Escolar Documentos

Profissional Documentos

Cultura Documentos

IJASR - Preservation of Tender Coconut Water Using Pulsed Electric

Enviado por

TJPRC PublicationsTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

IJASR - Preservation of Tender Coconut Water Using Pulsed Electric

Enviado por

TJPRC PublicationsDireitos autorais:

Formatos disponíveis

International Journal of Agricultural

Science and Research (IJASR)

ISSN(P): 2250-0057; ISSN(E): 2321-0087

Vol. 6, Issue 4, Aug 2016, 251-256

TJPRC Pvt. Ltd

PRESERVATION OF TENDER COCONUT WATER

USING PULSED ELECTRIC FIELD

S. SARANYA1 & G. SUJATHA2

1

Department of Food Technology, College of Food and Dairy Technology, Koduvalli, Chennai, Tamil Nadu., India

2

Assistant Professor, Department of Food Engineering, College of Food and Dairy Technology,

Koduvalli, Chennai, Tamil Nadu. India

ABSTRACT

This paper investigates preservation of tender coconut water (TCW) using non thermal processing techniques.

Thermal processing is one of the methods to increase shelf life by inactivating the spoilage microorganisms. As sensory

properties are degraded by heat, an alternative preservation technique is required. Pulsed Electric Field technology (PEF)

is one of the emerging technologies for the replacement of traditional thermal pasteurization. Hence TCW was processed

using PEF technology. Tender coconut water was filled in PEF processing chamber which was embedded with two

parallel plate electrodes. Square pulses of 35KV magnitude and pulse width 2.5sec were applied to the TCW through

under sterile conditions. The collected samples were stored at 5oC and shelf life studies were conducted. Physico chemical

parameters viz., pH, Acidity and TSS, microbiological parameters viz., standard plate count and e.coli and sensory

attributes viz., taste, colour and overall acceptability were measured in regular intervals. It was found that pH, acidity and

TSS did not have any significant difference in samples before and after processing. It was found that SPC count was less

than 5000 cfu/mL and E.coli was found to be absent. It was also observed that sensory attributes did not change after

PEF processing. The shelf life of the processed tender coconut water extended to 18 to 25 days at 5oC.

Original Article

electrodes. The pulses were applied for 2 min, 4 min and 6 min. the processed sample were collected in sterile containers

KEYWORDS: Tender Coconut Water, Pulsed Electric Field Treatment, Shelf Life and Sensory Properties

Received: Jul 10, 2016; Accepted: Aug 06, 2016; Published: Aug 11, 2016; Paper Id.: IJASRAUG201633

INTRODUCTION

Tender Coconut water (Cococus nucifera L.) is the liquid endosperm obtained from a young coconut

which is pure, nutritious and wholesome natural beverage. The sterile water, which is approximately 200 750 ml,

is enclosed with a hard shell and a well-lined layer (8 10 mm) of coconut meat. Coconut water is not a common

fruit juice and thus not easy to stabilize. And also availability of tender coconut is more in coastal area rather than

non coastal area. Tender coconut water is a refreshing drink with electrolytes (ionic mineral) similar to human

plasma (Jayasundera and Dharmasena, 2014). This refreshing drink is filled with many healthy natural nutrients

which can enhance the body's metabolism and immunity and is used more as a health supplement. The important

significant and useful components in coconut water are cytokinins. The potential anti-cancer properties of specific

cytokinins could bring encouraging and novel perspectives in finding cures for the different types of cancers.

The recent discovery of other medicinal values of coconut water signifies a good potential in improving human

health. Fresh food contains all the nutrients needed for good health, but because it may not always be possible to

obtain fresh food, preservation becomes necessary (Raju and Zahida, 2007). Thermal processing had been the most

www.tjprc.org

editor@tjprc.org

252

S. Saranya & G. Sujatha

commonly used in the food industry to increase shelf life and maintain food safety by inactivating spoilage and pathogenic

microorganisms (Sujatha et al., 2016). But studies have shown that colour, flavour and nutrients are degraded by heat and

also there is large amount of energy consumed in thermal processing (Reddy and Penchalaraju.M, 2012). In PEF

technology, electrical energy is applied in the form of short pulses, which destroys the bacterial cell membrane with no

significant heating of food (Canovas, 1999 and Iqbal Singh, 2012). Hence the present study was envisaged to process TCW

with PEF technology and carry out sensory analysis and shelf life studies.

MATERIALS AND METHODS

The PEF processing was conducted in a lab model PEF equipment available at College of Food and Dairy

Technology, TANUVAS, Koduvalli, Chennai. The system is incorporated with a HVDC supply, which produces 35KV

high voltage pulses, a pulse forming network (PFN) containing 10 L C (Inductor - Capacitor) stages which produces 2.5

microsecond square pulses. PEF chamber incorporated two parallel plate adjustable electrodes which enabled to apply

different voltage gradients to the tender coconut water for different treatments

Pre Processing

Good quality green tender coconuts were procured from the local market and surface was cleaned with sterile

water. The nut was cut open with the sterile knife and water collected through sterile muslin cloth prior to processing

(Kathiravan et al., 2014). The PEF processing chamber was washed and rinsed in distilled water and kept in autoclave for 1

hour. The TCW was PEF processed in laminar air flow chamber in sterile condition. Before processing the laminar air flow

chamber was wiped with 99% ethanol and exposed to UV radiation for sterilization. The packing materials

(glass bottles and poly ethylene sachets) were also sterilized before packaging.

PEF Treatment

120 milli liter of tender coconut water was suspended between two parallel plate electrodes in the PEF chamber.

The treatment region of the PEF chamber can be varied by adjusting the distance between electrodes. The applied high

voltage pulses resulted in production of electric field across the TCW between the electrodes that caused microbial

inactivation (Ho and Mittal, 2000). The electric field was applied in the form of square pulses with different treatment

gaps. The PEF system had a timer and number of pulses to be applied for PEF treatment was set before HVDC supply is

turned on. The voltage was increased to 0-35KV gradually. The experiment was carried out for different time intervals

with different voltage gradients. The PEF treatment for TCW was carried out for 2 minutes, 4 minutes and 6 minutes time

duration with two voltage gradients viz., 17 KV/cm and 35 KV/cm.

Collection of Processed Tender Coconut Water

The PEF treated TCW samples were immediately collected in sterile bottles and polythene pouches. The bottles

were corked and PE sachets were sealed immediately in sterile condition and stored at 5oC (Maciel et al., 1992).

METHOD OF ANALYSIS

Chemical Analysis

pH Value

The pH was determined with a Digital pH meter at 23oC. The pH meter was standardized using pH buffer of 4.0,

7.0 and 9.2 (Nadanasabapathy and Kumar, 1999; Manjunatha and Raju, 2014).

Impact Factor (JCC): 4.8136

NAAS Rating: 3.53

Preservation of Tender Coconut Water using Pulsed Electric Field

253

Acidity: (% of malic acid)

The titratable acidity (TA) was determined by titrating 1 mL of each sample (diluted to 20 mL final volume with

deionized water) using 0.1N NaOH. Results were expressed as percentage of malic acid 100 m/L samples

Total Soluble Solids (TSS):

The total soluble solids (oBrix) were measured using a hand refractometer. The refractometer prism was cleaned

with distilled water after each analysis.

Sensory Analysis

Sensory quality was carried out using 9 point Hedonic scale rating. For sensory, colour, taste and overall

acceptability, 10 untrained panelists were selected. 100 ml samples were presented to the panelists. The panelists rated the

preferred samples in comparison with control (untreated). The score produced by various panelists were analyzed

thereafter.

Microbial Analysis

For the microbial counts, samples were serially diluted, plated in plate count agar for total plate counts and

MacConkey broth for E.coli. Plates were incubated at 37oC for 48hrs for Total Plate Counts and 25oC for 24 hrs for E.coli.

RESULTS

Sensory Analysis

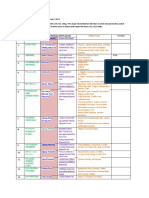

Table 1 shows the values in meanSE for colour, taste and OAA between the processed and control samples. It

was found that there was no significant difference in all the sensory attributes before and after treatment. It was also found

that there was no significant difference in the sensory attributes even during the third week of storage.

Table 1

Storage

Period

Parameter

Colour

1st

week

2nd

week

Taste

Overall

acceptability

F value

Control

8.23

0.07

8.23

0.09

8.04

0.09

2 Minutes

35 KV

17 KV

4 Minutes

35 KV

17 KV

8.21 0.16

8.31 0.11

8.19 0.07

8.23 0.07

8.21 0.10

8.23 0.09

8.16 0.07

8.23 0.07

8.09 0.09

8.28 0.09

8.04 0.09

8.23 0.09

NS

0.77

NS

0.89

NS

0.86

6 Minutes

35 KV

17 KV

8.66

8.45 0.07

0.07

8.57

8.40 0.08

0.05

8.50

8.45 0.05

0.07

NS

0.99

NS

0.77

Colour

8.11 0.17

8.51 0.11

8.22 0.11

8.13 0.12

8.44 0.23

Taste

8.01 0.14

8.23 0.34

8.26 0.23

8.20 0.13

8.44 0.10

8.29 0.12

8.22 0.11

8.44 0.01

8.21 0.27

8.55 0.21

Overall

acceptability

F value

NS

0.79

NS

0.56

NS

0.81

NS

0.92

NS

0.89

8.62

0.21

8.19

0.04

8.52

0.22

NS

0.86

NS

0.87

Physico Chemical Analysis

Table 2 shows mean values of pH for control and PEF processed samples. It was found that there was no

significant difference (p>0.05) found between control and PEF processed sample during the first week of storage. But a

www.tjprc.org

editor@tjprc.org

254

S. Saranya & G. Sujatha

significant difference in pH was observed during the 2nd week of storage between control and PEF processed sample.

Further during the 3rd week of storage, there was no significant difference (p>0.05) in pH was observed between the

processed samples. Table 3 shows mean values of pH for control and PEF processed samples. It was found that there was

no significant difference (p>0.05) found between control and PEF processed sample during the first week of storage. But a

significant difference in acidity was observed during the 2nd week of storage between control and PEF processed sample.

Further during the 3rd week of storage, there was no significant difference (p>0.05) in acidity was observed between the

processed samples. Table 4 shows mean values of total soluble solids for control and PEF processed samples. It was found

that there was no significant difference (p>0.05) found between control and PEF processed sample during the first week of

storage. But a significant difference in total soluble solids was observed during the 2nd week of storage between control and

PEF processed sample. Further during the 3rd week of storage, there was no significant difference (p>0.05) in total soluble

solids was observed between the processed samples.

Table 2: pH Value during the Storage Period

Days

1st

week

2nd

week

3rd

week

Parameter

Control

Processed

F value

Control

Processed

F value

Control

Processed (2nd week)

Processed (3nd week)

F value

2 Min

35 KV

17 KV

4.96 0.02 4.92 0.01

4.96 0.02 4.92 0.01

NS

4 Min

35 KV

17 KV

4.94 0.01 4.93 0.01

4.93 0.01 4.94 0.01

NS

0.00

4.33 0.03

4.96 0.02

4.88**

4.96 0.02

4.80 0.01

0.00

4.40 0.05

4.92 0.01

4.27**

4.92 0.01

4.50 0.03

NS

NS

0.01

4.42 0.06

4.93 0.01

2.86**

4.93 0.01

4.85 0.03

NS

0.01

0.10

6 Min

35 KV

17 KV

4.98 0.01 4.97 0.01

4.98 0.01 4.97 0.01

NS

0.01

4.41 0.04

4.94 0.01

4.22**

4.94 0.01

4.80 0.02

NS

0.03

NS

NS

0.02

NS

0.00

4.34 0.05

4.98 0.01

4.88**

4.98 0.01

4.96 0.02

0.00

4.33 0.04

4.97 0.01

4.27**

4.97 0.01

4.92 0.01

NS

NS

0.01

0.02

Table 3: Acidity Values during the Storage Period

Days

Parameter

control

1st

week

processed

F value

control

2nd

week

processed

F value

control

3rd

week

Processed(2nd week)

Processed(3rd week)

F value

Impact Factor (JCC): 4.8136

2 Min

35 KV

0.053

0.00

0.053

0.00

4 Min

17 KV

0.054 0.00

0.054 0.00

NS

0.00

0.078

0.00

0.054

0.00

4.88**

0.054

0.00

0.055

0.00

NS

0.00

0.077 0.00

0.055 0.00

4.27**

0.055 0.00

0.058 0.00

NS

0.01

35 KV

0.053

0.00

0.053

0.00

35 KV

0.053

0.00

0.053

0.00

NS

NS

NS

0.01

0.079

0.00

0.055

0.00

2.86**

0.055

0.00

0.055

0.00

0.01

0.078

0.00

0.056

0.00

4.22**

0.056

0.00

0.056

0.00

0.00

0.078

0.00

0.054

0.00

4.88**

0.054

0.00

0.054

0.00

NS

0.01

6 Min

17 KV

0.055

0.00

0.055

0.00

NS

0.00

NS

0.00

17 KV

0.054

0.00

0.054

0.00

NS

0.00

0.079

0.00

0.054

0.00

4.27**

0.054

0.00

0.055

0.00

NS

0.00

NS

0.00

NAAS Rating: 3.53

Preservation of Tender Coconut Water using Pulsed Electric Field

255

Table 4: Total Soluble Solids during the Storage Period

Days

1st

week

2nd

week

3rd

week

Parameter

control

processed

F value

control

processed

F value

control

Processed (2nd week)

Processed (3rd week)

F value

2 Min

35 KV

17 KV

4.58 0.04

4.66 0.03

4.58 0.04 4.66 0.03

NS

0.00

5.78 0.04

4.68 0.03

4.88**

4.68 0.03

4.89 0.03

NS

0.00

5.81 0.02

4.69 0.04

4.27**

4.69 0.04

4.91 0.01

NS

0.02

4 Min

35 KV

17 KV

4.61 0.02 4.68 0.02

4.61 0.02 4.68 0.02

NS

NS

0.00

5.83 0.01

4.62 0.03

2.86**

4.62 0.03

4.87 0.02

NS

0.05

0.00

5.86 0.02

4.69 0.01

4.22**

4.69 0.01

4.90 0.04

NS

0.04

6 Min

35 KV

17 KV

4.63 0.01 4.65 0.03

4.63 0.01 4.65 0.03

NS

0.00

5.85 0.02

4.65 0.02

4.88**

4.65 0.02

4.85 0.03

NS

0.05

NS

0.00

5.86 0.02

4.66 0.02

4.27**

4.66 0.02

4.88 0.06

NS

0.02

NS

0.03

Microbial Analysis

Shelf life of the processed tender coconut water was also determined by microbial analysis. The control sample

and the processed sample were tested periodically. The results are expressed in MeanSE. The control sample spoiled in

6th day but the processed TCW samples extended their shelf life with various treatment periods (2, 4 and 6 minutes).

Table 5 shows the percentage reduction in total microbial load for control and PEF processed samples during the storage

period.

Table 5

Type

CONTROL (A)

2 MIN (B)

4 MIN (B)

6 MIN (B)

17 KV

35 KV

17 KV

35 KV

17 KV

35 KV

Log 10 cfu/ml

35 0.32

25.5 0.28

22 0.24

13.7 0.13

8 0.11

3.2 0.07

-

Percent Reduction (%)

27.14 %

37.14 %

60.85 %

77.14 %

90.85 %

100 %

DISCUSSIONS

The sensory attributes (Colour, Taste and Overall acceptability) of the PEF treated samples revealed that there

was no significant difference with that of control samples. The microbial analysis, revealed that the standard plate count

was not more than 5000 cfu/ml and E.coli was absent in PEF processed samples. The chemical analysis

(pH, Acidity and TSS) showed that the shelf life of the PEF processed tender coconut water extended from 18 to 25 days

under 5oC. It was also found that on comparing to the PEF treatment times (2, 4, 6 minutes) and different voltage gradients

(17KV/cm and 35KV/cm), square pulses of 35 KV/cm magnitude and processing time for 6 minutes had an extended shelf

life than the other combination of treatment times and voltage gradients.

CONCLUSIONS

6 trials were conducted on tender coconut water with different combinations of voltage gradients and treatment

time. Sensory, chemical and microbial analysis was conducted. It was found that there was no significant difference in the

sensory attributes before and after PEF processing. It was also observed that there was no difference in pH, acidity and

TSS during the storage period for PEF processed samples. The shelf life of the PEF processed tender coconut water

extended to 18 - 25 days when square pulses of 35 KV/cm magnitude with a pulse width of 2.5 sec for a treatment time of

www.tjprc.org

editor@tjprc.org

256

S. Saranya & G. Sujatha

6 minutes.

REFERENCES

1.

Canovas. B. G. V., Gongora N, Pothakamury, U. R., and Swanson. B. G. (1999). Preservation of foods with pulsed electric

fields. Academic Press, San Diego, CA.

2.

Ho, S. Y and Mittal G. S. (2000). High voltage pulsed electrical field for liquid food pasteurization. Food Review

International, 16, 395434

3.

Iqbal singh (2012). Pulsed Electric Field Processing of Foods. International Journal of Farm Sciences 2(1):1-16

4.

Jayasundera, M and A. Dharmasena. (2014). Preservation of tender coconut water of Sri Lankan tall coconut variety. Annals.

Food Science and Technology, vol- 15.

5.

Kathiravan.T, R. Kumar, J. H. Lakshmana, M. R. Kumaraswamy and S. Nadanasabapathi. (2014). Pulsed electric field

processing of functional drink based on tender coconut water (Cocos nucifera L.) - nannari (Hemidesmus indicus) blended

beverage. Croat. J. Food Sci. Technol. 6 (2) 84-96.

6.

Maciel M.I., Oliveira S.L., Da Silva I.P., (1992). Effects of different storage conditions on preservation of coconut (Cocos

nucifera) water, J. Food Process. Preservation. 16:1322.

7.

Manjunatha, S.S. and Raju, P.S. (2013). Modelling the Rheological behaviour of tender coconut (Cocos nucifera L) water and

its concentrates. International Food Research Journal 20(2): 731-743.

8.

Nadanasabapathy, S. and Kumar, R. (1999). Physico-chemical constituents of tender coconut (Cocos nucifera) water. Indian

J. Agr. Sci. 69, 7

9.

Raju V.K and Zahida P.M. (2007) Minimal processing of tender coconut, Indian Coconut J. 37: 2223.

10. Reddy. K. M and Penchalaraju.M. (2012). Pulsed Electric Field Technology in Food Processing Industry-A Review.

International Journal of Science and Research (IJSR).

11. Sujatha G, Sivakumar T and Vadivoo VS. (2016). Milk preservation using pulsed electric field an alternate to pasteurization.

Indian Journal of Science, 23(77), 34-41

Impact Factor (JCC): 4.8136

NAAS Rating: 3.53

Você também pode gostar

- Thermal and Energetic Studies of Cellular Biological SystemsNo EverandThermal and Energetic Studies of Cellular Biological SystemsA. M. JamesAinda não há avaliações

- Pink Coco Water HPPDocumento39 páginasPink Coco Water HPPNet SupraluckAinda não há avaliações

- Nonthermal Sterilization of Green Coconut Water For PackagingDocumento15 páginasNonthermal Sterilization of Green Coconut Water For PackagingDamigo DiegoAinda não há avaliações

- Thermosonication and Optimization of Stingless Bee Honey ProcessingDocumento15 páginasThermosonication and Optimization of Stingless Bee Honey ProcessingsyazaqilahAinda não há avaliações

- Antioxidant Flavonoid Glycosides From The Leaves of Ficus Pumila L.Documento6 páginasAntioxidant Flavonoid Glycosides From The Leaves of Ficus Pumila L.Hajrah SuhardiAinda não há avaliações

- Innovative Food Science and Emerging TechnologiesDocumento6 páginasInnovative Food Science and Emerging TechnologiesAnyelo MurilloAinda não há avaliações

- 2018 Article 311 PDFDocumento7 páginas2018 Article 311 PDFNurul KhoirAinda não há avaliações

- Effect of Operating Condition On The Kinetic of Color Change of Concentrated PineappleDocumento7 páginasEffect of Operating Condition On The Kinetic of Color Change of Concentrated Pineapplenam nguyenAinda não há avaliações

- 565 78560 2 10 20180424Documento11 páginas565 78560 2 10 20180424Rismayani Miftahul IAinda não há avaliações

- Alves 2022Documento9 páginasAlves 2022Ingryd Mayer KrinskiAinda não há avaliações

- 1 Print PDFDocumento11 páginas1 Print PDFSitinurAinda não há avaliações

- Foods 11 01102Documento10 páginasFoods 11 01102FATIMA CHAUDHRYAinda não há avaliações

- Science Investigatory ProjectDocumento13 páginasScience Investigatory ProjectMedrano, SophiaAinda não há avaliações

- J Jfoodeng 2008 02 003Documento8 páginasJ Jfoodeng 2008 02 003Abraham Jesús Arzeta RíosAinda não há avaliações

- 56-Article Text-150-1-10-20171213Documento9 páginas56-Article Text-150-1-10-20171213Stery OrohAinda não há avaliações

- Trox 2011Documento6 páginasTrox 2011Daniel AriasAinda não há avaliações

- Antimicrobial Activity of Microencapsulation Liquid Smoke On Tilapia (Oreochromis Niloticus (Linnaeus, 1758) ) Meat For Preservatives in Cold Storage ( 5 C°) ..Documento9 páginasAntimicrobial Activity of Microencapsulation Liquid Smoke On Tilapia (Oreochromis Niloticus (Linnaeus, 1758) ) Meat For Preservatives in Cold Storage ( 5 C°) ..sunawiruddinAinda não há avaliações

- Screening of Pectinase Producing Bacteria and Their Efficiency in Biopulping of Paper Mulberry BarkDocumento5 páginasScreening of Pectinase Producing Bacteria and Their Efficiency in Biopulping of Paper Mulberry Barkaditi_joshee419Ainda não há avaliações

- Maduracion Mango PDFDocumento15 páginasMaduracion Mango PDFKali Gonzalez PetroAinda não há avaliações

- Effect On Orange Juice of Batch Pasteurization in An Improved Pilot-Scale Microwave OvenDocumento5 páginasEffect On Orange Juice of Batch Pasteurization in An Improved Pilot-Scale Microwave OvenNicoAinda não há avaliações

- IFRJ 19 (03) 2012 Rosnah PDFDocumento10 páginasIFRJ 19 (03) 2012 Rosnah PDFAyesha MurtazaAinda não há avaliações

- 230830-The-Shelf-Life-Estimation-Of-Cold-Steril-Dffda080 Ultraviolet Sterilization Not Adequate For IndustrialDocumento8 páginas230830-The-Shelf-Life-Estimation-Of-Cold-Steril-Dffda080 Ultraviolet Sterilization Not Adequate For IndustrialStery OrohAinda não há avaliações

- 1 s2.0 S0308814620322809 MainDocumento8 páginas1 s2.0 S0308814620322809 MainNelluri PujaAinda não há avaliações

- Nitrogen Dynamics in The Settlement Ponds of A Small-Scale Recirculating Shrimp Farm (Penaeus Monodon) in Rural ThailandDocumento12 páginasNitrogen Dynamics in The Settlement Ponds of A Small-Scale Recirculating Shrimp Farm (Penaeus Monodon) in Rural ThailandJorge RodriguezAinda não há avaliações

- .ZHOU Effect of Different Thawing Methods On The Quality of MackerelDocumento11 páginas.ZHOU Effect of Different Thawing Methods On The Quality of MackerelJuan Diego Espinoza AlvinesAinda não há avaliações

- Kha Thir 2021Documento8 páginasKha Thir 2021Monyet...Ainda não há avaliações

- Effect of Thermal Pasteurization On Shelf Life and Quality of Kalparasa (Coconut Sap)Documento4 páginasEffect of Thermal Pasteurization On Shelf Life and Quality of Kalparasa (Coconut Sap)v s patilAinda não há avaliações

- Hydrogen Production From Food Waste in Anaerobic Mesophilic and Thermophilic AcidogenesisDocumento9 páginasHydrogen Production From Food Waste in Anaerobic Mesophilic and Thermophilic AcidogenesisĐêmTrắngAinda não há avaliações

- Carranza-Concha 2012 Effects of Drying and Pretreatment On The Nutritonal and Functional Quality of RaisinsDocumento6 páginasCarranza-Concha 2012 Effects of Drying and Pretreatment On The Nutritonal and Functional Quality of RaisinsMildred CullenAinda não há avaliações

- Inhibitory Effects of High Pressure and Heat On AlicyclobacillusDocumento4 páginasInhibitory Effects of High Pressure and Heat On AlicyclobacillusYohanes ThedaAinda não há avaliações

- Pectinase Production and Clarification TreatmentsDocumento6 páginasPectinase Production and Clarification TreatmentscarolasbdAinda não há avaliações

- Science 2Documento4 páginasScience 2akayserefAinda não há avaliações

- tmp75F6 TMPDocumento8 páginastmp75F6 TMPFrontiersAinda não há avaliações

- EncurtidosDocumento7 páginasEncurtidosRoberto Tello UrreloAinda não há avaliações

- Coconut BrixDocumento4 páginasCoconut BrixShanaka KulasuriyaAinda não há avaliações

- Articulo Emirates Journal of Food and Agriculture.2019Documento9 páginasArticulo Emirates Journal of Food and Agriculture.2019cmguerraaAinda não há avaliações

- Art 1traducidoDocumento6 páginasArt 1traducidoGuadalupe Aburto PérezAinda não há avaliações

- Application of Citric AcidDocumento17 páginasApplication of Citric Acidsatish.viswaAinda não há avaliações

- 1 s2.0 S0023643824002810 MainDocumento13 páginas1 s2.0 S0023643824002810 Mainwaciy70505Ainda não há avaliações

- Ts-1 Production of Flavouring Agent From Shrimp HeadsDocumento8 páginasTs-1 Production of Flavouring Agent From Shrimp HeadsRemya PillaiAinda não há avaliações

- DR - 2020 - Changes of Chemical Contents During The Withering Process of White TeaDocumento6 páginasDR - 2020 - Changes of Chemical Contents During The Withering Process of White TeaDadan RohdianaAinda não há avaliações

- Agua de Coco AaaDocumento14 páginasAgua de Coco AaaMaría Del Mar LondoñoAinda não há avaliações

- Bioetanol Por TrichodermaDocumento7 páginasBioetanol Por TrichodermaJeah Gogh GoahhAinda não há avaliações

- Supercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYDocumento7 páginasSupercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYGuillermo Serralde PaezAinda não há avaliações

- Efficacy of Ohmic Vacuum Concentration For Orange Juice ConcentratesDocumento8 páginasEfficacy of Ohmic Vacuum Concentration For Orange Juice ConcentratesNisha ZahidAinda não há avaliações

- Nile Red - Kimura PDFDocumento8 páginasNile Red - Kimura PDFSharif M Mizanur RahmanAinda não há avaliações

- 240063-Article Text-862485-1-10-20201225Documento11 páginas240063-Article Text-862485-1-10-20201225Aiman HaziqAinda não há avaliações

- Evelyn 2016Documento8 páginasEvelyn 2016Oscar OspinoAinda não há avaliações

- Emerging Preservation Methods For Fruit Juices and BeveragesDocumento19 páginasEmerging Preservation Methods For Fruit Juices and BeveragesMark WebbAinda não há avaliações

- The Production of Ethanol and Hydrogen From Pineapple Peel by Saccharomyces Cerevisiae and Enterobacter AerogenesDocumento8 páginasThe Production of Ethanol and Hydrogen From Pineapple Peel by Saccharomyces Cerevisiae and Enterobacter AerogenesInayahWulandariAinda não há avaliações

- Nutritional Physicochemical and Microbial QualityDocumento7 páginasNutritional Physicochemical and Microbial QualityMuh. SubardinAinda não há avaliações

- 3496-Article Text-Jeruk Nipis Pada Bau Amis IkanDocumento8 páginas3496-Article Text-Jeruk Nipis Pada Bau Amis IkanJesiAinda não há avaliações

- Determination of The Best Cooking Time and The Characteristics of Nile Tilapia Pepes (An Indonesian Traditional Fish Product) Processed by Microwave OvenDocumento10 páginasDetermination of The Best Cooking Time and The Characteristics of Nile Tilapia Pepes (An Indonesian Traditional Fish Product) Processed by Microwave OvenMamta AgarwalAinda não há avaliações

- Ultraviolet-C Light Effect On Pitaya Stenocereus GDocumento11 páginasUltraviolet-C Light Effect On Pitaya Stenocereus GĐầu Tư Triệu Đô KênhAinda não há avaliações

- Drying Caulerpalentillifera-R3Documento11 páginasDrying Caulerpalentillifera-R3JULIENNE MAXINE DOLOTAinda não há avaliações

- Food Chemistry: Audrey Chingzu ChangDocumento6 páginasFood Chemistry: Audrey Chingzu ChangMohamed IbrahemAinda não há avaliações

- Processing and Preservation of Green Coconut Water: J. Innov - Dev.strategyDocumento5 páginasProcessing and Preservation of Green Coconut Water: J. Innov - Dev.strategyKoushik ChakrabortyAinda não há avaliações

- Assignment No 1Documento5 páginasAssignment No 1Millicent LanzuelaAinda não há avaliações

- Effect of Temperature On Color Transition of Anthocyanin and Possible-Application of Time-Temperature IndicatorDocumento8 páginasEffect of Temperature On Color Transition of Anthocyanin and Possible-Application of Time-Temperature IndicatorVarshita KothariAinda não há avaliações

- Bioethanol Production From Cassava (Manihot Esculenta) Peel Using Yeast Isolated From Durian (Durio Zhibetinus)Documento8 páginasBioethanol Production From Cassava (Manihot Esculenta) Peel Using Yeast Isolated From Durian (Durio Zhibetinus)Chinwuba Samuel EbukaAinda não há avaliações

- Baluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaDocumento14 páginasBaluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaTJPRC PublicationsAinda não há avaliações

- Development and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateDocumento10 páginasDevelopment and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateTJPRC PublicationsAinda não há avaliações

- Comparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanDocumento8 páginasComparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanTJPRC PublicationsAinda não há avaliações

- Flame Retardant Textiles For Electric Arc Flash Hazards: A ReviewDocumento18 páginasFlame Retardant Textiles For Electric Arc Flash Hazards: A ReviewTJPRC PublicationsAinda não há avaliações

- 2 29 1645708157 2ijtftjun20222Documento8 páginas2 29 1645708157 2ijtftjun20222TJPRC PublicationsAinda não há avaliações

- 2 52 1649841354 2ijpslirjun20222Documento12 páginas2 52 1649841354 2ijpslirjun20222TJPRC PublicationsAinda não há avaliações

- 2 4 1644229496 Ijrrdjun20221Documento10 páginas2 4 1644229496 Ijrrdjun20221TJPRC PublicationsAinda não há avaliações

- Self-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsDocumento8 páginasSelf-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsTJPRC PublicationsAinda não há avaliações

- 2 33 1641272961 1ijsmmrdjun20221Documento16 páginas2 33 1641272961 1ijsmmrdjun20221TJPRC PublicationsAinda não há avaliações

- 2 44 1653632649 1ijprjun20221Documento20 páginas2 44 1653632649 1ijprjun20221TJPRC PublicationsAinda não há avaliações

- Using Nanoclay To Manufacture Engineered Wood Products-A ReviewDocumento14 páginasUsing Nanoclay To Manufacture Engineered Wood Products-A ReviewTJPRC PublicationsAinda não há avaliações

- 2 51 1651909513 9ijmpsjun202209Documento8 páginas2 51 1651909513 9ijmpsjun202209TJPRC PublicationsAinda não há avaliações

- 2 51 1656420123 1ijmpsdec20221Documento4 páginas2 51 1656420123 1ijmpsdec20221TJPRC PublicationsAinda não há avaliações

- Dr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahDocumento12 páginasDr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahTJPRC PublicationsAinda não há avaliações

- Covid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangDocumento8 páginasCovid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangTJPRC PublicationsAinda não há avaliações

- 2 51 1647598330 5ijmpsjun202205Documento10 páginas2 51 1647598330 5ijmpsjun202205TJPRC PublicationsAinda não há avaliações

- An Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaDocumento10 páginasAn Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaTJPRC PublicationsAinda não há avaliações

- A Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)Documento8 páginasA Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)TJPRC PublicationsAinda não há avaliações

- Analysis of Bolted-Flange Joint Using Finite Element MethodDocumento12 páginasAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsAinda não há avaliações

- Effectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewDocumento14 páginasEffectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewTJPRC PublicationsAinda não há avaliações

- 2 67 1644220454 Ijmperdfeb202206Documento9 páginas2 67 1644220454 Ijmperdfeb202206TJPRC PublicationsAinda não há avaliações

- 2 67 1640070534 2ijmperdfeb202202Documento14 páginas2 67 1640070534 2ijmperdfeb202202TJPRC PublicationsAinda não há avaliações

- 2 67 1653022679 1ijmperdjun202201Documento12 páginas2 67 1653022679 1ijmperdjun202201TJPRC PublicationsAinda não há avaliações

- Vitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019Documento16 páginasVitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019TJPRC PublicationsAinda não há avaliações

- Effect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementDocumento8 páginasEffect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementTJPRC PublicationsAinda não há avaliações

- Comparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsDocumento22 páginasComparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsTJPRC PublicationsAinda não há avaliações

- 2 67 1641277669 4ijmperdfeb202204Documento10 páginas2 67 1641277669 4ijmperdfeb202204TJPRC PublicationsAinda não há avaliações

- Numerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingDocumento18 páginasNumerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingTJPRC PublicationsAinda não há avaliações

- 2 67 1645871199 9ijmperdfeb202209Documento8 páginas2 67 1645871199 9ijmperdfeb202209TJPRC PublicationsAinda não há avaliações

- Next Generation'S Energy and Time Efficient Novel Pressure CookerDocumento16 páginasNext Generation'S Energy and Time Efficient Novel Pressure CookerTJPRC PublicationsAinda não há avaliações

- Rangkuman Materi Dan Soal Bahasa Inggris Kelas IXDocumento20 páginasRangkuman Materi Dan Soal Bahasa Inggris Kelas IXMahsun SMKN2ELAinda não há avaliações

- Nuts Oil Seeds and Sugar UnitDocumento16 páginasNuts Oil Seeds and Sugar UnitIyappan SubramaniAinda não há avaliações

- EO 179 On The Coco Levy FundsDocumento5 páginasEO 179 On The Coco Levy FundsImperator FuriosaAinda não há avaliações

- Cocos CoconutDocumento27 páginasCocos Coconutleunamjr100% (3)

- Coconut-Value Added ProductsDocumento10 páginasCoconut-Value Added ProductsDHANARAJA D FOOD TECH (RESEARCH SCHOLAR)Ainda não há avaliações

- Copra, Coconut Products, Charcoal Market in India: Indonesian Trade Promotion Center (ITPC) Chennai 2021Documento88 páginasCopra, Coconut Products, Charcoal Market in India: Indonesian Trade Promotion Center (ITPC) Chennai 2021Astra CloeAinda não há avaliações

- Bio Term PaperDocumento8 páginasBio Term PaperJelord Rey GulleAinda não há avaliações

- Mock 6 Section4Documento13 páginasMock 6 Section4api-3708715Ainda não há avaliações

- Perfil Nutricional y Propiedades Funcionales Del Agua de Coco Comercializada en Las Calles de AbidjanDocumento11 páginasPerfil Nutricional y Propiedades Funcionales Del Agua de Coco Comercializada en Las Calles de Abidjanalexis fernandez ramosAinda não há avaliações

- Bacani vs. NacocoDocumento2 páginasBacani vs. NacocoGary VelasquezAinda não há avaliações

- Commercial Uses of SugercaneDocumento27 páginasCommercial Uses of SugercaneAisha AshrafAinda não há avaliações

- Triple Coconut MacaroonsDocumento2 páginasTriple Coconut MacaroonsmadduxdavidAinda não há avaliações

- Teste Admitere Clasa V A Liceul Ovidius Constanta PDFDocumento22 páginasTeste Admitere Clasa V A Liceul Ovidius Constanta PDFroxana100% (1)

- Comparison of The Combustion Characteristics of Rice HuskDocumento4 páginasComparison of The Combustion Characteristics of Rice HuskMicah Juguan SalgadoAinda não há avaliações

- Coconut - WikipediaDocumento22 páginasCoconut - WikipediaZam DresAinda não há avaliações

- KayieeeDocumento9 páginasKayieeeTsulot KulotAinda não há avaliações

- Intercropping 1Documento134 páginasIntercropping 1Almira Ivy PazAinda não há avaliações

- 100 Healthy Raw Snacks and TreatsDocumento41 páginas100 Healthy Raw Snacks and TreatsanescuveronicaAinda não há avaliações

- Engineering Properties of Five Varieties of Coconuts (Cocos Nucifera L.) For Efficient Husk SeparationDocumento10 páginasEngineering Properties of Five Varieties of Coconuts (Cocos Nucifera L.) For Efficient Husk SeparationJomar Eusebio TumaladAinda não há avaliações

- Coconut Marketing Strategies Kozhikode-Invest-MeetDocumento23 páginasCoconut Marketing Strategies Kozhikode-Invest-MeetTheophilus TyavAinda não há avaliações

- The Efficacy of Using Powdered SeashellDocumento4 páginasThe Efficacy of Using Powdered SeashellJose GerogalemAinda não há avaliações

- Feasibility Study On Native ChickenDocumento36 páginasFeasibility Study On Native Chickenclifford15201495% (19)

- Virgin Coconut Oil Production Manual ForDocumento114 páginasVirgin Coconut Oil Production Manual ForHilarionSabitangAinda não há avaliações

- Assessment of Density and Anatomical Properties of Nigerian Grown Cocos Nucifera WoodDocumento7 páginasAssessment of Density and Anatomical Properties of Nigerian Grown Cocos Nucifera Woodcharize burgosAinda não há avaliações

- Nama 04 01 2022Documento27 páginasNama 04 01 2022Nico YudiantoAinda não há avaliações

- 40 Association of PH Coconut Desiccators v. PH Coconut AuthorityDocumento2 páginas40 Association of PH Coconut Desiccators v. PH Coconut AuthorityHans LazaroAinda não há avaliações

- Matconana Cake With Matcha, Coconut, and Banana by Paola Chang - Pastry Recipes in So Good MagazineDocumento1 páginaMatconana Cake With Matcha, Coconut, and Banana by Paola Chang - Pastry Recipes in So Good MagazineCwt ChanAinda não há avaliações

- LP 5 The BamboosDocumento13 páginasLP 5 The BamboosSharlyn Joy Pizon MacaldoAinda não há avaliações

- Annex A VLFED FrameworkDocumento2 páginasAnnex A VLFED FrameworkDanden GerraAinda não há avaliações

- Diseases of Coconut.Documento14 páginasDiseases of Coconut.AtharvaJadhav AMPU-20-2098Ainda não há avaliações