Escolar Documentos

Profissional Documentos

Cultura Documentos

Non-Isothermal Dehydration Kinetics of Titania Gel

Enviado por

SEP-PublisherTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Non-Isothermal Dehydration Kinetics of Titania Gel

Enviado por

SEP-PublisherDireitos autorais:

Formatos disponíveis

www.acse-journal.

org

Advances in Ceramic Science and Engineering (ACSE) Volume 3, 2014

doi: 10.14355/acse.2014.03.006

Non-isothermal Dehydration Kinetics of

Titania Gel

Praveen Kumar Singh1, Jagannath Roy2, Soumya Mukharjee3, Chandan Kumar Ghosh4, Saikat Maitra1*

Government College of Engineering & Ceramic Technology, Kolkata-700010, India,

Camellia Institute of Technology, Kolkata-700129, India,

Department of Metallurgical and Material Engineering, Jadavpur University, India

School of Material Science & Nanotechnology, Jadavpur University, India

maitrasaikat@rediffmail.com

Received 5 March, 2014; Revised 10 April, 2014; Accepted 20 April, 2014; Published 18 May, 2014

2014 Science and Engineering Publishing Company

Abstract

Titania gel was synthesized by sol-gel method and

dehydration kinetics of the gel was studied using a thermo

gravimetric analyzer in the temperature range of 35-700oC at

three different heating rates. Dehydration of the gel was

observed to take place at two different stages. Kinetic

analysis for dehydration at both stages were performed by

Friedman model fitting and Kissinger Akahira Sunose

(KAS) model free methods to determine kinetic triplet. It

was observed that dehydration of the titania gel sample

followed second order reaction kinetics in both the stages.

Keywords

Sol-gel Process; Dehydration Kinetics; Activation Energy;

Friedman Method; Kissinger-Akahira-Sunose a Pproximation

Introduction

Thermogravimetric analysis (TG) is a widely accepted

method to study the course of solid state reactions. In

non-isothermal analysis, the mass loss of a sample at

different heating temperature is measured with

controlled heating rate. From the thermogravimetric

curves, the kinetic parameters can be calculated since

the shape of these curves depend on the reaction

kinetics followed at these stages. So to determine the

kinetic parameters several model fitting, (where a

reaction model is chosen) and model free (where no

reaction model is chosen) kinetic calculation methods

were developed. Friedman and Kissinger-AkahiraSunose (KAS) method are the examples of modelfitting and model-free kinetic calculation procedures

respectively.

Sol-gel process is one of the most advanced methods

for the synthesis of precursor powder for ceramics as it

46

results in the development of products with relatively

higher purity and homogeneity compared to other

conventional procedures. During the dehydration of

gel water and other volatiles are removed leaving

behind the solid residues. A number of works have

been reported on the dehydration kinetics of synthetic

gels based on thermogravimetric analysis and some of

the reported works have been mentioned here.

Hernandez-Escolano et al. (2012) performed TG

analysis of a gel sample and used model free integral

is oconversional non-isothermal procedure for kinetic

study. The n=6 kinetic model was observed to be the

best fitted for all the system during kinetic model

determination by applying Coats-Refern method.

Biedunkiewicz et al. (2010) performed TG-DSC

measurements under non-isothermal and isothermal

conditions at four different temperatures and used

Coats-Redfern method to describe the kinetic

parameters. Maitra et al. (2008) synthesized zeolite gel

and showed that gel dehydration followed first order

kinetics and it proceeded through low energy

diffusion controlled process. Budrugeac et al. (2007)

studied non-isothermal kinetics of decomposition of

zinc-acetate

based

gel

precursors

using

thermogravimetric data. Invariant kinetic parameter

(IKP) method was used by the authors for the

evaluation of activation energy, pre exponential factor

and kinetic model. It was observed that decomposition

of the gel sample followed F1 kinetic model. Want et al.

(2007) performed thermogravimetric and differential

thermal analysis of gel of ytterbium tartrate hydrate.

They observed that the decomposition of the gel was

started after 200oC and completed in two stages at

around 700oC. By using the integral method and

Advances in Ceramic Science and Engineering (ACSE) Volume 3, 2014

applying the Coats-Redfern approximation, the nonisothermal kinetics parameters like activation energy

and frequency factors were evaluated. Jankovic et al.

(2005) studied the dehydration process of swollen

polyhydrogel at different heating rates. Under nonisothermal condition, different kinetic parameters like

activation energy, pre-exponential factor and kinetic

model for the hydrogel dehydration process were

studied. The results obtained by applying methods

like Kissinger, Coats-Redfern etc. under the same

heating rates were in good agreement with each other.

In this present investigation, thermogravimetric

analysis of titania gel was performed at three different

heating rates. The kinetic triplet (reaction order,

activation energy and frequency factor) were

calculated using Friedman method and the results

were further verified by Kissinger-Akahira-Sunose

(KAS) approximation method.

Experimental Methods

Synthesis of Stable Titania Gel

7.08 gm of Potassium Titanium Oxalate [K2TiO

(C2O4)2.2H2O (LOBA CHEMIE, INDIA)] was mix with

200ml of distil water to make 0.1 M KTO solution. To

this solution (1:1) (volume /volume ratio) NH4OH was

added till the precipitation was complete. At around

pH-12, precipitation was found complete and it was

washed thoroughly with distilled water till pH~7. The

precipitate was filtered and finally dissolved in (1:1)

solution of 30% Hydrogen peroxide (MERCK, INDIA).

It was observed that the maximum concentration of

TiO2 would be achieved by the addition of 32 ml

solution of H2O2. Thereupon, the total solution was

kept at rest for 15-20 min so to dissolve the precipitate

completely. To the solution Diethanolamine C4H11NO2

(DEA) (MERCK, INDIA) was added dropwise till the

pH of the solution reached to ~10.

After complete addition of DEA, a stable sol was

formed and the sol was dried at 110oC overnight. The

dried gel was subjected to TGA study at three

different temperatures i.e. 4, 7 and 10oC/min using

Perkin Elmer, Pyris Diamond 480. Fourier Transform

Infrared studies of per titanic acid and the gel heat

treated at five different temperatures (110, 220, 330,

440 and 550oC) were performed using IRPrestige-21,

Shimadzu, Japan. X-ray diffraction (XRD) pattern of

the gel was taken by Rigaku Ultima III, Japan.

www.acse-journal.org

following reaction scheme:

Gel Solid residues + Volatiles

(1)

The fraction of dehydrated mass can be defined by

the following expression:

m0 mt

m0 m f

(2)

Where m0 is the mass of the gel at the beginning, mt

and mf are refer to the masses at timet and at the end

of the experiment respectively.

d

), is a linear function of

dt

temperature-dependent rate constant, k, and reaction

model (a temperature independent function of

conversion), f ( ) :

Rate of dehydration (

d

=k f ( )

dt

(3)

Vyazovkin et al. (2011) Studied Isoconversional

calculation methods by splitting it into two different

categories: differential and integral.

Differential Isoconversional Methods

Replacing the rate constant with Arrhenius equation

E

( k = A.e RT ), above equation becomes:

d A RT

f ( )

= e

dT

E

(4)

Where A is the pre-exponential factor, E is the

activation energy, R is the universal gas constant and

T is the absolute temperature.

By taking the logarithm of equation (3), we can get,

d

E

=

ln( ) ln[ A. f ( )]

dt

RT

(5)

This equation was proposed by Friedman as

Vyazovkin et al. (2011) By introducing heating rate

dT

( =

) in the above equation and rearranging,

dt

ln(

d

A

E

) ln[ f ( )] =

ln( )

RT

dT

(6)

Isoconversional Kinetic Calculations

1

d

would give a

) ln[ f ( )] versus

T

dT

straight line. The slope and intercept of the straight

line provided the values of activation energy and

frequency factor respectively. Values of f ( ) were

Dehydration of the gel can be represented by the

chosen arbitrarily from the Velyana et al. (2013) and

The plot of ln(

47

www.acse-journal.org

Advances in Ceramic Science and Engineering (ACSE) Volume 3, 2014

1

d

and

) ln[ f ( )] values were plotted against

T

dT

from these plots the best fit value of f ( ) was chosen

equation (8) for both stages. The activation energy E

and frequency factor were determined from the slope

and intercept of each plot using equation (8).

which showed the best correlation coefficient. Now

from the plot of best fitted f ( ) value, activation

Result and Discussion

ln(

energy and pre-exponential factor were calculated by

E

A

taking slope = and intercept= ln( ) at all the

R

heating rates.

Integral Isoconversional Methods

Integration of equation (3) will give the following form

Vyazovkin et al. (2011),

(

d

A T RT

g ( )

dT

=

e

0

0 f ( )

(7)

When ammonium hydroxide was added to the

solution of potassium titanium oxalate, basic titanium

hydroxide [TiO (OH)2] was precipitated. The

precipitate was dissolved by the addition of hydrogen

peroxide as Ti4+ and H2O2 interact strongly and form

peroxotitanic acid as Myers et al. (2004), To this

solution DEA was added to form the stable sol. The

solution brcome hot during the addition of DEA

indicating exothermic nature of the reaction.

The FTIR spectra of the samples have been shown in

the Fig. 1.

To get a solution of equation (7), several

approximations were proposed. Kissinger-AkahiraSunose (KAS) developed one of such approximation

and their proposed equation is the following,

AR

E

=

ln( 2 ) ln[

)]

g ( ).E

RT

T

(8)

Where g() is the reaction model which depends on

the conversion mechanism and its algebraic expression.

For a known reaction model and each degree of

1

will be a

conversion (), the plot of ln( 2 ) versus

T

T

straight line whose slope and intercept can provide the

AR

values of activation energy (E) and ln[

]

g ( ).E

respectively.

To determine the reaction order, the equation (8) has

been rearranged in the following way,

g ( )

AR

E

ln[=

] ln[

]

E RT

T2

(9)

g ( )

] versus 1/T would be a

T2

straight line with slope equal to -1.0000. Using linear

regressive of least square method and choosing

arbitrary values of g() available in the literature [4],

ln [g()/T2] values were plotted against 1/T and plot

having slope closet to -1.0000 and correlation

coefficient closet to unity was considered as the best fit

mechanism function of [g()].

Now the plot of ln[

Subsets of the TG-curves at certain values of and

corresponding temperatures were taken and the

dependence of ln [/T2] on 1/T was drawn according to

48

FIG. 1 FTIR SPECTRA OF (I) PEROXO TITANIC ACID AND GEL

HEATED AT (II) 110OC (III) 220OC (IV) 330OC (v) 440OC AND (vi) 550OC

The formation of peroxotitanic acid was confirmed

from the peak appeared at 900 cm-1 which was due to

the stretching vibrations of O-O bond in the Ti-O-O-H

bond of the peroxotitanic acid as studied by

Vasconcelos et al. (2011). The narrow band in the 410700 cm-1 with maxima at 550oC, the peaks at

480cm1 and 650cm1 were assigned to the anatase

form of titania as proposed by Bagheri et al. (2013).

The X-ray diffractogram of the gel heated at 550oC has

shown in the Fig. 2.

From the JCPDS data (Model-211272 & 181403), it was

observed that most of the phases were anatase. The TG

and DTG plots of the samples for heating rates 4, 7,

and 10oC min-1 have been shown in Fig. 3.

Advances in Ceramic Science and Engineering (ACSE) Volume 3, 2014

FIG. 2 XRD OF THE GEL HEATED AT 550OC

www.acse-journal.org

calculated. In the first stage, the dehydration was

complete with a mass loss of 24% on an average,

whereas in the second stage almost 8% mass loss was

observed. The initial temperature (ti), peak

temperature (tm) and final temperature (tf) of

dehydration process of both the stages were studied

for all the heating rates. It was observed that in both

the stages, dehydration temperatures were shifted to

higher values with increasing heating rates. This is

because at lower heating rates, heat transfer was not so

effective and efficient. At higher heating rates, heating

of gel particles occurred more gradually leading to an

improved and more effective heat transfer to the inner

portions and among the particles. The peak

temperature was also shifted to higher temperatures

with the increasing heating rate as a consequence of

increasing rate of volatilization process.

FIG. 3 TG AND DTG PLOTS OF THE GEL AT HEATING RATES 4,

7, AND 10OC MIN-1

In the TG plot two major changes were observed

within the range of 35-310oC and 325-590oC

respectively. So we have divided the total dehydration

process into two stages and kinetic calculations were

performed for the two stages separately. From the TG

data, fractional decomposition of the sample was

FIG. 4 FRIEDMAN PLOT OF F()=2 FOR (I) STAGE-1 AND (II)

STAGE-2.

49

www.acse-journal.org

Advances in Ceramic Science and Engineering (ACSE) Volume 3, 2014

Since dehydration of the gel took place in two

different stages, so the calculations were performed

for both the stages of dehydration separately at all

heating rates. During the calculations based on

Friedman differential method, it was found that best

fit value of n was equal to 2 in both the stages. So it

was concluded that dehydration of the gel in both the

stages followed second order kinetics. The plots have

been shown in Fig. 4.

It implies that the rate of dehydration was controlled

not only by the magnitude of hydroxyl group present

in the sample but also by the nature of the gel. Now

other two parameters (activation energy and preexponential factor) of the kinetic triplet were

calculated by taking best fit value of n=2 for all the

three heating rates for both the stages and values

found are given in Table-1. The average activation

energy for dehydration was found to be lower in

stage-1 compared to stgae-2. The calculated values of

the pre-exponential factor, signifying the fraction of

activated species participating in the reaction was

found to be much higher in the first stage of

dehydration compared to that of the second stage.

FIG. 5 KAS PLOT OF G()=2 FOR (I) STAGE-1 AND (II) STAGE-2.

TABLE 1 VALUES OF ACTIVATION ENERGY AND FREQUENCY FACTOR

BASED ON FRIEDMAN METHOD

Stage

Heating

Rate/min

Heating

Rate/sec

4

6

8

10

0.06666

0.1

0.13333

0.16666

4

6

8

10

0.06666

0.1

0.13333

0.16666

Average

II

Average

Activation

Energy

KJmole-1

R=8.314

51.50

51.43

50.59

49.27

50.70

70.61

70.13

68.46

66.92

69.03

Exponential

Factor

A x 104

8.64

7.90

7.62

7.09

1.95

2.26

2.36

2.86

2.36

During calculation based on KAS integral method, F2

mechanism function was found to be the best fit at all

three heating rates in case of both the stages. The plots

have been shown in Fig. 5.

So it can be confirmed that dehydration of the gel in

both stages followed second order based mechanism.

With the completion of dehydration at the first stage,

the gel framework followed a partial structural

collapse, to create more obstruction for the migration

of residual water molecules and other volatiles

through the structure. The values of activation energy

and pre-exponential factor were determined from the

slope and intercept of each plot Fig. 6.

50

FIG. 6 ISO-CONVERSIONAL PLOTS AT VARIOUS CONVERSION

DEGREE OF GEL ACCORDING TO KAS CALCULATION

PROCEDURE FOR (I) PHASE-1 (II) PHASE-2 TO DETERMINE

ACTIVATION ENERGY AND FREQUENCY FACTOR

Advances in Ceramic Science and Engineering (ACSE) Volume 3, 2014

using equation-8 were found to be in agreement to

those calculated by other method table-2.

TABLE 2 VALUES OF ACTIVATION ENERGY AND FREQUENCY FACTOR

Stage

Degree of

Conversion

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Average

II

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Average

(2010): 701-06.

isothermal kinetic study on the decomposition of

Exponential

Factor

A x 104

0.00440

0.00010

0.00009

0.01167

0.49427

6.7798

39.442

16.636

25.908

9.92

0.00836

1.1381

0.15202

0.14429

0.8926

8.0802

0.3642

1.4942

12.537

2.7568

Zn acetate-based sol-gel precursor. Journal of

Thermal Analysis and Calorimetry 88 (2007): 699702.

Hernandez-Escolano, M., X. Ramis, A. Jimenez-Morales, M.

Juan-Diaz,

and

J. Suay.

Study

of

the

thermal

degradation of bioactive solgel coatings for the

optimization of its curing process. Journal of Thermal

Analysis and Calorimetry 107 (2012): 499-508.

Jankovic, B., B. Adnadevic, and J. Jovanovic. Nonisothermal kinetics of dehydration of equilibrium

swollen poly(acrylic acid) hydrogel. Journal of

Thermal Analysis and Calorimetry 82 (2005): 7-13.

Maitra, S., S Das, R Ray, and N. K. Mitra. Role of some

transition

metal

cations

on

the

kinetics

of

thermadehydration of synthetic zeolites. Ceramics

International 34 (2008): 485-90.

Myers, W. D., P. A. Ludden, V. Nayigihugu, and B. W. Hess.

Conclusion

A procedure for the preparation and quantitative

Sol-gel method was used to synthesize titania gel. By

using different methods, non-isothermal dehydration

kinetics

of

gel

was

studied

from

the

thermogravimetric information under dynamic

conditions with multiple heating rates. The gel

dehydration was observed to take place in two stages

and both the stages followed second order kinetics.

The activation energy of the second stage was higher

than that of the first stage. The calculated values of the

pre-exponential factor, signifying the fraction of

activated species participating in the reaction was

found to be several orders of magnitude in the first

stage of dehydration compared to the second stage.

analysis of samples for titanium dioxide. Journal of

Animal Science 82 (2004): 179-83.

Vasconcelos , Daniela. C. L., V. C. Costa, E. H. M. Nunes, A.

C. S. Sabioni, M. Gasparon, and W. L. Vasconcelos.

Infrared Spectroscopy of Titania Sol-Gel Coatings on

316L

Stainless

Steel.

Materials

Sciences

and

Applications 2 (2011): 1375-82.

Velyana, Georgieva, D. Zvezdova, and L. Vlaev.

Non-isothermal kinetics of thermal degradation of

chitin.

Journal

of

Thermal

Analysis

and

Calorimetry 111 (2013): 763-771.

Vyazovkin, Sergey, A. K. Burnham, J. M. Criado, L. A.

REFERENCES

Perez-Maqueda, C. Popescu, and N. Sbirrazzuoli.

Bagheri, Samira, K. Shameli, and S. B. A. Hamid.

Synthesis

Journal of Thermal Analysis and Calorimetry 101

Budrugeac, P., V. Muat, and E. Segal. Non-

BASED ON KAS METHOD.

Activation Energy

KJ mole-1

R=8.314

33.68

24.12

26.60

45.44

60.39

70.32

76.34

71.53

70.90

53.26

61.23

81.03

71.73

71.21

80.50

90.95

74.63

82.17

91.61

78.34

www.acse-journal.org

and

Characterization

of

Anatase

ICTAC kinetics committee recommendations for

performing

kinetic

computations

on

thermal

Titanium Dioxide Nanoparticles Using Egg White

analysis data. Thermochimica Acta 520 (2011): 1-

Solution

19.

via

Sol-Gel

Method.

Journal

of

Chemistry (2013): Article ID 848205, 1-5. Accepted

October 23, 2012. doi.org/10.1155/2013/848205.

Biedunkiewicz, A., U. Gabriel, P. Figiel, and D. Grzesiak.

Application of thermal analysis in nanotechnology.

Want, Basharat, F. Ahmad, P. N. Kotru. Dielectric

and thermal characteristics of gel grown single

crystals of ytterbium tartrate trihydrate. Journal

of Materials Science 22 (2007): 9324-30.

51

Você também pode gostar

- Experimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesDocumento8 páginasExperimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesSEP-PublisherAinda não há avaliações

- Influence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearDocumento13 páginasInfluence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearSEP-PublisherAinda não há avaliações

- Improving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesDocumento5 páginasImproving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesSEP-PublisherAinda não há avaliações

- Contact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentDocumento7 páginasContact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentSEP-PublisherAinda não há avaliações

- Effect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesDocumento11 páginasEffect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesSEP-PublisherAinda não há avaliações

- Mill's Critique of Bentham's UtilitarianismDocumento9 páginasMill's Critique of Bentham's UtilitarianismSEP-PublisherAinda não há avaliações

- Microstructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesDocumento7 páginasMicrostructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesSEP-PublisherAinda não há avaliações

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocumento5 páginasMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherAinda não há avaliações

- Device For Checking The Surface Finish of Substrates by Tribometry MethodDocumento5 páginasDevice For Checking The Surface Finish of Substrates by Tribometry MethodSEP-PublisherAinda não há avaliações

- Reaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesDocumento9 páginasReaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesSEP-PublisherAinda não há avaliações

- A Tentative Study On The View of Marxist Philosophy of Human NatureDocumento4 páginasA Tentative Study On The View of Marxist Philosophy of Human NatureSEP-PublisherAinda não há avaliações

- FWR008Documento5 páginasFWR008sreejith2786Ainda não há avaliações

- Enhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentDocumento6 páginasEnhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentSEP-PublisherAinda não há avaliações

- Isage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophyDocumento8 páginasIsage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophySEP-PublisherAinda não há avaliações

- Delightful: The Saturation Spirit Energy DistributionDocumento4 páginasDelightful: The Saturation Spirit Energy DistributionSEP-PublisherAinda não há avaliações

- Quantum Meditation: The Self-Spirit ProjectionDocumento8 páginasQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherAinda não há avaliações

- Cold Mind: The Released Suffering StabilityDocumento3 páginasCold Mind: The Released Suffering StabilitySEP-PublisherAinda não há avaliações

- Mindfulness and Happiness: The Empirical FoundationDocumento7 páginasMindfulness and Happiness: The Empirical FoundationSEP-PublisherAinda não há avaliações

- Technological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsDocumento9 páginasTechnological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsSEP-PublisherAinda não há avaliações

- Metaphysics of AdvertisingDocumento10 páginasMetaphysics of AdvertisingSEP-PublisherAinda não há avaliações

- Architectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldDocumento5 páginasArchitectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldSEP-PublisherAinda não há avaliações

- Enhanced Causation For DesignDocumento14 páginasEnhanced Causation For DesignSEP-PublisherAinda não há avaliações

- Social Conflicts in Virtual Reality of Computer GamesDocumento5 páginasSocial Conflicts in Virtual Reality of Computer GamesSEP-PublisherAinda não há avaliações

- Legal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialDocumento4 páginasLegal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialSEP-PublisherAinda não há avaliações

- Ontology-Based Testing System For Evaluation of Student's KnowledgeDocumento8 páginasOntology-Based Testing System For Evaluation of Student's KnowledgeSEP-PublisherAinda não há avaliações

- Damage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationDocumento10 páginasDamage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationSEP-PublisherAinda não há avaliações

- Computational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpDocumento6 páginasComputational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpSEP-PublisherAinda não há avaliações

- The Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateDocumento8 páginasThe Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateSEP-PublisherAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Identify The Following: Cien 3090 Construction Materials & Testing Midterm ExamDocumento1 páginaIdentify The Following: Cien 3090 Construction Materials & Testing Midterm Examacurvz2005Ainda não há avaliações

- Dow Coring Asia ManualDocumento69 páginasDow Coring Asia ManualGULJAR SINGHAinda não há avaliações

- Submitted By:-Jatin GargDocumento26 páginasSubmitted By:-Jatin GargNANDHINI NAinda não há avaliações

- Global Talent 2021Documento48 páginasGlobal Talent 2021Mentari Clara dewantiAinda não há avaliações

- All Sites DPR 02-06-2017Documento16 páginasAll Sites DPR 02-06-2017San SvsAinda não há avaliações

- STEICO LVL Bonded LVL Sections EN IDocumento2 páginasSTEICO LVL Bonded LVL Sections EN IClaudiu BaditaAinda não há avaliações

- Ekstraksi: Riani Ayu Lestari, M. EngDocumento42 páginasEkstraksi: Riani Ayu Lestari, M. EngNathaliaSihombingAinda não há avaliações

- Laser Consumables PDFDocumento1 páginaLaser Consumables PDFAnonymous cXX1tYY2Ainda não há avaliações

- 9040 Washing and SterilizationDocumento1 página9040 Washing and SterilizationCalidad LassAinda não há avaliações

- Process Simulation of Ethanol Production From Biomass Gasification and Syngas Fermentation PDFDocumento33 páginasProcess Simulation of Ethanol Production From Biomass Gasification and Syngas Fermentation PDFramesh pokhrelAinda não há avaliações

- Integrated Waste Management PDFDocumento7 páginasIntegrated Waste Management PDFTechsrijan DriveAinda não há avaliações

- 3 Types of Traffic Count: 3.1 Manual CountsDocumento3 páginas3 Types of Traffic Count: 3.1 Manual CountsRichard BryanAinda não há avaliações

- Insert Bonded Metal CombinationsDocumento1 páginaInsert Bonded Metal CombinationsnorthstarleoAinda não há avaliações

- RAJKOT: Students of 6: Prof. Pratik Koradiya SirDocumento3 páginasRAJKOT: Students of 6: Prof. Pratik Koradiya Siryash kalavadiaAinda não há avaliações

- IGC Doc 24-08-EDocumento19 páginasIGC Doc 24-08-Elutfirashid87Ainda não há avaliações

- Pipeline Risk Management Basic ManualDocumento6 páginasPipeline Risk Management Basic ManualhemnAinda não há avaliações

- Thermal Lab PPT - Heat Balance SheetDocumento10 páginasThermal Lab PPT - Heat Balance SheetAyush SinghalAinda não há avaliações

- Chemical & Process Technology - Determine Latent Heat For Multi-Component and Relieving Area Using Rigorous Method in HYSYSDocumento6 páginasChemical & Process Technology - Determine Latent Heat For Multi-Component and Relieving Area Using Rigorous Method in HYSYSAnonymous q95lwCgAinda não há avaliações

- DaihatsuDocumento10 páginasDaihatsuMANIU RADU-GEORGIANAinda não há avaliações

- Manual Lavavajilla Electrolux NHT60Documento14 páginasManual Lavavajilla Electrolux NHT60Victor Hugo Quiñonez QuintanaAinda não há avaliações

- Mechatronics Electronic Control Systems in Mechanical and Electrical EngineeringDocumento19 páginasMechatronics Electronic Control Systems in Mechanical and Electrical EngineeringTanAinda não há avaliações

- Concrete Proportion and Concrete MixtureDocumento12 páginasConcrete Proportion and Concrete MixtureEnrico luis EscobarAinda não há avaliações

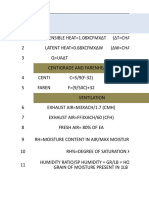

- All Formulas HvacDocumento11 páginasAll Formulas HvacrockAinda não há avaliações

- Concertina CoilDocumento4 páginasConcertina CoilvklsAinda não há avaliações

- Water Tree Cable JointsDocumento151 páginasWater Tree Cable JointsSellappan MuthusamyAinda não há avaliações

- Viper SM 21203788CDocumento158 páginasViper SM 21203788CarodassanchezAinda não há avaliações

- TMMDocumento21 páginasTMMAkash LohiAinda não há avaliações

- TDS Shell Gadus S2 V220 2Documento2 páginasTDS Shell Gadus S2 V220 2regisAinda não há avaliações

- Is 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsDocumento10 páginasIs 6158 - 1984 Recommended Practice For Safeguarding Against Embrittlement of Hot-Dip Galvanized Iron and Steel ProductsNadeem KhanAinda não há avaliações

- OverpressureDocumento2 páginasOverpressureampowersidAinda não há avaliações