Escolar Documentos

Profissional Documentos

Cultura Documentos

CSTPS 4 - 09 11 2013

Enviado por

SE ESTDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CSTPS 4 - 09 11 2013

Enviado por

SE ESTDireitos autorais:

Formatos disponíveis

Ref No : CHN/POG tTripping/C-42t

052 3 4

ill

Date:

'1

o DEC

2O?3

EVENT ANALYSIS REPORT

UNIT NO :4

1. *HO Code:

ITPS: GSTPS

Unit Capacity:210 MW

Station Code:

csTPS U4 T-0gl 2013-14

Time- 06:07

hrs

Last Overhaul (COH) synchronisation Date

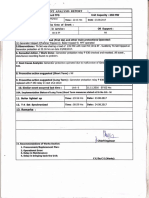

2. Operating conditions

12t08t2013

Date

09/1 1t2013

89.00

No. of days from last

sync.i- 25 Day

Days

0.24

Years

at the time of Event

Load MW

Coal Cycles in service

Oil Support

17s

A,B,C,D,F

Nir

3. Nature of Event : TA set Tripped on " MS temperature LoW' because of heavy g-oiler tube leakage in water wall

tube at front water wall. (Boiler Tube leakage)

4. Name of First Up, Main Protections & protection on which GCB tripped:

First up : MS temperature Low

Main Protection: Turbine trip,Boiler trip,

GGB Opened on : Low forward power relay (86 GT)

5A)observations:.FurnacedraughtwaSonhighersideandcouldnotbemaintaineo.Heav6

heard at I meter level near manhole. MS temperature started dropping and set tripped on Main steam temperature

low. Boiler tube leakage was at front water wall neck bend 21 al8 meter level. Secondary damage observed at bend

no 20 & 22 atlhe same 8 meter level,

5B)RemedialAction/workdone:-AllDamagedtubesreplacedbynewspootpiry

welding joints carried out . Radiography result found OK. Nearby bends checked for erosion found normal. Transition

zone tubes cleaning done by water jetting . Boiler Hydraulic test taken and found OK. Other shutdown jobs listed

below carried out.

1. Economiser lnlet NRV flange leakage attended. 2.superheater & Reheater drain valves replaced.

3. Steam tracing line leakages attended.4. Super heater Spray valve S-90 Glands and gasket replaced.

5.Economiser vent line leakage attended..6.All Three drum level transmitter checking and calibration carried out.

T.HPILP bypass oil filtration carried out.8.HPBP1,2LPBP1,2 servo valves cleaned and calibration done.9.MS flow

LHS transmitter calibrated& put in service.10. DC air heater panel cleaned and auto pick up trial taken found OK.

11.Works of BFP 48 discharge valve. FW -31 MC-39 carried out.

6. Root Gause Analysis

:-

Damage of water wall neck bends due to heavy impact due to tatlingrcf heavy clinkeri

7. Preventive action suggested (ShortTerm) :- l.Physicalsurvey of neck bend in accesEible. lcarried out.1

2. Restoration of damaged missing Wear bars on neck tubes. (Carried out during overhaul Aug-2013)

8. Preventive action suggested (Long Term) :- Checking of Front and rear water wall OenOs anO reptacernent of

bends during overhaul. ( Regular Practice. Worn out bends were replaced during OverhaulAug-2013)

9. Similar event occurred last time:- --

u#,

MW

Time:

-----

9A. lmplementation Status of Long Term/Short Term measures stated at Sr No

Date :- ----

0:-

----

10. Boiler lighted uP

11.

T-A Set Synchronised

12. Remark

Time- 22:30 Hrs

Date- 1011112013

Time - 07:42 Hrs

Date- 1111112013

:- Nil

Chief

CSTP

ffier

(O&M)

Chandrapur.

13. Recommendations of Works Section:

1. ProcuremenURePlacement Plan:

2. Operational Error:

3. Delay in Maintenance:

4. Delay in bringing back the Unit:

5. Training of Staff:

e. Whether remedial action is completed satisfactory & point is closed

CE/DyGE(Works)

*ftO Code will be given by Works Section.

Você também pode gostar

- CSTPS 1 - 13 11 2013Documento2 páginasCSTPS 1 - 13 11 2013SE ESTAinda não há avaliações

- Ffis:Chandrapursuperthermalpowerstutioffi:500Mw: Zuij Event Analysis ReportDocumento2 páginasFfis:Chandrapursuperthermalpowerstutioffi:500Mw: Zuij Event Analysis ReportSE ESTAinda não há avaliações

- PRL-4 20.11.2013Documento2 páginasPRL-4 20.11.2013SE ESTAinda não há avaliações

- PRL-4 20.11.2013Documento2 páginasPRL-4 20.11.2013SE ESTAinda não há avaliações

- 0 Gmar: Event Analysis ReportDocumento2 páginas0 Gmar: Event Analysis ReportSE ESTAinda não há avaliações

- 7 Station: FEB ?0t5'Documento2 páginas7 Station: FEB ?0t5'SE ESTAinda não há avaliações

- May 12Documento33 páginasMay 12dillipsh123Ainda não há avaliações

- Paras-3 18.12.2013Documento1 páginaParas-3 18.12.2013SE ESTAinda não há avaliações

- O Ffis:Chandrapursuperthermalpowerstationunitcapacity:500Mw: SuoolvDocumento2 páginasO Ffis:Chandrapursuperthermalpowerstationunitcapacity:500Mw: SuoolvSE ESTAinda não há avaliações

- Date, MAR: Event Analysis ReportDocumento2 páginasDate, MAR: Event Analysis ReportSE ESTAinda não há avaliações

- U3 Tripping 12 - 02 - 2009 - ADocumento2 páginasU3 Tripping 12 - 02 - 2009 - AGajanan JagtapAinda não há avaliações

- Event Analysis Report: DaieDocumento2 páginasEvent Analysis Report: DaieSE ESTAinda não há avaliações

- Morning MeetingDocumento5 páginasMorning MeetingFazalur Rehman BabarAinda não há avaliações

- Aug 2011Documento31 páginasAug 2011Basudev PatraAinda não há avaliações

- CHD-6 12.02.2015Documento2 páginasCHD-6 12.02.2015SE ESTAinda não há avaliações

- (!0 Mner, Ysisreport: G StationDocumento2 páginas(!0 Mner, Ysisreport: G StationSE ESTAinda não há avaliações

- Tdn2Nls: 7 Station: Date:17Documento2 páginasTdn2Nls: 7 Station: Date:17SE ESTAinda não há avaliações

- FL: 5 Station: Event AnalysisDocumento2 páginasFL: 5 Station: Event AnalysisSE ESTAinda não há avaliações

- Jun12 PDFDocumento30 páginasJun12 PDFSreekanthMylavarapuAinda não há avaliações

- CHD-6 22.12.2015Documento2 páginasCHD-6 22.12.2015SE ESTAinda não há avaliações

- PRS-4 16.12.2015Documento1 páginaPRS-4 16.12.2015SE ESTAinda não há avaliações

- Unit-2 Tripping 28 - 03 - 2009Documento1 páginaUnit-2 Tripping 28 - 03 - 2009Gajanan JagtapAinda não há avaliações

- PRL-4 09.11.2013Documento2 páginasPRL-4 09.11.2013SE ESTAinda não há avaliações

- BB. Docking Indent (Repair) Pioneer. 13th Feb.20Documento11 páginasBB. Docking Indent (Repair) Pioneer. 13th Feb.20Thiet PhamAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- 5 Station: O Ffo.R T?Documento2 páginas5 Station: O Ffo.R T?SE ESTAinda não há avaliações

- A, B, C (Ldle) : 1. Hrs SyncDocumento2 páginasA, B, C (Ldle) : 1. Hrs SyncSE ESTAinda não há avaliações

- BTPS-4 07.11.2013 BDocumento1 páginaBTPS-4 07.11.2013 BSE ESTAinda não há avaliações

- Scope of Work For Cranes: Utility & Power HouseDocumento2 páginasScope of Work For Cranes: Utility & Power HouseRana ImtiazAinda não há avaliações

- U6OHREPORT2008Documento89 páginasU6OHREPORT2008Anonymous pKsr5vAinda não há avaliações

- Event Ana U#7,2006 - CompletedDocumento31 páginasEvent Ana U#7,2006 - CompletedGajanan JagtapAinda não há avaliações

- OH2 REPORTDoc2Documento51 páginasOH2 REPORTDoc2Gajanan JagtapAinda não há avaliações

- Event Ana U#6-2006Documento32 páginasEvent Ana U#6-2006Gajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento2 páginasEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- ACID WASHING of Biocide Cells Started at 1730HDocumento2 páginasACID WASHING of Biocide Cells Started at 1730Hpatricia bacosaAinda não há avaliações

- Weekly Report 46Documento7 páginasWeekly Report 46TarekAinda não há avaliações

- U#2 Oh Report 2003Documento45 páginasU#2 Oh Report 2003Sony RamaAinda não há avaliações

- Takniki Darpan - Issue 6Documento40 páginasTakniki Darpan - Issue 6AmiteshAinda não há avaliações

- Event Analysis Report: 198 A, B, D, E, F NILDocumento1 páginaEvent Analysis Report: 198 A, B, D, E, F NILGajanan JagtapAinda não há avaliações

- Level A September 01 Answer 1Documento11 páginasLevel A September 01 Answer 1Ryan Joseph ManigbasAinda não há avaliações

- BHEL CFBC ExperienceDocumento31 páginasBHEL CFBC ExperiencesprotkarAinda não há avaliações

- FEB?als Station: AnalysnDocumento2 páginasFEB?als Station: AnalysnSE ESTAinda não há avaliações

- Vessel'S Midnight Ullage ReportDocumento33 páginasVessel'S Midnight Ullage ReportnawhiAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- TPS: Nasik Thermal Power StationDocumento2 páginasTPS: Nasik Thermal Power StationSE ESTAinda não há avaliações

- 2nd TA Modification Work List Rev1Documento71 páginas2nd TA Modification Work List Rev1Vy NguyenAinda não há avaliações

- HAZOP Footprint - UC Riverside, CHE175A, Chemical Process DesignDocumento9 páginasHAZOP Footprint - UC Riverside, CHE175A, Chemical Process DesignGabriel S. Gusmão (Freddie)Ainda não há avaliações

- Event Analysis Report :, DateDocumento2 páginasEvent Analysis Report :, DateSE ESTAinda não há avaliações

- Unit-1 Tripping 30-01-2009 Mod FormataDocumento1 páginaUnit-1 Tripping 30-01-2009 Mod FormataGajanan JagtapAinda não há avaliações

- 98676767Documento89 páginas98676767HiltonAinda não há avaliações

- Hydrotest Procedure - UTCL Hirmi AQC & PHDocumento12 páginasHydrotest Procedure - UTCL Hirmi AQC & PHJOHnAinda não há avaliações

- U#1 Aoh Major Jobs Planned: A Boiler MaintenanceDocumento7 páginasU#1 Aoh Major Jobs Planned: A Boiler Maintenanceanil peralaAinda não há avaliações

- MMD Monthly Report November 2019Documento5 páginasMMD Monthly Report November 2019biranchi satapathyAinda não há avaliações

- Unit-1 Tripping 28-3-2009Documento1 páginaUnit-1 Tripping 28-3-2009Gajanan JagtapAinda não há avaliações

- Delay in Opening of LP Bypass ValveDocumento94 páginasDelay in Opening of LP Bypass ValveCharu ChhabraAinda não há avaliações

- Jabung Weekly RPT April 04 10 2010Documento20 páginasJabung Weekly RPT April 04 10 2010Yoga RiKumoro100% (1)

- 2019-250 MW Barge Technical DiaryDocumento33 páginas2019-250 MW Barge Technical Diarydasnulmadi61Ainda não há avaliações

- BTPS-4 07.11.2013 ADocumento1 páginaBTPS-4 07.11.2013 ASE ESTAinda não há avaliações

- rEB: 6 Station: at inDocumento2 páginasrEB: 6 Station: at inSE ESTAinda não há avaliações

- Budge Budge VisitDocumento1 páginaBudge Budge VisitSE ESTAinda não há avaliações

- 2011 02 d2 R-InfraAuxPowerReductionDocumento47 páginas2011 02 d2 R-InfraAuxPowerReductionSE ESTAinda não há avaliações

- NTPS - Highlights and Records For FY 2017-18Documento2 páginasNTPS - Highlights and Records For FY 2017-18SE ESTAinda não há avaliações

- 01.new Technologies Best Practices of RelianceDocumento15 páginas01.new Technologies Best Practices of RelianceSE ESTAinda não há avaliações

- Sp. Raw Water & Sp. Soften Water Consumption Up To JAN-18Documento11 páginasSp. Raw Water & Sp. Soften Water Consumption Up To JAN-18SE ESTAinda não há avaliações

- Sop Chlorine and Ammonia GasesDocumento3 páginasSop Chlorine and Ammonia GasesSE ESTAinda não há avaliações

- All India Nov-17Documento2 páginasAll India Nov-17SE ESTAinda não há avaliações

- Station Capacity (MW) Rank PLF (%) : Central Central CentralDocumento2 páginasStation Capacity (MW) Rank PLF (%) : Central Central CentralSE ESTAinda não há avaliações

- Sept 17 New DataDocumento8 páginasSept 17 New DataSE ESTAinda não há avaliações

- Covering Letter NTPS-76TH ORTDocumento1 páginaCovering Letter NTPS-76TH ORTSE ESTAinda não há avaliações

- Sp. Raw Water & Sp. Soften Water Consumption Up To JAN-18Documento11 páginasSp. Raw Water & Sp. Soften Water Consumption Up To JAN-18SE ESTAinda não há avaliações

- Compiled by EST-HO MumbaiDocumento47 páginasCompiled by EST-HO MumbaiSE ESTAinda não há avaliações

- Sop Chlorine GasDocumento3 páginasSop Chlorine GashmtlionAinda não há avaliações

- Mahagenco BTL 15.02.2018Documento1 páginaMahagenco BTL 15.02.2018SE ESTAinda não há avaliações

- Covering Letter NTPS-76TH ORTDocumento1 páginaCovering Letter NTPS-76TH ORTSE ESTAinda não há avaliações

- At Of: Eyent Analysis NewlarliDocumento1 páginaAt Of: Eyent Analysis NewlarliSE ESTAinda não há avaliações

- Event Analysis: TPS: Unit - Date: Operating Coal SeruiceDocumento1 páginaEvent Analysis: TPS: Unit - Date: Operating Coal SeruiceSE ESTAinda não há avaliações

- All India Sept17Documento3 páginasAll India Sept17SE ESTAinda não há avaliações

- Sp. Raw Water & Sp. Soften Water Consumption Up To Aug17Documento11 páginasSp. Raw Water & Sp. Soften Water Consumption Up To Aug17SE ESTAinda não há avaliações

- CHD 4 - 27 12 2016Documento6 páginasCHD 4 - 27 12 2016SE ESTAinda não há avaliações

- All India Sept17Documento2 páginasAll India Sept17SE ESTAinda não há avaliações

- Sp. Raw Water & Sp. Soften Water Consumption Up To Aug17Documento11 páginasSp. Raw Water & Sp. Soften Water Consumption Up To Aug17SE ESTAinda não há avaliações

- BTL 500MW U4 Updated 06072017Documento1 páginaBTL 500MW U4 Updated 06072017SE ESTAinda não há avaliações

- KPKD-5 22.12.2015Documento10 páginasKPKD-5 22.12.2015SE ESTAinda não há avaliações

- CHD-6 22.12.2015Documento2 páginasCHD-6 22.12.2015SE ESTAinda não há avaliações

- KPKD-5 22.12.2015Documento10 páginasKPKD-5 22.12.2015SE ESTAinda não há avaliações

- CHD 3 - 06 12 2016Documento10 páginasCHD 3 - 06 12 2016SE ESTAinda não há avaliações

- PRS-4 16.12.2015Documento1 páginaPRS-4 16.12.2015SE ESTAinda não há avaliações

- PRS-4 16.12.2015Documento1 páginaPRS-4 16.12.2015SE ESTAinda não há avaliações

- CHD-6 22.12.2015Documento2 páginasCHD-6 22.12.2015SE ESTAinda não há avaliações

- Alcorcon Engineering Review Center: I. Diesel Power PlantDocumento6 páginasAlcorcon Engineering Review Center: I. Diesel Power PlantReinzo GallegoAinda não há avaliações

- 3s Steam BoilerDocumento13 páginas3s Steam BoilertahirAinda não há avaliações

- 71 OFFSHORE2011presentationDocumento19 páginas71 OFFSHORE2011presentationJACKAinda não há avaliações

- Particle Swarm Optimization PSO Algorithm Based MPPT For PV System Operating Under Partial Shading ConditionDocumento6 páginasParticle Swarm Optimization PSO Algorithm Based MPPT For PV System Operating Under Partial Shading ConditionEditor IJTSRDAinda não há avaliações

- SCRIPTDocumento2 páginasSCRIPTcelestineAinda não há avaliações

- RE-Unit 5Documento12 páginasRE-Unit 5PALAK GARGAinda não há avaliações

- 693 Super TrakDocumento2 páginas693 Super TraklandagoAinda não há avaliações

- Thermodynamic Cycle PresentationDocumento29 páginasThermodynamic Cycle PresentationAnonymous Oh1pxYX30% (1)

- Nissan J15 Specs - The Forklift Engine CoDocumento1 páginaNissan J15 Specs - The Forklift Engine CoMaratAinda não há avaliações

- SMR - GAG - Rooftop Solar PV Proposal - 26 October 2022 PDFDocumento51 páginasSMR - GAG - Rooftop Solar PV Proposal - 26 October 2022 PDFEssam KawrdyAinda não há avaliações

- MNT 029-03 Operation of Boiler Water SoftnerDocumento3 páginasMNT 029-03 Operation of Boiler Water SoftnerAniket kopateAinda não há avaliações

- Depcopower2023sep BR QuotationDocumento12 páginasDepcopower2023sep BR QuotationGilson EliasAinda não há avaliações

- Solar Panel Sizing - How To Calculate Home Solar System SizeDocumento12 páginasSolar Panel Sizing - How To Calculate Home Solar System SizealiAinda não há avaliações

- Technical English Course For Students in Renewable EnergiesDocumento16 páginasTechnical English Course For Students in Renewable Energiesdjoudi mouradAinda não há avaliações

- Mech 1442851569131Documento80 páginasMech 1442851569131Bilal ArqubAinda não há avaliações

- MS9001FA Gas Turbines: Maximum ReliabilityDocumento2 páginasMS9001FA Gas Turbines: Maximum ReliabilityPeter_Phee_341Ainda não há avaliações

- Lab Name: Demonstration and Operation of 5KW Steam Power PlantDocumento14 páginasLab Name: Demonstration and Operation of 5KW Steam Power PlantFarhan EdwinAinda não há avaliações

- AssignmentNo1 NozzlesDocumento1 páginaAssignmentNo1 NozzleskamalAinda não há avaliações

- Part - B Mechanical EngineeringDocumento176 páginasPart - B Mechanical EngineeringChandramohan GAinda não há avaliações

- Ei6002 Power Plant Instrumentation Question Bank PDFDocumento11 páginasEi6002 Power Plant Instrumentation Question Bank PDFLokesh Gopinath100% (1)

- Utility Automation Module: Recovering Pure Condensate Form Multi Utility ReactorsDocumento2 páginasUtility Automation Module: Recovering Pure Condensate Form Multi Utility ReactorsPrem ChandarAinda não há avaliações

- Practical Training ReportDocumento26 páginasPractical Training ReportNishant SharmaAinda não há avaliações

- Mec294 - Thermofluids Lab: Lesson Plan (Semester Mar2021 - Aug2021) Aug-21 Sept-2021Documento1 páginaMec294 - Thermofluids Lab: Lesson Plan (Semester Mar2021 - Aug2021) Aug-21 Sept-2021Farhan IkhwanAinda não há avaliações

- Intake ProcessDocumento9 páginasIntake ProcessHizanorhuda ZurghibaAinda não há avaliações

- Micro CHP PDFDocumento4 páginasMicro CHP PDFtrungnguyenphuocAinda não há avaliações

- Steam Turbine Product Overview enDocumento45 páginasSteam Turbine Product Overview enMohamed Adel100% (1)

- Datasheet - TSUN ESK SpiderDocumento2 páginasDatasheet - TSUN ESK SpiderELECTROSTATIC SPRAYERS GREECEAinda não há avaliações

- Thermoelectric Refrigerator For Travelling: Lalit Bansal Nitesh Kumar Jha Rohan Kanodiya Sandeep JhambDocumento3 páginasThermoelectric Refrigerator For Travelling: Lalit Bansal Nitesh Kumar Jha Rohan Kanodiya Sandeep JhambLalit BanaalAinda não há avaliações

- Volvo TAD731-2-3GEDocumento299 páginasVolvo TAD731-2-3GEmoises83% (6)

- 0044 - Small - Mini and Micro Hydro Power Stations in India - Publication No.-254 - Vol-1Documento372 páginas0044 - Small - Mini and Micro Hydro Power Stations in India - Publication No.-254 - Vol-1RAHUL BHUSHAN AmbedkarAinda não há avaliações

- University of Chicago Press Fall 2009 Distributed TitlesNo EverandUniversity of Chicago Press Fall 2009 Distributed TitlesNota: 1 de 5 estrelas1/5 (1)