Escolar Documentos

Profissional Documentos

Cultura Documentos

Installation - Direct Burial Guidelines

Enviado por

Daniel Lezama0 notas0% acharam este documento útil (0 voto)

49 visualizações3 páginasDirect burial fiber, installation guidelines

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDirect burial fiber, installation guidelines

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

49 visualizações3 páginasInstallation - Direct Burial Guidelines

Enviado por

Daniel LezamaDirect burial fiber, installation guidelines

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 3

OCC-206-4

Installation Direct Burial

Guidelines

Excerpt

from

Optical Cable Corporations

INSTALLATION GUIDE

OCC-206-4

CONTROLLED DOCUMENT

Rev. A

8 April 2008

Direct Burial Installation

Fiber optic cables are available for outdoor

use. These cables may be strictly outdoor

types or may be indoor/outdoor types which

may provide greater versatility in campus

type applications. The outdoor cable is quite

rugged in order to withstand a harsh

environment.

One outdoor method of

installation is direct burial.

A direct burial installation typically involves

heavy machinery and places the optical

cable underground in direct contact with the

earth and rocks that make up the

surrounding soil.

All direct burial cable should contain a

corrugated steel armor tape for protection

against rough terrain and rodents.

Before digging, all existing underground

utilities such as buried cables, pipes, and

other structures along the route should be

identified and located. Proper right-of-way

permits must also be obtained before

digging begins.

When direct burying fiber optic cable,

special consideration must be taken in

regards to the cables minimum bending

radius, and maximum pulling strength.

Further

considerations

include

the

installation temperature and preventing

cables twist during the installation. Please

refer to the General Guidelines section of

the Optical Cable Corporation Installation

Guide.

Fiber optic cables should always be buried

beneath the frost line. This depth may vary

depending on the geographical location of

the installation.

commonly used if multiple cables are to be

located in the same area along the same

path. Trenching is more time consuming

then direct plowing but allows for a more

controlled installation. Trenches can be dug

by hand or by machine to the required

depths.

Some advantages of trenching are; lower

cost of equipment, digging operation is

separate from cable placement, better depth

control, and less chance of damaging

underground utilities.

Some disadvantages of trenching are; the

cable placement is slower than plowing and

it is not suitable for all soil and terrain

conditions.

Trenching is typically performed by large

machinery. However, hand digging may be

necessary in some locations. Trenches

should be kept as straight as possible. The

bottom of the trench should be flat with no

large stones.

Once the trench is dug and inspected, clean

backfilling material should be placed 9

inches to 12 inches deep on the bottom of

the trench to provide protection for the cable

and to decrease optical fiber microbending

losses.

Once the cable has been laid on the backfill,

the trench should be filled in with clean

backfill and then earth, with a warning tape

placed 12 inches directly above the fiber

optic cable. The earth should be mounded

over the trench to compensate for future

settling. Caution: Always move the cable

reel along the trench during payout. Never

drag the cable from a stationary reel.

Marker Tape

Types of Direct Burial

Surface

Frost Line

Direct burial applications imply one of two

installation methods are being used;

trenching or plowing.

Trenching

Cable

Clean Backfilling Material

Cut-Away of Trenched Cable

Trenching can be defined as simply digging

a trench, placing the cable in it, and filling

the trench back up.

This method is

Installation Direct Burial Guidelines Excerpt from Optical Cable Corporations Installation Guide

Page 2 of 3

OCC-206-4

CONTROLLED DOCUMENT

Rev. A

8 April 2008

Any cables left for future splicing should

have protective caps installed on the ends of

the cables.

Plowing

Plowing involves using heavy machinery

that plows, or cuts, a groove of the

appropriate depth in the ground while

simultaneously feeding a single cable into

the groove. Plowing a cable into the ground

is faster than trenching, but special care

needs to be taken to ensure that cable is not

damaged during the installation. There are

two types of plowing; static and vibration.

Static Plowing

Static plowing simply plows right through the

ground like a knife often using multiple

tractors to pull it. This method is very fast

and effective in open areas and especially

when the ground is hard or wet.

Vibration Plowing

A vibratory plow shakes as it plows into the

ground. A shaker box on a plowing

attachment causes the plow blade to move

up and down while being pulled forward by a

tractor (usually smaller than that used in

static plowing). This method is best used in

smaller, tight areas such as right-of-ways

and dense locations.

It requires less

horsepower or force to pull the plow through

the ground and does not typically require an

additional tractor to pull it.

the surface if the plow is not moving. Never

back up the plow with cable still in the chute.

While plowing in the fiber optic cable,

warning tape should be placed 12 inches

directly above the cable.

Marker Tape

Surface

Frost Line

Cable

Cut-Away of Plowed Cable

Any cables left for future splicing should

have protective caps installed on the ends of

the cables.

Direct Buried Splice Enclosures

Excess fiber optic cable should be left at all

splice locations along the route. If the splice

enclosure is direct buried, the excess cable

should be stored in vertical positioned loops

that meet the minimum bending radius of

the cable. This limits damage to the cable if

ground settles or moves when the cable is

above the frost line (Optical Cable

Corporation strongly recommends that all

direct buried cables be installed beneath the

frost line).

Marker Tape Electronic Marker

Surface

Frost Line

Some advantages of plowing are; speed of

installation and less ground disturbance.

Some disadvantages of plowing are; high

cost

of

equipment

requires

skilled

equipment operators, not suitable for all soil

and terrain conditions, and the possibility of

damaging underground utilities.

During a plow installation, a reel carrier

should be used for ease of installing the

reel. All rollers or guides in the cable feed

system which cause a change in the

direction of the cable path must conform to

the minimum bend radius of the cable. The

cable path inside the feed chute must be

clean, free of burrs and sharp or rough

edges. The plow should never be raised to

Splice Enclosure

Clean Backfilling Material

Cut-Away of Slack Storage

Underground electronic markers or an

above ground marker should be installed at

every underground splice location. This

significantly reduces time and the possibility

of damaging cable when access to the

splice location is needed on future projects.

Installation Direct Burial Guidelines Excerpt from Optical Cable Corporations Installation Guide

Page 3 of 3

OCC-206-4

CONTROLLED DOCUMENT

Rev. A

8 April 2008

Cable Slack

Storage

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- SMP Gateway SoftPLC Reference ManualDocumento47 páginasSMP Gateway SoftPLC Reference Manualswalker948100% (1)

- VB Script ReferenceDocumento27 páginasVB Script ReferenceRajkumarAinda não há avaliações

- User'S Manual: Capstone MicroturbineDocumento56 páginasUser'S Manual: Capstone MicroturbinemassimocalviAinda não há avaliações

- Grundfos S Pump 5 - 29 KW Super VortexDocumento20 páginasGrundfos S Pump 5 - 29 KW Super Vortexdalveerchoudhary100% (1)

- Mech 3-Module 1Documento41 páginasMech 3-Module 1melkisidick angloanAinda não há avaliações

- Cif Purge Plug Systems en 3Documento3 páginasCif Purge Plug Systems en 3abdeljalil elbadrAinda não há avaliações

- RT 8090 TDocumento40 páginasRT 8090 TManuel100% (1)

- ASTM F 412 - 01a Standard Terminology Relating To Plastic Piping Systems1Documento13 páginasASTM F 412 - 01a Standard Terminology Relating To Plastic Piping Systems1JORGE ARTURO TORIBIO HUERTAAinda não há avaliações

- Curriculum Vitae: Augusto Javier Puican ZarpanDocumento4 páginasCurriculum Vitae: Augusto Javier Puican Zarpanfrank_d_1Ainda não há avaliações

- Gathering Network RequirementsDocumento30 páginasGathering Network RequirementsAmin ZangetsuAinda não há avaliações

- U042en PDFDocumento12 páginasU042en PDFTatiya TatiyasoponAinda não há avaliações

- Creating REST API Using NodeJS and Consuming in AngularJSDocumento8 páginasCreating REST API Using NodeJS and Consuming in AngularJSserignemodouAinda não há avaliações

- Panel 01-Eldora-Grand-1500V-2021-R01 - G1Documento2 páginasPanel 01-Eldora-Grand-1500V-2021-R01 - G1DHAVAL SHAHAinda não há avaliações

- Quality Assurance Plan (1) ..Documento5 páginasQuality Assurance Plan (1) ..ARUNKUMARANNANBHEDAAinda não há avaliações

- 25252525Documento38 páginas25252525Ivan GonzalezAinda não há avaliações

- Tutorial - 05 - Excavation Settle 3DDocumento13 páginasTutorial - 05 - Excavation Settle 3DAlejandro Camargo SanabriaAinda não há avaliações

- BurnerDocumento4 páginasBurnerAhmed Mohamed KhalilAinda não há avaliações

- 27C ChainDocumento19 páginas27C ChainyanaziAinda não há avaliações

- Bubbling Kun NiDocumento7 páginasBubbling Kun NiBelen CRAinda não há avaliações

- FL-02-01 PM SheetDocumento12 páginasFL-02-01 PM SheetBikas SahaAinda não há avaliações

- 06-901 Keyed Input SwitchesDocumento4 páginas06-901 Keyed Input Switchesmajed al.madhajiAinda não há avaliações

- Skytrain Avia Services: Emergency Procedures ManualDocumento32 páginasSkytrain Avia Services: Emergency Procedures ManualEndro RastadiAinda não há avaliações

- Portal Info StubDocumento11 páginasPortal Info Stubzamanqomaru8Ainda não há avaliações

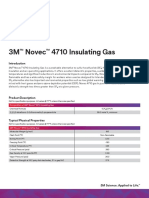

- SF6 Novec 4710Documento4 páginasSF6 Novec 4710Fidya Eka PrahestiAinda não há avaliações

- KST GlueTech 44 enDocumento80 páginasKST GlueTech 44 enLeandro RadamesAinda não há avaliações

- Justine J. Beroy: Career ObjectivesDocumento5 páginasJustine J. Beroy: Career ObjectivesJustine BeroyAinda não há avaliações

- Korantin PPDocumento4 páginasKorantin PPteddy garfieldAinda não há avaliações

- How Is Electrical Energy MeasuredDocumento4 páginasHow Is Electrical Energy MeasuredSonya ReddyAinda não há avaliações

- Exam Flashcards: by Jonathan DonadoDocumento520 páginasExam Flashcards: by Jonathan Donadosolarstuff100% (1)

- Tube Well Design Project SolutionDocumento5 páginasTube Well Design Project SolutionEng Ahmed abdilahi IsmailAinda não há avaliações