Escolar Documentos

Profissional Documentos

Cultura Documentos

Types of Cooling Towers

Enviado por

Joc LuisDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Types of Cooling Towers

Enviado por

Joc LuisDireitos autorais:

Formatos disponíveis

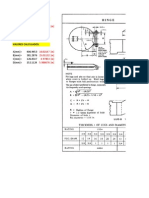

FIG.

11-6

E+B

Number of

=

Concentrations (cycles)

B

Mechanical Forced Draft Counterflow Tower

2.0 + (0.2 + 0.3)

=

= 5.0

(0.2 + 0.3)

Water

Sprays

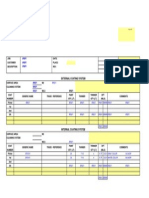

If the resultant concentrations are excessive and a desired concentration of 4.0 is required, what must the blowdown rate be?

B =

=

Air

Out

Air

In

E

Cycles 1

2.0

= 0.67%

4.0 1

The windage component of B is 0.3%, therefore the blowdown

rate required would be 0.67 0.3 = 0.37% or

(10,000 gpm) (0.0037) = 37 gpm

CONCENTRATION CYCLES

Water

Out

Fan

The concentration of compounds occurring in circulating

water systems that can cause scaling or corrosion of equipment must be controlled at a desirable level. This concentration level, developed on each system, is based on the quality of

makeup water and the water treating chemicals used to control corrosion or scaling. The concentration is usually reported

as concentration cycles and refers to the number of times the

compounds in the makeup water are concentrated in the blowdown water. For example, if the concentration in the makeup

water were 125 ppm and the concentration of the blowdown

were 563, the concentration cycles would be 563/125 or 4.5

cycles. The compounds are concentrated by the loss of water

through evaporation and windage. The evaporation loss is

based on the fact that 1,000 Btu are required to evaporate

one (1) pound of water. The heat of evaporation is furnished

by cooling the circulating water. One hundred (100) pounds of

water must be cooled 10 to furnish this amount of heat, therefore, evaporation loss is 1% of tower circulation for each 10

temperature drop through the tower.

FIG. 11-7a

Mechanical Induced Draft Counterflow Tower

Air

Out

Fan

Water

Inlet

Air In

Air In

Watet

Outlet

TYPES OF COOLING TOWERS

Cooling towers have two types of air flow: crossflow and

counterflow. In crossflow towers, the air moves horizontally

across the downward flow of water. In counterflow towers, the

air moves vertically upward against the downward fall of the

water.

FIG. 11-7b

Mechanical Induced Draft Cross Flow Tower

Air

Out

There are many types and sizes of cooling towers:

Mechanical Draft Towers

Fan

Fans are used to move the air through the mechanical draft

tower. The performance of the tower has a greater stability

because it is affected by fewer psychrometric variables. The

fans provide a means of regulating the air flow. Mechanical

draft towers are characterized as either forced draft or induced

draft.

Forced draft towers (Fig. 11-6) The fan is located on

the air stream entering the tower. This tower is characterized

by high air entrance velocities and low exit velocities, therefore, the towers are susceptible to recirculation thus having a

lower performance stability. The fans can also be subject to

icing under conditions of low ambient temperature and high

humidity.

11-13

Water

In

Air

In

Water

Out

Air

In

FIG. 11-8

FIG. 11-10

Mechanical Draft Coil Shed Tower

Hyperbolic Natural Draft Tower

Air

Outlet

Air

Outlet

Gear

Drive

Air

Inlet

Fill

Drift

Eliminators

Water

Inlet

Fan

Air

Inlet

Fill

Coils

Air

Inlet

Hot

Water

Inlet

Water

Outlet

Water Outlet

Natural Draft Towers

FIG. 11-9

Atmospheric spray towers (Fig. 11-9) Cooling towers

of this type are dependent upon atmospheric conditions. No

mechanical devices are used to move the air. They are used

when small sizes are required and when low performance can

be tolerated.

Atmospheric Spray Tower

Air Outlet

Water Inlet

Hyperbolic natural draft towers (Fig. 11-10) These

towers are extremely dependable and predictable in their

thermal performance. A chimney or stack is used to induce air

movement through the tower.

Distribution

System

Air In

Air In

REFERENCES AND BIBLIOGRAPHY

1. American Society of Heating, Refrigerating and Air-Conditioning

Engineers, "ASHRAE HandbookFundamentals," Table 1,

Chapter 6, Atlanta, Georgia.

Water Outlet

2. American Society of Heating, Refrigerating and Air-Conditioning

Engineers, "ASHRAE HandbookFundamentals," Tables 1, 2

and 3, Chapter 24, Atlanta, Georgia.

Cold Water

Collection Basin

Induced draft towers (Fig. 11-7) The fan is located on

the air stream leaving the tower. This causes air exit velocities

which are three to four times higher than their air entrance

velocities. This improves the heat dispersion and reduces the

potential for recirculation. Induced draft towers require about

one (1) horsepower of input for every 8000 cfm of air.3

Coil shed towers (Fig. 11-8) This application exists in

many older cooling towers. The atmospheric coils or sections

are located in the basin of the cooling tower. The sections are

cooled by flooding the surface of the coils with cold water. Reasons for discontinued use were scaling problems, poor temperature control, and construction costs. This type tower can

exist both as mechanical or natural draft.

11-14

3. Evans, Frank L., Jr., "Equipment Design Handbook for Refineries

and Chemical Plants," 2nd ed., Gulf Publishing Company, Houston, Texas.

Você também pode gostar

- Residence TimeDocumento1 páginaResidence TimeJoc LuisAinda não há avaliações

- Residence Time MixerDocumento1 páginaResidence Time MixerJoc LuisAinda não há avaliações

- Diagrama MoodyDocumento1 páginaDiagrama MoodyJoc LuisAinda não há avaliações

- R (MM) 469.9 T (In) Tabla 1.5 T (MM) Tabla Transf 38.1: Valores A IngresarDocumento2 páginasR (MM) 469.9 T (In) Tabla 1.5 T (MM) Tabla Transf 38.1: Valores A IngresarJoc LuisAinda não há avaliações

- External Coating System - Uninsulated Surface: FieldDocumento1 páginaExternal Coating System - Uninsulated Surface: FieldJoc LuisAinda não há avaliações

- MTD Correction FactorsDocumento1 páginaMTD Correction FactorsJoc LuisAinda não há avaliações

- FIG. 11-4 Cooling System CharacteristicsDocumento1 páginaFIG. 11-4 Cooling System CharacteristicsJoc LuisAinda não há avaliações

- Tolerance Heads FormDocumento3 páginasTolerance Heads FormJoc LuisAinda não há avaliações

- Sign Convention: Normal Axis 3Documento5 páginasSign Convention: Normal Axis 3Joc LuisAinda não há avaliações

- Industria Acero de Los Andes S.A.: Geometry and Volume of HeadsDocumento4 páginasIndustria Acero de Los Andes S.A.: Geometry and Volume of HeadsJoc LuisAinda não há avaliações

- P2 (Mpa) - 70.6679522 Potencia 13.8433934Documento3 páginasP2 (Mpa) - 70.6679522 Potencia 13.8433934Joc LuisAinda não há avaliações

- Efects of Cavitation in Hydraulic MachinesDocumento2 páginasEfects of Cavitation in Hydraulic MachinesJoc LuisAinda não há avaliações

- #REF! #REF! #REF!: External Coating SystemDocumento1 página#REF! #REF! #REF!: External Coating SystemJoc LuisAinda não há avaliações

- Best Practices Manual PIPINGDocumento40 páginasBest Practices Manual PIPINGrvnesariAinda não há avaliações

- Gea Westfalia Atmosferic Tank Ree-Pretreated Oil Tank-15M3 11881 - SH2Documento2 páginasGea Westfalia Atmosferic Tank Ree-Pretreated Oil Tank-15M3 11881 - SH2Joc LuisAinda não há avaliações

- Costos PinturaDocumento2 páginasCostos PinturaJoc LuisAinda não há avaliações

- GEA WESTFALIA ATMOSFERIC TANK COATINGDocumento2 páginasGEA WESTFALIA ATMOSFERIC TANK COATINGJoc LuisAinda não há avaliações

- SH3 WeDocumento1 páginaSH3 WeJoc LuisAinda não há avaliações

- GEA WESTFALIA ATMOSFERIC TANK COATINGDocumento2 páginasGEA WESTFALIA ATMOSFERIC TANK COATINGJoc LuisAinda não há avaliações

- #REF! #REF! #REF!: External Coating SystemDocumento1 página#REF! #REF! #REF!: External Coating SystemJoc LuisAinda não há avaliações

- PNT 30Documento1 páginaPNT 30Joc LuisAinda não há avaliações

- PNT 1Documento1 páginaPNT 1Joc LuisAinda não há avaliações

- Coating System SpecificationDocumento1 páginaCoating System SpecificationJoc LuisAinda não há avaliações

- Costos PinturaDocumento2 páginasCostos PinturaJoc LuisAinda não há avaliações

- PP SH3Documento1 páginaPP SH3Joc LuisAinda não há avaliações

- Seccion 8 AsmeDocumento12 páginasSeccion 8 AsmeJoc LuisAinda não há avaliações

- Paint Procedure Plan for Customers EquipmentDocumento1 páginaPaint Procedure Plan for Customers EquipmentJoc LuisAinda não há avaliações

- Seccion 8 AsmeDocumento12 páginasSeccion 8 AsmeJoc LuisAinda não há avaliações

- How To Create USB HeadDocumento37 páginasHow To Create USB HeadT Jefri Hatta MukhtarAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Tablas ft2 PDFDocumento3 páginasTablas ft2 PDFJunior Alexander Lazo ZeladaAinda não há avaliações

- Audrey Lei B. Pike IS209 Co6 Lab: Phy02: (Metal)Documento3 páginasAudrey Lei B. Pike IS209 Co6 Lab: Phy02: (Metal)MaikaAinda não há avaliações

- Refrigeration and Air Conditioning by C P AroraDocumento778 páginasRefrigeration and Air Conditioning by C P Arorasai babu100% (1)

- Lecture - 1Documento29 páginasLecture - 1Vignesh AyyathuraiAinda não há avaliações

- Boundary Layer Thickness and Heat Transfer CalculationsDocumento9 páginasBoundary Layer Thickness and Heat Transfer Calculationsannie100% (1)

- Design of Air Conditioning SystemDocumento6 páginasDesign of Air Conditioning SystemVIVA-TECH IJRIAinda não há avaliações

- Readme - Water Cooled Heat SinkDocumento3 páginasReadme - Water Cooled Heat SinkVijay NarayanAinda não há avaliações

- End Point Energy of Beta Rays Using GM TubeDocumento4 páginasEnd Point Energy of Beta Rays Using GM TubeSanjana DondadkarAinda não há avaliações

- Tut 1Documento2 páginasTut 1Ibraheem KhressAinda não há avaliações

- Igcse Phy 05Documento2 páginasIgcse Phy 05Kamrul Hasan SagarAinda não há avaliações

- Bull Nose Ref FailureDocumento1 páginaBull Nose Ref FailurejagrutAinda não há avaliações

- Ishrae PDFDocumento39 páginasIshrae PDFShivraj SawantAinda não há avaliações

- Ashrae: StandardDocumento52 páginasAshrae: StandardsamadonyAinda não há avaliações

- Introduction To Heat Transfer ModuleDocumento26 páginasIntroduction To Heat Transfer ModuleRolando Sixto Basurco CarpioAinda não há avaliações

- Slimair - Wired Remote ControlDocumento40 páginasSlimair - Wired Remote ControlSaer EspinozaAinda não há avaliações

- XHBQ-D series heat pump performance chartsDocumento1 páginaXHBQ-D series heat pump performance chartsarminsarajevoAinda não há avaliações

- MEF 312 - EXAMPLE PROBLEMS SOLUTIONSDocumento6 páginasMEF 312 - EXAMPLE PROBLEMS SOLUTIONSAJAinda não há avaliações

- Final Graphene Evaportaive CoolingDocumento10 páginasFinal Graphene Evaportaive CoolingSrikanthAinda não há avaliações

- Prysmian Delft HVac - 19Documento1 páginaPrysmian Delft HVac - 19lampujogjaAinda não há avaliações

- TM3040 - JW PumpDocumento6 páginasTM3040 - JW Pumpkman548Ainda não há avaliações

- Bob Herron Electric LTDDocumento8 páginasBob Herron Electric LTDকাফী ওয়াহিদAinda não há avaliações

- Operasi&DeteksiKerusakan PDFDocumento38 páginasOperasi&DeteksiKerusakan PDFService AC jayapuraAinda não há avaliações

- Vapor Absorption Refrigeration System DesignDocumento8 páginasVapor Absorption Refrigeration System Designwill14Ainda não há avaliações

- Correlations for Heat Transfer from Cylinders, Spheres, Bluff Bodies and Tube BundlesDocumento4 páginasCorrelations for Heat Transfer from Cylinders, Spheres, Bluff Bodies and Tube BundlesGaurvansh SharmaAinda não há avaliações

- ASHRAE Journal - A New Approach To Museum HVAC DesignDocumento8 páginasASHRAE Journal - A New Approach To Museum HVAC DesignSandy :pAinda não há avaliações

- AIR BLOWERS Calculation-of-Air-Pipe-SizeDocumento7 páginasAIR BLOWERS Calculation-of-Air-Pipe-SizeEngFaisal Alrai100% (3)

- Honeywell FocusPro Serie 6000 - Manual de UsuarioDocumento80 páginasHoneywell FocusPro Serie 6000 - Manual de UsuarioInversiones RAFEL 9090, C.A.Ainda não há avaliações

- Specific Heat Worksheet ProblemsDocumento3 páginasSpecific Heat Worksheet ProblemsjesudassajAinda não há avaliações

- Nusselt Number Calculation in Fluent - CFD Online Discussion ForumsDocumento6 páginasNusselt Number Calculation in Fluent - CFD Online Discussion ForumsmiladparsmanAinda não há avaliações

- Karakteristika Razmenjivača Toplote I Njen Uticaj Na Izbor Regulacionih Ventila Characteristic of Heat Exchanger and Its Influence On Selection of Control ValveDocumento10 páginasKarakteristika Razmenjivača Toplote I Njen Uticaj Na Izbor Regulacionih Ventila Characteristic of Heat Exchanger and Its Influence On Selection of Control Valvemjaric81Ainda não há avaliações