Escolar Documentos

Profissional Documentos

Cultura Documentos

J. Riley Edwards and Matthew Csende

Enviado por

Andita Tri BudiantoDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

J. Riley Edwards and Matthew Csende

Enviado por

Andita Tri BudiantoDireitos autorais:

Formatos disponíveis

Slide 1

Mechanistic Design of Rail Transit Concrete Crossties

Mechanistic Design of Concrete Monoblock

Crossties for Rail Transit Loading Conditions

APTA Rail Conference

Salt Lake City, UT

23 June, 2015

Matthew V. Csenge, Xiao Lin, Henry E. Wolf, Marcus S. Dersch, and J. Riley Edwards

Mechanistic Design of Rail Transit Concrete Crossties

Slide 2

Mechanistic Design of Concrete Monoblock

Crossties for Rail Transit Loading Conditions

2015 APTA Rail Conference

Salt Lake City, UT

23 June 2015

Matthew V. Csenge, Xiao Lin, Henry E. Wolf, Marcus S. Dersch,

J. Riley Edwards and Christopher P.L. Barkan

Slide 3

Mechanistic Design of Rail Transit Concrete Crossties

Outline

Background and Motivation

Project Introduction

Mission and Objectives

Methods and Technologies

Industry Partners and Potential Field

Experimentation Locations

Introduction to Mechanistic Design

Load Environment

Transit Focused Concrete Crosstie

Flexural Analysis

Future Work

Mechanistic Design of Rail Transit Concrete Crossties

Project Mission and Objectives

Mission:

Characterize the desired performance requirements for

concrete crossties and fastening systems for rail transit

Quantify the behavior of these systems under load

Develop resilient infrastructure component design solutions

for concrete crossties and fastening systems for rail transit

Objectives:

Investigate field performance demands on concrete crossties

and fastening systems for rail transit applications

Develop an analytical finite element model

Validate analytical model and further field research through

lab experimentation

Develop mechanistic design recommendations for rail transit

applications of concrete crossties and fastening systems

Slide 4

Mechanistic Design of Rail Transit Concrete Crossties

FTA Project Industry Partners

American Public Transportation

Association (APTA)

MTA New York City Transit

(NYCT)

MetroLink

Metra

TriMet

CXT Concrete Ties, Inc.

GIC

Pandrol USA

Amsted RPS

Hanson Professional Services, Inc.

Amtrak

Slide 5

Mechanistic Design of Rail Transit Concrete Crossties

Laboratory Experimentation

RailTECs Track Loading

System (TLS) will be

used to simulate field

loading conditions in the

laboratory

The TLS can apply up to

55 kips vertically at each

journal, and simulate L/V

ratios up to 0.6

Most field instrumentation

setups can be replicated

in the laboratory

Slide 6

Mechanistic Design of Rail Transit Concrete Crossties

Slide 7

Methods and Instrumentation Technologies

Instrumentation used in field and lab experimentation

will include:

Potentiometers displacement

Weldable strain gauges

rail seat loads

Matrix-based tactile surface sensors

pressure distribution at rail seat

Lateral load evaluation devices lateral load at

fastening system shoulder

Mechanistic Design of Rail Transit Concrete Crossties

Field and Laboratory

Experimentation Locations

Light rail: TriMet (Portland, OR)

MetroLink (St. Louis, MO)

Heavy rail: New York City Transit (New York, NY)

Commuter rail: Metra (Chicago, IL)

Slide 8

Slide 9

Mechanistic Design of Rail Transit Concrete Crossties

Introduction to Mechanistic Design

Design approach utilizing forces measured in track structure and

properties of materials that will withstand or transfer them

Uses responses (e.g. contact pressure, relative displacement) to

optimize component geometry and materials requirements

Based on measured and predicted response to load inputs that

can be supplemented with practical experience

Requires thorough understanding of load path and distribution

Allows load factors to be used to include variability due to

location and traffic composition

Used in other engineering industries (e.g. pavement design,

structural steel design, geotechnical)

Define Load

Inputs

Define

Design Criteria

Component

Design

System

Verification

Slide 10

Mechanistic Design of Rail Transit Concrete Crossties

Load Characterization

Load magnitude will vary according to:

Traffic type

Train speed

Track geometry

Vehicle and track health

Each component of the input load must be considered

Vertical

Lateral

Longitudinal

A complete understanding of the input loads can lead to optimized

component and system designs

As load magnitude and frequency change, the optimal design of

the crosstie and fastening system may change

Define Load

Inputs

Define

Design Criteria

Component

Design

System

Verification

Mechanistic Design of Rail Transit Concrete Crossties

Rail Transit Load Environment

Understanding of transit load environment is a

necessary first step for this project

Internet resources were used to preliminarily quantify

vehicle weights throughout the United States

Field experimentation will later be used to further

define load environment

Slide 11

Mechanistic Design of Rail Transit Concrete Crossties

Passenger Vehicle Weight Definitions

PB Light Rail Design Handbook defines:

AW0: Empty vehicle operating weight

AW1 (Seated Load)

Fully seated passenger load + AW0

AW2 (Design Load)

Standing passengers at 4/m2 + AW1

AW3

Load) Passenger Capacity

AW3 (Crush

= Maximum

Average

Passenger

Standing

passengers

at 6/m2 Weight

+ AW1 + AW0

AW4 (Structural Design Load)

Standing passengers at 8/m2 + AW1

Slide 12

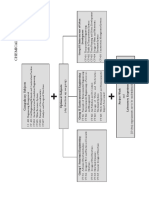

Mechanistic Design of Rail Transit Concrete Crossties

AW3 Vehicle Weight Calculation

Passenger car quantity and

capacity

National Transit Database

(NTD)

Revenue Vehicle Inventory

Number of active

vehicles

Seating and

standing capacity

Empty Car Weight

Manufacturer

data sheets

Slide 13

Mechanistic Design of Rail Transit Concrete Crossties

Slide 14

AW3 Vehicle Weight Calculation (cont.)

Average passenger weight:

Light Rail Design Handbook specifies 155 lbs

FAA specifies 195 lbs

Considers the increase in average weight

Includes clothing and luggage such as backpacks

Flight Standards Service. 2005. Aircraft Weight and Balance Control. Federal Aviation Administration, Washington, DC.

Slide 15

Mechanistic Design of Rail Transit Concrete Crossties

Light Rail, Heavy Rail, and Commuter Rail

Vehicle Weight Distribution

100%

Light Rail AW0

Light Rail AW3

Heavy Rail AW0

Heavy Rail AW3

Commuter Rail AW0

Commuter Rail AW3

90%

Percent Exceeding

80%

70%

60%

50%

40%

30%

20%

10%

0%

0

50

100

150

Weight (kips)

200

250

Slide 16

Mechanistic Design of Rail Transit Concrete Crossties

Light Rail, Heavy Rail, and Commuter Rail

Axle Load Distribution

100%

Light Rail AW0

Light Rail AW3

Heavy Rail AW0

Heavy Rail AW3

Commuter Rail AW0

Commuter Rail AW3

90%

Percent Exceeding

80%

70%

60%

50%

40%

30%

20%

10%

0%

0

10

20

30

Axle Load (kips)

40

50

60

Mechanistic Design of Rail Transit Concrete Crossties

Slide 17

Application: Flexural Design of Crossties

Critical Regions for Flexure

Center Negative (C-)

Rail Seat Positive (RS+)

Mechanistic Design of Rail Transit Concrete Crossties

Slide 18

Flexural Analysis MRS+ - AREMA 2014

+ =

Where: MRS+ = rail seat positive

bending moment

B = the bending moment

in inch-kips for a particular

crosstie length and spacing

A = the transit load

reduction factor

(axle load/82k)

V = the speed factor (1.0)

Factor

Crosstie Spacing (in)

B (8-3 Crosstie) (in-kips)

A (for a 33 kip axle)

Speed (mph)

V

Assumed or

Determined

Value

30

320

33/82=0.40

60

1.0

Equations and figures from Article 30.4.4.1 of the 2014 AREMA Manual

Mechanistic Design of Rail Transit Concrete Crossties

Slide 19

Flexural Analysis MRS+ - AREMA 2014

+ =

Where: MRS+ = rail seat positive

bending moment

B = the bending moment

in inch-kips for a particular

crosstie length and spacing

A = the transit load

reduction factor

(axle load/82k)

V = the speed factor (1.0)

Factor

Crosstie Spacing (in)

B (8-3 Crosstie) (in-kips)

A (for a 33 kip axle)

Speed (mph)

V

Assumed or

Determined

Value

30

320

33/82=0.40

60

1.0 1.0

Equations and figures from Article 30.4.4.1 of the 2014 AREMA Manual

Mechanistic Design of Rail Transit Concrete Crossties

Slide 20

Flexural Analysis MRS+ - AREMA 2014

+ =

Where: MRS+ = rail seat positive

bending moment

B = the bending moment

in inch-kips for a particular

crosstie length and spacing

A = the transit load

reduction factor

(axle load/82k)

V = the speed factor (1.0)

Factor

Crosstie Spacing (in)

B (8-3 Crosstie) (in-kips)

A (for a 33 kip axle)

Speed (mph)

V

MRS+=BAV=(320)(0.40)(1.0)

Assumed or

Determined

Value

30

320

33/82=0.40

60

1.0

128 in-kip

Equations and figures from Article 30.4.4.1 of the 2014 AREMA Manual

Mechanistic Design of Rail Transit Concrete Crossties

Slide 21

Flexural Analysis MC- - AREMA 2014

C = +

Where: MC- = center negative

bending moment

FC- = center negative

factor (per AREMA Table

30-4-1)

MRS+ = rail seat positive

bending moment

Factor

Crosstie Length

FCMRS+

MC-

Assumed or

Determined

Value

8-3

0.77

128 in-kip

99 in-kip

Equations and figures from Article 30.4.4.1 of the 2014 AREMA Manual

Slide 22

Mechanistic Design of Rail Transit Concrete Crossties

Flexural Analysis MRS+ Proposed

Comparison of bending moments

AREMA 2014

AREMA 2015 (proposed)

g

R

( )

+ =

8

Where: g = rail seat centerto-center distance

R = rail seat load

L = crosstie length

Crosstie Length (L)

AREMA 2014

Structural Analysis

8-3

128 in-kip

120.5 in-kip

Slide 23

Mechanistic Design of Rail Transit Concrete Crossties

Flexural Analysis MC- Proposed

Comparison of bending moments

AREMA 2014

AREMA 2015 (proposed)

g

R

2 1 2

=

2 2 1

Where: R = rail seat load

L = crosstie length

= center support factor

g = rail seat centerto-center spacing

c = center support

region = 2g - L

Crosstie Length (L)

AREMA 2014

Structural Analysis

8-3

99 in-kip

99 in-kip

(for = 0.42)

Center support factor () currently under review in AREMA

Committee 30 (Ties)

Mechanistic Design of Rail Transit Concrete Crossties

Future Work and Path Forward

Further expand the understanding of vehicle and

infrastructure characteristics for rail transit

Conduct field and laboratory experimentation to

more accurately characterize the loading

environment for light rail, heavy rail, and commuter

rail transit

Investigate maintenance equipment wheel loads to

ensure compliance in crosstie and fastener design

Conduct a survey on the use and performance of

concrete ties and fastening systems

Objective: Develop an understanding of the most

common types of failures and the design

requirements for optimizing component resiliency

Slide 24

Slide 25

Mechanistic Design of Rail Transit Concrete Crossties

Rail Transit Infrastructure Survey

RailTEC Researchers Need Your Help!

Survey will assist RailTEC

researchers in prioritizing

upcoming FTA-funded

research efforts

Questions are specific to

concrete crossties and

fastening systems

Need light, heavy, and

commuter rail responses

Survey should take only

10-15 minutes

Free RailTEC mug for first

20 respondents!

Survey of Rail Transit Track

Superstructure Design and

Performance

The Rail Transportation and Engineering Center

(RailTEC) at the University of Illinois at UrbanaChampaign (UIUC) has been awarded a grant

from the FTA titled Resilient Concrete Crosstie

and Fastening System Designs for Light Rail,

Heavy Rail, and Commuter Rail Transit

Infrastructure. The primary objective of this

project will be to develop new concrete crosstie

and fastening system designs used in light rail,

heavy rail, and commuter rail infrastructure that

take into account their unique loading conditions.

The RailTEC team, along with its Industry

Partners (listed on right), is conducting a survey to

help determine the most critical aspects of

crossties and fastening systems that should be

made resilient in the face of natural disasters or

other events that place increased stress on

infrastructure and its components. We invite you

to participate in this survey at the following link:

FTA Project

Industry Partners

APTA

NYCT

(New York

City, NY)

Metra

(Chicago, IL)

MetroLink

(St. Louis, MO)

TriMet

(Portland, OR)

Pandrol USA

GIC

https://goo.gl/QVJuyB

Survey results will be used to guide the field and

laboratory experimental efforts as well as the

analytical

finite

element

(FE)

modeling

components of this project.

If you have any questions about this survey,

please feel free to contact RailTEC Graduate

Research Assistant Xiao (Sean) Lin at

xiaolin4@illinois.edu.

Amsted RPS

LBFoster, CXT

Concrete Ties

Hanson

Professional

Services, Inc.

Amtrak

The first 20 individuals who complete the survey will receive a complimentary

RailTEC mug shipped to the address provided in the survey!

Slide 26

Mechanistic Design of Rail Transit Concrete Crossties

Acknowledgements

FTA Industry Partners:

Funding for this research has been provided by:

Federal Transit Administration (FTA) (starts 1 Aug. 2015)

National University Rail Center (NURail Center)

Industry Partnership and support has been provided by

American Public Transportation Association (APTA)

New York City Transit (NYCT)

Metra (Chicago)

MetroLink (St. Louis)

TriMet (Portland, Ore.)

Pandrol USA

Amsted RPS / Amsted Rail, Inc.

LBFoster

GIC Inc.

Hanson Professional Services, Inc.

Amtrak

UIUC Students Sean Lin and Henry Wolf

Mechanistic Design of Rail Transit Concrete Crossties

Contact Information

Matthew V. Csenge

Manager of Experimentation

csenge2@Illinois.edu

Xiao (Sean) Lin

Graduate Research Assistant

xiaolin4@Illinois.edu

Henry E. Wolf

Graduate Research Assistant

wolf24@Illinois.edu

Marcus S. Dersch

Senior Research Engineer

mdersch2@Illinois.edu

J. Riley Edwards

Sen. Lecturer and Research Sci.

jedward2@Illinois.edu

Slide 27

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- DATA SONDIR / DCPT (Dynamic Cone Penetration Test) : Depth Depth DepthDocumento3 páginasDATA SONDIR / DCPT (Dynamic Cone Penetration Test) : Depth Depth DepthAndita Tri BudiantoAinda não há avaliações

- Metric Block Catalog Low Res 10-14-13Documento4 páginasMetric Block Catalog Low Res 10-14-13Andita Tri BudiantoAinda não há avaliações

- Baseplate 111113145118 Phpapp01 PDFDocumento2 páginasBaseplate 111113145118 Phpapp01 PDFAndita Tri BudiantoAinda não há avaliações

- Baseplate 111113145118 Phpapp01 PDFDocumento2 páginasBaseplate 111113145118 Phpapp01 PDFAndita Tri BudiantoAinda não há avaliações

- SEMrush Keyword Research ChecklistDocumento1 páginaSEMrush Keyword Research ChecklistAndita Tri BudiantoAinda não há avaliações

- ATT-15/96, MOISTURE CONTENT, Oven Method, Soil and Gravel 1.0 ScopeDocumento3 páginasATT-15/96, MOISTURE CONTENT, Oven Method, Soil and Gravel 1.0 ScopeAndita Tri BudiantoAinda não há avaliações

- Wall Construction: Site PreparationDocumento4 páginasWall Construction: Site PreparationAndita Tri BudiantoAinda não há avaliações

- J. Riley Edwards and Matthew Csende PDFDocumento27 páginasJ. Riley Edwards and Matthew Csende PDFAndita Tri BudiantoAinda não há avaliações

- 1-6 Concrete Sleepers PDFDocumento16 páginas1-6 Concrete Sleepers PDFAndita Tri BudiantoAinda não há avaliações

- Retaining Wall DesignDocumento10 páginasRetaining Wall DesignklynchelleAinda não há avaliações

- Tmhuk009 Cbic 5fd FG Brochure 0106Documento8 páginasTmhuk009 Cbic 5fd FG Brochure 0106Andita Tri BudiantoAinda não há avaliações

- Crane Rails: American Tee Rail SectionsDocumento1 páginaCrane Rails: American Tee Rail SectionsUsmanAinda não há avaliações

- Crane Track Mounting IntroductionDocumento4 páginasCrane Track Mounting IntroductionAndita Tri BudiantoAinda não há avaliações

- Testing Grounding SystemsDocumento69 páginasTesting Grounding SystemsAndita Tri Budianto100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Nani PPT On TractionDocumento21 páginasNani PPT On TractionLovely TarakAinda não há avaliações

- Great Model Railroads 2008Documento124 páginasGreat Model Railroads 2008Ricardo KutzAinda não há avaliações

- Problems of Pakistan Railways and Its Privatization OdDocumento21 páginasProblems of Pakistan Railways and Its Privatization Odzohra45% (11)

- Part 5 Optimal Wheel and Rail Performance (M.roney - IHHA 2001) PDFDocumento45 páginasPart 5 Optimal Wheel and Rail Performance (M.roney - IHHA 2001) PDFDylkanWingsAinda não há avaliações

- RIE - Internship Brochure PDFDocumento20 páginasRIE - Internship Brochure PDFAnkur SinhaAinda não há avaliações

- 081 Westheimer SharpstownDocumento8 páginas081 Westheimer SharpstownTran Bich DiemAinda não há avaliações

- History of USA - Books 4-5Documento223 páginasHistory of USA - Books 4-5Dux MusicaeAinda não há avaliações

- Diesel Locomotive Power Pack AssemblyDocumento30 páginasDiesel Locomotive Power Pack AssemblyNishant Varshney88% (8)

- Automatic Electri Train BarrierDocumento3 páginasAutomatic Electri Train BarrierAbhishek Dubey100% (2)

- Nandan Kanan ExpDocumento2 páginasNandan Kanan ExpAnshu KumarAinda não há avaliações

- Soal UjianDocumento16 páginasSoal Ujianfarid sanky0% (1)

- SC-14 Safety Code For Work On Electric Overhead Travelling - EOT - CraneDocumento18 páginasSC-14 Safety Code For Work On Electric Overhead Travelling - EOT - CraneArdh0072Ainda não há avaliações

- Model Railroader How To Build A Model RailroadDocumento84 páginasModel Railroader How To Build A Model RailroadNickiedeposieAinda não há avaliações

- Fehmarnbelt Fixed Link Tunnel: Bridges & Tunnels Asia 2014 19.04.2014 Axel Emil Christensen, RambollDocumento54 páginasFehmarnbelt Fixed Link Tunnel: Bridges & Tunnels Asia 2014 19.04.2014 Axel Emil Christensen, RambollJohnAinda não há avaliações

- GPL DWNR PM 000110.a.exsubDocumento40 páginasGPL DWNR PM 000110.a.exsubJohnny RobertsonAinda não há avaliações

- Stanley Cobotics BrochureDocumento12 páginasStanley Cobotics BrochureEberthsonAinda não há avaliações

- G-33 (Rev. 1) : Indian Rail WaysDocumento29 páginasG-33 (Rev. 1) : Indian Rail Wayssenthil031277Ainda não há avaliações

- Kenworth t470 BrochureDocumento6 páginasKenworth t470 Brochurefdpc1987100% (1)

- 0 PTS Handbook PDFDocumento84 páginas0 PTS Handbook PDFSarpanch SidhuAinda não há avaliações

- Product Portfolio: GSM-R Cab RadioDocumento58 páginasProduct Portfolio: GSM-R Cab RadioTomekbwdAinda não há avaliações

- 111 Jadwal Perjalanan Kereta Api Sesuai Gapeka 2021Documento55 páginas111 Jadwal Perjalanan Kereta Api Sesuai Gapeka 2021DenyAinda não há avaliações

- Basic Components of RAILDocumento31 páginasBasic Components of RAILFaisal RasoolAinda não há avaliações

- Rail AssignmentDocumento11 páginasRail AssignmentQarin AliaAinda não há avaliações

- MEST 000002-05: Track Bonding For Signalling and Traction Return CurrentDocumento35 páginasMEST 000002-05: Track Bonding For Signalling and Traction Return CurrentMichaelAinda não há avaliações

- AMIE CivilDocumento10 páginasAMIE Civilসন্দীপ চন্দ্রAinda não há avaliações

- Training ReportDocumento78 páginasTraining ReportNavi SharmaAinda não há avaliações

- Tender No MSMCCOAL202001Documento61 páginasTender No MSMCCOAL202001Frianata ZrAinda não há avaliações

- Notice: Rail Carriers: Control Exemption— Moscow, Camden & San Augustine RailroadDocumento1 páginaNotice: Rail Carriers: Control Exemption— Moscow, Camden & San Augustine RailroadJustia.comAinda não há avaliações

- CRCDocumento98 páginasCRCSimon LiuAinda não há avaliações

- Kridha Logistics Pvt. Ltd. - Company ProfileDocumento9 páginasKridha Logistics Pvt. Ltd. - Company ProfilePrateek AgarwalAinda não há avaliações