Escolar Documentos

Profissional Documentos

Cultura Documentos

Chloride Chlorine Levels and Stainless S PDF

Enviado por

SH1961Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chloride Chlorine Levels and Stainless S PDF

Enviado por

SH1961Direitos autorais:

Formatos disponíveis

Chloride / Chlorine levels and Stainless Steel alloy Selection - Penflex

CL IENT LO GIN

ABOUT

BU ILD YO UR ASSE MBLY

PRODUC TS

1 1

RE QU EST QUOTE

TECHNIC AL TOOLS

R EG ISTE R FOR EMA IL UPDATE S

RESOURCES

CONTACT US

Search

Engineering Bulletins

Industry Links

Certifications

Non-Destructive

Testing Program

Chloride / Chlorine levels and Stainless Steel alloySelection

The 304 and 304L (18-8 alloys) have been utilized very successfully in fresh waters containing low levels of

chloride ion of up to 100 ppm. This level of chloride is considered to be the limit for the 18-8 alloys,

particularly if crevices are present. Higher levels of chloride might cause crevice corrosion and pitting. The

18-8 alloys are not recommended for exposure to marine environments which have much higher levels

ofchloride.

The resistance of the stabilized Alloys 321 to pitting and crevice corrosion in the presence of chloride ion is

similar to that of Alloy 304 or 304L stainless steels because of similar chromium content. And therefore 100

ppm chloride in aqueous environments is considered to be the limit for the stabilized alloys, particularly if

crevices arepresent.

For more severe conditions of higher chloride level, lower pH and/or higher temperatures, alloys with Mo

(molybdenum), such as Alloy 316, should be considered. The Mo-bearing Alloy 316 and Alloy 316L may

handle waters with up to about 2000 ppm ofchloride.

Another factor to consider is the amount of free Chlorine (Cl2) (usually derived from sodium hypochlorite)

which is added to water (well water, drinking water, swimming pool water, etc.) to kill bacteria. Cl2 (chlorine)

is a very potent oxidizer (reason it kills bacteria) and therefore high levels of Chlorine may accelerate

chloride corrosion of stainless steels. 304 and 304L, 321 SS may be used for water applications with up to 2

ppm chlorine, while 316 and 316L alloys may take up to 4ppm.

If you have any questions or comments, please contact us.

Disclaimer: The info presented here has been compiled from sources believed to be reliable. No guarantee is

implied or expressly stated here and the data given is intended as a guideonly.

ABOUT

PRODUCTS

TEC HNICAL TOOLS

RESOURCES

CONTACT US

Company History

Business Model

Why Use Metal Hose

Capabilities and Overview

Quality Management System Program

Careers

P4

P3

700 Series

800 Series

900 Series

1400 Series

400 Series

C276 Braided Hose

Braid & Braided Product

Interlock Hose

Expansion Joints

Product Catalog

Glossary

Build Your Assembly

Min Live Length Calculator

Velocity Calculator

Pressure Calculator

Temperature Adjustment Factors

Corrosion Resistance Chart

Common Alloys Cross-Reference

Engineering Bulletins

Industry Links

Certifications

Non-Destructive Testing Program

Driving Directions

Factory & Warehouse Locations

Request for Quote

/http://www.penflex.com/chloride-chlorine-levels-and-stainless-steel-alloy-selection

17/07/16

Você também pode gostar

- Selection of Stanless Steel For Fluids Containing ChlorideDocumento6 páginasSelection of Stanless Steel For Fluids Containing ChlorideADITYA_PATHAK100% (1)

- 2 - Low Temperature CorrosionDocumento65 páginas2 - Low Temperature CorrosiondennykvgAinda não há avaliações

- Corrosion in Stainless Steel ! - Know The Facts !!Documento22 páginasCorrosion in Stainless Steel ! - Know The Facts !!faith23dbagulAinda não há avaliações

- 316 316L DataBulletinDocumento7 páginas316 316L DataBulletinAbdurohman RawindaAinda não há avaliações

- Comparing American and British Piping StandardsDocumento7 páginasComparing American and British Piping Standardsyarzar17Ainda não há avaliações

- Poly Water Tank (Completed) PDFDocumento2 páginasPoly Water Tank (Completed) PDFSopi LabuAinda não há avaliações

- Ventilación en Altura-Bolivia PDFDocumento67 páginasVentilación en Altura-Bolivia PDFGrace Ayala EspinozaAinda não há avaliações

- Hempadur 85530Documento2 páginasHempadur 85530kumarnowabuAinda não há avaliações

- Guides and RestraintsDocumento8 páginasGuides and RestraintserikohAinda não há avaliações

- Halar-Lined Tank Questionnaire Rev3Documento2 páginasHalar-Lined Tank Questionnaire Rev3maxpower1984Ainda não há avaliações

- Pipe 36pulg Stress Analysis ReportDocumento3 páginasPipe 36pulg Stress Analysis ReportJhony MedranoAinda não há avaliações

- Thermoseal Klingersil C-4401Documento2 páginasThermoseal Klingersil C-4401timwright999Ainda não há avaliações

- Key Issues Related To Modelling of Internal Corrosion of Oil and Gas Pipelines-A ReviewDocumento16 páginasKey Issues Related To Modelling of Internal Corrosion of Oil and Gas Pipelines-A ReviewsanaamikhailAinda não há avaliações

- En 1092-1 PN-10 Steel Pipe Flange - ValviasDocumento5 páginasEn 1092-1 PN-10 Steel Pipe Flange - ValviasHoria ZecheruAinda não há avaliações

- Foam ChamberDocumento3 páginasFoam ChamberGonzalo CabreraAinda não há avaliações

- Guidelines For Alloy Selection For Waters and Waste Water Service PDFDocumento6 páginasGuidelines For Alloy Selection For Waters and Waste Water Service PDFssgentisAinda não há avaliações

- Effect Chlorine in FreshWaterDocumento5 páginasEffect Chlorine in FreshWaterEl Ehsan Abinya FatihAinda não há avaliações

- Stainless Steel Corrosion by Chloride IonsDocumento32 páginasStainless Steel Corrosion by Chloride Ionssureshjeeva0% (1)

- Corrosion and Surface 20properties 2.3Documento40 páginasCorrosion and Surface 20properties 2.3faizanAinda não há avaliações

- Chloride Local Corrosion in Stainless Acom - 3 - 2011Documento14 páginasChloride Local Corrosion in Stainless Acom - 3 - 2011Roelf MostertAinda não há avaliações

- A02 16 L Carpen PDFDocumento7 páginasA02 16 L Carpen PDFNitin BuZzAinda não há avaliações

- Chloride Stress Corrosion Cracking of 300 Series Stainless SteelDocumento5 páginasChloride Stress Corrosion Cracking of 300 Series Stainless SteelhboodhaiAinda não há avaliações

- Hydrostatic Testing of Welded Ss FabricationsDocumento12 páginasHydrostatic Testing of Welded Ss FabricationsKarin Soldatelli Borsato100% (1)

- B. Phosphoric Acid Processes It Is Estimated That Around 90% of The Phosphoric Acid (H3PO4)Documento3 páginasB. Phosphoric Acid Processes It Is Estimated That Around 90% of The Phosphoric Acid (H3PO4)nAinda não há avaliações

- Technical Bulletin - ECOSS - Critical Pitting TemperaturesDocumento2 páginasTechnical Bulletin - ECOSS - Critical Pitting TemperaturesINPAinda não há avaliações

- Corrosion in Hydrochloric AcidDocumento2 páginasCorrosion in Hydrochloric AcidbbmokshAinda não há avaliações

- Study of The Corrosion Behaviour of S32101 Duplex and 410 Martensitic Stainless Steel For Application in Oil Refinery Distillation SystemsDocumento11 páginasStudy of The Corrosion Behaviour of S32101 Duplex and 410 Martensitic Stainless Steel For Application in Oil Refinery Distillation SystemsBalaji BeliveAinda não há avaliações

- Stress Corrosion Cracking and Corrosion Susceptibility of Duplex SS in Caustic Solution-MinDocumento14 páginasStress Corrosion Cracking and Corrosion Susceptibility of Duplex SS in Caustic Solution-Minhasansm farabipcAinda não há avaliações

- Technical Bulletin - ECOSS - FAQDocumento3 páginasTechnical Bulletin - ECOSS - FAQINPAinda não há avaliações

- CUI: An In-Depth Analysis: Hira S. AhluwaliaDocumento6 páginasCUI: An In-Depth Analysis: Hira S. AhluwaliaJithuJohnAinda não há avaliações

- مقاومه الاستيل للتاكل في التركيزDocumento10 páginasمقاومه الاستيل للتاكل في التركيزFarouq AliAinda não há avaliações

- Galvanic CorrDocumento6 páginasGalvanic CorrdhlinvaAinda não há avaliações

- Difference Between 304 and 316 Stainless SteelDocumento4 páginasDifference Between 304 and 316 Stainless SteelsekarsanthanamAinda não há avaliações

- Electrochemical Corrosion Resistance Evaluationof Ferritic Stainless Steelin HCLDocumento13 páginasElectrochemical Corrosion Resistance Evaluationof Ferritic Stainless Steelin HCLparv serviceAinda não há avaliações

- Corrosion Resistance of Steels Used in Alcohol and Sugar IndustryDocumento10 páginasCorrosion Resistance of Steels Used in Alcohol and Sugar Industryrewatiraman KatiyarAinda não há avaliações

- SSAS4.92-Stainless Steels in Supply Waters by BSSA (British Stainless Steel Association)Documento4 páginasSSAS4.92-Stainless Steels in Supply Waters by BSSA (British Stainless Steel Association)Talha MahmoodAinda não há avaliações

- Engineering Failure Analysis: C.M.B. Martins, J.L. Moreira, J.I. MartinsDocumento7 páginasEngineering Failure Analysis: C.M.B. Martins, J.L. Moreira, J.I. Martinspaneisan100% (1)

- Crevice Corrosion of Stainless-Steel Fastening Components in An Indoor Marine-Water BasinDocumento5 páginasCrevice Corrosion of Stainless-Steel Fastening Components in An Indoor Marine-Water BasinRaul MamaniAinda não há avaliações

- Article - Selection of Stainless Steels For Handling Sulphuric Acid (H2SO4)Documento4 páginasArticle - Selection of Stainless Steels For Handling Sulphuric Acid (H2SO4)gbuckley9630Ainda não há avaliações

- Chemical Resistance Guide For Valves: March 25, 2010Documento11 páginasChemical Resistance Guide For Valves: March 25, 2010akramhomriAinda não há avaliações

- Stainless Steels and Drinking Water Around The WorldDocumento12 páginasStainless Steels and Drinking Water Around The WorldVizit31Ainda não há avaliações

- World Oil CorrosionDocumento4 páginasWorld Oil CorrosionmutemuAinda não há avaliações

- Corrosion of Carbon SteelDocumento3 páginasCorrosion of Carbon Steelvandanak_mechAinda não há avaliações

- ONGC Paper On Lean DSS PDFDocumento6 páginasONGC Paper On Lean DSS PDFMeet ShahAinda não há avaliações

- Chlorides CorrosionDocumento12 páginasChlorides CorrosionOlgalycos100% (1)

- Chloride Attack On Stainless SteelDocumento10 páginasChloride Attack On Stainless SteelgovimanoAinda não há avaliações

- Chloride Attack On Stainless SteelDocumento9 páginasChloride Attack On Stainless SteelAnand GuptaAinda não há avaliações

- Valve Material ApplicationDocumento16 páginasValve Material Applicationari_prasAinda não há avaliações

- Influence of Acidity and Naocl Concentration On The Corrosion Resistance of Stainless Steels in Chlorinated WaterDocumento10 páginasInfluence of Acidity and Naocl Concentration On The Corrosion Resistance of Stainless Steels in Chlorinated WaterswongAinda não há avaliações

- Stainless Tubing in BiotechDocumento14 páginasStainless Tubing in BiotechClaudia MmsAinda não há avaliações

- Rittal White Paper 104: Stainless Steel Enclosures in Industrial ApplicationsDocumento7 páginasRittal White Paper 104: Stainless Steel Enclosures in Industrial Applicationsphoneme79Ainda não há avaliações

- Companion Study Guide TO Short Course On Geothermal Corrosion and Mitigation in Low Temperature Geothermal Heating SystemsDocumento34 páginasCompanion Study Guide TO Short Course On Geothermal Corrosion and Mitigation in Low Temperature Geothermal Heating SystemsrandyooiscribdAinda não há avaliações

- 66 JMES 390 2013 LotoDocumento12 páginas66 JMES 390 2013 LotoAnonymous 1hOgJqwZuzAinda não há avaliações

- 1 PBDocumento9 páginas1 PBAbdul MalikAinda não há avaliações

- Materials Selection For Membrane Plants HandlingDocumento12 páginasMaterials Selection For Membrane Plants HandlingSiddharth VAinda não há avaliações

- SDSS For Submersible Pumps - 2017 11Documento3 páginasSDSS For Submersible Pumps - 2017 11Cimpoesu NicanorAinda não há avaliações

- Corrosion of Mild Steel in Various ConditionsDocumento8 páginasCorrosion of Mild Steel in Various ConditionsAabhas UpadhyayaAinda não há avaliações

- AL 316 - 317dataDocumento14 páginasAL 316 - 317dataClaudia MmsAinda não há avaliações

- The Effect of Heavy Metal Ions On The Localized CorrosionDocumento36 páginasThe Effect of Heavy Metal Ions On The Localized Corrosionnaren57100% (1)

- Unusual Corrosion Failures of Stainless SteeDocumento12 páginasUnusual Corrosion Failures of Stainless SteeMahmoud GamalAinda não há avaliações

- Data SF3300Documento2 páginasData SF3300Ingrid Johhana BalbinAinda não há avaliações

- Industrial Shaft Seals - 10919 - 2 EN PDFDocumento488 páginasIndustrial Shaft Seals - 10919 - 2 EN PDFAwan AJaAinda não há avaliações

- InTech-Corrosive Effects of Chlorides On MetalsDocumento41 páginasInTech-Corrosive Effects of Chlorides On MetalsAndrey756Ainda não há avaliações

- FSA Gasket Handbook - June 2017Documento138 páginasFSA Gasket Handbook - June 2017Dijin MaroliAinda não há avaliações

- Chloride SCC of 316 SSTDocumento5 páginasChloride SCC of 316 SSTSH1961100% (1)

- Industrial Shaft Seals - 10919 - 2 EN PDFDocumento488 páginasIndustrial Shaft Seals - 10919 - 2 EN PDFAwan AJaAinda não há avaliações

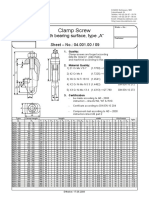

- Vba Edelmann Clamp FastenersDocumento2 páginasVba Edelmann Clamp FastenersSH1961Ainda não há avaliações

- 444 StainlessDocumento4 páginas444 StainlessSH1961Ainda não há avaliações

- 444 StainlessDocumento4 páginas444 StainlessSH1961Ainda não há avaliações

- Pipe Marking - Full Guide PDFDocumento27 páginasPipe Marking - Full Guide PDFSH1961Ainda não há avaliações

- Non Ferrous MaterialsDocumento8 páginasNon Ferrous MaterialsSH1961Ainda não há avaliações

- Aalco Datasheet ST ST BS enDocumento12 páginasAalco Datasheet ST ST BS enSH1961Ainda não há avaliações

- Klinger Gasket FactorsDocumento3 páginasKlinger Gasket FactorsGeorge TanasescuAinda não há avaliações

- Pickling HandbookDocumento20 páginasPickling HandbookRhona100% (1)

- FSA Gasket Handbook - June 2017Documento138 páginasFSA Gasket Handbook - June 2017Dijin MaroliAinda não há avaliações

- Non Returne ValvesDocumento22 páginasNon Returne ValvesSH1961Ainda não há avaliações

- Velan High Pressure Steam Trapping Brochure PDFDocumento8 páginasVelan High Pressure Steam Trapping Brochure PDFSH1961Ainda não há avaliações

- Pipe Symbols For Isometric DrawingsDocumento3 páginasPipe Symbols For Isometric DrawingsSH1961Ainda não há avaliações

- Tightening TorquesDocumento4 páginasTightening Torquesflanker76Ainda não há avaliações

- Bolt Tightening TorquesDocumento3 páginasBolt Tightening Torquesatanughosh125Ainda não há avaliações

- Lumi GlassDocumento1 páginaLumi GlassSH1961Ainda não há avaliações

- Passivating & Pickling Stainless SteelDocumento16 páginasPassivating & Pickling Stainless Steelfeki2607Ainda não há avaliações

- Gaskets - Graphite PDFDocumento4 páginasGaskets - Graphite PDFSH1961Ainda não há avaliações

- Complete CatalogDocumento52 páginasComplete CatalogrbsaylorsAinda não há avaliações

- Dynalene HC Engineering GuideDocumento38 páginasDynalene HC Engineering GuideSH1961Ainda não há avaliações

- Aalco Datasheet ST ST BS enDocumento2 páginasAalco Datasheet ST ST BS enSalai LokeshAinda não há avaliações

- Algoma Steel Sheet PDFDocumento10 páginasAlgoma Steel Sheet PDFSH1961Ainda não há avaliações

- Stainless Steel Pressure RatingsDocumento7 páginasStainless Steel Pressure RatingsNauman KhanAinda não há avaliações

- Corrosion Resistance ofDocumento44 páginasCorrosion Resistance ofalkem7Ainda não há avaliações

- Carbon Steel Swage Nipples and Bull Plugs: Price Sheet SN-908Documento18 páginasCarbon Steel Swage Nipples and Bull Plugs: Price Sheet SN-908rocknyvAinda não há avaliações

- 6 Alkaline Flooding - PPT StudentDocumento46 páginas6 Alkaline Flooding - PPT StudentEslam Atif Azkol100% (1)

- Installation Transfero TV Connect LowDocumento16 páginasInstallation Transfero TV Connect LowFabian Romeo100% (1)

- Acoelomates 2015Documento5 páginasAcoelomates 2015premeaunAinda não há avaliações

- Abebe DinkuDocumento119 páginasAbebe Dinkudan4books88% (16)

- KMML IV ReportDocumento24 páginasKMML IV ReportSajeer Savad100% (1)

- Quick DetailsDocumento2 páginasQuick DetailszdravkoAinda não há avaliações

- CSM Softener Brochure PDFDocumento2 páginasCSM Softener Brochure PDFintermountainwaterAinda não há avaliações

- Cross RefDocumento9 páginasCross RefJames CarterAinda não há avaliações

- An Analysis of Housing Conditions in AmacDocumento38 páginasAn Analysis of Housing Conditions in AmacGodswill EssienAinda não há avaliações

- Water Distribution NetworkDocumento3 páginasWater Distribution NetworkLorie Mae IIAinda não há avaliações

- MCAT Full Length2Documento79 páginasMCAT Full Length2Ali100% (1)

- Chemical Management D0cc1a52 2a03 4d29 Ac14 E8c1544c1c82Documento4 páginasChemical Management D0cc1a52 2a03 4d29 Ac14 E8c1544c1c82Arslan Haider100% (1)

- How To Go GreenDocumento11 páginasHow To Go GreenHiba MahdiAinda não há avaliações

- EMA Floods Warning Preparedness SafetyDocumento2 páginasEMA Floods Warning Preparedness SafetyMissy_T0% (1)

- Introduction To Sequence Stratigraphy SmallDocumento36 páginasIntroduction To Sequence Stratigraphy SmalljplohanaAinda não há avaliações

- Steelmaster 1200Wf: Technical Data Sheet Application GuideDocumento11 páginasSteelmaster 1200Wf: Technical Data Sheet Application GuideDominguez MegoAinda não há avaliações

- BWY SeriesDocumento24 páginasBWY Seriesjoe1256100% (1)

- Direct Pipe Levee CrossingDocumento9 páginasDirect Pipe Levee CrossingYap Wen Khong Yap Wen KhongAinda não há avaliações

- Bio With Answer KeyDocumento6 páginasBio With Answer KeyMari CrisAinda não há avaliações

- Water Policy Issues of IndiaDocumento96 páginasWater Policy Issues of IndiaAyyagari RavitejaAinda não há avaliações

- Surface WaterDocumento22 páginasSurface WaterLuis MenendezAinda não há avaliações

- JKGHKJDocumento7 páginasJKGHKJJitendra singh shivranAinda não há avaliações

- Drainage Handbook ADH1 (02-17) PDFDocumento52 páginasDrainage Handbook ADH1 (02-17) PDFSukanta Kumar PandaAinda não há avaliações

- GJESM Volume 8 Issue 2 Pages 237-250Documento14 páginasGJESM Volume 8 Issue 2 Pages 237-250GJESMAinda não há avaliações

- 2 - Water Quality Analysis and ManagementDocumento29 páginas2 - Water Quality Analysis and ManagementAntonio Z Manchete100% (3)

- JYOTHIDocumento25 páginasJYOTHIGanesh salluriAinda não há avaliações

- Energy Storage and Meta DataDocumento9 páginasEnergy Storage and Meta DataDamisha DamishaAinda não há avaliações

- Jabatan Kerja Raya Preliminary Detailed Abstract ForDocumento2 páginasJabatan Kerja Raya Preliminary Detailed Abstract ForFadzlini RamliAinda não há avaliações

- ChillersDocumento7 páginasChillersBRANDONAinda não há avaliações

- Guideline Green AuditorDocumento48 páginasGuideline Green AuditorHse Consultancy SgsbAinda não há avaliações