

55.5

Calorific Value

(MJ/kg)

34

44

43.5

42.2

40

at

In this experimental investigation, waste cooking oil

based biodiesel and its blends were used. It is easily

available from food industries and restaurants and in

some countries also there is a restriction to dump waste

cooking oil directly in land or in a river (Phan et al., 2008,

Misra et al. 2010). A single cylinder, 4 stroke, naturally

aspirated, direct injection, water cooled, rope brake

dynamometer assisted compression ignition engine was

used for testing of waste cooking oil and their blends.

These results were compared to petrodiesel for

comparison.

38.5

temperature range (60C). After reaction the FAME and

glycerol were collected in separate beaker. Scheme 1

shows an appropriate reaction in this regard (Kaplan et

al., 2006; Ulusoy et al., 2004, Prakash et al. 2013).

Experimental

Scheme 1. Transesterification of WCO

Materials

WCO, methanol (<99.9%, Merck), H2SO4 (98%, Merck)

and NaOH (99%, Merck) were used for chemical

reaction. WCO based s methyl ester was prepared

through transesterification process which turns WCO into

FAME and separated the glycerol with the presence of a

methanol, NaOH at 60C with one hour reaction

temperature. The glycerol was sinked to the bottom and

the biodiesel floats on the top can siphon off to the

reactor.

Preparation of WCO based methyl ester

Transesterification process is used for conversion of

triglycerides into esters(C etinkaya et. al., 2005, Dinesha

et al. 2012). Pretreated WCO from H2SO4, 200 ml (v/v) of

aqueous methanol (99+% pure) and 1% NaOH were

blended and stirred for one hour with a controlled

Physicochemical properties of petrodiesel and waste

cooking oil blends

Table 1 was shown the important physical and chemical

properties of biodiesel and its blends, petrodiesel and

palm oil was taken as a reference fuel. However, it was

indicated that WCO

is a potential substitute of

2

petrodiesel, but the viscosity ranging from 32 mm /sec

2

(waste cooking oil) to a maximum of 43 mm /sec (palm

oil) was considerably higher than petrodiesel, which

indicates that there is a need to bring the viscosity of oil

near to the petrodiesel either by physical or chemical

modification to convert it a perfect

substitute of

petrodiesel (Sukumar et. al., 2005; Shashikanth et. al.,

2005). Also the pour point of waste cooking oil was

higher to petrodiesel results difficult at low temperature

due to its solidification as compared to petrodiesel. So

Experimental investigation of four stroke single cylinder rope brake dynamometer assisted CI engine fueled with biodiesel from waste cooking oil

Int. Res. J. Power Energy Engin.

013

Table 2. Compression Ignition Engine test bed Specifications

Parameter

Specification

Make type

Kirloskar Engine

Bore

87.5 mm

Stroke

110 mm

Rated Output

5.2 KW at 1500 RPM

Rated Speed

1500 RPM

Loading Device

Rope Brake Dynamometer

Compression Ratio

17.5:1

Fuel tank capacity

Litre with measuring tube (045) ml

Air box

MS fabricated with orifice meter and manometer

Table 3. Technical Specifications of the gas analyzer used in this work

Measured quality

Measuring range

Resolution

Accuracy

CO:

0-10 % vol

0.01 % vol

<0.6 % vol: 0.03 % vol

0.6 % vol: 5% of ind. Val.

CO2:

0-20 % vol

0.1 % vol

<10 % vol: 0.5 % vol

10 % vol: 5% vol

HC:

0-20000 ppm vol

2000:1 ppm vol

>2000:10 ppm vol

<200 ppm vol: 10 ppm vol

200 ppm vol: 5% of ind.Val.

O2:

0-22 % vol

0.01 % vol

<2 % vol: 0.1 % vol

2 % vol: 5% of vol

NO:

0-5000 ppm vol

1 ppm vol

<500 ppm vol: 50 ppm vol

500 ppm vol: 10% of ind. Val.

Miscellaneous

Power

consumption:

Connector CAL.

Gas:

Connector

Gas

In:

Dimension

(WxDxH):

25 W

60-140 l/h, max. overpressure 450 hPa

180 l/h, max. overpressure 450 hPa

3

270320 x 85 mm

the chemical modification was required to overcome this

type of difficulties (Kiakalaieh et al., 2013).

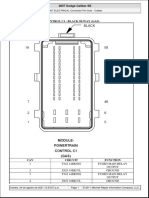

Experimental set-up (CI engine test rig)

A four stroke, single cylinder, direct injection, naturally

aspirated diesel engine was employed to carry out such

investigation. Table 2 was shown the detailed

specifications of the CI engine test rig. In this test setup

all the data were recorded manually and used the

appropriate relations to calculate performance of CI

enfine. The detailed description is give in section 2.5 for

analysis.

The AVL diGas 444 analyzer exhaust gas analyzer was

used to determine the concentration of CO, HC and NO x.

The technical specifications of the gas analyzer are given

in Table 3. The procedure of gas analyzer is approved by

Ministry of Road Transport and Highways, Government of

Experimental investigation of four stroke single cylinder rope brake dynamometer assisted CI engine fueled with biodiesel from waste cooking oil

Kumar H.

014

Figure 1. Compression Ignition Engine test rig. assisted with a rope brake type dynamometer

India, and specified in MoRTH/ CMVR/TAP-115/116,

Issue No. 3, Part-VIII. The AVL diGas 444 analyzer sucks

the exhaust gases and after that the analyzer shows the

different component of the exhaust recorded manually.

If the balance reading exceeds 20kg then the additional

dead weight of 10kg was placed on the hanger. The

balance reading was added with 10kg to find the total

weight.

Experimental procedure for testing

RESULTS AND DISCUSSION

The following procedure was followed to calculate the

brake specific fuel consumption, brake thermal efficiency

of the CI engine fuelled with WCO based biodiesel and its

blends are given in equation 2 and 3. The experimental

setup for determining the performance and emission

parameters are shown in figure 1. The protocol for

calculating the engine performance and emission

characteristics is listed below.

The rope brake dynamometer was coupled with

the crankshaft of CI engine properly on a suitable bed.

The Rope was fixed with the hanger (with a dead

weight) to the hook. (Once this hanger is fixed, it need

not to be removed, it can stay there permanently.)

A hand wheel is used to adjust the balance, so

that the pointer reads zero on the balance.

After that CI engine was started and bring up to

steady state.

Open the gates slowly by rotating the hand wheel

OPEN direction. There was a lock on the top gear

wheel.

Take reading in the balance.

Measure the speed of the rotation by

speedometer. At last used these values in equation 1,2

and 3 for brake thermal efficiency and brake specific fuel

consumption measurement.

Where S1= spring balance reading (kg), S2= spring

balance reading (kg)

Reff = effective radius of brake drum = (D+d)/2

D= brake drum diameter(mm),

d= rope

diameter(mm)

N= RPM

The tests were conducted at the rated speed of 1500

RPM and varying loads. The experimental data were

documented and presented using appropriate graphs.

These tests were aimed to optimized the concentration of

biodiesel in the petrodiesel blend for long-term engine

operation. In each experiment, engine parameters related

to the performance of CI engine such as BSFC and BTE

on different loads were measured for B10, B20 and B50.

These results were compared to petrodiesel for

comparison. A Notification Bxx represents the percentage

of ester (xx %) used in the mixture and D- Base is used

for petrodiesel (Kumar et al., 2015)

Brake specific fuel consumption

The variation of brake specific fuel consumption with

shaft load for different fuel blends were measured in the

present analysis and shown in the figure 2(a). For

different fuel blends, brake specific fuel consumption was

found to decrease with increase of shaft load. This is due

to increase in brake power with respect to the load. For

B10 and B20, the BSFC was comparable with

petrodiesel for all engine loads. At maximum load

condition, the specific fuel consumption of B50 was 6%

higher than petrodiesel. It was low due to the high

heating value of biodiesel and it was recorded that the

HHV was 14% lower than petrodiesel. With the increase

of biodiesel percentage in blends, the calorific value of

fuel was decreased. Hence the BSFC for higher

percentage of biodiesel blends were increased as

compared to petrodiesel.

Experimental investigation of four stroke single cylinder rope brake dynamometer assisted CI engine fueled with biodiesel from waste cooking oil

Int. Res. J. Power Energy Engin.

015

7

6

BSFC

Kg/KW

h

5

B10

B20

B50

D- Base

1

0

20

40

60

80

100

% Load

Figure 2 (a) Variation in brake specific fuel consumption for different blends with respect to load

45

40

35

% bte

30

B10

25

B20

20

B50

15

D- Base

10

5

0

20

40

60

80

100

% Load

Figure 2 (b). Variation in brake thermal efficiency for different blends with respect to load

Brake thermal efficiency:

EMISSION ANALYSIS

The variation of bte with respect to engine load for

different fuel blends were measured in the present

analysis and shown in the figure 2(b). For every test fuel

the bte was increased for increased engine load. This

was due to better combustion of fuel as per load

increased. The maximum bte was obtained 32.5% for

B10 and 32.2% for B20, quite higher to petrodiesel

(32%). The maximum bte for B50 was 25.7%. It was

concluded that bte was increased up to B20 and after that

it decreased. This was due to the oxygenated quality of

biodiesel. Also the lower bte was obtained for B50 was

due to a reduction in HHV results increases the fuel

consumption as compared to B10.

USA was the first country to start the control of air

pollution to vehicle in 1964. After that, all countries had

started a large number of regulations in forms of

standards to protect the environment. Euro 6 is the latest

emission standard implemented in most of countries

across the world. Keeping this figure in mind, an emission

analysis was carried out (Pugazhvadivu et al., 2005;

Muralidharan et al., 2011) and AVL diGas 444 analyzer

was used to determine the amount of pollutants in the

exhaust gases through CI engine.

During this

investigation, the major pollutants such as carbon mono

oxide (CO), unburnt hydrocarbon (UHC) and oxides of

nitrogen (NOx) were studied. This study was found the

Experimental investigation of four stroke single cylinder rope brake dynamometer assisted CI engine fueled with biodiesel from waste cooking oil

Kumar H.

016

45

40

35

% bte

30

B10

25

B20

20

B50

15

D- Base

10

5

0

20

40

60

80

100

% Load

Figure 2(b) Variation in brake thermal efficiency for different blends with respect to load

12

(a)

10

8

UHC

(ppm)

B10

6

B20

B50

D- Base

0

20

40

60

80

100

% Load

Figure 3 (a) Variation in Unburnt hydrocarbons for different blends with respect to load

most suitable blend for less pollution to CI engine with

respect to petrodiesel (Singh et al., 2015).

Unburnt hydrocarbon emission (UHC)

The deviation in UHC with respect to engine load for

different fuel blends were considered in the present

analysis and shown in the figure 3(a). UHC is produced

due to incomplete combustion during combustion also it

is the unburnt part of fuel exhausted into atmosphere

during exhaust stroke in CI engine. Unburnt hydrocarbon

was also less in case of biodiesel and its blends due to

oxygenated fuel and for B50 emission was higher due to

less calorific value.

Carbon Monoxide emission (CO)

The variation in CO with respect to load for different fuel

blends are considered in the present analysis and shown

in the figure 3(b). Carbon mono oxide was a transitional

combustion product and is generally formed due to the

lack of oxygen and incomplete combustion of fuel. If

combustion completed, CO will convert into CO 2. If the

combustion is incomplete due to shortage of air or due to

lower gas temperature, CO will formed. Usually high CO

emissions formed by rich mixtures of fuel with air, but as

petrodiesel combustion occurs with lean mixture then CO

emission from petrodiesel combustion were low. For all

blending categories CO is increased only with B50

Experimental investigation of four stroke single cylinder rope brake dynamometer assisted CI engine fueled with biodiesel from waste cooking oil

Int. Res. J. Power Energy Engin.

because of low calorific value of the fuel and due to this

the combustion should be incomplete. Because biodiesel

is a high oxygenated fuel, then for low blending like B10

and B20, the combustion should be complete and CO will

convert into CO2.

Oxides of nitrogen emission (NOx)

The variation of NOX with respect to load for different fuel

blends was considered in the present analysis and

shown in the figure 3(c). NOX is formed by chain

reactions involving nitrogen and oxygen in the air. These

reactions are highly temperature dependent. NO x

emissions were mainly as a function of gas temperature.

NOX was always become high in case of biodiesel

because biodiesel is an oxygenated fuel and due to this

the combustion temperature was always become high.

NOX was low in case of B50 because the combustion was

not complete and due to this temperature does not get in

high scale.

CONCLUSION

From the results it is clear that waste cooking oil based

methyl ester has a potential for biodiesel production and

application. Also the kinematic viscosity and density of

waste cooking oil based methyl ester blends were found

very close to petrodiesel. The lower concentrations of

biodiesel blends were found to improve the brake thermal

efficiency and emission of CI engine. B10 blends were

shown improvement in brake thermal efficiency of CI

engine to petrodiesel about 1.8% on full load condition.

Also brake specific fuel consumption was found

comparable for B20 with respect to petrodiesel. CO and

HC were also reduced due to complete combustion and

NOx was increased due to high combustion temperature.

The present experimental results were supported that

B20 methyl esters of waste cooking oil were successfully

used in existing CI engines without any modification. So

the biodiesel as a partial petrodiesel substitute can boost

the farm machinery need, reduce uncertainty of fuel

availability and more self-reliant. Also, this will helpful in

controlling of air pollution to a great extent.

ACKNOWLEDGMENTS

The author Himansh Kumar acknowledges Teerthanker

Mahaveer University, UP for giving waste cooking oil and

financial support and Apex Institute of technology, UP for

providing testing facility.

REFERENCES

Alamu OJ, Waheed MA , Jekayinfa SO (2007). Biodiesel

production from Nigerian palm kernel oil: effect of KOH

017

concentration

yield,

Energy

for

Sustainable

Development, 6;3.

Buyukkaya E (2010). Effects of biodiesel on a DI diesel

engine performance, emission and combustion

characteristics. Fuel, 89(30): 99105.

C etinkaya M, Ulusoy Y, Tekin Y, Kapaosmanoglu F

(2005). Engine and winter road test performances of

used cooking oil originated biodiesel. Energy

Conversion Management, 46:12791291.

Dinesha P, Mohanan P (2012). Experimental

Inverstigation on the performance and emissions

characteristics of diesel engine using preheated

pongamia methyl easter as fuel, International Journal of

Advances in Engineering & Technology.

Kaplan C, Arslan R, Surmen A (2006). Performance

characteristics of sunflower methyl esters as biodiesel.

Energy Source Part A 28:751755.

Kiakalaieh AT, Amin NAS., Mazaheri H (2013). A review

on novel processes of biodiesel production from waste

cooking oil. Appl Energy,104: 683710.

Kumar H, Yadav KY, Sarma KA (2015). Performance and

Emission Characteristics of CI Engine Fueled with

Alternative Fuel with Special Reference to Modification

for Combustion: A Literature Review. Springer

Proceedings in Energy, DOI 10.1007/978-81-322-27731_14.

Misra RD, Murthy MS (2010). Straight vegetable oils

usage in a compression ignition engine- A review.

Renewable and Sustainable Energy Reviews 14:

30053013.

Muralidharan K, Vasudevan D (2011). Performance,

emission and combustion characteristics of a variable

compression ratio engine using methyl esters of waste

cooking oil and diesel blends. Applied Energy

88(11):395968.

Prakash R, Singh RK, Murugan S (2013). Utilization of

Biomass Based Fuel in a Naturally Aspirated Diesel

Engine. Procedia Engineering 51: 501 507.

Patil PD, Gude VG (2012). Biodiesel Production from

Waste Cooking Oil Using Sulfuric Acid and Microwave

Irradiation Processes, Journal of Environmental

Protectio, 107113.

Subramaniam D, Murugesan A, Avinash A, Kumaravel A

(2013). Biodiesel production and its engine

characteristicsAn expatiate view. Renewable and

Sustainable Energy Reviews 22: 361370.

Sukumar P, Vedaraman N, Boppana VB, Ram

Shankaranarayanan G, Jaychandran K (2005). Mahua

Oil (Madhuca Indica Seed Oil) Methyl Ester as Bio

Diesel- preparation and Emission Characteristics,

Elsevier, Biomass & Bio Energy, Vol. 28, pp. 87-93.

Shashikanth VG, Raheman H (2005). Biodiesel

Production from Mahua (Madhuca Indica Oil) Having

High Free Fatty Acids, Biomass & Bio energy, Vol. 28,

pp. 601-605.

Salmani MH, Sharma RC, Kumar H, Dhingra M (2015).

Effect of used transformer oil on efficiency of

Compression Ignition Engine, International Journal For

Experimental investigation of four stroke single cylinder rope brake dynamometer assisted CI engine fueled with biodiesel from waste cooking oil

Kumar H.

018

Technological Research In Engineering, Vol.2, Issue 7.

Singh N, Kumar H, Jha MK, Sarma AK (2015) Complete

heat balance, performance, and emission evaluation of

a CI engine fueled with Mesua ferrea methyl and ethyl

esters blends with petroldiesel. J Therm Anal Calorim

2015. doi:10.1007/s10973-015-4777-8

Accepted 19 June, 2016

Citation: Kumar H (2016). Experimental investigation of

four stroke single cylinder rope brake dynamometer

assisted CI engine fueled with biodiesel from waste

cooking oil. International Research Journal of Power and

Energy Engineering, 2(1): 012-018.

Copyright: 2016. Kumar H. This is an open-access

article distributed under the terms of the Creative

Commons Attribution License, which permits unrestricted

use, distribution, and reproduction in any medium,

provided the original author and source are cited.

Experimental investigation of four stroke single cylinder rope brake dynamometer assisted CI engine fueled with biodiesel from waste cooking oil

Você também pode gostar

- Gas TurbineDocumento6 páginasGas TurbineAditya GuptaAinda não há avaliações

- REVIEW PAPE Bhavdip RaningaDocumento12 páginasREVIEW PAPE Bhavdip RaningaViraj ParmarAinda não há avaliações

- Ab 02417411746Documento6 páginasAb 02417411746IJMERAinda não há avaliações

- Performance and Emission Characteristics of Ci Engine Using Cerium Oxide Nanoparticle With Water Diesel EmulsionDocumento12 páginasPerformance and Emission Characteristics of Ci Engine Using Cerium Oxide Nanoparticle With Water Diesel EmulsionTJPRC PublicationsAinda não há avaliações

- D.I Engne ManuscriptDocumento12 páginasD.I Engne ManuscriptChandramanikandanAinda não há avaliações

- Evaluating Performance and Emissions of Ci Engine Run by Blends of Mosambi Peel Methyl Ester and Diesel FuelDocumento8 páginasEvaluating Performance and Emissions of Ci Engine Run by Blends of Mosambi Peel Methyl Ester and Diesel FuelTJPRC PublicationsAinda não há avaliações

- Experimental Investigations On Single Cylinder 4-Stroke Diesel Engine Using NanofuelsDocumento5 páginasExperimental Investigations On Single Cylinder 4-Stroke Diesel Engine Using NanofuelsT Hari PrasadAinda não há avaliações

- Seminar Report On Bio-Diesel: (In Partial Fulfilment To B.Tech Degree From MMEC, Mullana.)Documento9 páginasSeminar Report On Bio-Diesel: (In Partial Fulfilment To B.Tech Degree From MMEC, Mullana.)Karan TandonAinda não há avaliações

- Research ArticleDocumento12 páginasResearch Articlemert tıglıAinda não há avaliações

- Project Phase 2Documento18 páginasProject Phase 2Keerthana LAinda não há avaliações

- Effect of Piston Bowl Geometry On The Performance of ADocumento9 páginasEffect of Piston Bowl Geometry On The Performance of AMuhammad RonaldoAinda não há avaliações

- Effect of Supercharging On Engine PerformanceDocumento13 páginasEffect of Supercharging On Engine PerformanceanshurathoreAinda não há avaliações

- Performance and Emission Study of Mahua Oil (Madhuca Indica Oil) Ethyl Ester in A 4-Stroke Natural Aspirated Direct Injection Diesel EngineDocumento10 páginasPerformance and Emission Study of Mahua Oil (Madhuca Indica Oil) Ethyl Ester in A 4-Stroke Natural Aspirated Direct Injection Diesel EnginebalakaleesAinda não há avaliações

- Power and Torque Characteristics of Diesel Engine Fuelled by Palm-Kernel Oil BiodieselDocumento8 páginasPower and Torque Characteristics of Diesel Engine Fuelled by Palm-Kernel Oil BiodieselLawrence TanAinda não há avaliações

- Performance Combustion and Emission Characteristics On DI Diesel Engine Using Bio AdditiveDocumento6 páginasPerformance Combustion and Emission Characteristics On DI Diesel Engine Using Bio AdditiveSetiyo WibisonoAinda não há avaliações

- Impact of Ignition Enhancer On Performance and Emission Characteristics of Biodiesel Butanol Blends in Di-Diesel EngineDocumento5 páginasImpact of Ignition Enhancer On Performance and Emission Characteristics of Biodiesel Butanol Blends in Di-Diesel EnginegurusamyAinda não há avaliações

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocumento9 páginasResearch Journal of Pharmaceutical, Biological and Chemical Sciences1307114613 Handerson PanjaitanAinda não há avaliações

- Effect of Pyrogallol As An AntioxidantDocumento8 páginasEffect of Pyrogallol As An AntioxidantRegina ChristiantyAinda não há avaliações

- Addition of Nanoparticles With Diesel Fuel For Improving The Performance of EngineDocumento12 páginasAddition of Nanoparticles With Diesel Fuel For Improving The Performance of EngineaAinda não há avaliações

- Karanja OilDocumento16 páginasKaranja OilM tejaswiniAinda não há avaliações

- Ijmet: ©iaemeDocumento11 páginasIjmet: ©iaemeIAEME PublicationAinda não há avaliações

- Exhaust Emission Analysis of Diesel Engine Running on 20% Blends of Mahua BiodieselDocumento5 páginasExhaust Emission Analysis of Diesel Engine Running on 20% Blends of Mahua Biodieselbalasubramanian979Ainda não há avaliações

- Performance and Emission Characteristics of Compression Ignition (CI) Engine With Dual Fuel Operation (Diesel + Compressed Natural Gas (CNG) )Documento6 páginasPerformance and Emission Characteristics of Compression Ignition (CI) Engine With Dual Fuel Operation (Diesel + Compressed Natural Gas (CNG) )Mochammad Waris SAinda não há avaliações

- Characterization of Mahua Methyl Ester in DI Diesel EngineDocumento7 páginasCharacterization of Mahua Methyl Ester in DI Diesel EngineIJAERS JOURNALAinda não há avaliações

- 2012 BP Pattanaik Et Al. Performance & Emission Studies On A Single Cylinder DI Diesel Engine Fueled With Diesel and Rice Bran Oil Methyl Ester BlendsDocumento9 páginas2012 BP Pattanaik Et Al. Performance & Emission Studies On A Single Cylinder DI Diesel Engine Fueled With Diesel and Rice Bran Oil Methyl Ester BlendsBP PattanaikAinda não há avaliações

- 149 Ijmperdfeb2018149Documento12 páginas149 Ijmperdfeb2018149TJPRC PublicationsAinda não há avaliações

- Engine CharacteristicsDocumento7 páginasEngine Characteristicss sivaAinda não há avaliações

- 231 JT339Documento5 páginas231 JT339Vinoth Kumar VinsAinda não há avaliações

- 1 s2.0 S2214785317323489 MainDocumento7 páginas1 s2.0 S2214785317323489 MainBalaji BhukyaAinda não há avaliações

- 138 Ijmperdfeb2018138Documento10 páginas138 Ijmperdfeb2018138TJPRC PublicationsAinda não há avaliações

- Experimental Study On The Effects of Injection Timing Using Reuse of Waste Energy As A Fuel On A Diesel EngineDocumento9 páginasExperimental Study On The Effects of Injection Timing Using Reuse of Waste Energy As A Fuel On A Diesel EngineIJRES teamAinda não há avaliações

- Conversão de Nergia 2Documento6 páginasConversão de Nergia 2Ricardo PereiraAinda não há avaliações

- Methanol Mix Diesel - Yusaf - Hamawand - Baker - Najafi - PVDocumento11 páginasMethanol Mix Diesel - Yusaf - Hamawand - Baker - Najafi - PVasep saefullohAinda não há avaliações

- Artificial Neural Network Optimization Modeling OnDocumento16 páginasArtificial Neural Network Optimization Modeling OnWan NurdyanaAinda não há avaliações

- Studying The Effect of Compression Ratio On An Engine Fueled With Waste Oil Produced Biodiesel/diesel FuelDocumento11 páginasStudying The Effect of Compression Ratio On An Engine Fueled With Waste Oil Produced Biodiesel/diesel FuelSuresh ThillaiAinda não há avaliações

- Ijmet: ©iaemeDocumento11 páginasIjmet: ©iaemeIAEME PublicationAinda não há avaliações

- Performance and Emissions of a Single Cylinder CI Engine Running on Corn Oil Methyl Ester-Diesel BlendsDocumento5 páginasPerformance and Emissions of a Single Cylinder CI Engine Running on Corn Oil Methyl Ester-Diesel BlendsAnonymous kbBcnLXCZAinda não há avaliações

- The Optimization of The Esterification Reaction in BiodieselDocumento12 páginasThe Optimization of The Esterification Reaction in BiodieselPablo PaganiAinda não há avaliações

- Performance Analysis of Diesel Engine Using Hazel Nut Biodiesel With AntioxidantsDocumento8 páginasPerformance Analysis of Diesel Engine Using Hazel Nut Biodiesel With AntioxidantsTJPRC PublicationsAinda não há avaliações

- Effect of Waste Cooking Oil Biodiesel On The EmissDocumento4 páginasEffect of Waste Cooking Oil Biodiesel On The EmissRezi OktaviandriAinda não há avaliações

- 9.IJAEST Vol No 5 Issue No 1 Comparisons of Diesel Performance Neat and Preheated Transesterfied Cotton Seed Oil 067 071Documento5 páginas9.IJAEST Vol No 5 Issue No 1 Comparisons of Diesel Performance Neat and Preheated Transesterfied Cotton Seed Oil 067 071iserpAinda não há avaliações

- Jurnal Petrokimia Ivan AbrorDocumento10 páginasJurnal Petrokimia Ivan AbrorMuhamad Ivan AbrorAinda não há avaliações

- International Energy Journal PAPER Dual Biodiesel For Diesel EnginesDocumento14 páginasInternational Energy Journal PAPER Dual Biodiesel For Diesel EnginesAnonymous TPwGA2SAinda não há avaliações

- BiodieselpaperDocumento7 páginasBiodieselpaperSurahmanAinda não há avaliações

- Evaluating Pongamia biodiesel performance in diesel enginesDocumento6 páginasEvaluating Pongamia biodiesel performance in diesel enginesSetiyo WibisonoAinda não há avaliações

- Performance and Emission Analysis of Compression Ignition Engine in Dual Fuel Mode Using Rice Bran Biodiesel and LPGDocumento7 páginasPerformance and Emission Analysis of Compression Ignition Engine in Dual Fuel Mode Using Rice Bran Biodiesel and LPGAJER JOURNALAinda não há avaliações

- Coneference PaperDocumento8 páginasConeference PaperSeshaiah TurakaAinda não há avaliações

- Venkatesh and BhaghaviDocumento10 páginasVenkatesh and BhaghavilarryAinda não há avaliações

- Alternative Fuel Properties of Tall Oil Fatty Acid Methyl Ester-Diesel Fuel BlendsDocumento6 páginasAlternative Fuel Properties of Tall Oil Fatty Acid Methyl Ester-Diesel Fuel BlendsericconchamunozAinda não há avaliações

- Performance of CI Engine Using Soapnut BiodieselDocumento7 páginasPerformance of CI Engine Using Soapnut BiodieselVaibhav MoonAinda não há avaliações

- Experimental Investigation of Performance and Emission Characteristics of Diesel Engine With Jatropha Biodiesel BlendsDocumento4 páginasExperimental Investigation of Performance and Emission Characteristics of Diesel Engine With Jatropha Biodiesel BlendserpublicationAinda não há avaliações

- KenafDocumento4 páginasKenafNikhil NambiarAinda não há avaliações

- Process Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineDocumento3 páginasProcess Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineSivakumarAinda não há avaliações

- BiodieselDocumento25 páginasBiodieselmano19me019Ainda não há avaliações

- JurnalDocumento10 páginasJurnalMeriAinda não há avaliações

- I Amm 787 761Documento7 páginasI Amm 787 761YUVARAJAN DAinda não há avaliações

- Performance Comparison of 4-Stroke Multi-Cylinder CI-Engine Using Neem Biodiesel and Diesel As FuelDocumento7 páginasPerformance Comparison of 4-Stroke Multi-Cylinder CI-Engine Using Neem Biodiesel and Diesel As FuelnityamAinda não há avaliações

- E-AEC-011365: Feasibility Study of Using High Butanol-Diesel Blends in Commonrail EngineDocumento9 páginasE-AEC-011365: Feasibility Study of Using High Butanol-Diesel Blends in Commonrail EngineJoel ParrAinda não há avaliações

- 119 Ijmperdfeb2018119Documento8 páginas119 Ijmperdfeb2018119TJPRC PublicationsAinda não há avaliações

- Evaluation of Agro-Morphological Performances of Hybrid Varieties of Chili Pepper (Capsicum Frutescens L.) in Northern BeninDocumento9 páginasEvaluation of Agro-Morphological Performances of Hybrid Varieties of Chili Pepper (Capsicum Frutescens L.) in Northern BeninPremier PublishersAinda não há avaliações

- Influence of Nitrogen and Spacing On Growth and Yield of Chia (Salvia Hispanica) in Meru County, KenyaDocumento10 páginasInfluence of Nitrogen and Spacing On Growth and Yield of Chia (Salvia Hispanica) in Meru County, KenyaPremier PublishersAinda não há avaliações

- Causes, Consequences and Remedies of Juvenile Delinquency in The Context of Sub-Saharan Africa: A Study of 70 Juvenile Delinquents in The Eritrean Capital, Asmara.Documento20 páginasCauses, Consequences and Remedies of Juvenile Delinquency in The Context of Sub-Saharan Africa: A Study of 70 Juvenile Delinquents in The Eritrean Capital, Asmara.Premier PublishersAinda não há avaliações

- Influence of Harvest Stage On Yield and Yield Components of Orange Fleshed Sweet Potato (Ipomoea Batatas (L) Lam) at Adami Tullu, Central Rift Valley of EthiopiaDocumento14 páginasInfluence of Harvest Stage On Yield and Yield Components of Orange Fleshed Sweet Potato (Ipomoea Batatas (L) Lam) at Adami Tullu, Central Rift Valley of EthiopiaPremier PublishersAinda não há avaliações

- Improving The Efficiency of Ratio Estimators by Calibration WeightingsDocumento9 páginasImproving The Efficiency of Ratio Estimators by Calibration WeightingsPremier PublishersAinda não há avaliações

- Gender Analysis of Healthcare Expenditures in Rural NigeriaDocumento13 páginasGender Analysis of Healthcare Expenditures in Rural NigeriaPremier PublishersAinda não há avaliações

- Evaluation and Demonstration of Irrigation Regime On Hot Pepper (Capsicum Annuum L.) in Benna-Tsemay Woreda, Southern EthiopiaDocumento6 páginasEvaluation and Demonstration of Irrigation Regime On Hot Pepper (Capsicum Annuum L.) in Benna-Tsemay Woreda, Southern EthiopiaPremier PublishersAinda não há avaliações

- Enhancing Social Capital During The Pandemic: A Case of The Rural Women in Bukidnon Province, Southern PhilippinesDocumento10 páginasEnhancing Social Capital During The Pandemic: A Case of The Rural Women in Bukidnon Province, Southern PhilippinesPremier PublishersAinda não há avaliações

- Impact of Provision of Litigation Supports Through Forensic Investigations On Corporate Fraud Prevention in NigeriaDocumento8 páginasImpact of Provision of Litigation Supports Through Forensic Investigations On Corporate Fraud Prevention in NigeriaPremier Publishers100% (1)

- Multivariate Analysis of Tea (Camellia Sinensis (L.) O. Kuntze) Clones On Morphological Traits in Southwestern EthiopiaDocumento8 páginasMultivariate Analysis of Tea (Camellia Sinensis (L.) O. Kuntze) Clones On Morphological Traits in Southwestern EthiopiaPremier PublishersAinda não há avaliações

- Effect of Phosphorus and Zinc On The Growth, Nodulation and Yield of Soybean (Glycine Max (L.) Merrill)Documento11 páginasEffect of Phosphorus and Zinc On The Growth, Nodulation and Yield of Soybean (Glycine Max (L.) Merrill)Premier PublishersAinda não há avaliações

- Ijpher: Research ArticleDocumento9 páginasIjpher: Research ArticlePremier PublishersAinda não há avaliações

- Response of Hot Pepper (Capsicum Annuum L.) To Deficit Irrigation in Bennatsemay Woreda, Southern EthiopiaDocumento7 páginasResponse of Hot Pepper (Capsicum Annuum L.) To Deficit Irrigation in Bennatsemay Woreda, Southern EthiopiaPremier PublishersAinda não há avaliações

- Performance Evaluation of Upland Rice (Oryza Sativa L.) and Variability Study For Yield and Related Traits in South West EthiopiaDocumento5 páginasPerformance Evaluation of Upland Rice (Oryza Sativa L.) and Variability Study For Yield and Related Traits in South West EthiopiaPremier PublishersAinda não há avaliações

- Influence of Conferences and Job Rotation On Job Productivity of Library Staff in Tertiary Institutions in Imo State, NigeriaDocumento6 páginasInfluence of Conferences and Job Rotation On Job Productivity of Library Staff in Tertiary Institutions in Imo State, NigeriaPremier PublishersAinda não há avaliações

- Harnessing The Power of Agricultural Waste: A Study of Sabo Market, Ikorodu, Lagos State, NigeriaDocumento7 páginasHarnessing The Power of Agricultural Waste: A Study of Sabo Market, Ikorodu, Lagos State, NigeriaPremier PublishersAinda não há avaliações

- Scanning Electron Microscopic Structure and Composition of Urinary Calculi of Geriatric DogsDocumento7 páginasScanning Electron Microscopic Structure and Composition of Urinary Calculi of Geriatric DogsPremier PublishersAinda não há avaliações

- Transcript Level of Genes Involved in "Rebaudioside A" Biosynthesis Pathway Under Gibberellic Acid Treatment in SteviaDocumento5 páginasTranscript Level of Genes Involved in "Rebaudioside A" Biosynthesis Pathway Under Gibberellic Acid Treatment in SteviaPremier PublishersAinda não há avaliações

- Gentrification and Its Effects On Minority Communities - A Comparative Case Study of Four Global Cities: San Diego, San Francisco, Cape Town, and ViennaDocumento24 páginasGentrification and Its Effects On Minority Communities - A Comparative Case Study of Four Global Cities: San Diego, San Francisco, Cape Town, and ViennaPremier PublishersAinda não há avaliações

- Oil and Fatty Acid Composition Analysis of Ethiopian Mustard (Brasicacarinataa. Braun) LandracesDocumento11 páginasOil and Fatty Acid Composition Analysis of Ethiopian Mustard (Brasicacarinataa. Braun) LandracesPremier PublishersAinda não há avaliações

- Assessment of Experts' Opinion On Irish Potato Farmers Perceptions About Climate Change and The Use of Climate Smart Agriculture Adaptation Strategies in KenyaDocumento11 páginasAssessment of Experts' Opinion On Irish Potato Farmers Perceptions About Climate Change and The Use of Climate Smart Agriculture Adaptation Strategies in KenyaPremier PublishersAinda não há avaliações

- Antibiogram of Bacteria Isolated From Wounds of Diabetic Patients On Admission at Federal Medical Centre, Owerri, Imo State, NigeriaDocumento7 páginasAntibiogram of Bacteria Isolated From Wounds of Diabetic Patients On Admission at Federal Medical Centre, Owerri, Imo State, NigeriaPremier PublishersAinda não há avaliações

- Postharvest Loss Assessment of Banana at Jimma Town Market.Documento8 páginasPostharvest Loss Assessment of Banana at Jimma Town Market.Premier PublishersAinda não há avaliações

- Urban Liveability in The Context of Sustainable Development: A Perspective From Coastal Region of West BengalDocumento15 páginasUrban Liveability in The Context of Sustainable Development: A Perspective From Coastal Region of West BengalPremier PublishersAinda não há avaliações

- PDFTrade Liberalization and Agriculture Sector Trade Balance in Cameroon: Need For Policy ReformDocumento10 páginasPDFTrade Liberalization and Agriculture Sector Trade Balance in Cameroon: Need For Policy ReformPremier PublishersAinda não há avaliações

- Role of Organic and Inorganic Fertilizers On The Performance of Some Medicinal PlantsDocumento8 páginasRole of Organic and Inorganic Fertilizers On The Performance of Some Medicinal PlantsPremier PublishersAinda não há avaliações

- Spatio-Temporal Dynamics of Climatic Parameters in TogoDocumento19 páginasSpatio-Temporal Dynamics of Climatic Parameters in TogoPremier PublishersAinda não há avaliações

- Use of Orange Fleshed Sweet Potato (Ipomoea Batatas (L) Lam) To Combat Vitamin A Deficiency.Documento6 páginasUse of Orange Fleshed Sweet Potato (Ipomoea Batatas (L) Lam) To Combat Vitamin A Deficiency.Premier PublishersAinda não há avaliações

- "Land Consolidation" As A Solution For Rural Infrastructure ProblemsDocumento9 páginas"Land Consolidation" As A Solution For Rural Infrastructure ProblemsPremier PublishersAinda não há avaliações

- Occurrence and Extent of Fusarium Head Blight On Wheat Cultivars in SomaliaDocumento8 páginasOccurrence and Extent of Fusarium Head Blight On Wheat Cultivars in SomaliaPremier PublishersAinda não há avaliações

- VS1-2 Manual PDFDocumento284 páginasVS1-2 Manual PDFJorge InostrozaAinda não há avaliações

- Aufbau PrincipleDocumento4 páginasAufbau PrinciplecrbrumaAinda não há avaliações

- 50 Straw Bale House PlansDocumento9 páginas50 Straw Bale House Plansdarius-matuiza-81990% (1)

- Current Transformer - Electrical Notes & ArticlesDocumento47 páginasCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- Caliber Modulo PCM PinoutDocumento7 páginasCaliber Modulo PCM PinoutManuel Suarez100% (3)

- Microcontroller-Based Power Monitoring for COE RoomsDocumento8 páginasMicrocontroller-Based Power Monitoring for COE Roomskenneth_molenilla1475Ainda não há avaliações

- Transport Phenomena: Instructor: Assistant Professor Department of Chemical Engineering, BUET, Dhaka-1000Documento21 páginasTransport Phenomena: Instructor: Assistant Professor Department of Chemical Engineering, BUET, Dhaka-1000touhidAinda não há avaliações

- EE 004A DC and AC Machinery ExperimentDocumento9 páginasEE 004A DC and AC Machinery ExperimentJerome NuevoAinda não há avaliações

- LT AB Cable GTPsDocumento3 páginasLT AB Cable GTPsnishant sainiAinda não há avaliações

- TriPac EVOLUTION 55711-19-OPDocumento52 páginasTriPac EVOLUTION 55711-19-OPRodrigo Hernandez100% (1)

- Aviation Tinning and SolderingDocumento16 páginasAviation Tinning and SolderingRebecca RiversAinda não há avaliações

- 6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHDocumento22 páginas6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHsrikanthc8550% (2)

- Edexcel - IAS - Group 2 and Group 7 - 1Documento21 páginasEdexcel - IAS - Group 2 and Group 7 - 1mostafa barakatAinda não há avaliações

- AC TO AC Write UpsDocumento7 páginasAC TO AC Write UpsTin PelingonAinda não há avaliações

- 1Documento26 páginas1Maribel Bihag AlcantaraAinda não há avaliações

- Boundary Layer ThicknessDocumento23 páginasBoundary Layer ThicknessPridhar ThiagarajanAinda não há avaliações

- Siemens Actuator M3K20FXNDocumento10 páginasSiemens Actuator M3K20FXNbasil christopherAinda não há avaliações

- VXA 700 Owner ManualDocumento68 páginasVXA 700 Owner ManualjohnAinda não há avaliações

- Production Range: EUROPIPE. The World Trusts UsDocumento8 páginasProduction Range: EUROPIPE. The World Trusts UsIslam-Lotfi Hadj-ArabAinda não há avaliações

- LLG FaultDocumento8 páginasLLG Faultranjish_007Ainda não há avaliações

- Saudi Aramco Success Story (A4)Documento4 páginasSaudi Aramco Success Story (A4)raghu12421100% (1)

- LG Refridge ServiceManualDocumento79 páginasLG Refridge ServiceManualMichael Dianics100% (1)

- New Holland Cargador w170 B Tier III Na RepuestosDocumento555 páginasNew Holland Cargador w170 B Tier III Na Repuestosarmando vara chavez100% (2)

- Numatics Series 342Documento6 páginasNumatics Series 342Jebran FarazAinda não há avaliações

- Wiring Diagram FH, NH: GroupDocumento110 páginasWiring Diagram FH, NH: GroupStefan AslamAinda não há avaliações

- Q 1000Documento24 páginasQ 1000Fredy Vázquez VelázquezAinda não há avaliações

- Lab 5Documento9 páginasLab 5Cem UsmangilAinda não há avaliações

- Zaman of Chapter 1 - Introduction of HydraulicsDocumento35 páginasZaman of Chapter 1 - Introduction of HydraulicsFatin HazwaniAinda não há avaliações

- Budget of Lesson Science 9Documento14 páginasBudget of Lesson Science 9Hezl Valerie ArzadonAinda não há avaliações

- WCR For Canon Motor Relay FailureDocumento1 páginaWCR For Canon Motor Relay FailureIqmal WahabAinda não há avaliações