Escolar Documentos

Profissional Documentos

Cultura Documentos

Risk Assessment of A Post-Combustion and Amine-Based CO2 Capture Ready Process

Enviado por

scm996Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Risk Assessment of A Post-Combustion and Amine-Based CO2 Capture Ready Process

Enviado por

scm996Direitos autorais:

Formatos disponíveis

07/12/2014

Risk assessment of a post-combustion and amine-based CO2 Capture Ready Process

This is the html version of the file http://jsm.gig.eu/sites/default/files/articles/en/jsm_130404_full_text.pdf.

Google automatically generates html versions of documents as we crawl the web.

Page 1

Journal of Sustainable Mining

ISSN 2300-3960

The English-language online version (primary , reference version of J. Sust. Min.)

JOURNAL HOMEPAGE

jsm.gig.eu

J. Sust. Min. Vol. 12 (2013), No. 4, pp. 1823

http://dx.medra.org/10.7424/jsm130404

Received: 2013.11.19

Accepted: 2013.11.27

Available online: 2013.12.06

RISK ASSESSMENT OF A POST-COMBUSTION AND AMINE-BASED CO2

CAPTURE READY PROCESS

Alicja Krzemie1*, Angelika Wickol-Ryk1, Adam Duda2, Aleksandra Koteras 2

1

Department of Industrial Risk Assessment, Central Mining Institute (Katowice, Poland)

Central Mining Institute (Katowice, Poland)

* Corresponding author: e-mail: akrzemien@gig.eu, tel. +48 32 259 25 56, fax. +48 32 259 65 33

Abstract

CO2 Capture Ready Process, as a part of Carbon Capture and Storage (CCS) technology, is a response to international political pressure

and the priority of the European Commission to reduce anthropogenic CO2 emissions since it is connected with concerns regarding global

warming. T his is currently considered as an option for lessing CO2 emissions into the atmosphere. Many laboratory experiments, as well

as pilot projects, have been carried out using different capture systems, but until now no experience from the one-to-one size operational

installation has been gained. T he energy industry must meet several challenges associated with the start-up of the new full-scale project.

T his paper investigates the problems that can occur while linking a new technology like the CO2 Capture Ready Process to a working

fossil fuel power plant. A Hazard and Operability study (HAZOP) has been used, as it is a structured and systematic examination of

a planned or existing process or operation, in order to identify and evaluate problems that may represent risks to personnel or equipment.

A case study of a post-combustion CO2 capture system with an aqueous monoethanolamine as a solvent is presented, as it is the most

likely system to be used in Polish power plants. Basic problems in the analysis as well as the parameters that should be considered to

determine vulnerabilities of the process were successfully identified. Gaining experience about the installations behaviour while

connected to the existing equipment of any power plant is critical for future CCS projects.

Ke ywords

risk analysis, post-combustion, Carbon Capture Ready Process, HAZOP, amine

1. INTRODUCTION

The main objective of CO2 Capture Ready Process, as

a part of CCS technology, is to reduce carbon dioxide emissions into the atmosphere. M any projects that retrofit an

existing power plant with a CO2 Capture Ready Process in-

available from demonstration facilities, but those projects are

far too small to provide an answer regarding full-scale plant

problems. Gaining experience about the installations behaviour while connected to the existing equipment of any power

plant can be critical for future CO2 Capture Ready Process

http://webcache.googleusercontent.com/search?q=cache:http://jsm.gig.eu/sites/default/files/articles/en/jsm_130404_full_text.pdf

1/7

07/12/2014

Risk assessment of a post-combustion and amine-based CO2 Capture Ready Process

stallation are currently being conducted, among them a few

large pilot facilities (Global CCS Institute 2013) using different capture systems, but until now no experience from a full

size operational installation has been gained. Beginning

a new full-scale project seems to be a great challenge for the

energy industry. By building or modifying facilities to be

Capture Ready we are trying to reduce the amount of carbon

dioxide emissions using one of the three leading systems

for capturing CO2 from power generation, that is: precombustion, oxy-fuel combustion or post-combustion.

All new technologies should be investigated with special

care, considering that the lack of information regarding previous incidents or accidents may be a great challenge for an

evaluation team. Carrying out any study about CO2 Capture

Ready installation is time-consuming and very demanding

because it should be done with a stong emphasis on engineering details. The main problem is limited knowledge concerning some technical aspects of the full size installation. Data is

projects.

All this should

lead not Capture

only to identifying

problems

while constructing

and operating

Ready installations,

but also to evaluate the level of risk for any identified deviation, as well as to find credible ways in which they could be

overcome.

The main goal of the risk assessment is to identify all possible hazards that can appear within the system. They are not

only essential to the system itself, but also they may have

much wider influence, for example to the environment. Carrying out the research should give us an answer concerning

all possible operability problems within the system. This

seems to be quite demanding, especially considering that in

the first step of the study all relevant information about the

system must be carefully collected. Identifying hazards, analysing and evaluating the risks are the first steps towards

successfully managing risk. This is the way to eliminate

problems arising from the design or, in case it is impossible,

to reduce the magnitude of risks caused by them. Any organi-

Central Mining Institute 2013

Page 2

Alicja Krzemie et al. / J. Sust. Min. Vol. 12 (2013), No. 4, pp. 1823

zation has to establish its own risk criteria, based on the experience of its working team and some other external indicators

of possible hazards that may have the potential to cause negative consequences to the system. In this way unacceptable

risks can be found and consequently the right solutions can

be applied either by fundamental design changes or by

providing protection measures (M acdonald 2004).

2. RIS K AS S ES S MENT

Risk assessment is the first step to prevent incidents or accidents within technical processes. It is important to determine all possible deviations in the systems performance that

may lead to a risk (M acdonald 2004). This process can be

divided in three main steps: risk identification, risk analysis

and risk evaluation, being the most crucial part of the risk

management process as shown in Figure 1.

19

FTA should be used when focusing on specific problems

related to the technology, like the possibility of explosion,

fire or other critical events which may appear. When a detailed and comprehensive study is needed to guarantee that all

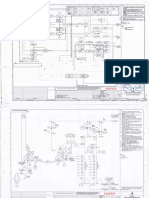

hazards, together with all deviations and operability problems, are identified and we have access to the technical information about the system like the Piping and Instrumentation Diagram (P&ID), then the best solution seems to be

HAZOP (BSI 61882 2001).

A systematic approach to the problem seems to be the biggest advantage of the HAZOP technique, known as a diagnostic tool from the late 1960s and still used for the identification of operational disturbances and deviations within the

systems. Over the years, the main HAZOP approach has not

changed, but the way of identifying potential operability

problems was developed by finding new applications within

many industries like power generation, mineral processing

and mining. HAZOP, if correctly applied, may indicate and

prevent possible deviations in the operation of a processing

plant, but can also cover unusual circumstances of the system

such as start-up, shutdown and plant maintenance. The first

step within the HAZOP study is to analyse the P&ID of the

process in order to divide it into specific portions called

nodes, where all parameters describing the system can be

identified. It is important to describe the essential features of

the plant items, to explain the intended methods of operations

and to prepare a process flow chart, so that the study team

can improve their understanding of the process dynamics.

This part of the study is crucial because any mistake at the

early stage of HAZOP can strongly influence the overall

analysis. The next step is to combine a series of guidewords

with each parameter to create deviations and to capture most

of the causes that may lead to risky situations. This is also

a good opportunity to identify the possible consequences of

http://webcache.googleusercontent.com/search?q=cache:http://jsm.gig.eu/sites/default/files/articles/en/jsm_130404_full_text.pdf

2/7

07/12/2014

Risk assessment of a post-combustion and amine-based CO2 Capture Ready Process

Figure 1. Contribution of risk assessment to the risk management process.

Based on ISO/IEC 31010 (2010) and PN-N-18002 (2011)

The most important step within the risk assessment process is to correctly choose an appropriate method to define

potential problems. The variety of techniques to identify

potential hazards is wide, from checklists to Preliminary

Hazard Analysis (PHA), Failure M ode and Effects Analysis

(FM EA), Fault Tree Analysis (FTA) and Hazard and Operability study (HAZOP), among others. Some of them are useful when there is not a lot information readily available about

the process. On the other hand, techniques like HAZOP require more information regarding the system under consideration (BSI 61882, 2001), being more detailed and time

consuming, but in some cases, especially when considering

a new technology, remaining indispensable in order to repel

threats to the success of a new project.

The right selection of the appropriate tool should be preceded by the definition of the main goal of each study. If

a less detailed analysis is needed and we have limited access

to information, a PHA may be the best solution, as it still

gives an overview of the problem and it is quite easy to conduct. If the nature of the process is under consideration then

FM EA is a good option, as it gives an answer regarding all

possible interactions between different parts of the system;

each deviation and to discuss among the evaluation team

safeguards and recommendations to prevent those events.

What is more visible at this stage of the study is that the result of HAZOP depends more upon the experience and attitudes of the team than on the procedures themselves (BSI

61882, 2001; Kletz 1999). It is important to conduct analysis

with the support of experts from the organization who may

provide information about possible problems in the systems

operation.

But what to do when a system does not exist and it is still

in an investigation phase? This is the right moment to implement a HAZOP approach to check if the P&ID was correctly

prepared and to study all possible deviations that may appear

within the future systems operation. Strong support of an

interdisciplinary group of experts is needed, so that all possible problems with the initial design can be identified. Also

laboratory test and demonstrational projects, although developed in a smaller scale compared with the industrial needs

would be a good source of information concerning process

behaviour and the complications which may appear with its

application to a full scale project.

3. POS T-COMBUS TION AND AMINE-BAS ED CO 2

CAPTURE READY PROCES S

Chemical absorption processes based on organic solvents

such as amines are currently the preferred option for postcombustion CO2 capture. The most widely-studied solvent

Page 3

Alicja Krzemie et al. / J. Sust. Min. Vol. 12 (2013), No. 4, pp. 1823

for post-combustion CO2 capture is an aqueous solution of

monoethanolamine (M EA) (Abu-Zahra et al. 2007; Amann,

Bouallou 2009; Global CCS Report 2012; Harun et al. 2012;

IPCC 2005; Johnson, Reddy, Brown 2009; Notz,

M angalapally, Hasse 2012; Rao, Rubin, Berkenpas 2004;

Reddy, Gilmartin 2008; Snderby et al. 2013; Tenaska 2012).

Systems using commercially available chemical solvents like

M EA (mostly 30 wt % solution), with inhibitors to prevent

degradation and equipment corrosion, are the best near-term

option for CO2 capture from power plants.

In general we can say that in a post-combustion system,

CO2 is captured from flue gas by passing it through equipment which separates most of the CO2 . The biggest advantage of this system is its ability to capture the carbon dioxide

at the end of the flue gas production chain. In this way it is

possible to retrofit any existing power plant with a capture

unit. There are several commercially available process tech-

20

nologies which can be used for CO2 capture from flue gases:

chemical absorption, physical absorption, adsorption (pressure/temperature swing), gas membrane separation and cryogenic distillation (IEAGHG 2012). In Poland the most likely

to be used in the near future is one based on chemical absorption, it was used in the Bechatw Project which although

was cancelled due to economic problems, had a great chance

to be the first full scale CO2 Capture Ready Installation.

Among the most commercially available technologies for

chemical absorption of CO2 the following five should be

mentioned: Fluors Econamine FG+, M itsubishi Heavy Industries KS solvent, Cansolv Technologies, Aker Clean Carbon and Alstoms Chilled Ammonia Process (Global CCS

Report 2012; IPCC 2005). In this paper we will focus on

Capture Ready Post-Combustion Process based on aqueous

M EA (30 wt % solution) as a solvent (Fig. 2), where CO2 is

removed from flue gas stream at low-pressure.

http://webcache.googleusercontent.com/search?q=cache:http://jsm.gig.eu/sites/default/files/articles/en/jsm_130404_full_text.pdf

3/7

07/12/2014

Risk assessment of a post-combustion and amine-based CO2 Capture Ready Process

Figure 2. Simplified Amine Capture Ready Process flow diagram based on (Sanpasertparnich et al. 2010)

In the first step of this process flue gas from the Flue-Gas

Desulfurization (FGD) unit is delivered to the cooler where it

is cooled by circulating water at a temperature of about 40C

tom of the absorber, it is known as rich amine stream. The

rich amine stream leaves from the bottom of the absorber and

it is pumped to the cross-heat exchanger in order to exchange

the heat with the lean stream from the desorber. Then the lean

stream is further cooled, bringing its temperature down to

around 40C and it proceeds to the absorber. By that time

(other parameters of this process are presented in Table 1). In

case of a high level of impurities in the flue gas, which may

contain SO2 and SO3 , it is necessary to scrub it by using

a desulfurizing solution. The flue gas exits through the top of

the cooler and is sent to a blower where it is slightly compressed. Then the gas enters at the bottom of the absorber,

while at the same time M EA enters at the top of the absorber.

CO2 is removed from the feed gas by the lean amine solvent.

Treated flue gas, consisting mainly of N2 and O2 , is washed

with a circulating water stream before leaving through the top

of the absorber. When the amine stream is loaded with CO2 ,

as it is the case with the stream that leaves through the bot-

a rich amine enters at the second stage of the desorber and

flows down the column, going in the direction of the vapours

from the reboiler. The overhead vapour from the desorber is

cooled and most of the water is condensed out of the low

pressure CO2 product. The majority of the condensed water

reflux returns to the top of the desorber, while the balance

returns to the absorber. The remaining low pressure CO2

product is routed to the compression section (Reddy,

Gilmartin 2008; Sanpasertparnich et al. 2010; Tenaska 2012).

Page 4

Alicja Krzemie et al. / J. Sust. Min. Vol. 12 (2013), No. 4, pp. 1823

Table 1. Basic parameters of a post-combustion process based on MEA

2004). It can appear in the absorber when O2 concentration in the flue gas is over 5% or when heat stable

solids are formed (Davidson 2007; Yu, Huang, Tan

Pressure

[kPa]

Temperature

[o C]

Flow rate

[kg/s]

101

45

725

109

40

Flue gas before

CO 2 removal

Flue gas + amine

b 2 Absorber

P ipeline with rich amine

c

to cross-heat exchanger

P ipeline from cross-heat

d1

exchanger to desorber

P ipeline from cross-heat

d2

exchanger to desorber

e1 Desorber

109

57

Flue gas + amine

109

57

3009

Rich amine

109

107

3009

Rich amine

109

103

3009

Rich amine

186

103

Amine + CO 2

e2 Desorber

P ipeline from reflux drum

f

to compressor

P ipeline from reboiler

g

to cross-heat exchanger

P ipeline from cross-heat

h exchanger to lean amine

186

123

Amine + CO 2

183

40

151

CO 2

109

123

2858

Lean amine

decrease of flow rate or lack of flow rate to the absorber,

both flue gas and M EA, caused by a pipeline blockage, an

equipment failure or human error

109

67

2858

Lean amine

loss of solvent and/or flue gas, as a consequence of pipeline leakage

No

Component

P ipeline from the FGD

unit to the cooler

b 1 Absorber

a

Medium

21

2012). The degradation could be mainly catalysed by

the presence of iron and copper but also by nickel and

chromium (Goff, Rochelle 2003)

thermal degradation leads to the formation of high molecular weight degradation products. It only takes place

around the desorber, the cross-heat exchanger or the

reboiler, where temperature is above 205C (Davidson,

2007)

http://webcache.googleusercontent.com/search?q=cache:http://jsm.gig.eu/sites/default/files/articles/en/jsm_130404_full_text.pdf

4/7

07/12/2014

Risk assessment of a post-combustion and amine-based CO2 Capture Ready Process

overflow or reversed flow due to human errors or equipment failures (valves, pumps etc.)

cooler

4. THE US E OF HAZOP FOR RIS K AS S ES S MENT

OF CO 2 CAPTURE READY PROCES S

According to the USA Standard for process safety management (OSHA 1910.119, 1992), a Preliminary Hazard Analysis

technique (PHA) is recommended for certain types of chemical

facilities. This is way it has become a widely accepted technique for other industrial processes as CO2 Capture Ready

installations, although they are not mentioned within this regulation. This technique seems to be a good option for planned

facilities but in some cases it may not be sufficient while analysing a new technology. That is why a HAZOP study might

be a better and more effective solution. HAZOP analysis identifies the potential operability problems, but also other safety

related risks as well as environmental hazards, which is the

great added value of this study (Tenaska 2012).

While conducting a HAZOP analysis of the installation, 41

parts (nodes) were identified. All of them were reviewed in

sequential order following a P&ID, so possible problems

with the intended design would be found; equipment failures

and safety hazards among them. The most important system

parameters taken into account were: temperature, pressure,

flow rate, material corrosion, composition, integrity and ma-

increase of pressure caused by an excessive accumulation

of gas within the system (for example, caused by a gas

outlet obstruction in the absorber)

change in the flue gas composition (high level of impurities) as a consequence of a gas supply system failure or

pipeline corrosion

Some other examples of nodes taken into consideration

together with deviations analysed by the experts team are

presented in Figure 3. While conducting a HAZOP study the

main problem which has to be overcome is the need to demonstrate system capabilities in a power plant setting where the

quantities of CO2 to be captured are typically several times

larger than at any currently operating demonstration plant.

terial properties.

Some of the possible deviations identified within the study

are mentioned below, showing the complexity of the problem:

material corrosion, resulting from the use of wrongly

selected material, not resistant to monoethanolamine corrosive properties and CO2 influence. Some cases of valves

corrosion due to the lack of stainless steel usage - are

known from post-combustion tests, as well as some traces of condensation that were observed within the CASTOR project (Kittel et al. 2006), demonstrating that at a

specific height in the gas pipeline a risk of local corrosion

can appear (the corrosion rate of carbon steel was considerable in the lean amine areas, at the outlet of the desorbed and at the inlet of the absorber);

monoethanolamine degradation:

carbamate polymerization is the most common mechanism of amine degradation and it may appear in the desorber and in the reboiler with the presence of CO2 and

high temperature (over 100C)

oxidative degradation leads to the formation of high

molecular weight degradation products (Goff, Rochelle

Figure 3. Example of a HAZOP worksheet for some elements

of a post-combustion and amine-based CO2 Capture Ready Process

Page 5

Alicja Krzemie et al. / J. Sust. Min. Vol. 12 (2013), No. 4, pp. 1823

Also we must remember that an amine-based postcombustion system may introduce a number of environmental

risks that must be evaluated. They could result from process

emissions to the air and land, but also from big system

changes in mass and energy flows when a capture unit is

added to a power plant (IRGC 2009).

22

6. Global CCS Report (2012): CO2 Capture T echnologies. Post

Combustion Capture (PCC). Australia: T he Global Carbon

Capture and Storage Institute http://www.globalccsinstitute.com.

7. Goff G.S., Rochelle G.T . (2003): Oxidative degradation of

aqueous monoethanolamine in CO2 capture. In: International

T est Network for CO2 Capture: report on 5th workshop. Vol.

Report PH4/22, pp. 202222. USA: IEA Greenhouse Gas R&D

Programme.

http://webcache.googleusercontent.com/search?q=cache:http://jsm.gig.eu/sites/default/files/articles/en/jsm_130404_full_text.pdf

5/7

07/12/2014

Risk assessment of a post-combustion and amine-based CO2 Capture Ready Process

8. Goff G.S., Rochelle G.T . (2004): Monoethanolamine

Degradation: O2 Mass T ransfer Effects under CO2 Capture

Conditions. Industrial & Engineering Chemistry Research Vol.

43(20), pp. 6400-6408. DOI: 10.1021/ie0400245

9. Harun N., Nittaya T ., Douglas P.L., Croiset E., RicardezSandoval L.A. (2012). Dynamic simulation of MEA absorption

process for CO2 capture from power plants. International Journal

of Greenhouse Gas Control Vol. 10(0), pp. 295309. DOI:

http://dx.doi.org/10.1016/j.ijggc.2012.06.017.

10. IEAGHG (2012): CO2 Capture at Gas Fired Power Plants. Vol.

2012/08: T he International Energy Agency Greenhouse Gas

R&D Programme. http://www.ieaghg.org.

11. IPCC (2005): IPCC Special Report on Carbon Dioxide Capture

and Storage: Prepared by Working Group III of the

Intergovernmental Panel on Climate Change. B. Metz, O.

Davidson, H.C. de Coninck, M. Loos, and L.A. Meyer (eds.).

IPCC, Cambridge University Press, Cambridge, United

Kingdom and New York, USA, 442 pp. Vol. 2.

12. IRGC (2009): Power plant CO2 capture technologies. Risks and

risk governance deficits (Concept Note). International Risk

Governance Council. http://www.irgc.org.

13. ISO/IEC 31010 (2010): ST ANDARD. Risk management Risk

assessment techniques. Geneva: ISO/IEC.

14. Johnson D.W., Reddy S., Brown J.H. (2009): Commercially

Available CO2 Capture T echnology. Power. Retrieved from

POWER website: http://www.powermag.com/commerciallyavailable-co2-capture-technology/

15. Kittel J., Pasquier D., Ropital F., Boudou C., Bonneau A.

(2006): Corrosion experiments for CO2

solvents. Paper

presented at the 8th International Conference on Greenhouse

Gas Control T echnologies.

16. Kletz T .A. (1999): Hazop and Hazan Identifying and

Assessing Chemical Industry Hazards. Rugby, UK, Institution

of Chemical Engineers.

17. Macdonald D. (2004): Practical hazops, trips and alarms:

Newnes.

18. Notz R., Mangalapally H.P., Hasse H. (2012): Post combustion

CO2 capture by reactive absorption: Pilot plant description and

results of systematic studies with MEA. International Journal of

Greenhouse Gas Control, Vol. 6(0), pp. 84112. DOI:

http://dx.doi.org/10.1016/j.ijggc.2011.11.004.

19. OSHA 1910.119 (1992): ST ANDARD. Process safety

management of highly hazardous chemicals.

20. PN-N-18002: 2011 System zarzdzania bezpieczestwem i higien pracy. Oglne wytyczne do oceny ryzyka zawodowego.

5. CONCLUS IONS

CCS technology is relatively young and is of interest to

many researchers all over the world, but is still being developed within a process of technology changes. M any laboratory experiments, as well as pilot projects, have been undertaken using different capture systems, but until now no experience from full-size operational installations has been

gained. The energy industry must meet several challenges

associated with the start-up of new full-scale projects, which

may introduce new technical problems. M ost of them are

related with the properties of the materials used and the technologies applied, and can be identified at the first stage of the

project if the appropriate tool is implemented. That is why

a HAZOP analysis seems to be a good option for identifying

potential operability problems and further risk assessment, as

industrial process operations are never completely risk-free.

The main goal of any risk assessment is to identify all possible failures of the intended design, so that safeguards and

actions required for improving the safety of the process could

be implemented when scaling up the technology to a constructible design at a commercial size. All this can only be

done properly in the context of a particular power plant, employing a specific Capture Ready Technology. Although it

seems that Capture Ready Technology has little potential to

cause major hazards both to the environment and humans, at

the same time the complexity of the process and the specific

instrumentation introduce a wide range of possible deviations

in the operation of a full-size plant. This makes a HAZOP

analysis very complex and time-consuming, but it is the only

approach to guarantee that everything possible was done to

prevent accidents and other harmful consequences.

Acknowledgments

This research was supported by the Polish M inistry of

Science and Higher Education under the contract No. 401/E263/S/2012-1, Task: 10011223-143.

Re fe re nce s

1. Abu-Zahra M.R.M., Niederer J.P.M., Feron P.H.M., Versteeg

G.F. (2007): CO2 capture from power plants: Part II. A

parametric study of the economical performance based on

mono-ethanolamine. International Journal of Greenhouse Gas

Control, 1(2), 135142. DOI: http://dx.doi.org/10.1016/S17505836(07)00032-1

2. Amann, J.-M.G., Bouallou C. (2009): CO2 capture from power

stations running with natural gas (NGCC) and pulverized coal

(PC): Assessment of a new chemical solvent based on aqueous

solutions of N-methyldiethanolamine + triethylene tetramine.

Energy

Procedia,

1(1),

909-916.

http://dx.doi.org/10.1016/j.egypro.2009.01.121

3. BSI 61882 (2001). ST ANDARD. Hazard and operability studies

(HAZOP studies) Application guide: IEC.

4. Davidson R.M. (2007): Post-combustion carbon capture from

coal fired plants solvent scrubbing. Vol. CCC/125, pp. 58:

IEA Clean Coal Centre.

5. Global CCS Institute (2013): T he Global Status of CCS: 2013

Melbourne, Australia, (pp. 204).

DOI:

21. Rao A.B., Rubin E.S., Berkenpas M.B. (2004): An Integrated

Modelling Framework for Carbon Management T echnologies.

Volume 1 T echnical Documentation: Amine-Based CO2

Capture and Storage Systems for Fossil Fuel Power Plant.

Pittsburgh, Pennsylvania: Carnegie Mellon University.

22. Reddy S., Gilmartin J. (2008): Fluors Econamine FG PlusSM

T echnology for Post-Combustion CO2 Capture. Paper presented

at the GPA Gas T reatment Conference, Amsterdam, T he

Netherlands.

23. Sanpasertparnich T ., Idem R., Bolea I., deMontigny D.,

T ontiwachwuthikul P. (2010): Integration of post-combustion

capture and storage into a pulverized coal-fired power plant.

International Journal of Greenhouse Gas Control Vol. 4(3), pp.

499510. DOI: http://dx.doi.org/10.1016/j.ijggc.2009.12.005.

Page 6

Alicja Krzemie et al. / J. Sust. Min. Vol. 12 (2013), No. 4, pp. 1823

http://webcache.googleusercontent.com/search?q=cache:http://jsm.gig.eu/sites/default/files/articles/en/jsm_130404_full_text.pdf

6/7

07/12/2014

Risk assessment of a post-combustion and amine-based CO2 Capture Ready Process

23

24. Snderby T .L., Carlsen K.B., Fosbl P.L., Kirboe L.G., von

Solms N. (2013): A new pilot absorber for CO2 capture from

flue gases: Measuring and modelling capture with MEA

solution. International Journal of Greenhouse Gas Control Vol.

12(0),

pp.

181192.

http://dx.doi.org/10.1016/j.ijggc.2012.10.010.

DOI:

25. T enaska (2012): Final Front-End Engineering and Design Study

Report. Report to the Global CCS Institute. Retrieved from

http://cdn.globalccsinstitute.com.

26. Yu C.-H., Huang C.-H., T an C.-S. (2012): A review of CO2

capture by absorption and adsorption. Aerosol Air Qual. Res.

Vol. 12, pp. 745769.

http://webcache.googleusercontent.com/search?q=cache:http://jsm.gig.eu/sites/default/files/articles/en/jsm_130404_full_text.pdf

7/7

Você também pode gostar

- 7 Steps To Making A Killing Trading FX EbookDocumento10 páginas7 Steps To Making A Killing Trading FX Ebookkrishnan112Ainda não há avaliações

- Basics of Process SimulationDocumento36 páginasBasics of Process SimulationArjun GujarAinda não há avaliações

- ON Overview of Ongc C2-C3 Plant, Dahej, Gujarat: Winter Training ProgramDocumento46 páginasON Overview of Ongc C2-C3 Plant, Dahej, Gujarat: Winter Training ProgramU19CH076 ZEELKUMAR PATEL SVNITAinda não há avaliações

- An Evaluation of General "Rules of Thumb" in Amine Sweetening UnitDocumento18 páginasAn Evaluation of General "Rules of Thumb" in Amine Sweetening Unitrohl55Ainda não há avaliações

- Perspectives On Project Management PDFDocumento180 páginasPerspectives On Project Management PDFehsan_baheriAinda não há avaliações

- Introduction To Project Management: Malcolm KearDocumento56 páginasIntroduction To Project Management: Malcolm KearRaj ShravanthiAinda não há avaliações

- Week 11 Fires and Explosions in Chemical and Petrochemical IndustriesDocumento37 páginasWeek 11 Fires and Explosions in Chemical and Petrochemical Industriessamuel100% (1)

- Health and Safety Procedure - Hazard Identification Risk Assessment and ControlDocumento6 páginasHealth and Safety Procedure - Hazard Identification Risk Assessment and ControlMohamad Zakwan Zach ZakariaAinda não há avaliações

- Liquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessDocumento8 páginasLiquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessHaru MasaAinda não há avaliações

- COSO Fraud Risk Management Guide Executive SummaryDocumento13 páginasCOSO Fraud Risk Management Guide Executive SummaryJosimar Gonzales TrigoAinda não há avaliações

- BMC Control M Workload AutomationDocumento4 páginasBMC Control M Workload AutomationSriram BalasubramanianAinda não há avaliações

- Tail Gas Treatment Unit Facility Inspection ReportDocumento7 páginasTail Gas Treatment Unit Facility Inspection Reportabdelkader benabdallahAinda não há avaliações

- Engineering Encyclopedia: Mass and Energy BalancesDocumento39 páginasEngineering Encyclopedia: Mass and Energy BalancesLogeswaran AppaduraiAinda não há avaliações

- Statistics for Process Control Engineers: A Practical ApproachNo EverandStatistics for Process Control Engineers: A Practical ApproachAinda não há avaliações

- Oims Framework BrochureDocumento20 páginasOims Framework BrochureJorge Rodríguez100% (1)

- 2500-15-00-80-001 - R1 (Unit 15 Operating Manual)Documento185 páginas2500-15-00-80-001 - R1 (Unit 15 Operating Manual)Clash with HBAinda não há avaliações

- PA Site Process Safety ConceptDocumento49 páginasPA Site Process Safety Conceptmehul10941100% (1)

- Good Practice in Pygas Hydrogenation Operations Through Advanced Process Control-English PDFDocumento7 páginasGood Practice in Pygas Hydrogenation Operations Through Advanced Process Control-English PDFsalvatore raffa100% (1)

- Anaerobic Digestion Fundamentals IIDocumento45 páginasAnaerobic Digestion Fundamentals IIscm996Ainda não há avaliações

- Corrosion Management in Gas Treating Pla PDFDocumento8 páginasCorrosion Management in Gas Treating Pla PDFTaghreed ZewailAinda não há avaliações

- Vertical KO Drum Sizing (Ver 1.0.0) : 1.0 DescriptionDocumento21 páginasVertical KO Drum Sizing (Ver 1.0.0) : 1.0 Descriptionrameshkarthik810Ainda não há avaliações

- Dixell XR06CXDocumento3 páginasDixell XR06CXscm996100% (3)

- Aminas - Iran IDocumento4 páginasAminas - Iran IJesus BcAinda não há avaliações

- Packed Amine Absorber Simulation Tracks Plant PerformanceDocumento14 páginasPacked Amine Absorber Simulation Tracks Plant Performancematrix69Ainda não há avaliações

- User Guide For Models and Physical Properties - Multiflash 4.3Documento74 páginasUser Guide For Models and Physical Properties - Multiflash 4.3GalileosaysAinda não há avaliações

- Amine ReportDocumento14 páginasAmine ReportM qasimAinda não há avaliações

- Improve Flow Measurement Accuracy With Proper Meter CorrectionsDocumento23 páginasImprove Flow Measurement Accuracy With Proper Meter CorrectionsHuu NguyenAinda não há avaliações

- Control of Vapor Recovery Units (VRU)Documento8 páginasControl of Vapor Recovery Units (VRU)Yasmine ياسمينAinda não há avaliações

- Methyldiethanolamine As A Solvent For Gas DesulfurizationDocumento66 páginasMethyldiethanolamine As A Solvent For Gas DesulfurizationAnime MtAinda não há avaliações

- Control of Foaming in Amine Systems - Brimstone 07 Rev A-2-2 PDFDocumento13 páginasControl of Foaming in Amine Systems - Brimstone 07 Rev A-2-2 PDFscm996100% (1)

- 8 Risk Management in Contemporary Pharmacy PracticeDocumento36 páginas8 Risk Management in Contemporary Pharmacy PracticeLollyAinda não há avaliações

- AGR OptimizationDocumento43 páginasAGR Optimizationinara amatullahAinda não há avaliações

- Amine Best Practices GuideDocumento63 páginasAmine Best Practices GuideJerold100% (2)

- Design of Distillation Column PDFDocumento25 páginasDesign of Distillation Column PDFRobert DsouzaAinda não há avaliações

- SWEETENING (Chemical Absorption) PresentationDocumento54 páginasSWEETENING (Chemical Absorption) Presentationarsalan amirpour75% (4)

- Biogas UpgradingDocumento67 páginasBiogas Upgradingscm996100% (1)

- Petroleum Refining and Natural Gas ProcesingDocumento27 páginasPetroleum Refining and Natural Gas ProcesingNaud Avendaño RodríguezAinda não há avaliações

- 13 Heat Integration in A Crude Distillation Unit Using Pinch Analysis ConceptsDocumento29 páginas13 Heat Integration in A Crude Distillation Unit Using Pinch Analysis ConceptsxinghustAinda não há avaliações

- Hydrocracker SafeguardingDocumento14 páginasHydrocracker SafeguardingyusinovskyAinda não há avaliações

- Design of A 90 MTPD Methanol Production Plant FinalDocumento147 páginasDesign of A 90 MTPD Methanol Production Plant FinalFardin Faruk KhanAinda não há avaliações

- CHN CHP 7Documento5 páginasCHN CHP 7Charmaine Rose Inandan Triviño100% (3)

- Nebosh Igc2 QuestionsDocumento7 páginasNebosh Igc2 QuestionsMuhammad Younas100% (1)

- PP Aaa PP1 102Documento29 páginasPP Aaa PP1 102Rabah AmidiAinda não há avaliações

- Third Party Risk Management Solution - WebDocumento16 páginasThird Party Risk Management Solution - Webpreenk8Ainda não há avaliações

- Distillation PDFDocumento6 páginasDistillation PDFAmit SawantAinda não há avaliações

- Risk Assessment of A Post-Combustion and Amine-BasDocumento7 páginasRisk Assessment of A Post-Combustion and Amine-BasYusdianAinda não há avaliações

- Aspect of Degradation of Monoethanolamine PDFDocumento379 páginasAspect of Degradation of Monoethanolamine PDFFaisal MoeAinda não há avaliações

- Portugieser EN lCpzOAp PDFDocumento44 páginasPortugieser EN lCpzOAp PDFscm996Ainda não há avaliações

- 2019jan - IECM Amine-Based CO2 Capture PDFDocumento63 páginas2019jan - IECM Amine-Based CO2 Capture PDFFunky labsAinda não há avaliações

- Chapter 3. Acid Gas RemovalDocumento88 páginasChapter 3. Acid Gas RemovalTu Dang TrongAinda não há avaliações

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlDocumento77 páginasAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- Optimization of Biogas Generation From Press Mud in Batch ReactorDocumento6 páginasOptimization of Biogas Generation From Press Mud in Batch Reactorscm996Ainda não há avaliações

- Operator Training Simulator BrochureDocumento5 páginasOperator Training Simulator Brochuremaximusala83Ainda não há avaliações

- Biogas Upgrading PDFDocumento31 páginasBiogas Upgrading PDFscm996Ainda não há avaliações

- Biogas Upgrading PDFDocumento31 páginasBiogas Upgrading PDFscm996Ainda não há avaliações

- Self-Optimizing Control of A Gas Oil HydrodesulfurizationDocumento167 páginasSelf-Optimizing Control of A Gas Oil Hydrodesulfurizationvu anh ducAinda não há avaliações

- ProMax 3 BrochureDocumento20 páginasProMax 3 BrochureNila Gama100% (2)

- Solvent ImportanceDocumento6 páginasSolvent ImportanceAbhiAinda não há avaliações

- TK01 - Report - FinalDocumento264 páginasTK01 - Report - FinalHafiz HakimAinda não há avaliações

- AdapT ProTreat GuidelinesDocumento7 páginasAdapT ProTreat GuidelinesAlek KrótkiAinda não há avaliações

- Thesis On CatalystDocumento36 páginasThesis On CatalystMahfuzur Rahman SiddikyAinda não há avaliações

- Operating ManualDocumento102 páginasOperating ManualLulu ChaniagoAinda não há avaliações

- Pipephase 9.1: User's GuideDocumento104 páginasPipephase 9.1: User's GuideGabi AraujoAinda não há avaliações

- SOP-013-Testing of Acid Gas Loading in MDEADocumento9 páginasSOP-013-Testing of Acid Gas Loading in MDEAAmnaKamranAinda não há avaliações

- Foaming in A Mine SystemsDocumento16 páginasFoaming in A Mine SystemsAhmad FarooqAinda não há avaliações

- Chemical Engineering Thermal and Catalytic Processes in Petroleum Refining S. RaseevDocumento920 páginasChemical Engineering Thermal and Catalytic Processes in Petroleum Refining S. RaseevJay LawsonAinda não há avaliações

- En Analysis of Thermal Efficiency Limit of Steam Methane Reforming ProcessDocumento8 páginasEn Analysis of Thermal Efficiency Limit of Steam Methane Reforming ProcessAgam HanasichulaAinda não há avaliações

- Amine Sweetening With DEADocumento14 páginasAmine Sweetening With DEARoza SavitriAinda não há avaliações

- Inprocess-BP Lingen Project ArticleDocumento3 páginasInprocess-BP Lingen Project Articlejrz85Ainda não há avaliações

- SulfolaneAppendices A EDocumento158 páginasSulfolaneAppendices A Erkhandelwal9604Ainda não há avaliações

- ENGINEERING DESIGN GUIDELINES Boiler Systems Rev1.3web PDFDocumento29 páginasENGINEERING DESIGN GUIDELINES Boiler Systems Rev1.3web PDFMohsen KadivarAinda não há avaliações

- GAS TREATING PLANTS: IMPROVE EFFICIENCY BY OPTIMIZING CONDITIONSDocumento4 páginasGAS TREATING PLANTS: IMPROVE EFFICIENCY BY OPTIMIZING CONDITIONSRobert MontoyaAinda não há avaliações

- PETROFED workshop discusses Oxy Enrich process for increasing sulfur recovery capacityDocumento22 páginasPETROFED workshop discusses Oxy Enrich process for increasing sulfur recovery capacitysara25dec689288Ainda não há avaliações

- Flare System Data SheetDocumento5 páginasFlare System Data SheetrutujaAinda não há avaliações

- Cricondentherm & Cricondenbar PressuresDocumento7 páginasCricondentherm & Cricondenbar PressuresdesertflowAinda não há avaliações

- 4 Girish ChitnisDocumento22 páginas4 Girish ChitnisridanormaAinda não há avaliações

- CPE666 - Chapter 4 PDFDocumento71 páginasCPE666 - Chapter 4 PDFbruce bartonAinda não há avaliações

- Sulfinol D Evaluation.Documento24 páginasSulfinol D Evaluation.Clibert RodríguezAinda não há avaliações

- Starting Up Hydrotreating Units With Cracked FeedsDocumento5 páginasStarting Up Hydrotreating Units With Cracked FeedsAle SanzAinda não há avaliações

- Hyfit Engineers: Series Iso A (Wp:350 Bar)Documento19 páginasHyfit Engineers: Series Iso A (Wp:350 Bar)scm996Ainda não há avaliações

- Dissertation - Biogas From Forage and Sugar BeetDocumento170 páginasDissertation - Biogas From Forage and Sugar Beetscm996Ainda não há avaliações

- Controlling Foam in Anaerobic DigestersDocumento4 páginasControlling Foam in Anaerobic Digestersscm996Ainda não há avaliações

- A Novel and Cost-Effective H2S Removal Technology Using Tire Derived Rubber ParticlesDocumento93 páginasA Novel and Cost-Effective H2S Removal Technology Using Tire Derived Rubber Particlesscm996Ainda não há avaliações

- Scaw Chain Products BrochureDocumento7 páginasScaw Chain Products Brochurescm996Ainda não há avaliações

- Trickling FilterDocumento20 páginasTrickling FilterMuhammadUsmanAinda não há avaliações

- Activated Carbon3 PDFDocumento4 páginasActivated Carbon3 PDFscm996Ainda não há avaliações

- Quimica Organica IIDocumento18 páginasQuimica Organica IIvskywokervsAinda não há avaliações

- SP Multitech - Dry FermentationDocumento2 páginasSP Multitech - Dry Fermentationscm996Ainda não há avaliações

- Electrodialysis-Effective Amine Reclamation With Minimal Operational ImpactDocumento15 páginasElectrodialysis-Effective Amine Reclamation With Minimal Operational Impactscm996Ainda não há avaliações

- Basic Heat Transfer Concepts for Polymer ProcessingDocumento26 páginasBasic Heat Transfer Concepts for Polymer Processingpriyanka236Ainda não há avaliações

- Motor Current RM TechnicalDocumento1 páginaMotor Current RM TechnicalPhani VarmaAinda não há avaliações

- Canada - Gas Utilization From Sewage Waste - Page 3 Oxygen or Air Dosing in Digester For Removing H2SDocumento13 páginasCanada - Gas Utilization From Sewage Waste - Page 3 Oxygen or Air Dosing in Digester For Removing H2Sscm996Ainda não há avaliações

- WA State - Compost Facility Resource Handbook PDFDocumento141 páginasWA State - Compost Facility Resource Handbook PDFscm996Ainda não há avaliações

- Biogas CleanupDocumento7 páginasBiogas CleanupNaren CAinda não há avaliações

- Developing A Slow-Release Nitrogen Fertilizer From Organic SourcesDocumento5 páginasDeveloping A Slow-Release Nitrogen Fertilizer From Organic Sourcesscm996Ainda não há avaliações

- Treating Holistically 3 Part Series HEDocumento12 páginasTreating Holistically 3 Part Series HEscm996Ainda não há avaliações

- Thermal Degradation of Amines For CO2 CaptureDocumento8 páginasThermal Degradation of Amines For CO2 Capturescm996Ainda não há avaliações

- Removal of h2s & Co2 - From - Biogas - by Amine - AbsorptionDocumento19 páginasRemoval of h2s & Co2 - From - Biogas - by Amine - Absorptionzubair19550% (2)

- Module Study Guide: Academic Year 2021 - 2022Documento18 páginasModule Study Guide: Academic Year 2021 - 2022yehasha0% (1)

- NORSOK S-WA-006 02 (En) ApprovalDocumento78 páginasNORSOK S-WA-006 02 (En) ApprovalCL LeidyAinda não há avaliações

- What Google Learned From Its Quest to Build the Perfect TeamDocumento15 páginasWhat Google Learned From Its Quest to Build the Perfect TeamcepolAinda não há avaliações

- Man Sci Case Study FINALDocumento19 páginasMan Sci Case Study FINALMai Mai VarelaAinda não há avaliações

- An Introduction To The Concept of Environmental Audit: Indian ContextDocumento8 páginasAn Introduction To The Concept of Environmental Audit: Indian ContextAbhi VishwakarmaAinda não há avaliações

- CHAPTER 1 N 2Documento16 páginasCHAPTER 1 N 2Maria Erika GarcesAinda não há avaliações

- CCGL Asm1 WANG XINRUI 3036128298 2023Documento4 páginasCCGL Asm1 WANG XINRUI 3036128298 2023XINRUI WANGAinda não há avaliações

- APIA PE Code of Practice guides CSG industry pipeline constructionDocumento182 páginasAPIA PE Code of Practice guides CSG industry pipeline constructionroostercockburnAinda não há avaliações

- 639544869Documento589 páginas639544869Anonymous Co8uNuzAinda não há avaliações

- Chapter 4 On Bank AdequacyDocumento9 páginasChapter 4 On Bank AdequacyAcademic portAinda não há avaliações

- Risk Assessment of Cascading Outages: Methodologies and ChallengesDocumento12 páginasRisk Assessment of Cascading Outages: Methodologies and ChallengesBala MAinda não há avaliações

- Pi Is 0955395907001430Documento6 páginasPi Is 0955395907001430Sebastian DelafuenteAinda não há avaliações

- Guidelines on processing personal data in whistleblowingDocumento16 páginasGuidelines on processing personal data in whistleblowingMario Gomez100% (1)

- Full Paper 347Documento8 páginasFull Paper 347zamriAinda não há avaliações

- Managing The Insider Threat To Your Business: A Personnel Security HandbookDocumento28 páginasManaging The Insider Threat To Your Business: A Personnel Security HandbookRakesh Ricki RadharamanAinda não há avaliações

- Research Project AssignmentDocumento27 páginasResearch Project AssignmentSam CleonAinda não há avaliações

- Ohsas180012007 Hsms ManualDocumento36 páginasOhsas180012007 Hsms ManualPrem Shanker RawatAinda não há avaliações

- Contractors All Risk Vs Professional Indemnity InsuranceDocumento11 páginasContractors All Risk Vs Professional Indemnity InsurancehieutlbkreportAinda não há avaliações

- Internal Audit in BanksDocumento19 páginasInternal Audit in BanksSayali DhuriAinda não há avaliações

- TR-Mechatronics Servicing NC II 11-16-2018Documento86 páginasTR-Mechatronics Servicing NC II 11-16-2018Mark Orly IñosaAinda não há avaliações