Escolar Documentos

Profissional Documentos

Cultura Documentos

UOP 555-10 Trace Impurities in Benzene by GC

Enviado por

Morteza SepehranDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

UOP 555-10 Trace Impurities in Benzene by GC

Enviado por

Morteza SepehranDireitos autorais:

Formatos disponíveis

Trace Impurities in Benzene by GC

UOP Method 555-10

Scope

This gas chromatographic method is for determining individual and total trace hydrocarbon

impurities in olefin-free, high-purity benzene. C8 and lower boiling paraffins, naphthenes, toluene, and

C8 aromatics are determined. The lower limit of quantitation for any single component is 1 mg/kg

(mass-ppm).

Benzene purity can also be determined by ASTM Method D4492, where the lower detection limit is

50 mg/kg per component. Although benzene is not listed in their scopes, ASTM Methods D2360,

D5917, and D7504 may also be used to measure impurities in benzene. All of these ASTM Methods

determine the non-aromatics as a total whereas this method also provides a distribution.

References

ASTM Method D2360, Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas

Chromatography, www.astm.org

ASTM D4307, Preparation of Liquid Blends for use as Analytical Standards, www.astm.org

ASTM Method D4492, Standard Test Method for Analysis of Benzene by Gas Chromatography,

www.astm.org

ASTM Method D5917, Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas

Chromatography and External Calibration, www.astm.org

ASTM Method D7504, Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas

Chromatography and Effective Carbon Number, www.astm.org

Scanlon, J. T. and Willis, D. E., Journal of Chromatographic Science, 23, 333-340 (1985)

UOP Method 999, Precision Statements in UOP Methods, www.astm.org

Outline of Method

The sample is injected into a gas chromatograph that is equipped with an autoinjector, a fused silica

capillary column internally coated with cross-linked methyl silicone, and a flame ionization detector.

The concentrations of individual or group impurities are determined by the external standard method of

quantitation, wherein peak areas of the sample components are compared to the peak areas of a

IT IS THE USER'S RESPONSIBILITY TO ESTABLISH APPROPRIATE PRECAUTIONARY PRACTICES AND TO DETERMINE

THE APPLICABILITY OF REGULATORY LIMITATIONS PRIOR TO USE. EFFECTIVE HEALTH AND SAFETY PRACTICES

ARE TO BE FOLLOWED WHEN UTILIZING THIS PROCEDURE. FAILURE TO UTILIZE THIS PROCEDURE IN THE MANNER

PRESCRIBED HEREIN CAN BE HAZARDOUS. MATERIAL SAFETY DATA SHEETS (MSDS) OR EXPERIMENTAL

MATERIAL SAFETY DATA SHEETS (EMSDS) FOR ALL OF THE MATERIALS USED IN THIS PROCEDURE SHOULD BE

REVIEWED FOR SELECTION OF THE APPROPRIATE PERSONAL PROTECTION EQUIPMENT (PPE).

COPYRIGHT 1970, 1977, 1992, 1996, 2010 UOP LLC. All rights reserved.

Nonconfidential UOP Methods are available from ASTM International, 100 Barr Harbor Drive, P.O. Box C700, West

Conshohocken, PA 19428-2959, USA. The UOP Methods may be obtained through the ASTM website, www.astm.org, or by

contacting Customer Service at service@astm.org, 610.832.9555 FAX, or 610.832.9585 PHONE.

2 of 11

calibration blend analyzed under identical conditions and injection volumes. See Note for an alternative

means of calibration and calculation.

Apparatus

References to catalog numbers and suppliers are included as a convenience to the method user. Other

suppliers may be used.

Balance, analytical, readable to 0.0001 g

Chromatographic column, 50 m of 0.21-mm ID fused silica capillary, internally coated to a film

thickness of 0.5-m with cross-linked methyl silicone, Agilent Technologies, Cat. No.

19091S-001

Gas chromatograph, temperature programmable, built for capillary column chromatography,

utilizing a split injection system having a glass injection port insert, and equipped with a flame

ionization detector that will give a minimum peak height response of 10 times the background

noise for 1 mg/kg n-octane when operated at the recommended conditions, Agilent Technologies,

Model 7890

Data system, electronic, for obtaining peak areas. This device must integrate areas at a sufficiently fast

rate so that narrow peaks typically resulting from use of a capillary column can be accurately

measured. Agilent Technologies, ChemStation.

Hood, fume

Leak detector, gas, Alltech Associates, Cat. No. 21-250

Refrigerator, flammable storage or explosion proof

Regulator, air, two-stage, high purity, delivery pressure range 30-700 kPa (4-100 psi), Matheson

Tri-Gas, Model 3122-590

Regulator, hydrogen, two-stage, high purity, delivery pressure range 30-700 kPa (4-100 psi),

Matheson Tri-Gas, Model 3122-350

Regulator, nitrogen, two-stage, high purity, delivery pressure range 30-700 kPa (4-100 psi), Matheson

Tri-Gas, Model 3122-580

Sample injector, any syringe or injector capable of injecting a repeatable 0.5-L volume of sample.

The use of an automatic injection device is required to achieve necessary repeatable injection

volumes. See Note and Appendix. Agilent Technologies, Model 7683.

Reagent and Materials

References to catalog numbers and suppliers are included as a convenience to the method user. Other

suppliers may be used.

Air, zero gas, total hydrocarbons less than 2.0 ppm as methane, local supply

Benzene, 99.9% minimum purity, Sigma-Aldrich, Cat. No. 270709. CAUTION: Benzene is

especially hazardous. Perform all work with benzene in a fume hood, using appropriate personal

protection equipment, as directed by local regulations and the MSDS.

Gas purifier, for hydrogen, to remove oxygen and moisture from carrier gas, VICI Mat/Sen, Cat. No.

P200-1

555-10

3 of 11

Hydrogen, zero gas, 99.99% minimum purity, total hydrocarbons less than 0.5 ppm as methane, local

supply

Nitrogen, zero gas, 99.99% minimum purity, total hydrocarbons less than 0.5 ppm as methane, local

supply

n-Octane, 99.0% minimum purity, Sigma-Aldrich, Cat. No. 74821

Pipets, disposable, Pasteur, VWR, Cat. No. 14673-043

Pipet bulbs, VWR, Cat. No. 15001-362

Syringe, replacement, for recommended sample injector, 5-L, Agilent Technologies, Cat. No.

5181-1273

Vials, 22-mL, with polyseal-lined caps, VWR, Cat. No. 16087-068

Vials, autosampler, for recommended sample injector, with caps, Agilent Technologies, Cat. No.

5182-0864

Calibration

Preparation of Calibration Blend

Quantitative results are based on the injection of repeatable volumes of both the calibration blend and

the sample. Absolute response factors, derived from the calibration blend, are used to relate the peak

areas of each known component to mg/kg.

1. Prepare a stock solution as described in ASTM Method D4307 to contain approximately 1.5

mass-% n-octane in benzene. Thoroughly mix the solution by shaking. Record all weights to the

nearest 0.1 mg.

Obtain the purest benzene possible to prepare the blend. Analyze it, looking for impurities that elute

at the n-octane site. If impurities in the benzene are present at this site, the concentration must be

accounted for in the calculation of the respective concentrations of the octane in the blend. This

blend will be used as the stock solution in the preparation of the actual calibration blend. Label this

mixture as the stock solution.

2. Prepare the calibration blend to contain approximately 1.5 mass-% of the stock solution in benzene.

Thoroughly mix the calibration blend by shaking. Record all weights to the nearest 0.1 mg.

If refrigerated, the stock solution and calibration blend should remain stable for five months. The

benzene solutions may freeze in the refrigerator. If frozen, thaw at room temperature; do not heat.

3. Calculate the concentration of n-octane in the calibration blend to the nearest mg/kg using

Equation 1. Using the above dilutions, the resulting calibration blend should contain

approximately 225 mg/kg of n-octane.

M=

10 6 A B

+E

CD

(1)

where:

A=

B=

C=

D=

E=

mass of n-octane in the stock solution, g

mass of stock solution in the calibration blend, g

total mass of the stock solution prepared, g

total mass of the calibration blend prepared, g

concentration of n-octane, if any, in the benzene as analyzed as described in

Appendix B; see first bullet under Step 1 above, mg/kg

M = concentration of n-octane in the calibration blend, mg/kg

555-10

4 of 11

106 = factor to convert to mg/kg

4. Analyze the calibration blend in triplicate as described under Chromatographic Technique.

The peak areas from each of the triplicate runs should not deviate from the average by more than

3% (relative) of the value. If greater deviations occur, make certain that there are no problems with

the equipment and then make additional runs until the required repeatability is obtained on three

consecutive runs.

Confirm the stability of the chromatographic system by analyzing the calibration blend again at the

end of a series of analyses. If the results differ by more than 5% from the average of the triplicate

runs, a problem has developed with the chromatographic system, and the series of samples must

be rerun after the problem is resolved. Typical problems to look for include a leaky septum and a

dirty or partially plugged syringe.

5. Use the average peak areas to calculate the absolute response factor for n-octane, to three

significant figures, using Equation 2.

M

L=

(2)

P

where:

L = absolute response factor for n-octane

M = concentration of n-octane in the calibration blend, from Equation 1, mg/kg

P = average peak area for n-octane in the calibration blend

6. Determine the response factor daily or each time analyses are performed.

Procedure

The analyst is expected to be familiar with general laboratory practices, the technique of gas

chromatography, and the equipment being used.

Chromatographic Technique

1. Install the gas purifier in the supply line between the carrier gas source and the carrier gas inlets

on the gas chromatograph.

Column life is significantly reduced if the gas purifier is not used.

2. Install the fused silica capillary column in the gas chromatograph according to the column and gas

chromatograph manufacturers instructions.

CAUTION: Hydrogen leakage into the confined volume of the column oven can cause a violent

explosion. Therefore, it is mandatory to check for leaks each time a connection is made and

periodically thereafter.

3. Establish the recommended operating conditions as given in Table 1.

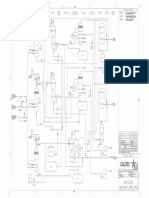

Different conditions may be used provided they produce the required sensitivity and

chromatographic separations equivalent to those shown in the Typical Chromatogram (Figures 1-3).

4. Program the column oven to 250C (see Table 1) and maintain this temperature until a stable

baseline has been obtained at the required sensitivity.

5. Cool the column oven to a stabilized 32C.

6. Mix the sample by shaking. Fill an autosampler vial with an aliquot of the sample and place in the

autosampler (or autoinjector) tray.

Multiple samples may be prepared in advance for unattended operation.

7. Inject nominally 0.5 L (repeatable) of sample into the gas chromatograph and start the data

system and the column oven programming sequence.

555-10

5 of 11

The use of an autoinjector or autosampler automates the injection of the sample into the GC, starts

the data system, and the GC oven program simultaneously.

To minimize cross contamination in trace level analyses, an injection of carbon disulfide is to be

made between each sample or blend. Also use carbon disulfide in the syringe wash vial, and replace

it after every series of injections.

8. Identify the components in the resultant chromatogram and determine the areas of the impurity

peaks.

A typical chromatogram is shown in Figure 1. Expanded regions are given in Figures 2 and 3.

Unidentified impurities are summed and reported as a composite.

Table 1

Recommended Operating Conditions

Carrier gas

hydrogen

Mode

constant flow

Column flow rate

1.2 mL/min

Head pressure @ 32C

138 kPa gauge (20 psig)

Linear velocity @ 32C

36 cm/sec

Split flow

50 mL/min

Injection port temperature

250C

Column temperature program

Initial temperature

32C

Initial hold time

6 min

Programming rate

5C/min

Final hold temperature

52C

Final Time

14 min

Rate 2

20C/min

Final Temperature 2

250C

Final hold time 2

0 min

Detector

flame ionization

Detector temperature

250C

Hydrogen flow rate*

39 mL/min

Air flow rate*

450 mL/min

Makeup gas

nitrogen

Makeup gas flow rate*

45 mL/min

Sample size

0.5 L, repeatable

*Consult the manufacturer's instrument manual for suggested flow rates.

Calculations

Obtain peak areas for each individual component or group of components except benzene and

calculate the composition of the sample to the nearest mg/kg using Equation 3. Since the flame

ionization detector does not respond equally on a mass basis to all the components determined, relative

response factors are required to correct the responses of the components. It has been found that using

effective carbon number factors, sometimes called theoretical factors, provides accurate quantitation.

The theoretical response factors, relative to the n-octane external standard, were calculated using the

effective carbon number (ECN) concept as described by Scanlon and Willis. These factors are listed in

Table 2 and are used in Equation 3.

Component, mg/kg = S L F

(3)

where:

555-10

6 of 11

F = response factor for component, relative to n-octane

L = absolute response factor for n-octane, previously defined, Equation 2

S = peak area of individual component or group of components

Table 2

Theoretical Response Factors, Relative to n-Octane, Mass Basis

All components except as listed below (all non-aromatics) 1.003

Toluene

0.922

Ethylbenzene, m-xylene, p-xylene, and o-xylene

0.929

Report each measured component or group of components to the nearest mg/kg.

Note

The external standard method of quantitation is preferred for best efficiency when analyzing multiple

samples. It does, however, require the use of an autoinjector (or autosampler) for best precision. If an

autoinjector is not available or if only one or two samples are to be analyzed, the internal standard

technique may be a suitable alternative. In this technique, the peak areas for the impurity components

are compared to the peak area for a known amount of internal standard weighed into each sample. The

procedure for using the internal standard technique is described in the Appendix of this method.

The external standard technique will be the referee in case of dispute.

Precision

Precision statements were determined using UOP Method 999, Precision Statements in UOP

Methods, from precision data obtained using an autosampler.

Repeatability and Site Precision

A nested design was carried out for determining impurities in benzene by two analysts, with each

analyst performing analyses on two separate days, performing three analyses each day for a total of 12

analyses. Using a stepwise analysis of variance procedure, the within-day estimated standard deviations

(esd) were calculated at the concentration means listed in Table 3. Two analyses performed in one

laboratory by the same analyst on the same day should not differ by more than the repeatability allowable

differences shown in Table 3 with 95% confidence. Two analyses performed in one laboratory by

different analysts on different days should not differ by more than the site precision allowable differences

shown in Table 3 with 95% confidence.

Table 3

Repeatability and Site Precision, mg/kg

Repeatability

Site Precision

Component

Mean

WithinDay esd

Allowable

Difference

WithinLab esd

Allowable

Difference

2,2-Dimethylbutane

3-Methylpentane

2,4-Dimethylpentane

Cyclohexane

1,4-Dimethylcyclopentane

n-Heptane

Toluene

1.1

13.3

5.1

86.7

4.2

24.1

134.8

0.05

0.13

0.10

0.68

0.08

0.19

0.97

0.2

0.4

0.3

2.2

0.3

0.6

3.2

0.05

0.14

0.12

0.79

0.11

0.22

1.09

0.2

0.5

0.4

2.7

0.4

0.7

3.7

555-10

7 of 11

The data in Table 3 represent short-term estimates of the repeatability of the method. When the test is

run routinely, use of a control standard and a control chart is recommended to generate an estimate of

long-term repeatability.

Reproducibility

There is insufficient data to calculate the reproducibility of the test at this time.

Time for Analysis

The elapsed time for one analysis is 0.85 hour. The labor requirement is 0.35 hour.

Suggested Suppliers

Agilent Technologies, 2850 Centerville Rd., Wilmington, DE 19808-1610 USA (302-633-8000)

www.agilent.com

Matheson Tri-Gas, 166 Keystone Dr., Montgomeryville, PA 18936 USA (215-641-2700)

www.mathesontrigas.com

Sigma-Aldrich, 1000 West Saint Paul Ave., Milwaukee, WI 53233 USA (414-273-3850)

www.sigma-aldrich.com

VICI Mat/Sen, 7806 Bobbitt, Houston, TX 77055 USA (713-688-9345) www.vicimatsen.com

VWR International, 1310 Goshen Pkwy., West Chester, PA 19380 USA (610-431-1700) www.vwr.com

555-10

8 of 11

555-10

9 of 11

Appendix

Alternative Calibration and Analysis Using Internal Standard

Scope

This Appendix describes an alternative means of calibration and calculation for the analysis of

impurities in high-purity benzene. It is useful when no autoinjector is available or only a few samples

are to be analyzed.

Outline of Method

The sample is injected into a gas chromatograph that is equipped with a fused silica capillary column

internally coated with cross-linked methyl silicone, and a flame ionization detector. The mg/kg

concentration of the impurities is obtained on an absolute basis by the internal standard method of

quantitation, wherein the peak areas for the impurities are compared to the peak area for a known amount

of internal standard.

Apparatus

The apparatus required is the same as that listed in the body of the method, except that the use of an

autosampler or autoinjector is not mandatory.

Reagents and Materials

References to catalog numbers and suppliers are included as a convenience to the method user. Other

suppliers may be used.

The following reagents and materials are an addition or substitution to that listed in the body of the

method.

Vial, 15-mL, with screw cap, VWR, Cat. No. 16087-062

Procedure

Calibration

An internal standard is added to the sample in order to accurately quantitate the low levels of

impurities expected. Since the flame ionization detector does not respond equally on a mass basis to the

components determined and the internal standard, response factors are required to relate the peak areas

of the recorded impurities to mg/kg. It has been found that using effective carbon number factors,

sometimes called theoretical factors, provides accurate quantitation. The theoretical response factors,

relative to the n-octane internal standard, were calculated using the effective carbon number (ECN)

concept as described by Scanlon and Willis. These factors are listed in Table 2 in the body of the method

and are used in the Calculations portion of the Appendix.

Sample Preparation

1. Transfer 10 0.1 g of the sample to be analyzed to a tared vial and weigh to the nearest 0.0001 g.

The sample is deposited in the center of the vial with a Pasteur pipet so that the liquid does not

contact the neck.

2. Add approximately 0.1 g of n-octane internal standard using a Pasteur pipet and quickly reweigh

to the nearest 0.0001 g.

555-10

10 of 11

The internal standard is added to the vial while on the balance pan and deposited into the center of

the liquid - not on the side of the vial.

3. Cap the vial and mix well by inverting several times.

Sample Analysis

1. Follow the Chromatographic Technique, Steps 1 through 5, as described in the body of the

method.

2. Inject nominally 0.5 L of sample containing the internal standard into the gas chromatograph and

start the data system and the column oven programming sequence.

If an autoinjector or autosampler is used, it automates the injection of the sample into the GC, starts

the data system, and the GC oven program simultaneously.

3. Identify the components in the resultant chromatogram and determine the areas of the specific

impurities and the n-octane peaks.

A typical chromatogram is shown in Figures 1, 2 and 3 in the body of the method. The location of the

n-octane internal standard is shown.

Unidentified impurities are summed and reported as a composite.

Calculations

Calculate the concentration of each impurity or group of impurities in the benzene sample to the

nearest mg/kg using Equation A1:

Impurity, mg/kg = 10 6

DFG

JH

(A1)

where:

D=

F=

G=

H=

J=

106 =

peak area of component of interest

component response factor, from Table 2 in the body of the method

mass of n-octane added to sample, g

mass of sample, g

peak area of the n-octane

factor to convert to mg/kg

Report each measured component or group of components to the nearest mg/kg. Also state that the

analysis was performed by the internal standard technique.

Precision

Precision statements were determined using UOP Method 999, Precision Statements in UOP

Methods, from precision data obtained using an autosampler.

Repeatability and Site Precision

A nested design was carried out for determining impurities in benzene by two analysts, with each

analyst performing analyses on two separate days, performing three analyses each day for a total of 12

analyses. Using a stepwise analysis of variance procedure, the within-day estimated standard deviations

(esd) were calculated at the concentration means listed in Table A1. Two analyses performed in one

laboratory by the same analyst on the same day should not differ by more than the repeatability allowable

differences shown in Table A1 with 95% confidence. Two analyses performed in one laboratory by

different analysts on different days should not differ by more than the site precision allowable differences

shown in Table A1 with 95% confidence.

555-10

11 of 11

Table A1

Repeatability and Site Precision, mg/kg

Repeatability

Site Precision

Component

Mean

WithinDay esd

Allowable

Difference

WithinLab esd

Allowable

Difference

2,2-Dimethylbutane

3-Methylpentane

2,4-Dimethylpentane

Cyclohexane

1,4-Dimethylcyclopentane

n-Heptane

Toluene

1.1

13.4

5.1

87.8

4.3

25.0

136.8

0.05

0.16

0.11

0.12

0.06

0.22

0.09

0.2

0.5

0.4

0.4

0.2

0.7

0.3

0.05

0.17

0.13

0.23

0.06

0.27

0.13

0.2

0.5

0.4

1.4

0.2

0.9

0.5

The data in Table A1 represent short-term estimates of the repeatability of the method. When the test

is run routinely, use of a control standard and a control chart is recommended to generate an estimate of

long-term repeatability.

Reproducibility

There is insufficient data to calculate the reproducibility of the test at this time.

555-10

Você também pode gostar

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNo EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsAinda não há avaliações

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)No EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)Ainda não há avaliações

- Trace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDocumento12 páginasTrace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDavinAinda não há avaliações

- Trace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCDocumento6 páginasTrace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCgoodcharacter1Ainda não há avaliações

- Determination of C Through C Hydrocarbons in Gasolines by Gas ChromatographyDocumento7 páginasDetermination of C Through C Hydrocarbons in Gasolines by Gas Chromatographyrimi7alAinda não há avaliações

- Gpa 2261 2000Documento21 páginasGpa 2261 2000Lalang Dwiyoga SaktiAinda não há avaliações

- Hydrogen Content of Gases by Gas ChromatographyDocumento3 páginasHydrogen Content of Gases by Gas ChromatographyDavinAinda não há avaliações

- UOP 989-14 Trace Sulfur in LPG and Gaseous Hydrocarbons by Oxidative Combustion With UltravioletDocumento7 páginasUOP 989-14 Trace Sulfur in LPG and Gaseous Hydrocarbons by Oxidative Combustion With UltravioletMorteza SepehranAinda não há avaliações

- Method 12 PDFDocumento27 páginasMethod 12 PDFMichael StevenAinda não há avaliações

- Uop 987Documento11 páginasUop 987pramod23septAinda não há avaliações

- Total Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceDocumento5 páginasTotal Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceJesus Gonzalez GracidaAinda não há avaliações

- UOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCDocumento6 páginasUOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCMorteza SepehranAinda não há avaliações

- D 1946 - 90 R00 - Rde5ndyDocumento5 páginasD 1946 - 90 R00 - Rde5ndyCalvinAinda não há avaliações

- Texas TNRCC 1006Documento21 páginasTexas TNRCC 1006Fabio IkaczykAinda não há avaliações

- TEXAS NATURAL RESOURCE CONSERVATION COMMISSION PETROLEUM HYDROCARBON METHODDocumento26 páginasTEXAS NATURAL RESOURCE CONSERVATION COMMISSION PETROLEUM HYDROCARBON METHODSusana DiazAinda não há avaliações

- Astm d5580Documento9 páginasAstm d5580Nhu SuongAinda não há avaliações

- UOP 99-07 Pentane-Insoluble Matter in Petroleum Oils Using A Membrane FilterDocumento10 páginasUOP 99-07 Pentane-Insoluble Matter in Petroleum Oils Using A Membrane FilterMorteza SepehranAinda não há avaliações

- 5989 7259enDocumento82 páginas5989 7259enKung KleeAinda não há avaliações

- UOP 1005-14 Trace Metals in Organics by ICP-MSDocumento11 páginasUOP 1005-14 Trace Metals in Organics by ICP-MSMorteza SepehranAinda não há avaliações

- D1159Documento9 páginasD1159rpajaro75Ainda não há avaliações

- NGA ISO 6974 ManualDocumento89 páginasNGA ISO 6974 ManualhopkhtnAinda não há avaliações

- Is Iso 1066 1975Documento9 páginasIs Iso 1066 1975Clausius ClapeyronAinda não há avaliações

- Uop 778-81 PDFDocumento3 páginasUop 778-81 PDFhadiranjiAinda não há avaliações

- Determination of Total Oxygen in Gasoline and Methanol Fuels by Reductive PyrolysisDocumento5 páginasDetermination of Total Oxygen in Gasoline and Methanol Fuels by Reductive Pyrolysisjawed iqbalAinda não há avaliações

- Properties of Petroleum ProductsDocumento30 páginasProperties of Petroleum ProductsBharath KumarAinda não há avaliações

- Agilent - Determination of Methanol Content in Biodiesel According To En-14110Documento2 páginasAgilent - Determination of Methanol Content in Biodiesel According To En-14110anuradha.d.bhat9860Ainda não há avaliações

- Wijs-Cyclohexane MethodDocumento4 páginasWijs-Cyclohexane Methodnuur iffahAinda não há avaliações

- Analysis of Gasoline Blends-By GC-using ASTM D 6839, IsO 22854Documento4 páginasAnalysis of Gasoline Blends-By GC-using ASTM D 6839, IsO 22854Balas43Ainda não há avaliações

- Ethylene, Other Hydrocarbons, and Carbon Dioxide in High-Purity Ethylene by Gas ChromatographyDocumento7 páginasEthylene, Other Hydrocarbons, and Carbon Dioxide in High-Purity Ethylene by Gas ChromatographyFebrianca KharismaAinda não há avaliações

- EN 14103 - ThermoDocumento4 páginasEN 14103 - ThermoLuciana TrisnaAinda não há avaliações

- Principle and Sensor Information TOX-100Documento3 páginasPrinciple and Sensor Information TOX-100Sachin SawantAinda não há avaliações

- AminetitrationsDocumento19 páginasAminetitrationsjt_master100% (1)

- Free Chlorine Test MethodDocumento8 páginasFree Chlorine Test MethodarjunanpnAinda não há avaliações

- Determinacion de Aromaticos ASTM D5186Documento8 páginasDeterminacion de Aromaticos ASTM D5186Carlos GonzalesAinda não há avaliações

- Determination of Potassium in Sodium ChlorideDocumento5 páginasDetermination of Potassium in Sodium ChlorideNguyễn Khắc HảiAinda não há avaliações

- NatGas 1Documento2 páginasNatGas 1Mierza SaputraAinda não há avaliações

- D6352Documento13 páginasD6352rimi7alAinda não há avaliações

- Operating Manual: Ac Oxytracer Analyzer On 7890 GCDocumento49 páginasOperating Manual: Ac Oxytracer Analyzer On 7890 GCstemman95Ainda não há avaliações

- Uop 614 Heptane-Insoluble Matter in Petroleum Oils Using A Membrane FilterDocumento10 páginasUop 614 Heptane-Insoluble Matter in Petroleum Oils Using A Membrane FilterLuis Ernesto Marin JaimesAinda não há avaliações

- Metler Toledo TtitratorDocumento138 páginasMetler Toledo TtitratorteddydeAinda não há avaliações

- UOP 9 Hydrogen Sulphide in Gases by The Tutweiller MethodDocumento4 páginasUOP 9 Hydrogen Sulphide in Gases by The Tutweiller MethodmkmejavierAinda não há avaliações

- Jlpga S 07Documento16 páginasJlpga S 07hopkhtnAinda não há avaliações

- Sulfur in Petroleum Products by Wavelength Dispersive X-Ray Fluorescence SpectrometryDocumento12 páginasSulfur in Petroleum Products by Wavelength Dispersive X-Ray Fluorescence SpectrometrySebastian ChaverraAinda não há avaliações

- D4913Documento4 páginasD4913Fredi Cari CarreraAinda não há avaliações

- Astm D 4628-02 AasDocumento6 páginasAstm D 4628-02 AasAntony HoAinda não há avaliações

- Octane Number PDFDocumento9 páginasOctane Number PDFLê Ngọc Huyền80% (5)

- Comparacion Entre ASTM D7169 y TBPDocumento28 páginasComparacion Entre ASTM D7169 y TBPDesiree Molina100% (1)

- Comparison of Chloride MethodDocumento2 páginasComparison of Chloride Methodmbusairi100% (1)

- Cuantificacion Diesel HPLCDocumento8 páginasCuantificacion Diesel HPLCJose Antonio Martinez VillalbaAinda não há avaliações

- D2505 24472Documento7 páginasD2505 24472Stef AnyAinda não há avaliações

- ASTM D3606-17 Determinación de Benceno y Tolueno en Ignición Por Chispa Por Cromatografía de GasesDocumento23 páginasASTM D3606-17 Determinación de Benceno y Tolueno en Ignición Por Chispa Por Cromatografía de GasesarmandAinda não há avaliações

- D7220-06 MEDXRF Sulfur AutomotiveDocumento6 páginasD7220-06 MEDXRF Sulfur AutomotiveVladimir KrzalicAinda não há avaliações

- Determination of Hydrocarbons and Non-Hydrocarbon Gases in Gaseous Mixtures by Gas ChromatographyDocumento10 páginasDetermination of Hydrocarbons and Non-Hydrocarbon Gases in Gaseous Mixtures by Gas ChromatographyСамсонова НатальяAinda não há avaliações

- Bromine Number in Petroleum ProductsDocumento7 páginasBromine Number in Petroleum Productskir223Ainda não há avaliações

- Trace Metals in Oils by Wet Ash / Icp-Aes: UOP Method 389-86 ScopeDocumento5 páginasTrace Metals in Oils by Wet Ash / Icp-Aes: UOP Method 389-86 ScopeMuhannad NasifAinda não há avaliações

- Determination of benzene and aromatics in gasolineDocumento11 páginasDetermination of benzene and aromatics in gasolinerenatoAinda não há avaliações

- Alkalinity, Sulfide and Mercaptide Analyses of Used Refinery Caustic SolutionsDocumento16 páginasAlkalinity, Sulfide and Mercaptide Analyses of Used Refinery Caustic Solutionssasan100% (6)

- Ip 469Documento7 páginasIp 469Natalia Kovalova100% (1)

- Sist en 14110 2019Documento9 páginasSist en 14110 2019Ahmed NoreldinAinda não há avaliações

- UOP 826-81 Carbon Dioxide in Ammine SolutionDocumento7 páginasUOP 826-81 Carbon Dioxide in Ammine SolutionMorteza Sepehran100% (1)

- Tetranex Solutions IncDocumento2 páginasTetranex Solutions IncMorteza SepehranAinda não há avaliações

- How To Design Tank Heating Coils - Parte1Documento2 páginasHow To Design Tank Heating Coils - Parte1Morteza SepehranAinda não há avaliações

- UOP 99-07 Pentane-Insoluble Matter in Petroleum Oils Using A Membrane FilterDocumento10 páginasUOP 99-07 Pentane-Insoluble Matter in Petroleum Oils Using A Membrane FilterMorteza SepehranAinda não há avaliações

- Large-Scale Sulfur Recovery: AS RocessingDocumento3 páginasLarge-Scale Sulfur Recovery: AS RocessingMorteza SepehranAinda não há avaliações

- UOP 212-05 - Hydrogen Sulfide, Mercaptan Sulfur, and Carbonyl Sulfide in Hydrocarbon Gases by Po PDFDocumento25 páginasUOP 212-05 - Hydrogen Sulfide, Mercaptan Sulfur, and Carbonyl Sulfide in Hydrocarbon Gases by Po PDFMorteza Sepehran100% (5)

- UOP 1005-14 Trace Metals in Organics by ICP-MSDocumento11 páginasUOP 1005-14 Trace Metals in Organics by ICP-MSMorteza SepehranAinda não há avaliações

- UOP 304-08 Bromine Number and Bromine Index of Hydrocarbons by Potentiometric TitrationDocumento13 páginasUOP 304-08 Bromine Number and Bromine Index of Hydrocarbons by Potentiometric TitrationMorteza SepehranAinda não há avaliações

- UOP 989-14 Trace Sulfur in LPG and Gaseous Hydrocarbons by Oxidative Combustion With UltravioletDocumento7 páginasUOP 989-14 Trace Sulfur in LPG and Gaseous Hydrocarbons by Oxidative Combustion With UltravioletMorteza SepehranAinda não há avaliações

- UOP79Documento18 páginasUOP79amishraiocAinda não há avaliações

- UOP79Documento18 páginasUOP79amishraiocAinda não há avaliações

- Process Analytics in ClausDocumento9 páginasProcess Analytics in ClausMorteza SepehranAinda não há avaliações

- UOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSDocumento11 páginasUOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSMorteza Sepehran100% (1)

- UOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCDocumento6 páginasUOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCMorteza SepehranAinda não há avaliações

- UOP79Documento18 páginasUOP79amishraiocAinda não há avaliações

- The Cascade Control Architecture - Control GuruDocumento9 páginasThe Cascade Control Architecture - Control GuruMorteza SepehranAinda não há avaliações

- EE4CL4 Lecture31 PDFDocumento16 páginasEE4CL4 Lecture31 PDFMorteza SepehranAinda não há avaliações

- MeroxDocumento1 páginaMeroxMorteza SepehranAinda não há avaliações

- Elec Eng 4Cl4:: Control System DesignDocumento20 páginasElec Eng 4Cl4:: Control System DesignMorteza SepehranAinda não há avaliações

- Elec Eng 4Cl4:: Control System DesignDocumento31 páginasElec Eng 4Cl4:: Control System DesignMorteza SepehranAinda não há avaliações

- Handout Jacobs CSS - Claus ProcessDocumento1 páginaHandout Jacobs CSS - Claus ProcessMorteza SepehranAinda não há avaliações

- Elec Eng 4Cl4:: Control System DesignDocumento12 páginasElec Eng 4Cl4:: Control System DesignMorteza SepehranAinda não há avaliações

- Acid 3 PDFDocumento1 páginaAcid 3 PDFMorteza SepehranAinda não há avaliações

- Metallurgy and Corrosion Control in Oil and Gas ProductionDocumento1 páginaMetallurgy and Corrosion Control in Oil and Gas ProductionMorteza SepehranAinda não há avaliações

- Refining Industry Solutions: Experience, Knowledge, and Technology... in RefiningDocumento44 páginasRefining Industry Solutions: Experience, Knowledge, and Technology... in RefiningMorteza SepehranAinda não há avaliações

- Pages From 08 - Condensate and LPG DehydrationDocumento1 páginaPages From 08 - Condensate and LPG DehydrationMorteza SepehranAinda não há avaliações

- 8-Dehydrations 10 PDFDocumento1 página8-Dehydrations 10 PDFMorteza SepehranAinda não há avaliações

- Basic Glycol Dehydrator System Process Diagram: Dry Sales GasDocumento1 páginaBasic Glycol Dehydrator System Process Diagram: Dry Sales GasMorteza SepehranAinda não há avaliações

- 8-Dehydrations 9 PDFDocumento1 página8-Dehydrations 9 PDFMorteza SepehranAinda não há avaliações

- The Science of MeasurementDocumento10 páginasThe Science of MeasurementHeHe HaHaAinda não há avaliações

- Significant FiguresDocumento12 páginasSignificant FiguresJyannejm MaylasAinda não há avaliações

- 2016 NCSE Math Paper IIDocumento15 páginas2016 NCSE Math Paper IIDarryan Dhanpat0% (1)

- Error and Uncertainty - Engineering Surveying by W. SchofieldDocumento24 páginasError and Uncertainty - Engineering Surveying by W. SchofieldSakuntala UteebrirovaAinda não há avaliações

- Mathematics Coursebook Solution Grade7 Week: 3 & 4 Topic: Decimals Session: 1Documento14 páginasMathematics Coursebook Solution Grade7 Week: 3 & 4 Topic: Decimals Session: 1shrikantAinda não há avaliações

- 0580 s19 QP 41 PDFDocumento16 páginas0580 s19 QP 41 PDFMANOS TUBEAinda não há avaliações

- Gold by Fire Assay & Gravimetric FinishDocumento19 páginasGold by Fire Assay & Gravimetric FinishKobby100% (1)

- Unit 3 Edexcel BiologyDocumento9 páginasUnit 3 Edexcel BiologyFatma Zorlu67% (3)

- As 2752-2003 Preferred Numbers and Their UseDocumento9 páginasAs 2752-2003 Preferred Numbers and Their UseSAI Global - APACAinda não há avaliações

- Chapter 17 - Creating A Block: BlocksDocumento57 páginasChapter 17 - Creating A Block: BlocksIkram Ait AbdellahAinda não há avaliações

- Great Pyramid Passages Volume II, by John Edgar and Morton Edgar, 1924Documento162 páginasGreat Pyramid Passages Volume II, by John Edgar and Morton Edgar, 1924sirjsslut50% (2)

- Fundamental Chemistry ConceptsDocumento99 páginasFundamental Chemistry ConceptsMazar KhanAinda não há avaliações

- Data collection and processing stepsDocumento15 páginasData collection and processing stepsVishal Jalan100% (1)

- GACTI+Rubric FinishedDocumento3 páginasGACTI+Rubric FinishedBishoy GirgisAinda não há avaliações

- wph14 01 Rms 2023.10Documento22 páginaswph14 01 Rms 2023.10jie714408Ainda não há avaliações

- EDA Lecture NotesDocumento113 páginasEDA Lecture Notesyusif samAinda não há avaliações

- Lecture Notes 01-Introduction and Error Analysis (Print Version)Documento37 páginasLecture Notes 01-Introduction and Error Analysis (Print Version)Juan Sebastian Yela VAinda não há avaliações

- Uncertainty Budget TemplateDocumento4 páginasUncertainty Budget TemplateshahazadAinda não há avaliações

- 1291TAManual F16Documento134 páginas1291TAManual F16fatjonAinda não há avaliações

- Grade 9 MATHS Term End Exam 1Documento13 páginasGrade 9 MATHS Term End Exam 1samanthi rabbidigalaAinda não há avaliações

- Physic Xi 2011Documento230 páginasPhysic Xi 2011Ashok PradhanAinda não há avaliações

- Activity 2 Calculations Used in Analytical Chemistry PDFDocumento10 páginasActivity 2 Calculations Used in Analytical Chemistry PDFKobe AcobAinda não há avaliações

- Tables PDFDocumento38 páginasTables PDFvandreAinda não há avaliações

- Test Bank For Chemistry 8th Edition by ZumdahlDocumento20 páginasTest Bank For Chemistry 8th Edition by ZumdahlPedro Chun100% (29)

- Grade 11 Chemistry TextbookDocumento368 páginasGrade 11 Chemistry TextbookWai Wai67% (6)

- Scientific Notation With Significant FiguresDocumento58 páginasScientific Notation With Significant FiguresJasonTenebroso100% (2)

- Grade 5 q2 Mathematics LasDocumento102 páginasGrade 5 q2 Mathematics LasJohn Walter B. RonquilloAinda não há avaliações

- WPH03 01 Rms 20170301 PDFDocumento11 páginasWPH03 01 Rms 20170301 PDFRichard Davidson12Ainda não há avaliações

- Chapter 1 Chemistry The Study of ChangeDocumento61 páginasChapter 1 Chemistry The Study of ChangeRohanAinda não há avaliações

- January 2017 (IAL) MS - M1 EdexcelDocumento19 páginasJanuary 2017 (IAL) MS - M1 EdexcelNewton JohnAinda não há avaliações