Escolar Documentos

Profissional Documentos

Cultura Documentos

Elkem Poster For Ductile Iron PDF

Enviado por

vivek1312Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Elkem Poster For Ductile Iron PDF

Enviado por

vivek1312Direitos autorais:

Formatos disponíveis

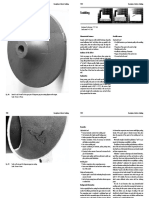

GRAPHITE STRUCTURES IN CAST IRONS

GRAPHITE DISTRIBUTION IN GREY CAST IRON

TYPE A

GRAPHITE FORMS

Random flake graphite

in a uniform distribution

Diagrammatic representations of the standard graphite forms in cast irons

Form

II

TYPE B

III

Rosette flake graphite

Form

IV

VI

TYPE C

GRAPHITE SIZES IN GREY CAST IRON

Kish graphite

Diagrammatic representations of the standard flake graphite sizes in grey cast iron at

x100 magnification (Form I Distribution A)

(hyper-eutectic compositions)

TYPE D

Largest

Flakes

100mm or more

50 - 100mm

25 - 50mm

12 - 25mm

Undercooled

flake graphite

TYPE E

Largest

Flakes

6 - 12mm

3 - 6mm

1.5 - 3mm

less than 1.5mm

Interdendritic

flake graphite

(hypo-eutectic compositions)

GRAPHITE SIZES IN DUCTILE IRON

Diagrammatic representations of the standard graphite nodule sizes in ductile

iron at x100 magnification(Form VI)

SOME ABNORMAL GRAPHITE FORMS IN DUCTILE IRON

EXPLODED GRAPHITE

Largest

Nodules

25 - 50mm

12 - 25mm

6 - 12mm

Caused by high purity charge materials

and excess rare earth additions in

high carbon equivalent irons or in

thicker section castings

CHUNKY GRAPHITE

Largest

Nodules

3 - 6mm

1.5 - 3mm

less than 1.5mm

Caused by high purity charge

materials and excess rare earth

additions in large section castings

or at high carbon equivalent

INOCULANTS

Elkem manufactures and markets a series of high quality inoculants to treat cast iron

and ensure the production of the ideal graphite form, distribution and freedom from chill (cementite).

Inoculant

Active Elements

Advantages and Uses

Superseed 75/50

Si, Sr

Low Al content. Low eutectic cell count through lower addition rates. High chill reduction.

Foundrisil/Barinoc Si, Ba, Ca, (Al)

High chill reduction. Resistance to fading. Used in all cast irons.

Ultraseed

Si, Ca, Ce, (Al,S,O) High nodule count. Improved nodularity. Helps to prevent micro-shrinkage. Reactivates "dead" irons.

Reseed

Si, Ca, Ce, (Al)

SPIKY GRAPHITE

Caused by small amounts of tramp

elements, e.g. lead, bismuth, antimony

and titanium, in the absence of cerium

High nodule count. Improved nodularity. Controls tramp elements in ductile irons. Low S grey iron.

All inoculants are available in sizes suitable for ladle or in-stream additions. Other inoculants for specialist applications are available.

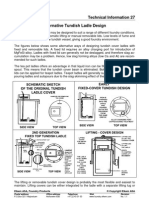

NODULARISERS

Elkem manufactures and markets a range of high quality nodularising alloys to produce ductile and compacted graphite cast irons.

They contain balanced ratios of the active elements to control reactivity, minimise slag and neutralise tramp elements.

Product

Active Elements

Advantages and Uses

Elmag

Si, Mg, Ca, Rare Earths

Magnesium contents from 4 to 10%. Calcium from 0.2 to 3.5%. Rare Earths from 0.1 to 3%.

Allows the choice of the ideal alloy for all foundry conditions.

Remag

Si, Mg, Ca, Rare Earths

High RE, low Mg alloy for low reactivity. Suited to thin section ductile iron castings.

Lamet

Si, Mg, Ca, La

Alloy for in-the-mould treatment of ductile iron. Helps to prevent shrinkage.

CompactMag

Si,Mg, Ca, Rare Earths

Highly effective alloy for the production of compacted graphite irons with reduced section

sensitivity and wide production window.

Description of a structure should follow the convention

Form : Distribution : Size, e.g. Type IA4 for a grey cast iron Type VI5 for a ductile iron

Revised September 2004 Copyright Elkem ASA

Please refer to your local Elkem representative for further information on the range of products available for grey, compacted and ductile irons.

Barinoc, Elmag, Foundrisil, Remag, Reseed, Superseed and Ultraseed are registered trademarks of Elkem ASA.

CompactMag and Lamet are trademarks of Elkem ASA.

The graphite form, distribution and size diagrams are taken from the international standard EN ISO 945:1994

by kind permission of the British Standards Institution, London. W4 4AL.

Photographs of the graphite structures are reproduced by kind permission of Elkem Research, Kristiansand, Norway

and the Castings Development Centre, Alvechurch. Birmingham. B48 7QB.

www.foundry.elkem.com

Elkem ASA, Foundry Products Division, Hoffsveien 65B, PO Box 5211 Majorstua, N-0303 Oslo, Norway. Tel: +47 22 45 01 00 Fax: +47 22 45 01 52

Você também pode gostar

- Engineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeNo EverandEngineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeAinda não há avaliações

- 50 Casting DefectsDocumento49 páginas50 Casting DefectsmohammadAinda não há avaliações

- 26-ELKEM - Poster-Graphite Structures in Cast IronsDocumento1 página26-ELKEM - Poster-Graphite Structures in Cast IronsSalvador Rocha100% (2)

- Common Metallurgical Defects in Ductile Iron EnglishDocumento1 páginaCommon Metallurgical Defects in Ductile Iron EnglishedgarestevessAinda não há avaliações

- Seminar S.G IronDocumento32 páginasSeminar S.G Ironravikataria02Ainda não há avaliações

- Cast Iron MicrostructuresDocumento41 páginasCast Iron MicrostructuresNeo TarunAinda não há avaliações

- Common Metallurgical Defects in Grey Iron English (1Documento1 páginaCommon Metallurgical Defects in Grey Iron English (1sateeshkori100% (2)

- 26-ELKEM Poster-Graphite Structures in Cast IronsDocumento1 página26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENAinda não há avaliações

- Mapa MetalograficoDocumento1 páginaMapa MetalograficoBreno DellaAinda não há avaliações

- SG Iron ProductionDocumento20 páginasSG Iron ProductionShreyashri Nayak100% (1)

- Elkem - Alloying Elements and Their EffectsDocumento8 páginasElkem - Alloying Elements and Their EffectsDeep Shikha Gupta100% (8)

- Poor Nodularity in Ductile IronDocumento2 páginasPoor Nodularity in Ductile Ironarnaldorcr864675% (4)

- Selection of Inoculants For Grey Cast IronDocumento2 páginasSelection of Inoculants For Grey Cast Ironarnaldorcr8646Ainda não há avaliações

- Recommended Target Analysis For Ductile IronDocumento2 páginasRecommended Target Analysis For Ductile Ironarnaldorcr8646100% (2)

- ELMAGDocumento2 páginasELMAGthomazfabricioAinda não há avaliações

- Shrinkage in Ductile IronDocumento5 páginasShrinkage in Ductile Ironkarthikkanda100% (1)

- Inoculation of Heavy Section CastingsDocumento2 páginasInoculation of Heavy Section Castingsarnaldorcr8646100% (1)

- Common Metallurgical Defects in Ductile Cast Iron PDFDocumento1 páginaCommon Metallurgical Defects in Ductile Cast Iron PDFsskiitb100% (2)

- Factors Influencing The Recovery and Addition of MagnesiumDocumento4 páginasFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Ainda não há avaliações

- Common Metallurgical Defects in Ductile Iron English (1Documento1 páginaCommon Metallurgical Defects in Ductile Iron English (1sateeshkori100% (2)

- A367-11 Standard Test Methods of Chill Testing of Cast Iron PDFDocumento4 páginasA367-11 Standard Test Methods of Chill Testing of Cast Iron PDFCarlos Guillermo Somoza Alvarenga100% (1)

- Sampling of Liquid Cast IronDocumento2 páginasSampling of Liquid Cast Ironarnaldorcr8646Ainda não há avaliações

- Effect of Bismuth in Ductile IronDocumento4 páginasEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Composition of Grey Cast IronDocumento2 páginasComposition of Grey Cast IronPranil GhatageAinda não há avaliações

- SG Iron CompositionDocumento5 páginasSG Iron CompositionamirgukharAinda não há avaliações

- Chunky GraphiteDocumento16 páginasChunky GraphitesachinguptachdAinda não há avaliações

- Fading of InoculationDocumento2 páginasFading of Inoculationarnaldorcr8646Ainda não há avaliações

- Common Metallurgical Defects in Grey Cast Irons 2Documento1 páginaCommon Metallurgical Defects in Grey Cast Irons 2Rasool MohammadiAinda não há avaliações

- Selection of Inoculants For Ductile Cast IronDocumento1 páginaSelection of Inoculants For Ductile Cast Ironarnaldorcr8646100% (1)

- Ductile Dross Formation MonitoringDocumento27 páginasDuctile Dross Formation MonitoringsachinguptachdAinda não há avaliações

- Effects of Minor and Trace Elements in Cast IronDocumento2 páginasEffects of Minor and Trace Elements in Cast Ironarnaldorcr864667% (3)

- Magnesium Contents in Ductile IronDocumento2 páginasMagnesium Contents in Ductile Ironarnaldorcr8646Ainda não há avaliações

- Late Metal Stream InoculationDocumento2 páginasLate Metal Stream Inoculationarnaldorcr8646Ainda não há avaliações

- Effect of Minor and Trace Elements in Cast IronDocumento2 páginasEffect of Minor and Trace Elements in Cast IronsachinguptachdAinda não há avaliações

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocumento2 páginasPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646Ainda não há avaliações

- Surface Graphite Degeneration in Ductile Iron CastDocumento8 páginasSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarAinda não há avaliações

- BCIRA Broadsheet 41Documento4 páginasBCIRA Broadsheet 41Justin Dixon100% (1)

- Effect of Minor and Trace Elements in Cast IronDocumento2 páginasEffect of Minor and Trace Elements in Cast IronsachinguptachdAinda não há avaliações

- Cerium in Ductile IronDocumento2 páginasCerium in Ductile Ironvivek1312100% (2)

- S.G.Iron GuidelinesDocumento28 páginasS.G.Iron GuidelinesTarun Chakraborty100% (3)

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFDocumento23 páginas1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Cast IronDocumento15 páginasCast IronJohnAinda não há avaliações

- Elkem 10 Tundish Cover Ladle NodularizationDocumento2 páginasElkem 10 Tundish Cover Ladle Nodularizationmarcotulio123Ainda não há avaliações

- 16 ScabbingDocumento4 páginas16 Scabbingvivek13120% (1)

- GraphiteStructuresInCI PDFDocumento1 páginaGraphiteStructuresInCI PDFAnonymous B3I6zYNhqdAinda não há avaliações

- Sand Molding Processes: Thanuj Kumar MDocumento47 páginasSand Molding Processes: Thanuj Kumar MVDAinda não há avaliações

- Selection of NodularizersDocumento2 páginasSelection of Nodularizersarnaldorcr8646100% (2)

- Astm A532 PDFDocumento4 páginasAstm A532 PDFJuan Leon100% (1)

- Shrinkage in Iron CastingsDocumento10 páginasShrinkage in Iron CastingskarthikkandaAinda não há avaliações

- Ferroalloy Storage Bin DesignDocumento2 páginasFerroalloy Storage Bin Designarnaldorcr8646Ainda não há avaliações

- Carbide Dissolution in Thin Wall Ductile Iron PDFDocumento8 páginasCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdAinda não há avaliações

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocumento8 páginasRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazAinda não há avaliações

- Plain Carbon Steels GuideDocumento7 páginasPlain Carbon Steels GuideaadhithyarajasekaranAinda não há avaliações

- Alternative Tundish Ladle DesignDocumento2 páginasAlternative Tundish Ladle Designarnaldorcr8646Ainda não há avaliações

- Back to BASICS: Nitrogen fissures defects in iron castingsDocumento2 páginasBack to BASICS: Nitrogen fissures defects in iron castingsJustin DixonAinda não há avaliações

- Casting DefectsDocumento61 páginasCasting DefectsVikas NagarAinda não há avaliações

- Cast Iron PropertiesDocumento8 páginasCast Iron PropertiesGerardo JM Palacios100% (1)

- Types of Cast IronDocumento7 páginasTypes of Cast IronEddy VëraAinda não há avaliações

- Metallurgy and Machinability PDFDocumento34 páginasMetallurgy and Machinability PDFromanosky11Ainda não há avaliações

- ALSTOM Different-Types-of-Mills PDFDocumento39 páginasALSTOM Different-Types-of-Mills PDFvivek1312100% (1)

- Thermal Analysis of Cast Iron PDFDocumento27 páginasThermal Analysis of Cast Iron PDFRasoul SadeghiAinda não há avaliações

- Final Kanban Dr. Tammy SagastizadoDocumento71 páginasFinal Kanban Dr. Tammy Sagastizadovivek1312Ainda não há avaliações

- Sand Testing ProcedureDocumento34 páginasSand Testing Procedurevivek1312100% (5)

- PAC4200 DatatsheetDocumento4 páginasPAC4200 DatatsheetmringkelAinda não há avaliações

- AFS Effects of Hot SandDocumento10 páginasAFS Effects of Hot Sandvivek1312Ainda não há avaliações

- HIC Conveyor Belts Product SpecificationsDocumento8 páginasHIC Conveyor Belts Product SpecificationsShravan VogulamAinda não há avaliações

- Green Sand, MouldingDocumento92 páginasGreen Sand, MouldingKrishna Deo100% (1)

- The Oolitization Rate Determination of Bentonite Moulding MixturesDocumento4 páginasThe Oolitization Rate Determination of Bentonite Moulding Mixturesvivek1312Ainda não há avaliações

- E 6aDocumento12 páginasE 6aDamanveerAinda não há avaliações

- 16 ScabbingDocumento4 páginas16 Scabbingvivek13120% (1)

- Cold Box Binder UseDocumento3 páginasCold Box Binder Usevivek1312Ainda não há avaliações

- 592Documento4 páginas592vivek1312Ainda não há avaliações

- Takt TimeDocumento17 páginasTakt Timevivek1312Ainda não há avaliações

- Quality ManualDocumento36 páginasQuality Manualvivek1312Ainda não há avaliações

- Toyota PDFDocumento8 páginasToyota PDFOHAinda não há avaliações

- Yogyata VikasDocumento11 páginasYogyata Vikasvivek1312Ainda não há avaliações

- Influence MN S Properties Cast IronDocumento14 páginasInfluence MN S Properties Cast Ironvivek1312Ainda não há avaliações

- Common Metallurgical Defects in Ductile IronDocumento1 páginaCommon Metallurgical Defects in Ductile IronMehdi Koneshlou100% (1)

- FIPSDocumento23 páginasFIPSvivek1312Ainda não há avaliações

- 4 OEE ExampleDocumento8 páginas4 OEE Examplevivek1312Ainda não há avaliações

- ISO 9000 Awareness Presentation 8-27-15Documento19 páginasISO 9000 Awareness Presentation 8-27-15mahinda100% (1)

- Nov Sand DataDocumento12 páginasNov Sand Datavivek1312Ainda não há avaliações

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFDocumento23 páginas1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Gating System DesignDocumento8 páginasGating System Designvivek1312Ainda não há avaliações

- 11x17 Lost Foam Brochure LFBv1201405 DraftDocumento2 páginas11x17 Lost Foam Brochure LFBv1201405 Draftvivek1312Ainda não há avaliações

- Gating System DesignDocumento11 páginasGating System DesignChinmay Das95% (19)

- GREEN SAND PREPARATION Manufacturing Lab Foundry PDFDocumento21 páginasGREEN SAND PREPARATION Manufacturing Lab Foundry PDFvivek1312100% (1)

- $ix $igma: Remarkable Results and Rave ReviewsDocumento29 páginas$ix $igma: Remarkable Results and Rave ReviewsdSolarianAinda não há avaliações

- Determination Active Clay Percentage of Moulding Sand by Using Methylene BlueDocumento9 páginasDetermination Active Clay Percentage of Moulding Sand by Using Methylene Bluevivek1312100% (2)

- Ductile Iron Data Sheet in DIN 1693Documento4 páginasDuctile Iron Data Sheet in DIN 1693Leandro de BittencourtAinda não há avaliações

- Proposed Residence Bill of QuantitiesDocumento20 páginasProposed Residence Bill of QuantitiesArnold Tunduli86% (7)

- Electroplating and Corrosion: Unit-4Documento50 páginasElectroplating and Corrosion: Unit-4Hadis SyoumAinda não há avaliações

- Project Standards and Specifications Piping Materials Rev01webDocumento12 páginasProject Standards and Specifications Piping Materials Rev01webroy_b200933% (3)

- Chemistry and MetallurgyDocumento80 páginasChemistry and MetallurgyborgiamatriceAinda não há avaliações

- Asme PQRDocumento4 páginasAsme PQRHong Dae Yoon100% (2)

- Cutting Oil for Non-Ferrous Metals and Carbon SteelsDocumento1 páginaCutting Oil for Non-Ferrous Metals and Carbon SteelsahmetAinda não há avaliações

- CLASS 11412 DESIGN LIMITSDocumento12 páginasCLASS 11412 DESIGN LIMITSZIED MAGHREBIAinda não há avaliações

- Aluminium Anode Activation Research - A Review: 2. History of Galvanic AnodesDocumento6 páginasAluminium Anode Activation Research - A Review: 2. History of Galvanic AnodesMusa WijanarkoAinda não há avaliações

- INDUSTRIAL GALVANIZERS HOT-DIP SEMINARDocumento27 páginasINDUSTRIAL GALVANIZERS HOT-DIP SEMINARaziz50% (2)

- Repair and Maintenance Weld Overlay Solutions For Steel MillsDocumento28 páginasRepair and Maintenance Weld Overlay Solutions For Steel MillsMike CheAinda não há avaliações

- Defects in Hot Dip GalvanisingDocumento16 páginasDefects in Hot Dip GalvanisingMathews Joseph100% (1)

- A370 PDFDocumento53 páginasA370 PDFsayuri0410Ainda não há avaliações

- Datasheet For Steel Grades Specialsteel 0Cr18Ni9Documento3 páginasDatasheet For Steel Grades Specialsteel 0Cr18Ni9Umar AslamAinda não há avaliações

- Tolomatic IMA 2011 CatalogDocumento18 páginasTolomatic IMA 2011 CatalogElectromateAinda não há avaliações

- AISI 4145 Alloy Steel: Form of SupplyDocumento3 páginasAISI 4145 Alloy Steel: Form of SupplyIvy LiAinda não há avaliações

- Metal Powder TechnologyDocumento8 páginasMetal Powder TechnologyVenkateswaran Krishnamurthy100% (1)

- Electrolysis SolutionsDocumento8 páginasElectrolysis SolutionsauricayunneAinda não há avaliações

- Design and manufacturing of plastic injection mould materialsDocumento8 páginasDesign and manufacturing of plastic injection mould materialsBa BuAinda não há avaliações

- Nimonic 105Documento12 páginasNimonic 105sunsirAinda não há avaliações

- Essar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1Documento17 páginasEssar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1ashish_rocksAinda não há avaliações

- Steel Bars, Selection Guide, Composition, and Mechanical PropertiesDocumento9 páginasSteel Bars, Selection Guide, Composition, and Mechanical Propertiesvinicius_bacellarAinda não há avaliações

- Latihan SoalDocumento3 páginasLatihan SoalDaus100% (1)

- The Iron-Iron Carbide Equilibrium DiagramDocumento15 páginasThe Iron-Iron Carbide Equilibrium DiagramjhangeerAinda não há avaliações

- Chemistry Project STPM 2016Documento13 páginasChemistry Project STPM 2016Sabri Bri EDAinda não há avaliações

- Astm A36-A36m-02 STD Specs For Carbon Structural SteelDocumento4 páginasAstm A36-A36m-02 STD Specs For Carbon Structural SteelCharwin PicaoAinda não há avaliações

- Range of Trim MaterialsDocumento1 páginaRange of Trim MaterialsAbu___AbdullahAinda não há avaliações

- D 500203 X 012Documento20 páginasD 500203 X 012Aarthi PadmanabhanAinda não há avaliações

- Panduit Metal Raceway CatalogDocumento112 páginasPanduit Metal Raceway CatalognumnummoAinda não há avaliações

- Metal Matrix CompositesDocumento43 páginasMetal Matrix CompositesapatelAinda não há avaliações